Solid fuel boiler long burning pros and cons

In the absence of a gas main, there are not many alternatives to build a heating system. You can install a gas tank, provided that gas supplies are established in the region. You can use environmentally friendly, but expensive electricity by connecting an electric boiler. But what if these options are not affordable? Or are gas and electricity resources limited or non-existent?

A solid fuel boiler for long burning will not require significant installation costs from the owner and will provide a reasonable replacement for the listed heating methods.

Advantages:

Simple operation. Traditional work on wood, pellets or coal does not require special skills. Ash removal takes no more than an hour a week.

Durability. Service life exceeds 10 years. A long-burning boiler is an unpretentious technique. A simple design, with careful operation, can regularly serve for several decades.

Ecologically pure. The afterburner ensures almost complete combustion of the fuel. Emissions of harmful substances are a natural product of combustion - they are processed as a result of photosynthesis.

High efficiency. There are models on the market with a value of up to 90 - 95%. Minimal heat losses are ensured. Engineering solutions optimize the process of afterburning pyrolysis gases. The design of the heat exchanger is designed with maximum heat transfer to the heat carrier.

Efficiency and economy. Modern equipment is not much inferior to gas counterparts. The effectiveness of long-term burning reaches seven or more days.

Acceptable cost of fuel. Sometimes the only possible one. Frees you from dependence on expensive gas equipment.

There is no permit documentation for the installation of the boiler. It is not required to conclude contracts with gas services for service.

Solid fuel boiler long burning allows you to provide homeownership with hot water, in the case of a second circuit. In addition, an indirect heating boiler will help expand the functionality.

Flaws:

Permanent participation of the owner. Despite the long burning process from one load, sooner or later one has to return to replenishing the loading compartment with fuel.

Regular cleaning. Probably the most unpopular process in maintenance requires constant cleaning of ash. It remains only to envy clean gas equipment or electric devices.

Separate room. You will have to allocate a separate room with good ventilation and a chimney. A long-burning solid fuel boiler for a private house, as a rule, has significant dimensions, it may be necessary to prepare a special installation site with a reinforced foundation.

Maintenance of fuel stocks. Replenishment and storage of fuel residues will require additional financial investments. Compliance with safety measures and maintaining a certain moisture content of the product also add to the problems in solving warehousing issues.

Features of the operation of wood boilers with long burning

The burning time of one bookmark of firewood is from 8 to 24 hours. The battery life depends on several factors:

- Boiler type.

- Fuel quality.

- Proper operation.

Learning how to heat a boiler correctly is much easier than it might seem at first glance. During kindling and further operation, adhere to the requirements specified by the manufacturer in the technical documentation. After a few fires, the process becomes habitual.

How to achieve long burning wood

You can achieve long-term burning of firewood by carefully following the manufacturer's recommendations:

- Firewood is kindled with a fully open damper.

- In the mode of long burning, the boiler is transferred only after reaching a temperature of 600 ° C.

- The humidity of firewood should not exceed 20%. Heating with coniferous wood is not recommended.

Violations of the rules of operation leads to the fact that tar is formed from firewood in the boiler. Most often, the following conditions are not met:

- The minimum outlet temperature of the coolant must not fall below 65°C.

- It is correct to heat the boiler with hard wood: aspen, beech, acacia, oak, etc.

- The high humidity of firewood leads to an abundant release of resin.

Proper operation of long-burning boilers extends the life of the equipment and increases heat transfer.

How to properly load firewood

Ignition is carried out exclusively with dry splinters. It is forbidden to use gasoline or kerosene to kindle firewood. From time to time, it is recommended to use special chemical briquettes that remove tar deposits on the walls.

How much firewood do you need for the winter season

The device of a long-burning boiler allows you to save on fuel, approximately 15-30%, depending on the model chosen. The approximate consumption of firewood is calculated as follows:

- It is generally accepted that for heating every 100 m², 3 Gcal / month will be required.

