Content

Despite all the popularity of natural gas in the modern world, there are places where its use is still not available. In this situation, a stove stove in a wooden house, which is heated with wood fuel or coal, will help a person. You can buy such fuel at any time of the year.

Classic potbelly stove design

In appearance, the potbelly stove resembles an ordinary rectangle with legs. It is completed with a door and a compartment for fuel, an ash box for combustion waste. In addition, any potbelly stove is equipped with a branch pipe, where an exhaust pipe with a length of 5 meters or more is placed. The traction and power of the device directly depend on the length of the pipe. The furnace body is made of steel or cast iron. We also recommend reading about the chimney for a potbelly stove in the garage on our portal.

Potbelly stoves are classified into two varieties:

- metal devices.

- Brick buildings.

Brick models are perfectly combined with a small country house and are able to heat several rooms in it at once. The stove evenly heats the rooms and allows you to keep warm for a long time. The only drawback of a brick potbelly stove is a long heating process. But the brick adds more functionality to the device, for example, during masonry, you can build a place for cooking. Masters can equip a recess for the oven.

Models of cast iron stoves are compact and easy to install, because they can be placed in any suitable place. The main thing is to properly fold the chimney so that it can be easily moved thanks to the corrugated pipes.

Difficult climatic conditions are a factor that everyone living in the vast Russian territory has to take into account. With the onset of cold weather, houses, apartments, industrial buildings are connected to district heating systems that supply heat and create comfortable conditions for us throughout the entire heating period.

Basic masonry techniques

Having decided to fold a brick oven with your own hands, the first thing you need to do is choose a design that meets your needs, find an ordering scheme and a description of the masonry, after which you can start buying material and purchased items. Laying a brick oven requires knowledge of basic working methods.

- A foundation is required for a brick oven, the dimensions of which exceed the dimensions of the hearth of the oven by 100-150 mm on each side. It can be made of reinforced concrete, as well as made of concrete blocks or rubble. The main requirement that must be observed is that the foundation for the furnace should not have a rigid connection with the foundation of the house, otherwise, seasonal ground shifts may damage the furnace or pipe.

- For laying the furnace with their own hands, two types of bricks are used: red full-bodied ceramics and refractory fireclay, yellow in color. The most heated surfaces are laid from fireclay bricks - a firebox, smoke channels, while using a refractory masonry mortar based on fireclay clay. The price of these materials is higher than that of conventional bricks, so fireclay is used only where necessary. All other elements of the furnace and the chimney are laid out of ceramic bricks, and a mortar based on furnace red clay or a purchased composition, including heat-resistant cement, is required.

Between the fireclay and ceramic masonry, it is imperative to maintain a gap of about 5 mm in order to compensate for the different temperature deformation of these materials.

- Purchased elements - grates, doors, views and hobs - are placed in accordance with the scheme. The doors are fixed with annealed steel wire at least 30-40 cm long.Its one end is inserted into the holes intended for this in the door frame, and the other end is fixed between the bricks on the masonry mortar. The slab and grate are placed on the previous row of masonry in the grooves selected in the brick. To compensate for the different thermal expansion of brick and cast iron, asbestos cloth or cord is used.

- The chimney of a brick oven is usually also made of brick, but an industrial-made ceramic block chimney can also be used. It is characterized by a long service life, increased resistance to condensate containing carbonic acid, creates stable traction, and does not clog.

- To give the stove an aesthetic appearance, it can be lined with finishing stone, clinker, tiles. Finishing gives the stove not only a beautiful appearance, but also protects it from the harmful effects of water and dust, and although the price of such a stove is somewhat higher, its service life is significantly increased.

Video: do-it-yourself oven masonry

Choosing the right stove design and high-quality masonry is the key to its long and safe operation. A do-it-yourself brick wood-burning stove will decorate any home, moreover, this heating method is reliable and allows you to create comfort and a favorable temperature regime.

