Advantages and disadvantages of PPU pipes with galvanized insulation

Industrially produced pipes with polyurethane foam insulation have the following distinctive features and parameters:

- The manufacturing technology of PPU insulation consists in foaming the material, after it hardens, a fine-meshed structure is formed with a gas content of about 95%. Due to this, PPU is lightweight and has low thermal conductivity. Of the entire class of foam plastics - products made from foamed synthetic materials, PPU has the lowest thermal conductivity of 0.02 W. / m. * K., which is 2 times lower than that of foam plastic.

- Polyurethane foam insulation is light in weight, its average density is about 50 kg. per cubic meter, which is comparable to extruded polystyrene foam (Penoplex) and 2 times higher compared to polystyrene foam.

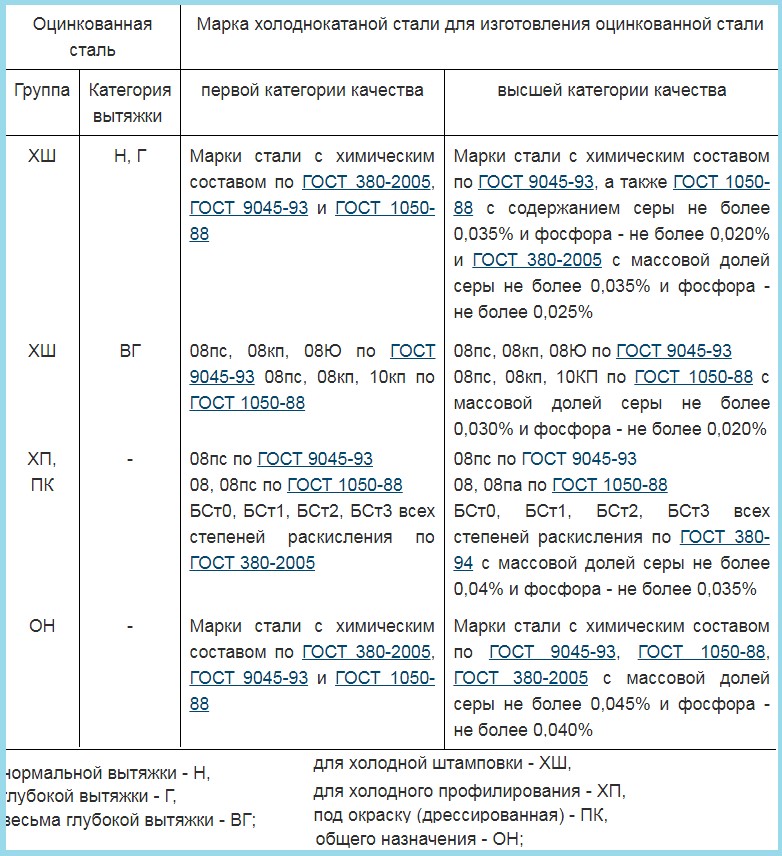

Rice. 5 Mechanical properties of galvanized steel

- PPU insulation does not absorb water, its water absorption does not exceed 1%, the material has low vapor permeability and excellent adhesion to all building materials.

- PPU is afraid of ultraviolet radiation, therefore it is used in structures closed from daylight.

- The temperature range at which the material does not change its characteristics is -150 - +150º C.

- Polyurethane foam refers to moderately flammable self-extinguishing materials, the burning time of which is less than 30 seconds (combustibility class G2), the flue gas temperature does not exceed 235º C.

- The service life of the PPU protective layer is 30 - 50 years, the steel anti-corrosion coating of the pipe shell has a similar durability.

- Polyurethane foam refers to chemically neutral components, does not interact with most aggressive chemicals, decomposes when exposed to saturated solutions of acids (nitric, sulfuric, hydrochloric).

- Polyurethane foam is environmentally friendly, does not emit harmful substances in its normal state.

- The material has a high resistance to biological influences (fungus, mold), is not damaged by rodents.

- In case of damage, repair and insulation are carried out without dismantling the defective area, which distinguishes galvanized products from PPU with a polyethylene sheath.

