Physics of processes inside the wall

Condensation

Why dry the wall? Is she getting wet? Let it get wet. And in order for it to get wet, it does not need to be watered from a hose. The temperature difference from the heat of the day to the coolness of the night is enough. The problem of getting the wall, all its layers, wet as a result of moisture condensation could be irrelevant in a frosty winter, but here the heating of our house comes into play. As a result of the fact that we heat our houses, the warm air tends to leave the warm room and moisture condenses again in the thickness of the wall. Thus, the relevance of drying the wall remains at any time of the year.

Convection

Please pay attention to the fact that the site has a good article about the theory of condensate in the walls

Warm air tends to rise up and cold air sinks down. And this is very unfortunate, since we, in our apartments and houses, do not live on the ceiling, where warm air collects, but on the floor, where cold air collects. But I seem to have digressed.

It is completely impossible to get rid of convection. And this is also very unfortunate.

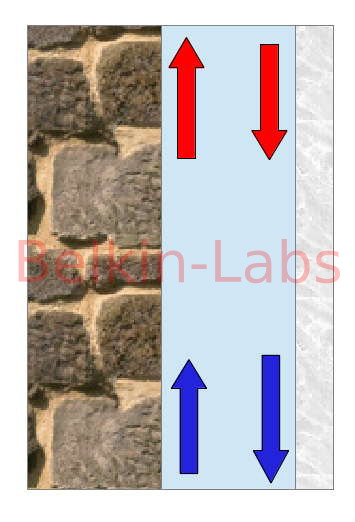

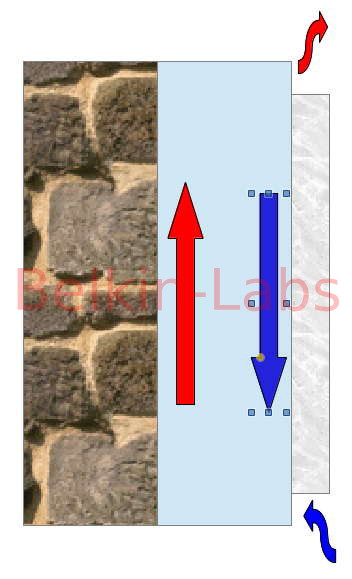

Now let's look at a very useful question. How does convection in a wide gap differ from the same convection in a narrow one? We have already understood that the air in the gap moves in two directions. It moves up on a warm surface and down on a cold surface. And this is where I want to ask a question. And what happens in the middle of our gap? And the answer to this question is rather complicated. I believe that the layer of air directly at the surface moves as quickly as possible. It pulls the layers of air that are nearby. As far as I understand, this is due to friction. But the friction in the air is rather weak, so the movement of neighboring layers is much less fast than the "wall" ones. But there is still a place where the air moving up comes into contact with the air moving down. Apparently in this place, where multidirectional flows meet, something like turbulence occurs. The eddies are the weaker, the lower the flow velocity. With a sufficiently wide gap, these swirls may be completely absent or completely invisible.

But if the gap we have is 20 or 30 mm? Then the twists can be stronger. These turbulences will not only mix the flows, but also slow each other down. It seems that if you make an air gap, then you should strive to make it thinner. Then two differently directed convection flows will interfere with each other. And that's what we need.

Let's look at some fun examples.

First example

Suppose we have a wall with an air gap. The gap is deaf. The air in this gap has no connection with the air outside the gap. Warm on one side, cold on the other. Ultimately, this means that the inner sides in our gap also differ in temperature in the same way. What's going on in the gap? On a warm surface, the air in the gap rises. It goes down in the cold. Since it is the same air, a cycle is formed. During this cycle, heat is actively transferred from one surface to another. And actively. It means strong. Question. Does our air gap perform a useful function? Looks like no. It looks like he actively cools the walls for us. Is there anything useful in this air gap of ours? No. There doesn't seem to be anything useful in it. Basically, forever.

Second example.