The main advantages of stove heating

Installing the stove is not only a simple process, but also quite inexpensive in terms of the cost of materials. Using firewood is the most environmentally friendly way to heat a space that won't harm your family. The installation of the stove can be combined with the installation of a fireplace, then there will be not only a standard type of heating, but also a stylish design element in the room.

Furnace maintenance is a simple and relatively cheap process. The main advantage is the ability to regulate the degree of combustion and the ability to save heat with the help of special dampers installed in the furnace.

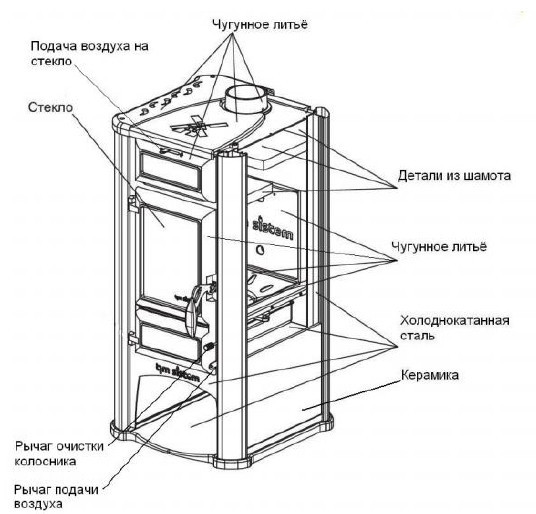

Solid fuel heating furnace Professor Butakov Student

Modern solid fuel equipment is constantly evolving, improving the appearance, design and technological processes. Despite this, simple metal stoves remain quite popular among ordinary consumers. A series of furnaces, Professor Butakov, named after its designer, is one of the few examples of domestically produced equipment that has created full-fledged competition with foreign analogues, and in some respects has surpassed them.

For heating small areas up to 150 m # 179, an excellent option would be to install a wood-burning stove, Professor Butakov Student, with a capacity of 9 kW. Despite the modest thermal power, the space is heated within the shortest possible time, no more than 2-3 hours from the moment of launch. Fast heating is ensured by the special design of the air heat exchanger, which ensures uniform convection heating.

The device of furnaces and the principle of operation

The heating furnace Professor Butakov Student is equipped with a combustion chamber capable of burning wood and afterburning the pyrolysis gas resulting from the combustion of the main fuel. The use of this technology made it possible to obtain a significant increase in efficiency and increase it to 90%, which is an excellent indicator for stoves operating on ordinary wood.

To obtain the maximum effect and the largest volume of pyrolysis gas, it is necessary to use natural, as dry wood as possible.

The heat exchanger of the heater is made of steel pipes encircling the firebox. In fact, the fire-tube heat exchanger is the body of the combustion chamber, absorbing the maximum heat released as a result of the combustion of wood. The lower air intake ends of the pipes are located almost parallel to the floor, this allows cold air to be drawn in.Getting into the tubes of the heat exchanger, the air heats up quickly, leaving through the upper free ends of the tubes, creating a constant draft and convection flow.

To ensure long service life, the bottom of the furnace is equipped with a cast-iron grate that is resistant to prolonged thermal effects. Through the grate, the residual combustion products in the form of ash, ash, and unburned fuel fractions enter the ash box, which allows you to clean the stove from debris directly during its operation.

The upper plane of the oven is a hob that allows you to heat or cook food on it.

Some model differences

Currently, this heater model is available in three configurations:

- Heating furnace Professor Butakov Student with a cast-iron door and glass. Glass makes it possible to observe the living flame in the furnace.

Heating equipment with a deaf damper.

Furnaces Butakov Student with the possibility of rear connection of the chimney. Compared to the classic design, where the chimney pipe is located on the upper plane, the rear connection increases the area of \u200b\u200bthe cooking surface and allows the stove to be connected to a chimney built into the wall.

Advantages and disadvantages

Despite a number of disadvantages inherent in such equipment, Professor Butakov Student's solid fuel heating furnaces have a wide list of advantages.