Rice. 6 Application of protective covers for pipes made of galvanized steel

Pipe insulation with galvanized steel casings

Galvanized insulation is designed to protect engineering networks from environmental temperature effects, impact and condensation, reduce heat loss. When using galvanized casings, protected communications have an aesthetic appearance, besides, their service life increases. Casings made of galvanized steel have a standard thickness of about 0.55 mm. Their service life depends on external conditions and averages 30 years.

In the manufacture of composite cylindrical shells, various types of beading are often used - processing the edges and surface of the product on a special machine. When the edges of cylindrical blanks are bent, an expanded pipe is obtained - this allows you to insert pipes into each other when installing extended insulation, as well as increase the strength of products in the longitudinal section. With another common type of zigzag, a bend is made along the edges, which makes it possible to obtain a strong locking connection of the longitudinal edges or transverse ends.

Rice. 11 Galvanized fittings for coating insulation on pipelines

Casings are made for a standard pipe size; for a longitudinal connection, an overlap of 30 - 50 mm is made. or bend the edges in such a way as to obtain a locking connection in which they are securely fixed by snapping.

Usually packaged products are made by private firms and individual entrepreneurs by pressing or cold stamping, their main types are: tees, bends, adapters, cones, a casing of any shape and size can be made to order.

Molded products are used on shell-type heaters made of polystyrene foam, polystyrene foam, polyurethane foam, with their help it is convenient to keep heat-resistant glass wool on the surface of pipes, which is widely used in the insulation of chimneys and in-house hot water lines.

The frames for the photo are taken from the video clip on the installation of HOTPIPE cylinders.

Rice. 12 Installation of casings with insulation on the pipeline

When installing galvanized insulation from shells, the connection is made using locks and self-tapping screws screwed into pre-prepared holes.

Functions of heat insulators for heating pipelines

If we consider a private house, then the heating boiler can be located inside the knowledge in the basement or outside in a separate technical annex. The latter option is often used in the absence of a gas pipeline and the use of solid dirty materials as fuel - coal, firewood, peat, briquettes, pellets.

Many private houses have outdoor baths or saunas, so as not to complicate the design by installing a separate tank for heating water in them, it is brought into the premises from the boiler, while the distance between objects can be quite significant. When deciding how to insulate heating pipes, choose materials that meet the conditions below.

Reduced heat loss

The principle of operation of any insulation is to protect the insulated surface of the protected object from contact with the environment. At the same time, due to the low thermal conductivity of the insulator, there is a decrease in heat loss, and the equalization of the temperatures of the air and the hotter pipeline proceeds much more slowly than in the absence of a heat insulator.

Any heating main can be placed on the surface of the earth and under the ground, in the first case, a soft insulation is usually installed for heating pipes in the open air, while underground placement, due to soil pressure, protection from hard materials is installed.

Rice. 3 Mineral wool - a popular heat-insulating material for heating pipes

Frost protection

If hot water in an individual heating system is supplied from the boiler to an object located at a considerable distance from it, the water supply system is usually laid underground at a distance from the surface below the freezing point. At the same time, it is not always possible to locate the pipeline at a sufficient depth, so if the hot water supply is interrupted for a long time, the liquid remaining and cooling in the pipes during severe frosts may freeze. To protect the underground line from freezing, it can be thermally insulated by placing it in hard shells or in soft shells located in pipe channels.

Prevention of condensation

Building codes prohibit the laying of metal pipes in the ground in the absence of insulation or protection of the outer shell with auxiliary materials, the situation is different indoors, where steel, galvanized steel, and copper pipelines are often laid. When the heating is turned off, the liquid in the metal pipes cools down and condensation appears on their surface, water drops cause corrosion of the outer wall and, if accumulated, fall down to form puddles on the floor - this can cause damage to the flooring.

To combat this phenomenon, porous thermal insulation materials for pipelines are used, resistant to water or with good vapor permeability.

Rice. 4 Foamed polyethylene - thermal insulation for outdoor heating pipes

Protection against thermal burns

In public utilities and households, the temperature of the coolant transported through pipes can reach values close to 100 ° C, so the task of protecting maintenance personnel or residents of a private house from burns when in contact with pipes becomes relevant. To do this, their outer walls are covered with thermal protection from various types of heat insulators, the shell of which cannot have a high temperature, by definition.

