Installation process

In order to carry out the installation, you must first prepare all the components. For example, VALTEC collector systems are delivered unassembled. To get started you need:

- Remove one of the device mounting brackets with a screwdriver.

- Install isolation valves.

- Screw automatic air vents on them.

- Next are the drain valves.

- After the plugs are placed and the mounting bracket is returned to its place.

Do-it-yourself installation instructions for the collector are not particularly difficult:

- To begin with, a place is chosen so that the length of all heating circuits is approximately the same.

- Next, you should fix the device on the wall so that the collector cabinet assembly for underfloor heating with a liquid pump can easily fit in it, and all adjustments are carried out quickly and conveniently. Usually this is a box no larger than 1x1 m in size and 12 cm thick.

- After fixing, all pipes are connected and the cabinet is assembled.

Tips & Tricks

Before you buy a collector, calculate the required length of pipes, their position. It would be better to put two of 6 instead of one for 12 flow meters, which will help equalize pressure and temperature in areas that are too remote. The collector installation scheme should provide for its location at a level higher than the warm floor or heating circuit in order for the air to be removed from the pipes correctly in automatic mode.

https://youtube.com/watch?v=JuPDaHfrBL0

| Manufacturer | Cost depending on the number of flow meters, rubles | ||||

| 2 | 3 | 4 | 5 | 6 | |

| Oventrop | 4 100 | 5 150 | 6 100 | 7 000 | 8 100 |

| Watts | 3 550 | 4 650 | 5 700 | 6 750 | 7 800 |

| Kermi | 3 500 | 4 400 | 5 500 | 6 450 | 7 500 |

| rehau | 8 200 | 9 350 | 10 700 | 12 150 | 13 550 |

| Valtec | — | 6 600 | 7 950 | 9 300 | 10 700 |

| Manufacturer | Price | |||||

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Oventrop | 9 250 | 10 200 | 11 300 | 12 250 | 13 400 | 14 400 |

| Watts | 9 000 | 9 950 | 11 000 | 12 050 | 13 100 | 14 250 |

| Kermi | 8 550 | 9 600 | 10 700 | 11 750 | 12 700 | 13 850 |

| rehau | 15 250 | 16 900 | 18 350 | 19 800 | 21 450 | 22 550 |

| Valtec | 12 400 | 13 850 | 15 250 | 17 200 | 18 050 | 19 450 |

Based on the data in the table, we can conclude that the cost of the Kermi collector for the underfloor heating system is one of the most affordable today, despite the fact that this is a quality product from a German company made of stainless steel.

The expensive price category is represented by the young Russian-Italian company Valtec and the German "dinosaur" Rehau. The first, having appeared in 2002, has already managed to enrich its range with brass and steel appliances and manifold cabinets. The second, with the same range, has more than 60 years of experience behind it. That is why Rehau collectors for underfloor heating systems with flow meters occupy the highest price category in the table, because, trusting professionals, the chances of failure are minimal.

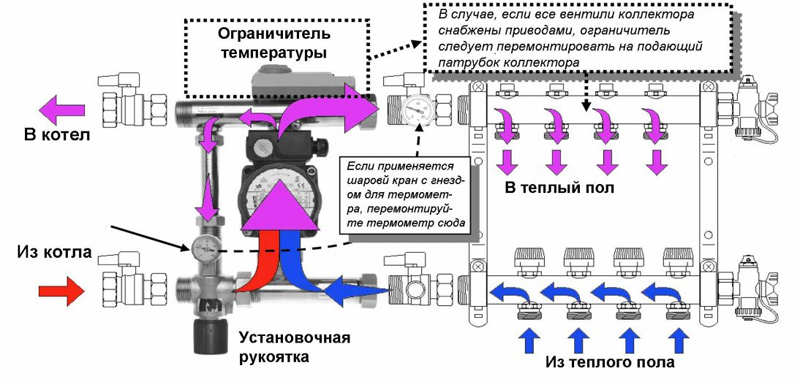

The principle of operation of the collector

The heating manifold is a metal comb on which the leads are installed. They provide a connection between the distributor and heating devices. The collector can be installed in different sizes, it can also be extended if necessary.

Metal combs are equipped with shutoff valves. It distributes and regulates the heat supply to all circuits of the heating system. At the outlet of the heating manifold, two types of taps can be mounted:

- adjusting; they dose the coolant supply;

- cutting off; they allow you to completely turn off the hot water supply from the circuit.

Heating collector device. Click on the photo to enlarge.

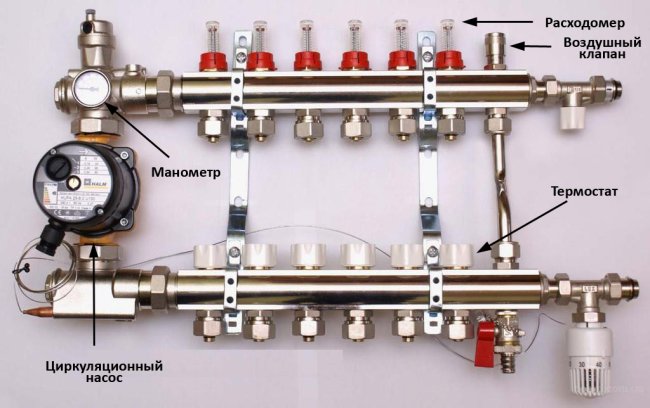

In addition to taps, the collector is equipped with air outlet and drain valves. It is also customary to place heat meters here.

