Do I need radiators if there is a water heated floor

Don't forget the radiators.

Firstly, radiators are needed under the windows in living quarters so that there is no condensation.

|

Of course, you can run pipes into the wall under the windowsill, as shown in the forum post.

But this is a difficult decision. |

Secondly, in the event of an accident and the absence of a 220V network, only the boiler can still be powered from an uninterrupted power supply. The uninterrupted power supply of the underfloor heating mixer pump will also be strained.

And thirdly - the accident of the warmest floor. The underfloor heating system is technically complex and something can break. Then you can fully turn on the radiators during the repair.

Fourthly, I already had radiators installed up to the warm floor - let them hang.

Concrete screed

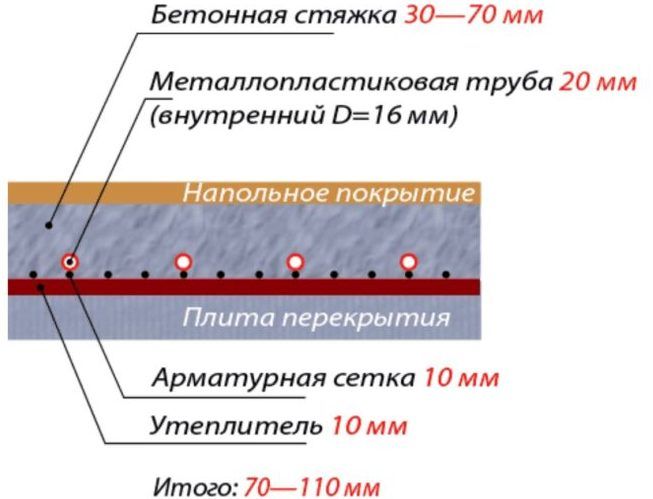

Installation of floors with water heating circuits is done on the basis of a concrete screed or without it. The first method is more time consuming than the other options.

Concrete and cement-sand screeds perform heat exchange and waterproofing functions. They create the integrity of metal-plastic elements, protecting them from mechanical damage, and exclude the possibility of gusts. The heating water system is located in their thickness.

All work is carried out in stages:

- First, the subfloor is prepared. It is dried and cleaned of debris.

- Then a waterproofing coating is made, a damper tape is laid.

- Reinforcement is underway.

- Thermal insulation is installed with heating pipes of small cross section. They can be parallel or spiral.

- The system is checked for functionality. It is recommended to carry out a trial run to check how the pipes will heat up.

- At the final stage, a concrete screed is made, on which a waterproofing flooring with a substrate under the laminated coating is placed.

https://youtube.com/watch?v=-lM_Ip91yEs

Varieties of substrates for laminate

Other options

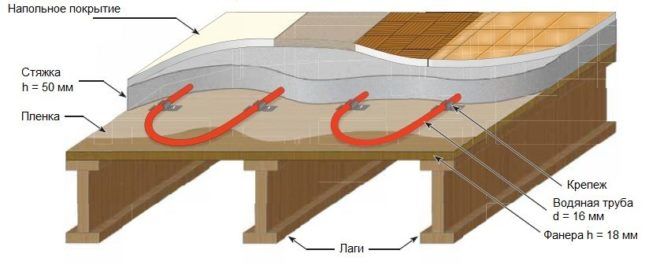

A water heated floor under a laminate without using a screed can be done in several ways. In all cases, only fasteners of the structure are used.

Wooden-rack installation system is used on the second floor of the house with ceilings. It differs in that special slats made of boards or moisture-resistant plywood are used for the support layer. The water circuit is laid between the lags, the gaps are filled with insulation. A thin plywood is laid on top, on which a substrate is placed under the laminated parquet.

Modular wooden construction is done in the same way as rack.

Only communications are not laid between the lags, but in square slabs of chipboard - modules that are interconnected by locks. In such a system, an additional layer under the substrate and heat exchangers from wide metal plates are used.

A warm water floor made of polystyrene foam has its own characteristics. Aluminum plates are inserted into the grooves of the plates as heat distributors. They contain pipes. The structure is waterproofed with a film. Then the laminate is mounted on the polystyrene floor.

Comfortable temperature in the rooms of a private house.

I would never have thought that the comfortable temperature of a person is in such a narrow range.

Until I started using thermostats.

Although they lived without thermostats before and did not grieve.

|

|

It turned out that at 21.5 degrees you want to add heating, and at 23 - turn it down.