Wood is a natural fuel that does not pollute the environment during processing.

The use of a fairly simple design and reliable materials, steel, cast iron, ensures long service life.

Wood, for many regions, is the most profitable fuel from an economic point of view.

Increased efficiency rates of at least 90%.

Ease of operation.

The possibility of cyclic use only when necessary, unlike most heaters that require constant operation at minimum power.

Low cost.

Of the minuses of the equipment, the heating furnace, Professor Butakov Student, is not equipped with automation, therefore, it is necessary to constantly monitor the presence of fuel in the furnace and, for safety reasons, it is impossible to leave it unattended for a long time.

Installation

The entire line of heating equipment by Professor Butakov does not require lengthy preparatory work during the installation process. Furnaces are installed and fastened directly to the floor. Of the prerequisites is the observance of the air gap between the furnace body and the nearest surface, especially important for wooden houses. The heaters can be equipped with any suitable chimney system with a height of at least 5 meters to ensure normal draft and, accordingly, a constant combustion process.

Fire safety standards for the installation and operation of the furnace

In order to secure your home in the presence of a potbelly stove, you should follow some fire safety rules:

- Use only dry wood or logs as fuel.

- To ignite the device, open the firebox damper and put the required amount of fuel there, and then set it on fire.

- When the fuel has flared up enough, the power of the potbelly stove can be set by opening and closing the ash drawer.

- To clean the potbelly stove from the ashes, you need to completely cool the body, remove the ash drawer and discard its contents.

To clean the potbelly stove from ashes, you need to cool the body, remove the ash drawer and throw out the garbage from it

At the first ignition, you can smell the burning paint, but subsequently this effect will not be repeated.

Any flammable items should be at least 80 cm away from the potbelly stove.

It is forbidden to put more than 3 kg of fuel into the furnace at one time

It is important to keep the firebox door closed at all times.

It is forbidden to use the ovens if there are malfunctions in the functioning of the exhaust pipe.

It is forbidden to leave the potbelly stove unattended for a long time and in the presence of small children.

When the oven is in operation, do not touch the body of the oven, as it heats up to a very high temperature.

It is forbidden to place combustible materials near the potbelly stove.

It is possible to install a potbelly stove only on a non-combustible base.

It is possible to install a potbelly stove in a wooden house only on a non-combustible base

The furnace of the new furnace

In the morning after the installation of the furnace, it was decided to check its capacity. The entire firebox was not filled with firewood, small ¼ were laid. The logs were made of birch and aspen. After the firewood was in the firebox and set on fire, then smoke began to appear - probably, the paint burned through. All the time of burning, the work took place at the maximum of possibilities, later I wanted to ventilate the room. The entire incomplete bookmark burned out in 30 minutes.

What we have:

After some red coals remained in the stove, it was decided to throw in another portion of firewood. The floor under the stove became very hot, you can touch it, but you can’t hold it with your hand. The wall behind the stove, opposite the stove, is hot, but you can hold your hand for a couple of seconds.

Sandwich also - you can hold for a few seconds. Further, for one and a half hours, the firebox took place in the mode of long burning.

After the first furnace, the temperature was +22 degrees in the room, after the second +25.

Already after the first fire, it was possible to say that the stove works well and I like it very much, the power adjustments are simple, but at first it was not clear how the glass blowing works.

Glass after operation of a fire chamber remained pure. After the end of the furnace, after two hours the furnace was warm enough. I won’t argue about the heat capacity comparable to brick ovens, it is necessary to demand from each heating device what it can give, and receive from it what it is adapted for. It can be concluded that the Chinese-made cast iron stove is very functional in operation and gives an impressive result.

Self-installation of a potbelly stove

When choosing a stove option for a country house, it is important to carefully calculate the required power for heating the selected area. A potbelly stove with an area of 1 sq.m can heat a room with an area of 35 sq.m

When choosing a stove for a country house, it is important to carefully calculate the required power for heating the selected area.