Suppose we made holes at the top and bottom so that the air in the gap communicated with the outside world. What have we changed? And the fact that now there is no cycle. Or it is, but there is both a suction and an air outlet.Now the air is heated from the warm surface and, possibly, partially flies out (warm), and from below, cold air from the street comes in its place. Is this good or bad? Is it very different from the first example? At first glance, it gets even worse. Heat goes out.

I will note the following. Yes, now we are heating the atmosphere, and in the first example we were heating the skin. To what extent is the first option worse or better than the second? You know, I think these are about the same options in terms of their harmfulness. This is my intuition telling me, so I, just in case, do not insist on my being right. But on the other hand, in this second example, we got one useful function. Now our gap has become from air ventilation, that is, we have added the function of carrying out moist air, which means drying the walls.

Is there convection in the ventilation gap or is there air moving in one direction?

Of course have! Similarly, warm air moves up while cold air moves down. It's just not always the same air. And there is also harm from convection. Therefore, the ventilation gap, just like the air gap, does not need to be made wide. We don't need wind in the ventilation gap!

What's good about drying a wall?

Above, I called the process of heat transfer in the air gap active. By analogy, I will call the process of heat transfer inside the wall passive. Well, maybe such a classification is not too strict, but my article, and in it I have the right to such outrages. So. A dry wall has a much lower thermal conductivity than a wet one. As a result, heat will reach the harmful air gap from inside the warm room more slowly, and less will be carried out. Tritely, convection will slow down, since the left surface of our gap will no longer be so warm. The physics of increasing the thermal conductivity of a damp wall is that vapor molecules transfer more energy when colliding with each other and with air molecules than just air molecules when colliding with each other.

Ventilated facade device types of hinged facade systems

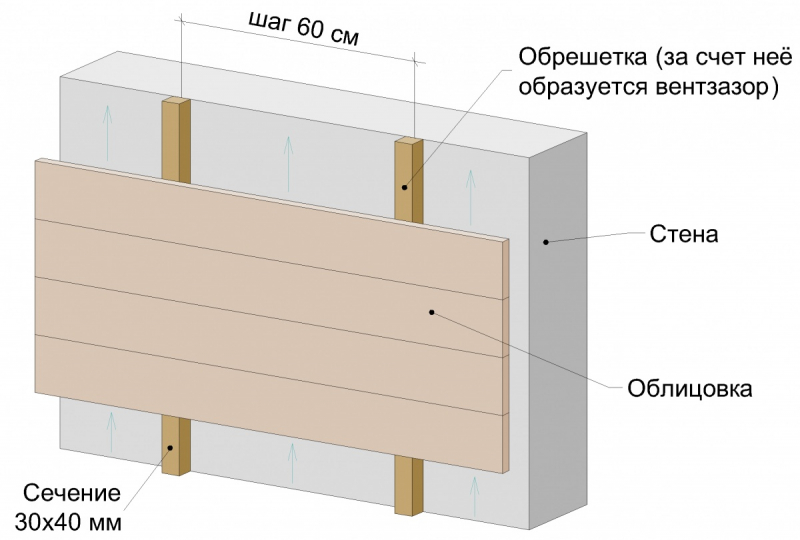

Scheme of installation of ventilated facades without insulation Ventilated facade without insulation

There are no thermal insulation materials or there is no ventilation gap between the insulation and the finishing material.

In the latter case, the wall is insulated, but it is impossible to talk about the construction of a ventilated facade.