Neutralization of geometric deformations

The ability of all materials to expand when heated is well known, therefore, a hot pipeline, when passing through walls or floor slabs, is placed in steel sleeves of a larger diameter. A heat-insulating shell is applied to the pipe, which protects the assembly from hard contact of the shell that has increased in diameter with the wall of the sleeve.

When laying pipelines in walls or under the floor, their expansion can lead to cracks in the plaster, screed, so the use of an elastic sheath that takes part of the thermal expansion helps to avoid problems associated with the geometric deformation of pipes.

Rice. 5 Expanded polystyrene shell - material for insulating heating pipes in the ground

Ways to insulate water pipes

If, during the underground laying of the pipeline, the depth of the line was maintained correctly and there is no danger of water freezing in this area, then when entering the house, the water supply system rises closer to the surface and enters the soil freezing zone.

After that, he enters the building and walks some distance along the basement (underground). If the rooms below the zero mark of the house are warm, then it is only necessary to isolate the underground section of the pipe rise and the input unit. Otherwise, the work on the thermal insulation device is divided into two stages:

- insulation of water pipes in the ground;

- thermal insulation of pipes of open laying in the basement.

This separation is due to the different technologies used for each case. The insulation of the underground laying must be rigid, moisture-proof and not attract rodents and insects. For open pipe laying in the basement of a building, the requirements are less stringent and make it easier.

Heating pipeline insulation

During the heating process, the liquid that is used as a heat carrier circulates throughout the system. In order not to lose useful heat and avoid excessive overheating of the room, insulation of heating pipelines is carried out.

Such work is necessary in country houses, if the heating pipelines run down the street from the boiler room, or when the boiler is located in the far wing of the building, and the pipes are stretched along cold corridors. This helps to deliver more heat into the room, keeping it along the entire route: from the boiler room to the heating radiators.

Several types of heaters are used as a material, they differ in thermal conductivity and installation methods, and when choosing a material, you need to know at least a little about its qualities.

Technology and installation of heaters in everyday life the best options

To save money on space heating, owners of private houses often have to decide how to insulate heating pipes, considering various types of pipe insulation. At the same time, heating networks can be located anywhere in an individual site: inside a house or outbuilding, underground or on its surface.

Rice. 18 Application of Thermal Paint

Insulation of heating pipes on the street

When deciding how to insulate heating pipes on the street with your own hands, you should first consider PE shells of a suitable inner diameter with closed cells. They have a surface film of various colors to close the longitudinal seam, use tape, staples, self-adhesive varieties of tubes or any adhesive for polyethylene.PE tubes, depending on the ease of use, acquire a standard length of 2 or 10 m, installation work is carried out in the following sequence:

- They clean the pipeline from dirt and dust and put a PE tube of the required size on it, when the seam is going to be coated with glue, it is placed at the top.

- If a non-self-adhesive variety is used, coat the walls of the longitudinal section with glue and connect them until completely dry, then turn the shell over with the seam down.

- In a similar way, the ends of whole tubes or cut sections are glued together, resulting in a solid and aesthetically beautiful protective sheath.

Rice. 19 Installation of PVC pipes - main steps

Insulation of heating pipes in an unheated room

Indoors, for the insulation of pipelines, it is possible to use cheaper open-cell PE tubes in comparison with the option discussed above, and options for mounting protection with a foil surface layer are also often used. Some manufacturers, for example Energoflex, sell together with their tubes a special glue for joining PE products and an additional tool in the form of a special knife for cutting PE casings and a plastic miter box for cutting tubes straight or at an angle of 45 degrees. PE thermal insulation for heating pipes in an apartment or a private house of the Energoflex brand is mounted as follows:

- A dedicated longitudinal seam is additionally cut in the tube with a special knife.

- The seam is expanded and the product is placed on the pipe.

- The edges of the seams are fastened with special plastic clips in the form of half rings, for this they are connected together and clamping brackets are inserted in the amount of 4-5 pieces per linear meter.

