The device and operation of gas-wood boilers

A universal gas-fired boiler for home heating, available in three different versions, differing in design and functionality.

- Module, with the possibility of conversion to gas.

- A boiler that has two combustion chambers at once, separately for firewood and gas.

- Heat generator with built-in electric heating element.

Combined boilers of mixed type, for gas and firewood, have built-in automation that fully automates the combustion process. After burning firewood in the firebox, the module automatically switches to gas or electricity. For domestic hot water, water is heated by an electric heater.

Simultaneous installation of a wood and gas boiler in the same system requires significant financial costs. Purchase and installation of universal equipment reduces costs by 30-40%.

Bi-fuel wood-gas boilers

Combined gas-firewood boilers are widely used in domestic conditions. The design includes the following nodes:

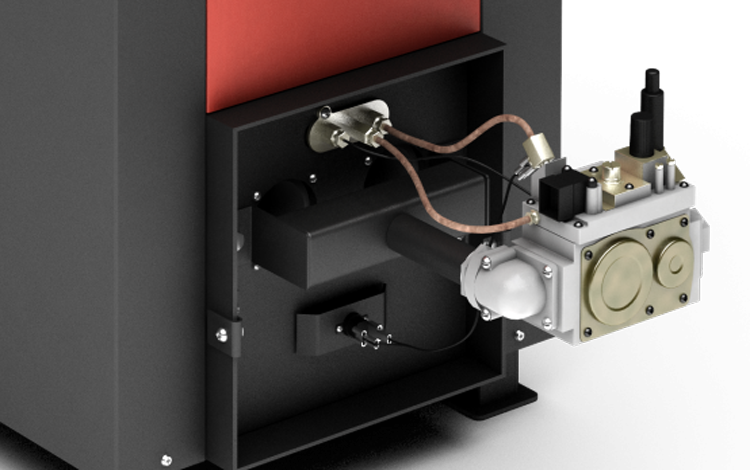

- The combustion chamber is made of steel or cast iron. One or two fireboxes are installed in the design. Modification with two combustion chambers, more convenient. A gas burner is installed in the lower furnace. In the upper chamber there are grates for burning firewood.

- Heating and hot water circuits - manufacturers produce models designed exclusively for heating (with the possibility of subsequent connection to an indirect heating boiler), as well as for obtaining hot water and space heating. The latter are equipped with two circuits. Heating of hot water occurs in a flowing way.

Heating of water for domestic hot water, depending on the performance of the TT boiler, reaches 700 l / h. There are modifications with a built-in storage tank for 40-120 liters of water.

Electric-gas-wood boilers

Combined heating boilers, gas, wood and electricity, have a device that resembles that used by dual-fuel units. The main difference is the installed electric heater. The principle of operation of combined boilers, gas, wood, electricity, is as follows:

- Wood is considered the main type of fuel. After the combustion of wood, the gas burner turns on automatically. The heating process continues without stopping.

- The heating element is used to maintain the minimum temperature of the coolant after the gas and firewood have run out. Operation in the antifreeze mode is allowed. The electric heater maintains the minimum temperature in the heating system, preventing the freezing of the water circuit.

Some universal heating boilers - gas, wood, electricity, use the principle of gas generation in their work, which increases the battery life up to 6-12 hours, from one log bookmark.

Recommendation for choosing a boiler for gas and wood

The choice of combined heating boilers for wood and gas is influenced by the technical parameters of the heated building, the need to automate the combustion process

Pay attention to the presence or absence of additional functions in the device

The main selection criteria are:

- Productivity - one kilowatt of power is enough to heat 10 m² of a building. The boiler is selected in accordance with the need for thermal costs of the building. For a room of 100 m², you will need to install a 10 kW model, for 200 m² - 20 kW, etc.

- The presence of a hot water circuit - choosing a universal boiler with hot water is somewhat more difficult. During operation, a certain amount of power will be spent to heat domestic water. Therefore, the calculation of the required power of double-circuit boilers is carried out taking into account the reserve in thermal energy of 15-20%.For a typical building of 100 m², the minimum power of heating equipment will be 12 kW.

- Built-in heating element - the presence of an electric heater, significantly increases the functionality of the boiler. Automatic switching to heating with a heating element occurs thanks to the installed sensitive controller. In the settings of most models, there is a mode that allows you to maintain a minimum heating of the coolant (+ 5-10 ° C) and spend a minimum amount of electricity, which is convenient if you want to leave the building for some time in winter, without proper heating.

- Design features - as already noted, multi-fuel boilers can have one universal combustion chamber designed for the alternate use of gas and firewood, or separate furnaces for each type of fuel. The second option is preferable due to the fact that the transfer of the boiler from wood to gas is carried out automatically.

When connecting the boiler to the main gas, you will need to make a project and obtain all the necessary permits for commissioning. Installation rules are the same as for any other gas equipment.