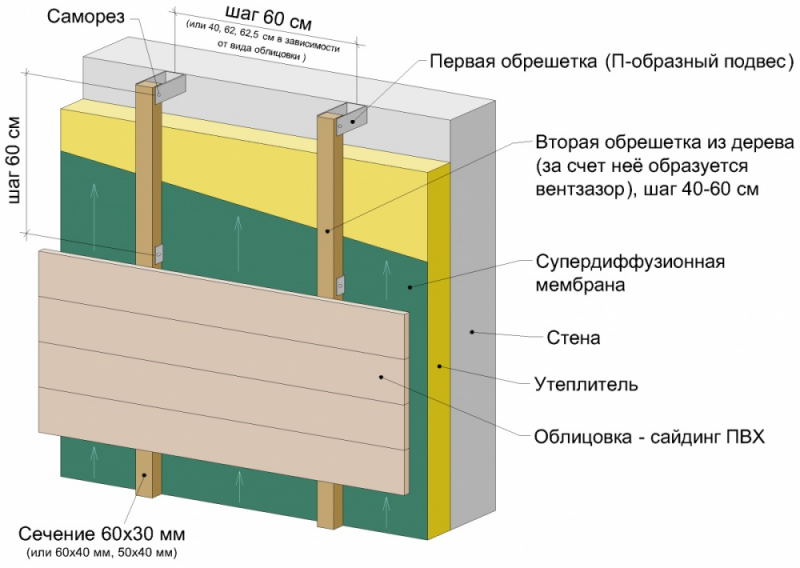

Scheme of installation of ventilated facades with insulation Ventilated facade with insulation

The insulated ventilated facade must meet the following conditions:

- there is a vapor-permeable insulation (vapor permeability -\u003e 0.1-0.3 mg / (m * h * Pa)); - the insulation is covered with a film (vapor permeability -> 800 g / m2 per day); - equipped with a ventilation gap (size - 40-60 mm).

A lined wall cannot be classified as a ventilated facade if:

- there is a gap between the wall and the insulation;

- when using a heat-insulating material with low vapor permeability (

- a heater with specified steam transmission parameters is used (0.1-0.3 mg / (m * h * Pa)), but it is covered with a film with low vapor transmission capacity (

- there is no ventilation gap, subject to the requirements for vapor permeability of the heat-insulating material and the film.

In these cases, other methods of facade cladding are used.

Water vapor in the wall where does it come from

In order to understand the consequences of the absence of a ventilated gap in walls made of two or more layers of different materials, and whether gaps in walls are always needed, it is necessary to recall the physical processes occurring in the outer wall in the case of a temperature difference on its inner and outer surfaces.

As you know, air always contains water vapor. The partial vapor pressure depends on the air temperature. As the temperature rises, the partial pressure of water vapor increases.

In the cold season, the partial vapor pressure inside the room is much higher than outside.Under the pressure differencewater vapor tends to get from inside the house to an area of \u200b\u200blower pressure, i.e. on the side of the layer of material with a lower temperature - on the outer surface of the wall.It is also known that when the air is cooled, the water vapor contained in it reaches its maximum saturation, after which it condenses into dew.

Dew point is the temperature to which the air must be cooled so that the vapor contained in it reaches a state of saturation and begins to condense into dew.

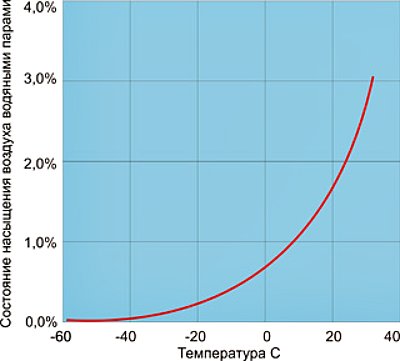

The diagram below, Fig. 1, shows the maximum possible water vapor content in the air depending on the temperature.

|

|

| Fig.1. Dew point graph. The maximum possible vapor content in the air depending on the temperature. |

The ratio of the mass fraction of water vapor in the air to the maximum possible fraction at a given temperature is called relative humidity, measured as a percentage.

For example, if the air temperature is 20°C and the humidity is 50%, this means that the air contains 50% of the maximum amount of water that can be found there.

As you know, building materials have different ability to pass water vapor contained in the air, under the influence of the difference in their partial pressures. This property of materials is called vapor permeability, measured in m2*hour*Pa/mg.

Briefly summarizing the above, in winter, air masses, which include water vapor, will pass through the vapor-permeable structure of the outer wall from the inside to the outside.

The temperature of the air mass will decrease as it approaches the outer surface of the wall, Fig.2. The dew point in a properly designed wall will be in the thickness of the wall, closer to the outer surface of the thermal insulation layer, where the steam will condense and moisten the wall.