- If it is necessary to isolate the corner fragment of the pipeline, proceed as follows:

- A pipe cut is inserted into a special miter box and the middle fragment is cut out, and the ends of the elements to be joined are cut at the desired angle.

- The resulting parts are glued together, smearing their edges with Energoflex special glue.

- The resulting corner element is cut along with a special knife, its longitudinal ends are smeared with glue and the parts are put on the corner of the pipeline, the halves can be wrapped with tape for 2 to 3 hours until the glue dries, after which the shaped assembly is ready for operation.

Rice. 20 Installation of Energoflex insulation corner element inside the building

Insulation of heating pipes underground

When deciding how to insulate heating pipes on the street during underground laying in the household, hard shells are usually used or soft porous materials are placed in polymer pipes of a larger diameter. For thermal insulation of pipelines with a foam shell, proceed as follows:

- The pipeline lying on the surface is cleaned of dirt and shell segments are placed on it by connecting a tongue into a groove so that the upper and lower elements lie with a shift.

- As the fragments are laid, they are tied together with adhesive tape; for connection, you can also use special foam glue.

- After installation on the surface, the pipeline is placed in a trench on a pre-filled pillow of sand and sprinkled with earth.

Rice. 21 Installation of hard shells

When insulating heating pipelines, materials used in the construction industry are widely used; for ease of use on pipelines, they are produced in the form of cylindrical shells or hollow tubes of various lengths. To insulate external and internal heating pipelines, the most rational option is to use soft pipes made of foamed polyethylene; an underground pipeline is usually insulated with hard foam or polyurethane foam shells.

Energoflex

Energyflex insulation for heating pipes is the most demanded material in our time. It is used for thermal insulation of pipelines with a small diameter.Energoflex for pipes is produced in rolled material, as well as in the form of hollow tubes 1-2 m long, having the shape of a cylinder of different diameters with a longitudinal technological notch.

There are a few things to keep in mind when using this product. Before performing insulation, the surface of the pipes should be checked, which should be cleaned and degreased. The water supply during work is stopped and after they are carried out it is turned off for another day. It is impossible to carry out installation at sub-zero temperatures. First, the reinforcement and protrusions are insulated, and then the flat sections of the pipes. When carrying out work with rolled material, it is necessary to ensure that the upper layer of insulation overlaps the lower joint. The covering during laying should not be stretched.

This type of insulation has hygienic certificates and meets all European and Russian standards. Energoflex for pipes has low thermal conductivity, good sound insulation, resistance to chemical compositions, frost and heat resistance, strength, durability, flexibility, ease of installation.

What is zinc tubing

The use of PPU insulation on pipes is necessary to protect against two negative factors: the influence of the external environment and physical exertion, leading to compression of the insulation and, accordingly, lowering its thermal insulation properties.

Also, the use of the outer shell is an important part of the technological process, in which the liquid polyurethane foam mixture is poured into the space between the inner steel pipe conducting the working medium and the outer one, which forms the insulation layer of the required thickness and shape. For the production of external heat-insulating galvanized pipes, thin-walled steel up to 1 mm thick is used; in the manufacture of pipe products, they are immersed in a bath of hot zinc (hot-dip galvanizing method) - thus a double-sided protective anti-corrosion shell is obtained

In production, zinc grades Ts0 and Ts1 are used according to GOST 3640-94, aluminum, lead are added to the bath (melted with zinc grade Ts2)

For the production of an external heat-insulating galvanized pipe, thin-walled steel up to 1 mm thick is used; in the manufacture of pipe products, they are immersed in a hot zinc bath (hot-dip galvanizing method) - thus a double-sided protective anti-corrosion shell is obtained. Zinc grades Ts0 and Ts1 according to GOST 3640-94 are used in production, aluminum and lead are added to the bath (melted with zinc grade Ts2).

To increase the strength, the outer pipe is produced with stiffeners, often a copper wire is embedded in the shell, which is necessary to control the integrity of the pipeline, the insulation coating and its outer shell.