- When burning a kilogram of firewood, 3200 kcal is released.

- To get 1 Gcal, long-burning boilers burn 312 kg of firewood.

- To obtain 3 Gcal, approximately a ton of wood is required.

During the heating season, 7-8 tons of firewood are needed to heat a house of 100 m².

Rules and regulations for the installation of a long-burning wood-burning boiler

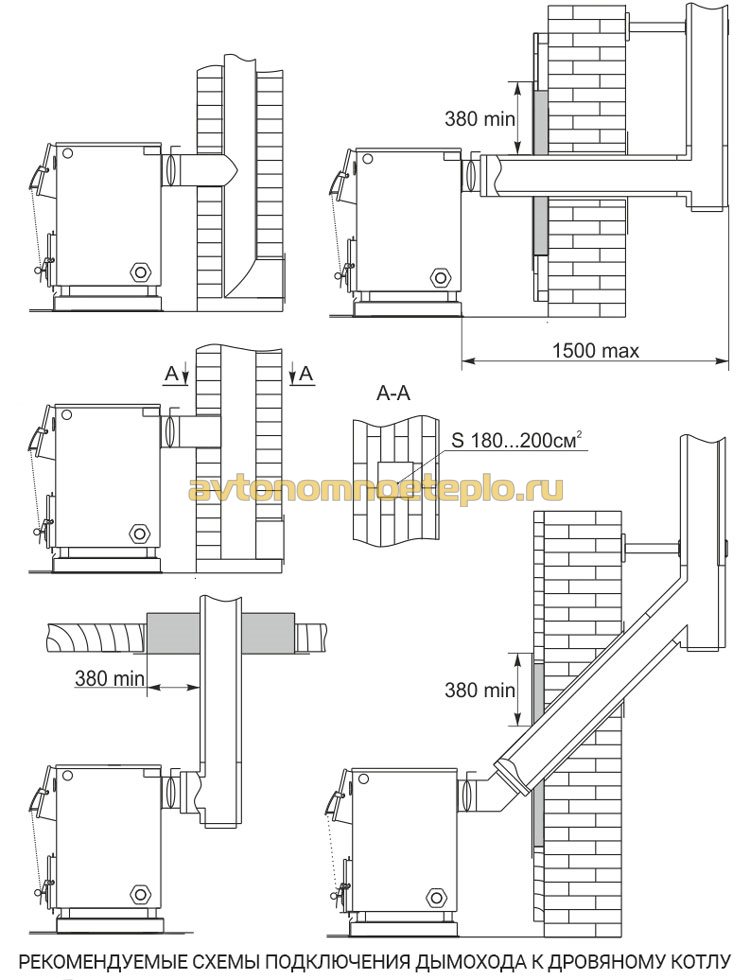

The installation of a long-burning boiler is carried out in compliance with the standards applicable to all wood-fired boilers. During installation work, the existing requirements of PPB and SNiP are taken into account:

- Installation is carried out on a solid non-combustible base. The walls and floor are lined with non-combustible building materials.

- The chimney is carried out in compliance with fire safety cuts. At the junction with the wall of combustible material, fire-resistant insulation is laid. The material is lined with steel sheet.

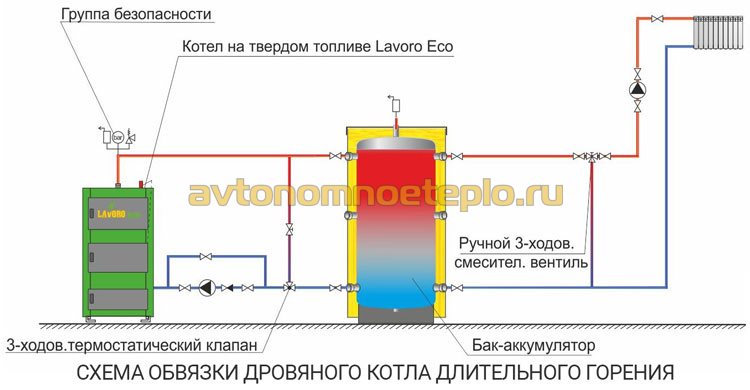

Water heating from a long-burning wood-fired boiler is connected to special outlets located on the boiler body. The instructions indicate in detail which pipe goes to the supply and return of the water circuit.