The essence of the problem

Let's deal with the subject matter and agree on terms, otherwise it may turn out that we are talking about one thing, but we mean completely opposite things.

Wall

This is our main subject. The wall can be homogeneous, for example, brick, or wood, or foam concrete, or cast. But the wall can also consist of several layers. For example, the wall itself (brickwork), a layer of insulation-heat insulator, a layer of exterior finish.

Air gap

This is the wall layer. Most often it is technological. It turns out by itself, and without it it is either impossible to build our wall, or it is very difficult to do it. An example is such an additional wall element as a leveling frame.

Example

Suppose we have a newly built wooden house. We want to finish it off. We first apply the rule and make sure that the wall is curved. Moreover, if you look at the house from a distance, you see a quite decent house, but when you apply a rule to the wall, it becomes clear that the wall is terribly crooked. Well ... there's nothing to be done! This happens with wooden houses. We align the wall with a frame. As a result, a space filled with air is formed between the wall and the exterior finish. Otherwise, without a frame, it will not work to make a decent exterior finish for our house - the corners will “spread”. As a result, we get an air gap.

Let us remember this important feature of the term under consideration.

ventilation gap

This is also a wall layer. It looks like an air gap, but it has a purpose. Specifically, it is designed for ventilation. In the context of this article, ventilation is a series of measures aimed at removing moisture from the wall and keeping it dry. Can this layer combine the technological properties of the air gap? Yes, maybe this is what, in essence, this article is being written about.

What is an air gap and why is it needed

The air gap in hinged ventilated facades is the distance between the insulation layer and the inner surface of the facing material.An air gap is needed to circulate air under the cladding. Nothing should interfere with the air flow. Violation of this rule is a violation of the principle of the organization of illegal armed formations. Due to the draft in the air gap, a pipe effect occurs, the speed of the air flow is such that it breaks the windproof membrane, which is not fixed according to the rules. Without a membrane, only insulation with a special cached layer can be used. The cached layer is denser compared to the usual density of the insulation, with a density of more than 100 kg / m 3. The insulation without a cached layer in the ventilation gap will break into flat pieces, in some places the thickness will decrease, and in some places it will disappear to the base.

Due to air circulation, everything that is under the cladding is dried. Therefore, no one closes rustications in ventilated facades. Rust is the distance between the cladding panels. Even with slanting rain, when a large amount of water enters the insulation through rustication, this is not a problem, everything will dry out. It is known that when using the technology of a hinged ventilated facade on a panel house, the fungus disappears, the rusting of the reinforcement in the concrete slab stops. All thanks to the ventilated gap.

The best insulation, as you know, is air. The purpose of modern heaters is to keep the air motionless. But it must also be vapor-permeable, must breathe. Based on these characteristics, the best insulation is mineral wool. But mineral wool loses all properties when wet. We cannot exclude getting wet, because the air is also humid. Conclusion - it is necessary to constantly dry the insulation. Everything ingenious is simple. And so the hinged ventilated facade was invented. With a hinged facade, we do not protect the insulation from water - we dry it, using natural methods and constantly. For this, a ventilated gap is needed.

Features of moisture accumulation in walls with facade insulation with foam plastic, expanded polystyrene

Foamed polymer insulation - polystyrene foam, polystyrene foam, polyurethane foam, have a very low vapor permeability. A layer of insulation boards made of these materials on the facade serves as a vapor barrier. Steam condensation can occur only at the border of the insulation and the wall. A layer of insulation prevents condensation from drying out in the wall.

To prevent the accumulation of moisture in a wall with polymer insulation, it is necessary to exclude steam condensation at the boundary between the wall and the insulation. How to do it? To do this, it is necessary to make sure that at the border of the wall and the insulation, the temperature is always, in any frost, higher than the dew point temperature.

The above condition for the distribution of temperatures in the wall is usually easily met if the heat transfer resistance of the insulation layer is noticeably greater than that of the wall being insulated. For example, insulation of a “cold” brick wall of a house with foam plastic 100 mm thick. in the climatic conditions of central Russia, it usually does not lead to the accumulation of moisture in the wall.