Rice. 2 Rolled steel grades for the manufacture of PPU pipe coating with galvanized steel

Polyurethane foam, from which the thermal protective shell is made, is found in everyday life in the form of foam rubber, it consists of mounting foam, widely used in the construction industry. The component is obtained from the combination of two products of chemical processing of oil - polyol and polyisocyanate, when a small amount of water is added to the mixture, carbon dioxide CO2 is formed, and its intensive release causes foaming.

polyurethane foam

This insulation is applied by spraying. A specially prepared composition is sprayed onto the mounted pipeline. It reliably adheres to the surface and, foaming, forms a dense protective mass with high strength.

Due to the fact that this insulation does not tolerate exposure to sunlight, the insulation of pipes located in the open air with it must be accompanied by their protection: winding with roofing felt or aluminum foil.

For high-quality insulation of pipes, heaters can be combined. For example, in the boiler room and on the street they can be covered with mineral wool or basalt insulation.And in the house there are places for connecting to radiators - with foamed polyethylene, which looks more aesthetically pleasing.

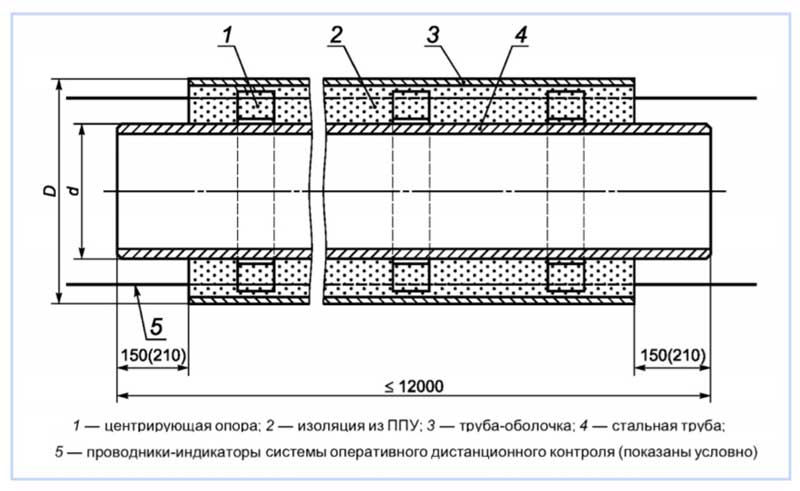

What are PPU pipes

Standard pipes with polyurethane foam (PPU) insulation have a two-layer coating consisting of a foam insulator with an air content of about 98% and an outer strong polyethylene (HDPE) jacket as protection. Sometimes the production technology provides for a three-layer coating of two HDPE shells, between which there is a polyurethane foam insulator.

The industry produces pipes in insulation, placed in another type of outer shell - galvanized insulating steel, which allows for a higher coating strength. Some galvanized and polyethylene shells are additionally equipped with stiffeners, which further increase their strength. In the marking for shells, an additional designation is introduced - PE for polyethylene and OC for galvanizing.

In critical highways, pipes with a built-in electric cable of the control system (SODK) are used, which perform the functions of an indicator diagnostic conductor. This allows you to monitor the integrity of the line throughout and easily find problem areas during equipment operation.

Fig. 2 Pipes in PPU - device

Installation of galvanized PPU protection

Installation of pipes is carried out by welding, for sealing joints, a polyurethane foam mixture is used, which is poured into an empty space using a formwork made of galvanized sheet. To connect galvanized pipelines, a two-component composition of polyurethane foam is used, a cover cuff from a zinc sheath segment and a bitumen-rubber adhesive tape, the work is carried out in the following sequence:

- After checking and examining the quality of the weld, a workplace is prepared to ensure free access for the worker to the joint, a temporary shelter is constructed from precipitation, the air temperature should not fall below -25º C.

- The surface of the zinc sheath is cleaned, washed and dried, the pipe is cleaned from dirt, paint, traces of scale and rust with a stiff brush to a metallic sheen, the inner surface of the casing and the galvanized sheath in the contact zone are degreased with solvent brand No. 646.

- Remove the waterproofing from the ends of the pipes to a depth of 15 - 20 mm, when wet, remove the layer until a dry surface appears.