An important factor in the operation of the device is the blowing of heat from the room and the influx of cold air there. For example, gaps in windows or floors that create a draft will noticeably disrupt the work of a potbelly stove. An excellent solution for a two-story country house is a two-story potbelly stove with a common chimney. Read more about installing a homemade potbelly stove in a country house on our website.

Video: installing a potbelly stove and chimney

If you want to reduce the cost of installing and purchasing the oven, you can try to make it yourself in accordance with the instructions.

Self-assembly of a potbelly stove

How to install a potbelly stove in the country

When installing a potbelly stove, it should be remembered that the metal case heats up quite quickly. Stainless steel ovens heat up less and cool faster. Potbelly stoves, which are made of cast iron, will store heat for much longer, therefore they must be installed in such a way that they are visible during operation and for some time after the flame has died out.

In the case of installing stoves on metal legs, it must be remembered that these auxiliary structures will also heat up. The heating temperature will be lower than that of the case, but still not too small. It will be necessary to carry out the installation of stoves in the country house on a fireproof base. In this case, you can use:

Scheme of the device stove potbelly stove.

- tin products;

- concrete structures;

- ceramic tiles;

- brickwork.

Fire hazards are:

- those made of plastic of any kind;

- plank or parquet floors;

- bases made of laminate;

- linoleum bases;

- Do not use carpet or other soft coverings.

If the house has wooden walls or panels, it is necessary to install a potbelly stove at a distance of 1 m from them. Chimney pipes in the room are installed from 1 section, without the use of joints. If for some reason this cannot be done, you need to make a tight connection, while one section must necessarily go into another. If the pipe passes through a wall, you will need to make a ceramic or brick thermal barrier. In this case, concrete can also be used, but with temperature changes it will crumble.

The fuel storage container will need to be placed next to the door so that sparks do not get into it.

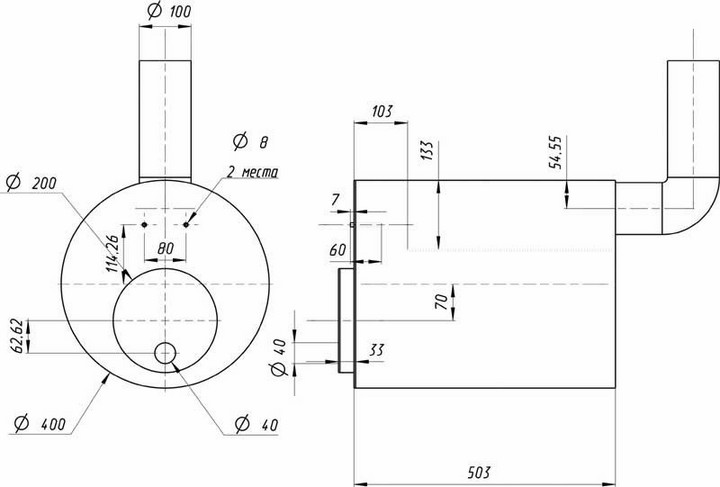

Diagram of a potbelly stove with dimensions.

Quite often, potbelly stoves in the country are used not only to provide heating. There are a large number of designs that combine several functions. Such designs include a heating potbelly stove with a cast iron stove. They can be used for cooking and at the same time for heating a country house. A cast iron household stove with 1 burner can easily replace a gas or electric stove in the country. If there is a need to feed several people at the same time, you should make or purchase a stove with a solid surface for cooking or with 2-4 burners.

Also popular are stoves that have a water tank. Their design is similar to a samovar. A water tank is mounted around a wood-burning cast-iron stove.

General recommendations for installing a potbelly stove with your own hands

Scheme of installation of a chimney for a potbelly stove.

It is necessary to first familiarize yourself with some information about the installation of a similar design in order to know what nuances you will have to face.

You can install a potbelly stove if you have basic construction skills and learning abilities.