It is a completely different matter if a wall made of “warm” timber, logs, aerated concrete or porous ceramics is insulated with foam plastic. And also, if you choose a very thin polymer insulation for a brick wall. In these cases, the temperature at the boundary of the layers can easily be below the dew point and it is better to make an appropriate calculation to make sure that there is no moisture accumulation.

The figure above shows a graph of the temperature distribution in an insulated wall for the case when the heat transfer resistance of the wall is greater than that of the insulation layer. For example, if the wall is made of aerated concrete with a masonry thickness of 400 mm. insulated with foam plastic 50 mm thick., then the temperature at the border with the insulation in winter will be negative. As a result, steam will condense and moisture will accumulate in the wall.

The thickness of the polymer insulation is chosen in two stages:

- They are chosen based on the need to provide the required resistance to heat transfer of the outer wall.

- Then check for the absence of steam condensation in the thickness of the wall.

If the check according to item 2. shows the opposite it is necessary to increase the thickness of the insulation. The thicker the polymer insulation, the lower the risk of steam condensation and moisture accumulation in the wall material. But, this leads to an increase in construction costs.

A particularly large difference in the thickness of the insulation, selected according to the above two conditions, occurs when insulating walls with high vapor permeability and low thermal conductivity. The thickness of the insulation to ensure energy saving is relatively small for such walls, and to avoid condensation - the thickness of the plates should be unreasonably large.

Therefore, for the insulation of walls made of materials with high vapor permeability and low thermal conductivity, it is more profitable to use mineral wool insulation. This applies primarily to walls made of wood, aerated concrete, gas silicate, large-pore expanded clay concrete.

A vapor barrier from the inside is mandatory for walls made of materials with high vapor permeability for any type of insulation and facade cladding.

For a vapor barrier device, the interior decoration is made of materials with high resistance to vapor permeability - a deep penetration primer is applied to the wall in several layers, cement plaster, vinyl wallpaper, or a vapor-proof film is used.

All of the above applies not only to walls, but also to other structures enclosing the thermal contour of the building - attic and basement ceilings, mansard roofs.

Watch the video, which clearly shows the thermophysical processes in the insulated roof slopes. Similar processes occur in the outer walls of buildings.

https://youtube.com/watch?v=6i5qGiQ5PUo

After reading this article, you have learned how to make a wall dry.

The wall must also be warm. Read about it in the next article.

Why then all the numerous membranes Is it worth overpaying for them

To say out loud that the membrane is a waste of money somehow doesn’t turn the tongue, it’s too tight they have come into use. For those who want to understand what a vapor barrier membrane is, we advise you to conduct a simple experiment. Call any manufacturer and report that the builders installed the membrane on the wrong side and you are afraid of serious last because of their mistake. The answer will be that the membrane is vapor-tight on both sides and there is no big difference between how it is laid, just like for a polyethylene film. In general, the stories that the vapor barrier "breathes" unlike polyethylene are, to put it mildly, exaggerated.

Wind and waterproof films are another matter. These are the ones that protect the insulation from the outside. It is not indicated which side they should be installed, this information can be taken from the instructions for a specific membrane

When installing them, it is really important not to confuse the sides. A properly installed membrane removes water vapor from the insulation and prevents moist air from outside from penetrating into the insulation

If you are not sure about the builders and their ability not to mix up the sides, then you can buy a three-layer membrane that can be placed on either side. They are a little more expensive, but they guarantee the result.

How to reduce the harm from air convection in the ventilation gap

Obviously, to reduce convection means to prevent it. As we have already found out, we can prevent convection by colliding two convection currents. That is, to make the ventilation gap very narrow. But we can also fill this gap with something that would not stop convection, but would significantly slow it down. What could it be?

Foam concrete or gas silicate? By the way, foam concrete and gas silicate are quite porous and I am ready to believe that there is weak convection in a block of these materials. On the other hand, we have a high wall. It can be 3 and 7 or more meters high. The more distance the air needs to travel, the more porous the material we need to have.Most likely, foam concrete and gas silicate are not suitable.