- Connect or pair together the conductors of the operational remote control system (SODK) of adapters and pipes.

- Cut out two strips of adhesive tapes with a pipe circumference of 50 mm, heat the pipe ends with a gas burner to 80 - 90º C and stick the strips on the surface, which melt slightly upon contact with the metal.

- In the same way, a strip is glued to the longitudinal surface of the metal casing after heating the contact point with a gas burner.

- Install the protective cover on the surface of the pipes with an overlap so that one edge goes from top to bottom, fix it along the edges with tightening straps.

- Gas burners heat the surface of the casing along the edges and in the place of the longitudinal connection, gradually tightening the belts, the procedure is continued until the steel casing begins to tightly fit the joints and squeezed out adhesion appears at the edges. To bleed air and fill in the upper part, a hole with a diameter of about 10 mm is drilled.

- Using a screwdriver and self-tapping screws, the edges of the casing are connected along the entire length and along the circumference with a step of 100 - 250 mm, a distance of 10 -15 mm retreats from the edges. Fig. 9 Adhesive tape, which is installed at the joints of the PPU pipeline

- The joint is poured at its temperature of 20 - 25º C, if the ambient temperature is below -10º C, the casing is heated with a burner in the range from 20 to 40º C, two drainage holes with a diameter of 3 mm are drilled along the edges of the cuff.

- PPU components are mixed at a temperature of 18 - 25º C in the amount necessary to cover a given volume, first pour the contents of the container with composition A and add a normalized amount of B, mix for 20 - 30 seconds until a homogeneous composition is obtained using an electric drill and a mixing nozzle.

- The composition is poured through the upper 10 mm hole of the metal casing, and the entrance is closed, previously cut with a small metal plate (140x50 mm).

- The appearance of foam in the drainage holes indicates the complete filling of the volume, after 20 - 30 minutes the cover is removed and excess PPU is removed from it, drainage 3 mm channels are cleaned of polyurethane from above.

- The casing is heated in the area of the filler hole to a temperature of 80 - 90º C, an adhesive tape is applied to it and then a cover is applied, the lining is pressed with a tightening belt and fixed at the corners with four self-tapping screws (rivets).

- Pieces of tape 40x40 close the drainage 3 mm external outlets along the edges, applying them to a surface preheated by a gas burner, after which the holes are closed with plugs using self-tapping screws or rivets.

Rice. 10 Galvanized pipe insulation example of installation at joints

Insulation materials for heating pipes and their application

In many houses (from buildings that have been standing for more than a dozen years to newly built cottages), people overpay considerable amounts for heating just because the heating system wastes a significant part of the energy (in particular, those networks that run down the street).

Very often this happens due to errors made during the installation of pipelines of heating networks - while losses can reach 40-60%, which, of course, is a lot.

Moreover, this situation not only increases your costs, but also reduces the service life of heating network equipment, which would have worked longer with lower loads.

For this reason, the thermal insulation of pipelines of heating networks is a rather relevant solution that should not be neglected. Consider how the heating pipelines are insulated, what material is used and how exactly this procedure is performed.

Important conditions for laying underground water supply

The prerequisites for freezing water in pipes arise even at the stage of installation of an external water supply system. Construction rules expressly indicate that the depth of underground water lines should be below the standard freezing point of the soil.

For our northern country in most regions, this value exceeds 1.2 meters. You usually do not want to dig such a deep trench and take it as a truth (hope) that the soil does not freeze to such a depth, and as a result, the water supply is laid at a depth of half a meter, thereby making a gross mistake. In one of the winters, the water in it will definitely freeze. And dig frozen soil in winter ... Draw your own conclusion.

Why insulate pipelines

To begin with, let's take a closer look at whether it is necessary to use the material for insulating heating pipes or for thermal insulation of heating networks, and if necessary, then why and where exactly.

The heating system of any building is arranged as follows: indoor air heats the coolant (water) circulating through pipelines to radiators.

Giving off its heat through the walls of the pipes, the water returns back to the boiler, which again heats it. This is if in general terms.