The main problem for heating equipment that runs on wood is the installation of a chimney system. The potbelly stove has simplified requirements when compared with a fireplace. In this case, it is not necessary to make a vertical chimney.

For fire safety purposes, a potbelly stove needs an insulation layer. To do this, you need to make a brick pad or use a stainless steel sheet. You can also use asbestos-cement sheet, which is covered with galvanization. This design is able to withstand temperatures up to +400°C.

It is allowed to use metal legs to install the furnace. This design can save building materials and own forces that can be spent on installing the furnace.

Scheme of a potbelly stove with a heat exchanger.

It is necessary to retreat 80 cm from the wall or add a thermal insulation layer to the wall. It is also recommended to arrange a protective coating around the perimeter of the furnace, which can prevent fire if sparks fall on the floor.

The chimney can be led out of the wall at an angle. In this case, it is necessary to take care of the hermetic connection of the sections of the chimney structure. In most cases, a sandwich construction is used, which has a high level of safety due to the fact that the chimney pipe is partially insulated in the structure. It is not allowed to use thin stainless steel for the chimney structure, because it will burn out quickly. The pipe must be led outside through a drilled hole in the wall or roof. At the end, the cracks formed must be covered with clay.

In order to be able to regulate the draft, it is necessary to purchase a gate valve, which is installed in the chimney structure and can block it completely or partially, if necessary. The gate will need a few mm less than the diameter of the pipe.Make 2 holes in the pipe. Next, you should thread a rod into them, to which the gate is fixed.

The walls next to the stove must be protected with a steel screen or lined with ceramic tiles. It is preferable to use the latter option.

At the end, cosmetic work is carried out, consisting in filling up the cracks and ennobling the site on which it is planned to place the potbelly stove.

How is the chimney installed?

To install a chimney, the following materials are needed:

- knee 1200x100 mm;

- 2 knees 1200x160 mm;

- 3 butt elbows;

- tee;

- plug;

- fungus.

For the device of the chimney, heat-insulating material and a passage glass can be useful. To seal the seams, a sealant or asbestos cord is used.

The chimney installation process is as follows:

- It is necessary to fix 1 piece of pipe on the chimney opening.

- Pipe elbows will need to be extended to the floor line.

- In the ceiling, you need to make a hole with a diameter of 170 mm or more. In places where the chimney must pass through the ceiling, it will be necessary to remove the heat-insulating layer. This is necessary in order to exclude the possibility of ignition of this layer.

- It is necessary to insert a passage glass into the hole that has been made, and then pass the chimney pipe through it.

- Next, the pipe is docked with the outer chimney structure.

- A layer of bitumen is applied to the outer part of the pipe. All this is wrapped in thermal insulation material.

https://youtube.com/watch?v=SMVD6li2QI4

Installing a potbelly stove is quite simple if you know all the nuances and have all the tools.

Features of furnace heating

Stove heating has a number of advantages, thanks to which wood-fired brick ovens have not lost their popularity for several centuries. The most important advantage is the ability of ceramic bricks, from which stoves are laid, to accumulate and give off heat for a long time.

At the same time, radiant energy useful for the human body is released into the space, giving a feeling of warmth and comfort. With regular heating in the cold season, the house is always warm and dry, and due to stove draft, natural ventilation is formed. In the heat, the stove, on the contrary, cools the rooms by removing excess heat into the ground and air through the foundation and chimney.

In addition to creating a comfortable microclimate, a brick oven can carry additional functions, the presence of which depends on the design:

- cooking - boiling, frying, stewing and baking;

- drying clothes, shoes, food;

- heating beds for sleeping;

- the opportunity to admire the open flame.

Furnaces that provide several functions are called combined. These types of stoves include heating and cooking stoves, fireplace stoves, as well as several popular basic models, including a Russian stove.

Stove heating also has disadvantages, these include the inability to effectively heat remote rooms. Therefore, in large-area houses, several stoves with separate or combined chimneys are usually installed, or stove heating is combined with other types of heating.