The main manufacturers of wood-gas boilers

Another important aspect influencing the choice of a dual-fuel boiler is the country of origin and brand of the heating unit. High-quality equipment is manufactured in the EU, Russia and Ukraine:

- Ukrainian and Russian combined boilers are fully adapted to the realities of domestic operation, insensitive to fuel quality, voltage drops in the network. Heating boilers for wood and gas, Russian-made, are produced by several leading manufacturers: Kupper PRO (Teplodar company), Zota MIX, Karakan (Novosibirsk concern STEN), PARTNER (Novosibirsk manufacturer KOSTER), STS (Ukrainian manufacturer Steel Solid Fuel Systems) .

- European combined boilers - more than a dozen different companies offer products on the heating equipment market. The following brands are in constant demand: Wirbel (Austrian-German company of the same name), Jaspi (Finnish concern specializing in the production of solid fuel boilers).

As for build quality and reliability, European units are somewhat ahead of their domestic counterparts. Shortcomings are clearly visible in Russian boilers, especially with regard to the automation of the device and operation in the gas generation mode.

The quality of Russian equipment is constantly improving, the wishes of customers are taken into account. Over time, we can expect the release of competitive products.

How much does gas and wood burning equipment cost

Pricing policy depends on the location of the manufacturer and brand awareness. A multi-fuel boiler PARTNER, a Russian manufacturer, will cost 22-24 thousand rubles, depending on the power and configuration.

The Finnish analogue of Jaspi costs from 120 to 150 thousand rubles. Significant difference. True, the consumer, for this money, receives an almost completely autonomous station with a storage capacity and automation that fully controls the combustion process. In the case of a Russian boiler, all processes will have to be adjusted manually.

Self-conversion of a gas boiler for firewood often costs the approximate cost of a conventional domestic-made multi-fuel unit.

Design features

The range of heating boilers is represented by different models. Some operate on gas, others on electricity, and others on liquid fuel. Each variety has its own operational advantages and disadvantages. The disadvantages of using certain installations haunt designers and technicians. Therefore, they decided to combine some models, and combined heating devices were born.They can operate, for example, on solid fuel and gas at the same time.

Such a combination made it possible to minimize emergency risks and organize the operation of the same solid fuel boiler in an autonomous mode. How do such installations work, and where is their use more than justified? As a rule, universal boilers are always supplied with an additional number of nozzles. They can be used to connect underfloor heating, heating radiators, greenhouse control systems, heating water in a pool or heating a sauna.

The gas burner in such a boiler is located below the combustion chamber, where firewood, briquettes, sawdust or coal are laid. Therefore, if necessary and switching, it allows you to completely burn the remaining solid fuel. If the work is transferred to solid fuel, the gas burner automatically closes. For ease of use, a steel heat exchanger responsible for space heating runs through the entire body. All walls are thermally insulated with special mineral wool, so the efficiency of the unit is almost 92%. And this is a very high figure.

The DHW heat exchanger is made of copper and is located at the top of the unit. Copper is not afraid of corrosion, so the service life of the coil is equal to the service life of the entire device as a whole. Universal boilers have lever and air dampers, which ensure the supply of the necessary portion of air.

How the installation works

The principle of operation of the gas-firewood boiler is trivially simple. The design uses two autonomous cameras. The furnace is located above the gas. This feature allows you to use two types of fuel at the same time. Gas burners are capable of operating at low pressure. Therefore, you can often see models that are not connected to the central gas pipelines, but to liquefied gas cylinders.

Note! When the electricity is turned off, the gas-firewood boiler will not be able to work on gas. And all because the products of its combustion in this case will not be independently removed through the chimney to the outside, and condensate instantly accumulates on its walls, clogging the chimney

If there is no light in the house, the boiler is heated exclusively with wood.

Benefits of installations

There are quite a few advantages for gas-firewood boilers, so we will only indicate the most basic ones:

- The main factor is the ability to save money and use cheap firewood instead of expensive blue fuel. If the firewood runs out, you can switch to gas in automatic mode.

- The combined design allows the use of autonomous heating. Gas ensures the operation of the plant at night without additional fuel loading. It is also nice to come home after work to a well-heated house, knowing that the gas will maintain the right temperature when there is no one to throw firewood into the stove.

- Universal combined boilers can have one or two circuits, thanks to which the installation can be used not only for heating, but also for supplying hot water for technical needs. Today, universal gas-firewood boilers are equipped with storage boilers, and there are models that can heat water to the desired temperature in a flow way. The choice is great, and it pleases.

But before deciding to purchase such installations, experts recommend studying the features of their operation and disadvantages.