However, heat transfer is not necessary along the entire length of the pipe. For example, if the boiler room in your house is located far from residential premises (or even in a separate building on the street) that need to be heated.

In the process of transportation from the boiler to the area requiring heating, the water will lose some of the heat. As a result, more energy (fuel) will have to be spent on heating the air for living rooms, which means more money.

Often, boiler rooms are located in basements, where the temperature is significantly lower than for a living room. So Energoflex insulation for heating pipes in the basement will give a serious result in saving fuel.

But thermal insulation for heating pipes for an apartment is no longer so important and indispensable. The only caveat is that the insulation of heating risers is relevant: in this case, more heat will reach the battery

In addition, the pipeline also needs mechanical protection - from possible damage. First, this applies to sections that run along the street - it is their isolation that needs to be thought about first of all.

Alternative ways to protect water pipes from freezing

It is possible to protect the water supply in a private house not only with the help of thermal insulation, but also in other ways. These include:

- pipe heating with electric heating cable;

- creation of excess pressure;

- with an air shell.

These three protection technologies are widely used in practice and therefore deserve more detailed consideration.

Using a heating cable

This method involves direct heating of the pipeline using a special electrical cable. It can be on the surface of the pipe or inside it. The average heating power consumption is 20 W per linear meter of water supply, but the exact value is determined by the way the wire is located and the diameter of the pipeline.

The use of external heating technology allows you to lay water pipes at a depth of less than 1 meter, as well as once and for all solve the problem of how to insulate a water pipe on the street. However, the additional consumption of electricity in the cold season makes one think about the feasibility of this method.

A good option would be to use the heating cable and thermal insulation together. In this case, it is placed under the heat-insulating layer along the pipes on the surface. Heat loss will be minimal and power consumption will be significantly reduced.

Air insulation

This anti-freeze technology is only applicable to underground plumbing. The essence of the method is the presence of an air gap between the surface of the pipeline and the soil. It is created using a plastic corrugated pipe put on top, the diameter of which is 20-25 mm larger than the diameter of the water pipe.

The result is a "pipe in pipe" system with an air gap of sufficient size. Tap water, having a positive temperature, heats the air and provides itself with protection against freezing. However, such a system requires a water intake, and if water is not used in the house for 3-4 days, the air will cool down and the insulating effect will disappear. Therefore, this technology is not suitable for giving.

Building high pressure

This method is based on the physical property of water to lower the freezing point at elevated pressure, similar to the property of boiling at temperatures below 100°C in the highlands.

Excess pressure is created by means of a pump and a receiver. However, there are technical difficulties here. The fact is that the water fittings in the house are not designed to work with high water pressure. So, for example, the standard pressure for a shower mixer is 0.1 MPa. Therefore, it is necessary to create a rather complex engineering system:

- a receiver is installed in the pit at the wellhead, in which, using a powerful deep-well pump with a check valve, high pressure is created in the water supply system;

- the pipe material used must withstand the load;

- a water pressure regulator is installed inside the building in a warm room, which will ensure the operation of the internal system under normal operating conditions;

- after the pressure regulator, it is necessary to install a safety valve with water discharge into the drain pipeline in case of valve failure.

As a result, the system turns out to be quite complex, which means that the level of its reliability and safe operation decreases.

Automation of water supply control

Today on sale you can find a variety of temperature sensors of submersible and overhead type. By installing such devices on the underground part of the water supply, you can receive timely information about the approaching time of a possible emergency. After that, open the taps and warm up the water supply, since the water coming from the well always has a positive temperature.

Signals from sensors can be sent through the microprocessor to the sounder, and in more complex systems, send messages to the phone or e-mail. If there is a heating cable, you can automate its activation when a critical temperature is reached.

Thermal insulation paint

Thermal insulation paint is a paste-like composition that has a high heat transfer resistance. It consists of foam glass, perlite, ceramic microspheres. It is applied to pipes of any configuration, has no seams, fire-resistant, provides protection against condensate and corrosion. One applied layer can replace polyethylene insulation, which is about 50 mm thick. Thermal paint is an environmentally friendly product that does not require additional ventilation during use. The main advantage of the material is the possibility of insulation in hard-to-reach places.