In compact houses, consisting of one or more rooms, the stove is usually located in the center, so that its walls are located in all rooms. The hob and oven are placed on the side of the kitchen, the stove bench is in the bedroom or nursery, and the open fireplace insert is in the living room or dining room.

Equipment characteristics

Recently, due to the variety of potbelly stove design, you can complement the overall style of the interior of the room. Thus, it is not only a device for heating, but also a kind of room decoration. The stove runs on wood no more than 25 cm long or on other solid fuels, it all depends on the preferences of the owners and their financial capabilities.

The main functions of a potbelly stove installed in the country:

- Heating.

- Possibility of cooking.

- Interior decoration.

Increasingly, a stylish potbelly stove is becoming a serious competitor for fireplaces, because, in addition to other positive qualities, the device is compact. It is easy to connect it, if necessary, transfer it to a new place or place it on the street for the purpose of frying meat in the fresh air.

A modern potbelly stove not only heats the room, but also decorates the room

If you need to frequently transport the stove from one place to another, then it is better to give preference to collapsible models. They, as a rule, easily remove the top cover, which often acts as a hob. This potbelly stove is also equipped with detachable legs and a chimney consisting of several sections. The stove does not take up much free space, is a mobile piece of furniture and is easily transported. The use of a potbelly stove completely eliminates the risk of carbon monoxide poisoning for people, because it leaves the room through a pipe. It turns out that the safety of the device and the power of operation depend on the installation of the pipe.

Collapsible model of a potbelly stove

How is the frame potbelly stove installed

The device of a frame stove is somewhat different from simple structures. To equip a garage with a heating structure, you must have:

- Metal sheet;

- corner;

- pipe;

- steel fittings;

- thick wire.

From the tools you need to find:

Scheme of installation of a potbelly stove.

- roulette;

- fasteners;

- apparatus for welding;

- jigsaw.

The order of work will be as follows:

- A frame is made from the corner. To do this, the metal is sawn into separate strips. Next are the legs. 2 rectangles of the same size are welded, legs are welded to one of them. The 2nd rectangle is installed half a meter above the earth's surface and is attached by welding or bolts.

- Corps is attached. Rectangular parts are cut out of steel. For this purpose, you must use a jigsaw. The structure is connected by bolts or welding.

- Next, a door with a handle is attached to the body.

- A grate is made from the existing wire or steel reinforcement, after which the structure is placed on the bottom.

- Next, you need to make a chimney pipe. One end of the structure is inserted into the oven, and the other end must be taken outside.

To get a large amount of heat, you need to come up with a long and wavy pipe path through a heated private house. The chimney can be led out through a window, roof or wall. When doing this, make sure that all connections are tight. If this is not taken into account, smoke will enter the room.

Benefits of using in a wooden house

A standard wood-fired brick structure has many advantages over other methods of heating a structure. Instead, even a fireplace with a beautiful appearance can be formed. These designs look very good in wooden houses, and also have the following advantages:

- Construction can be done by hand, which reduces the financial cost of paying workers.

- A stove or fireplace is suitable for a house made of timber or SIP panels, as well as for a frame structure.

- Heating is highly efficient.

- It is possible to create a cooking and heating structure that can be used for the cooking process.

- A quality stove or fireplace can heat two or more rooms.

- If the heating structure is built in accordance with all the rules using high-quality bricks, and the correct project is created in advance, then it will have a long service life and high reliability.

- Since the stove and fireplace are wood-fired, the operating costs will be low.

The disadvantages of stove heating in a house made of timber, SIP panels or in a frame house include uneven heating and the need to constantly store a large amount of fuel, since the structure runs on wood and needs regular replenishment. Also, if the work is done with your own hands, then you need to make a special project in advance, which will reflect the scheme of the future structure and the phased process of its creation.