A boiler with a capacity of more than 40 kW is installed in a separate room.

Volatile boilers are connected to the power supply through a stabilizer and an uninterruptible power supply. Be sure to use the machines. The connection is made directly from the switchboard.

In the room used for the boiler room, it is necessary to have supply and exhaust ventilation and natural lighting. If necessary, it is allowed to place the boiler in the basement.

The principle of operation of a wood-fired heating boiler, long burning

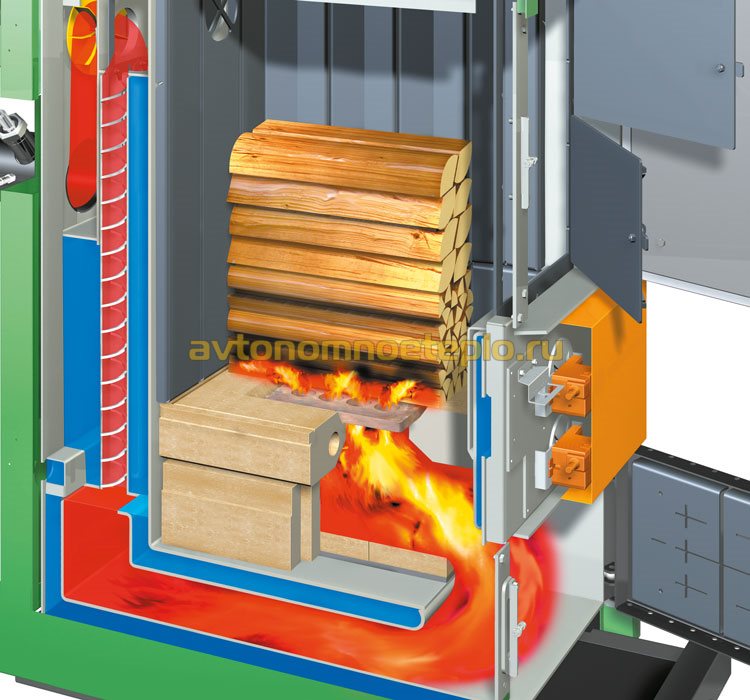

The device and principle of operation of a wood-burning boiler for long-term operation from one load is aimed at recreating such conditions in a limited space of the combustion chamber. Firewood does not burn in the full sense of the word, but smolders. The operating time increases, and the lack of heat is compensated by the afterburning of the emitted gases.

The design of long-burning boilers includes the following components:

- Combustion chamber - the device has two combustion chambers at once. The first furnace (with vertical or horizontal loading) is designed for burning wood. The second chamber is used for afterburning the produced carbon dioxide. To ensure complete combustion of the gas, the firebox is made of fireclay bricks, which prevents heat loss and helps maintain a temperature of about 800°C.

Design features and principle of operation

The inside is used as a firebox.It is designed so that combustion occurs from top to bottom. This is facilitated by a special air supply directly to the combustion zone. The process is more like smoldering with the production of gases from carbonaceous fuels. Most of these gases are flammable. Due to their afterburning in the upper part of the furnace, the maximum use of thermal energy occurs, which allows to increase heat transfer and reduce fuel consumption.

The boiler chamber is divided into two parts by an air distributor. It has the form of a tube, to which a platform with blades is attached at one end, and the other end serves to supply oxygen.

Boilers with top combustion are characterized by cyclical operation, and until the first tab burns out, adding a second batch of fuel is not required.