Moreover, wood, ceramic bricks and so on are not suitable.

Styrofoam? Not! Styrofoam doesn't work either. It is not too easily permeable to water vapor, especially if they have to travel more than three meters.

Bulk materials? Like expanded clay? Here's an interesting suggestion. It probably can work, but expanded clay is too inconvenient to use. Dust, wakes up and all that.

Wool low density? Yes. I think that very low density wool is the leader for our purposes. But cotton wool is not produced in a very thin layer. You can find canvases and plates at least 5 cm thick.

As practice shows, all these arguments are good and useful only in theoretical terms. In real life, you can do much easier and more prosaic, which I will write about in a pretentious form in the next section.

How is the process of ventilation of the wall

Well, it's simple. Moisture appears on the surface of the wall. Air moves along the wall and carries moisture away from it. The faster the air moves, the faster the wall dries out if it is wet. It's simple. But more interesting.

What wall ventilation rate do we need? This is one of the key points of the article. By answering it, we will understand a lot in the principle of constructing ventilation gaps. Since we are not dealing with water, but with steam, and the latter is most often just warm air, we need to remove this very warm air from the wall. But by removing warm air, we cool the wall. In order not to cool the wall, we need such ventilation, such a speed of air movement, at which steam would be removed, and a lot of heat would not be taken away from the wall. Unfortunately, I cannot say how many cubes per hour should pass our wall. But I can imagine that not much at all. Some compromise is needed between the benefits of ventilation and the harm of heat removal.

When you need a ventilation gap ventilation gap in a frame house

So, if you are thinking about whether you need a ventilation gap in the facade of your carousel house, pay attention to the following list:

- When wet

If the insulation material loses its properties when wet, then a gap is necessary, otherwise all work, for example, on home insulation will be completely in vain - Steam pass

The material your walls are made of allows steam to pass through to the outer layer. Here, without the organization of free space between the surface of the walls and the insulation, it is simply necessary. -

Prevent excess moisture

One of the most common questions is the following: do I need a ventilation gap between the vapor barrier? In the case when the finish is a vapor barrier or moisture-condensing material, then it must be constantly ventilated so that excess water does not remain in its structure.

As for the last point, the list of such models includes the following types of sheathing: vinyl and metal siding, profiled sheet. If they are tightly sewn onto a flat wall, then the remnants of the accumulated water will have nowhere to go. As a result, materials quickly lose their properties, and also begin to deteriorate externally.

Do I need a ventilation gap between siding and OSB (OSB)

When answering the question of whether a ventilation gap is needed between the siding and OSB (from English - OSB), it is also necessary to mention its need. As already mentioned, siding is a product that insulates steam, and OSB does consist of wood chips, which easily accumulate moisture residues and can quickly deteriorate under its influence.

Additional reasons to use a vent

Let's analyze a few more mandatory points when the gap is a necessary aspect:

-

Prevention of rot and cracks

The material of the walls under the decorative layer is prone to deformation and damage under the influence of moisture. To prevent rot and cracks from forming, it is enough to ventilate the surface, and everything will be in order. -

Condensation Prevention

The material of the decorative layer may contribute to the formation of condensation. This excess water must be removed immediately.

For example, if the walls of your house are made of wood, then an increased level of moisture will adversely affect the condition of the material. The wood swells, begins to rot, and microorganisms and bacteria can easily settle inside it. Of course, a small amount of moisture will collect inside, but not on the wall, but on a special metal layer, from which the liquid begins to evaporate and be carried away with the wind.

The cost of installing ventilated facades

Consider how to calculate the amount of material and the total cost of a ventilated facade project.

An example of calculating the amount of material for mounting a hinged ventilated facade of a private house:

Given:

- one-story house;

- total area 80 sq.m.;

- construction material - structural foam block (density 900 kg / sq.m.);

- house dimensions 10x8 m.p.;

- wall height - 3 r.m.;

- window area:

Task:

Arrangement of a ventilation facade with the specified parameters:

- insulation - basalt wool;

- insulation thickness - 50 mm;

- facing material - metal siding.