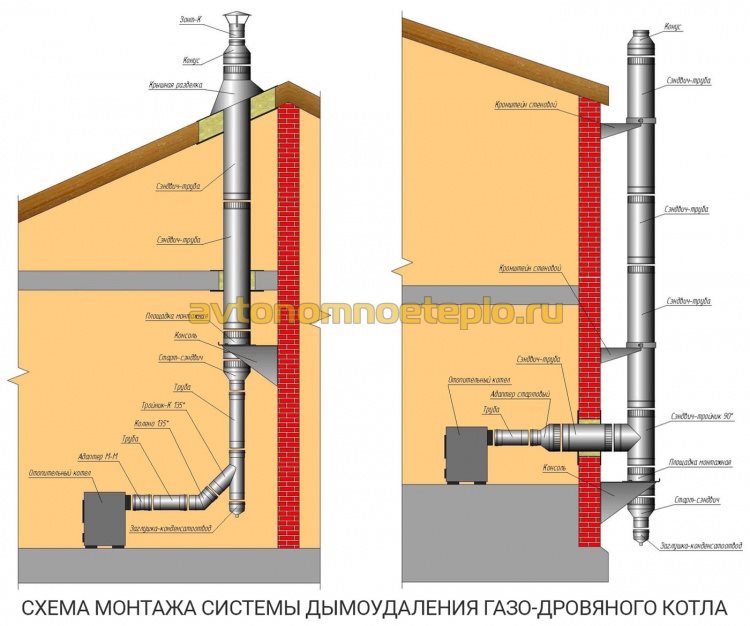

Standards for the installation of a gas-wood heating boiler

For the installation of a gas boiler with the possibility of burning wood, there are higher requirements than for conventional solid fuel equipment. Operation and connection standards are described in SNiP, SP and PPB. In particular, it states:

- Boiler room - a room with a total area of at least 12 m² and a ceiling height of 2.2 m is chosen for the installation of the boiler.

- The walls and floor are lined with non-combustible material: plaster and ceramic tiles.

- Supply and exhaust ventilation is required. For better air flow, the door frame is installed without a lower threshold.

- The boiler is connected to the electrical network through automatic machines located outside the boiler room. Modern multi-fuel small-sized boilers gas, wood and electricity, have protection against power surges. Despite this, manufacturers recommend connecting through an uninterruptible power supply with a built-in stabilizer.

- Natural lighting is a must. The dimensions of the window openings are calculated, depending on the performance of the boiler.

- Universal heating boilers for gas and wood, with a capacity of up to 40 kW, can be installed in any room used for household needs. A heat generator over 40 kW is installed in a separate room, designed exclusively for the needs of the boiler room.

- In the place where the chimney passes through the floor slabs and the roofing cake, fire-prevention cuttings are provided. The pipe is insulated with a non-combustible mineral sealant.

- A spark arrester and a deflector are installed on the chimney head to increase the traction force.

When connected to the main gas, the first start-up of the boiler is carried out in the presence of an inspector. In the absence of violations, the inspector of the Gas Service will make a note in the passport of the equipment about putting it into operation.

Pros and cons of using wood and gas boilers

Heating boilers for the home, running on wood, gas and electricity, as practice has shown, are easy to use and easily replace two single-fuel units. The advantages of universal multi-fuel models are:

- Automation of the combustion process.

- Long operating time from one bookmark of firewood.

- Lower cost compared to two boilers operating separately on gas and wood.

- Fast switching to a backup fuel source.

- Ability to work in an unheated building to prevent freezing of the coolant.

- Small dimensions.

- Meeting the needs of hot water supply - floor double-circuit heating combined gas-firewood boilers, operate as a flowing water heater. Single-circuit analogues are connected to an indirect heating boiler.

Household hot water gas-fired heating boilers have several disadvantages:

- High price.

- A lot of weight, due to the fact that several combustion chambers are built into the design.

This is where the disadvantages of universal boilers end. It is clear that domestic equipment has flaws, but in general, even Russian units work flawlessly. Multi-fuel boilers are easy to use and in many ways superior to units operating on only one type of fuel.

Calculation of power and temperature of a warm water floor

Combined heating boilers wood gas description and application

Many manufacturers of heating equipment, in order to increase the competitiveness of their products and create more comfortable conditions for their customers, have seriously begun to engage in the production of combined heating boilers. Such boilers are known for being able to operate simultaneously on several types of fuel. Today you can find such boilers that can operate on four types of fuel at once. But in view of their small functionality, combined heating boilers operating on gas and wood have reached special popularity among the population.

Combined heating boilers wood gas

Are there any features in operation

When buying a combined boiler with wood and gas heating, several operational points must be taken into account, without which the use of wood as the main source of heat can lead to the fact that the universal method will cause considerable problems.

So, a wood-burning boiler during its operation gradually clogs the chimney with soot, which must be periodically cleaned. Without this, the efficiency of smoke removal will gradually decrease, up to the appearance of problems with ignition, smoke in the room, etc.

If heating on gas or electricity can operate continuously, then the wood-burning boiler burns out completely after a maximum of 3-4 hours, after which the heating system inevitably begins to cool down. Loading a new portion is done manually, which requires the presence of the owner's home. Therefore, often combined modifications with wood or pellet fuels are used, if possible, in gas heating mode.

Pellets partly allow you to automate the procedure for heating with wood fuel, but you still have to follow the process. Yes, and the stock must be created in advance, otherwise you can be left without heating in the coldest period of the year.