Several collectors of the heating system are best combined into one unit. One of the combs is used to supply hot water, the other is installed on the return line. Each manifold requires its own set of fittings.

Private high-rise buildings require a different approach. A separate heating distribution manifold is installed for the heating circuit of each floor. Thanks to the autonomous operation of the circuit, it is possible to set the optimal temperature regime on each floor.Thus, it is possible to significantly reduce costs. Turning off the heating on one of the floors will not be a problem, while maintaining heat is possible only in certain rooms. Not only radiators, but also a warm floor system can be connected through a collector distribution system.

The main point in the organization of this heating system will be the supply of individual pipes with coolant to each battery. Installing a collector in the house is accompanied by serious financial costs. However, later they will pay off during the operation of the heating system. In addition, it will be possible to make a quick repair of any radiator or circuit. It is enough to turn off the taps of the corresponding branch and you can service a whole group of devices.

Manifold cabinet parts

The collector cabinet for a water-heated floor includes two main components:

- Pumping and mixing unit;

- collector block.

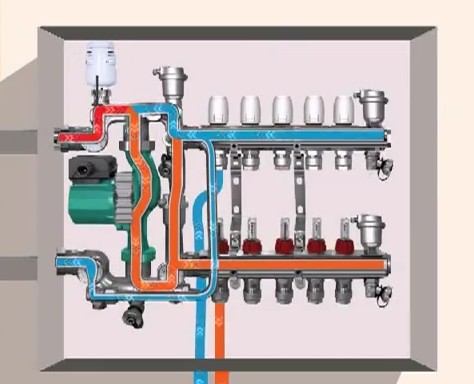

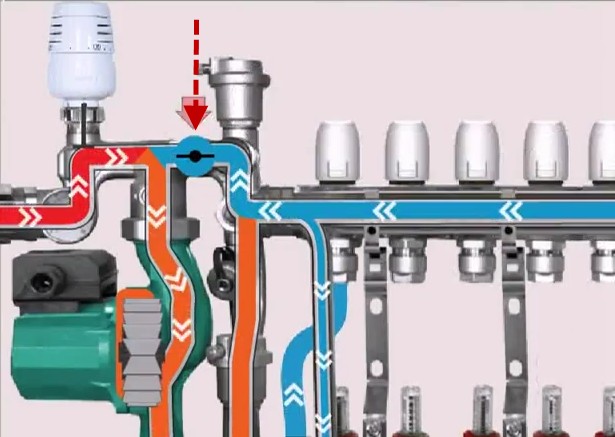

Pumping and mixing unit

In the pumping and mixing unit, the hot water entering the water-heated floor system is mixed with the cooled water that has already passed through the system pipeline. Mixing occurs due to the impellers of the pump.

The pump supplies the mixed warm water to the system piping. Water, passing through the pipeline, gives off heat to the room and, cooled, returns to the pumping and mixing unit of the manifold cabinet.

Manual adjustment of the thermal power is made by a balancing valve. The balancing valve regulates the flow of cooled water in the system. For heating a small room, the balancing valve opens, for a large room it closes.

The temperature in the system is regulated by a thermal head, and a temperature sensor controls the temperature. The thermal head opens or closes the valve on the hot water supply line.

When the water supply is interrupted, the bypass valve opens and water circulates through the free bypass.

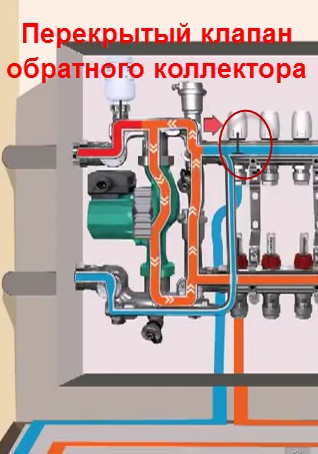

In a simple collector cabinet assembly, the floor temperature is controlled manually. For automatic regulation, servomotors are used together with room thermostats. The servomotor receives signals from the temperature sensor and automatically closes or opens the return manifold valve, and the movement through the floor pipeline is regulated.

The collector block of the manifold cabinet is responsible for regulating the water entering the system pipeline and the water returning from the pipeline.

manifold block

The manifold block is assembled from two rows of bypasses. One row of bypasses regulates the flow of warm water, the second row regulates the flow of cooled water. The first row is called the direct row of collectors, the second is the row of reverse collectors.

Technical characteristics of the manifold cabinet for water floor heating

Characteristics of the pumping and mixing unit

- Maximum working pressure: 10 bar;

- Maximum water temperature: 90°C;

- Working temperature range: 20-60 °c;

Characteristics of the manifold block

- Pipe diameters: 1” (Inch) or inch and a quarter;

- Number of inputs / outputs from 3 to 12;

- Working pressure 10 bar;

- The maximum water temperature is 120°C.

That's all! Walk on the warm floor!

-

Polystyrene floor heating system

-

Floor heating in an apartment and a house: types of floor heating

-

Screed for underfloor heating: options, thickness and solutions

-

Three heating cable applications: roof, floor and pipe heating

-

Concrete and floor heating systems