Payment:

- we calculate the surface area to be covered with a hinged facade:

- total area of walls - area of windows and doors = 98 sq.m.

- calculate the need for materials:

Installation of ventilated facades - price per m2 of wall with work (indicative data are given in the table)

| Type of facing material | Cost, rub/sq.m. |

|---|---|

| Porcelain stoneware | 2960 |

| Fiber cement boards | 3170 |

| Decking (profiled sheet)/td> | 2530 |

| Composite panels | 3480 |

| Porcelain stoneware (interfloor system) | 3030 |

| Ceramic granite (light) | 2890 |

Facing material for suspended ventilation facade

Typical mistakes when installing a ventilated facade

- errors in calculations. As a result of which, the frame cannot cope with the load;

- use of deformed elements;

- change in the technology of the device of the guide system;

- unreasonable savings on material, fasteners and tools;

- the use of low-quality insulation;

- safety violation.

Tips for installing a hinged ventilated facade

- it is better to entrust the calculation and design of the system to professionals, because without experience, it is difficult to install with your own hands;

- check the quality of the dowels before starting work;

- installation error must be within acceptable limits;

- installation of a paronite gasket between the wall and the bracket will reduce heat loss and allow compensating for the movement of the system during operation;

- installation of a ventilation facade is a complex job, so it is advisable to involve serious companies with authority in the construction market for their implementation.

A properly installed and assembled ventilated facade will increase the energy efficiency of the house and improve its appearance (exterior).

The main result, or what, after all, to do in practice

- When building a personal home, you should not specifically create air and ventilation gaps. You will not achieve great benefits, but you can cause harm. If the construction technology can do without a gap - do not do it.

- If you can’t do without a gap, then you need to leave it. But you should not make it wider than circumstances and common sense require.

- If you have an air gap, is it worth bringing (turning) it to a ventilation one? My advice: “Don't worry about it and act according to the circumstances. If it seems that it is better to do it, or you just want to, or this is a principled position, then make a ventilation one, but if not, leave an air one.

- Never, under any circumstances, use materials that are less porous than the materials of the wall itself to ensure the durability of the exterior finish. This applies to roofing felt, foam plastic and, in some cases, to foam plastic (expanded polystyrene) and also to polyurethane foam.Note that if a thorough vapor barrier is arranged on the inner surface of the walls, then failure to comply with this paragraph will not bring harm, except for cost overruns.

- If you are making a wall with external insulation, then use wool and do not make any ventilation gaps. Everything will dry out wonderfully right through the cotton wool. But in this case, it is still necessary to provide air access to the ends of the insulation from below and from above. Or just above. This is necessary in order for convection, although weak, to exist.

- But what if the house is finished with waterproof material on the outside according to technology? For example, a frame-panel house with an outer layer of OSB? In this case, it is necessary either to provide for air access to the inter-wall space (from below and from above), or to provide a vapor barrier inside the room. I like the last option much better.

- If a vapor barrier was provided during the interior decoration, is it worth making ventilation gaps? No. In this case, ventilation of the wall is unnecessary, because there is no access to moisture from the room. Ventilation gaps do not provide any additional thermal insulation. They just dry the wall and that's it.

- Wind protection. I don't think wind protection is needed. The role of wind protection is wonderfully performed by the exterior trim itself. Lining, siding, tiles and so on. Moreover, again, my personal opinion, the slots in the lining are not so conducive to blowing heat to use wind protection. But this is my personal opinion, it is rather controversial and I do not instruct on it. Again, manufacturers of windscreens also "want to eat." Of course, I have the justification for this opinion, and I can give it for those who are interested. But in any case, we must remember that the wind cools the walls very much, and the wind is a very serious cause for concern for those who want to save on heating.

ATTENTION!!!

There is a comment for this article. If there is no clarity, then read the answer to the question of a person who also did not understand everything and he asked me to return to the topic .. I hope that the above article answered many questions and brought clarity Dmitry Belkin

I hope that this article has answered many questions and clarified Dmitry Belkin

Article created 01/11/2013

Article edited 04/26/2013