Water heating in a wooden house

This is the most common type of heating. The heat carrier (water) is heated by a heating boiler and, circulating through a system of pipes and radiators, heats the house. As a fuel for the boiler, natural gas, diesel fuel, solid fuels - coal, firewood, pellets, peat, etc. can be used. Electricity can also be used to heat water in the boiler.

The most economical option for water heating a wooden house is gas heating. Therefore, if it is possible to connect to the gas main, it makes sense to use it. Heating with an electric boiler is quite expensive, it can be recommended in well-insulated houses, where electricity consumption for heating will be minimal. Diesel boilers are quite economical, but require the construction of a separate building.

The above heating systems are volatile, i.e. If there is a power outage, the heating will not work. What these types of heating are good for is that they are carried out automatically, human participation in this process is minimal. This cannot be said about solid fuel boilers, which require constant maintenance - every 3-4 hours they need to be filled with fuel. But this fuel has a relatively low cost, and heating with a solid fuel boiler is non-volatile, it will work even when there is a power outage.

When installing water heating of a wooden house, it must be taken into account that wooden houses shrink over time, and also tend to dry out from exposure to high temperatures and deteriorate from dampness, which can be caused by condensate falling on cold pipes. Therefore, when laying heating and water pipes in wooden houses, the following conditions must be met:

- Compensators and sliding type fasteners must be provided on vertical sections of pipes.

- All pipes must be protected with thermal insulation. Heating - to avoid heating the walls, and plumbing - to prevent dampness.

- With hidden laying of horizontal pipes, drilling of technological holes in the floor and ceiling beams is inevitable. In order not to harm their bearing capacity, it is necessary to coordinate this issue with the designers.

The process of building a brick potbelly stove

Installing a potbelly stove in a wooden house in the country requires the preparation of the following materials and tools:

- Ceramic brick.

- Furnace accessories.

- Plaster with lime and clay content.

- clay solution.

Read also how to install a potbelly stove in an apartment for heating on our website.

Stages of construction

The first row of the furnace is laid out very accurately, because it affects the entire subsequent construction. Inexperienced beginners can lay 25 bricks a day, and then check the result the next day.

The first row of the oven is laid out very accurately using a level and corners.

- For the straightness of the structure, corners made of metal and wooden slats are located in the corners.

- When laying the second and subsequent rows, an opening should be left for the future door.

When laying subsequent rows, you need to leave an opening for the future door

- Starting from the 6th row, a refractory mixture is added to the masonry, replacing clay with it.

- At the end of the work, a pipe is attached to the top of the structure - smoke will come out of the potbelly stove through it.

A pipe is attached to the top of the structure - smoke will come out of the potbelly stove through it

Conclusion

How potbelly stoves are installed in houses depends on the type of house, the materials from which it was built, the number of storeys, and the dimensions of the free space.

It is important to determine the place, prepare the floor and walls, observing fire safety rules

Installing the potbelly stove is easy. The most time-consuming work is the preparation, assembly and fastening of the pipe. By following all the rules, you can create a useful and beautiful heating structure.

Table of contents

There is an Evergreen 147 stove, a cast-iron potbelly stove of small size (width 43 cm, depth 40 cm, height with legs 58 cm), the power according to the passport is 7 kW, the size of the firewood used is up to 30 cm. The country of origin of the stove is China. In appearance, the casting of the structure is very similar to the Invicta oven, the door, glass with seals, there are air distribution adjustments.

The chimney was purchased brand "BaltVent" 150/250 mm inner pipe acid-resistant stainless steel 1 mm thick steel 316, insulation 50 mm, outer - stainless steel 0.5 mm thick steel 304, the first 1.5 meters from the stove is a black single-layer chimney made of steel 2 meters.

The photographs immediately show what exactly happened - the result of the installation.

Immediately after the entire installation of the structure, two small logs were thrown inside the furnace, to check how it burns and in which direction the smoke spreads. The temperature was +34 degrees in the shade. As a result, the temperature throughout the day is 33-39 degrees. There is simply no need to heat harder and at full power.