It is believed that at night, during sleep, the temperature should be low. During the day, when most likely no one is at home, there is also no need to heat up to 22 degrees. Of course, such desires arise when there is a way to put them into practice. Actually, this is what weekly room thermostats are for. |

In the new programmable weekly room thermostats, the night temperature is factory set to 16 degrees.

It's probably the way it is in China. I can’t imagine that in Russia someone would sit at +16 degrees, if there is a thermostat with a “+” button.

Another thing is when there is a child in the house. And when the house has laminate floors with screed and no carpets.

In the interior corridor I have linoleum, and there are no warm floors, and no carpets. And nothing. There is no desire to put a carpet. The screed, placed on a layer of polystyrene, does not cool down much.

But there are other rooms around this room and no one sits on the floor in it.

In residential areas, the operation of a laminate on concrete would not be very pleasant.

The floor with laminate on the screed needs to be heated.

Ways to improve the temperature regime of a water-heated floor.

1. Weather-dependent automation (PZA).

All ears buzzed already on the forums of this PZA.

But this requires a special thermal controller that will do this, and the mixing unit for underfloor heating for weather-dependent automation will be more difficult.

I think that for a situation where room thermostats are installed, PZA is not needed.

Room thermostats are simpler, cheaper, more reliable and more convenient.

2. Smart thermostats.

To improve temperature management, use the artificial intelligence functions in room thermostats.

Not sure if it's worth paying more for them.

Except to play around.

These functions have nowhere to manifest themselves in my conditions on the case.

3. The second (limiting floor temperature sensor) in the floor heating thermostat.

It is possible that if the thermostat has a limiting temperature sensor set, say, to 32, then the coolant can be supplied to 40 and 60. But then bounce is possible.

Yes, and I have already noted that the sensations, when the floor is warmer than the air, then vice versa, are uncomfortable: the body gets confused and does not understand whether it is cold now or hot.

The issue could be studied in more detail if the thermostats had the ability to display the temperature of the floor (along with the temperature in the room) and choose which temperature to regulate.

4. Dynamic change of supply temperature.

I already recalled in the context of PZA the ability to change the supply temperature.

The flow temperature can also be changed by the difference between the return temperature and the set temperature.

It is possible, but difficult and expensive.

6. Dynamic heads.

For each direction of the underfloor heating, it would be possible to measure the return temperature in this direction and open the valve more or less.

I met a mention of such a method and even someone practically did it.

I'm not that big of a fanatic.

7. Changing the speed of rotation of the engine.

This is an interesting topic.

It would be possible to change the rotation speed of the pump depending on the temperature.

For example, depending on the return/flow temperature difference.

There are pumps with the possibility of a smooth external speed reference.

It would not hurt me just to switch the pump rotation speed from I to II when all directions of the warm floor are turned on.

It seems to be easy to do, but among the many central controllers considered for controlling underfloor heating, I have not met a single one with such an opportunity.

In general, the solution will be either complex, or expensive, or not reliable.

So far, I have not even put the pump on the second or third speed.

Noise increases in second gear.

Installation of laminated parquet

Material properties

Before laying the slabs, it is necessary that they lie in the room untouched for several days.

This will allow the material to adapt to the surrounding conditions and stabilize the humidity. During the connection of the coating elements, it is necessary to make small damper indents, up to 1 cm in size, between the walls of the room.They will close with a plinth, but at the same time they will perform several important functions:

- provide adequate ventilation;

- save the laminate from possible deformation in the event of temperature fluctuations.

Mounting methods

Proper installation of modern flooring is reminiscent of traditional brickwork, where the butt joint is located over the central part of the top and bottom row panels. It should be borne in mind that during laying the laminate will have to be cut with a jigsaw or a miter saw. The plates are interconnected by a special fastening system:

- Lock-locks allow you to put the comb into the groove of the adjacent panel horizontally or vertically.

- Click-devices dock the panel and the comb at a designated angle.

For fastening, you need to make a small effort to move the part to a horizontal position and make a click.

Many builders believe that it is convenient to build up laminate flooring in rows. However, the plank can be attached to the laid row through the longitudinal ridge and connected to the adjacent slab of the current row using the end ridge. You can not use a hammer to tighten the fastening. When laying the material, slight deviations in height are allowed - no more than 3 mm.

Lighting features

The method of laying wood flooring depends on the personal preferences of the homeowners and the characteristics of the room. When choosing a coating installation scheme, you need to consider where the doors are located and where the light direction comes from. Laying laminate on a warm water floor can be done in several ways:

- In the direction of the light, to visually hide the joints between the panels and create the effect of a solid coating.

- Perpendicular to natural light in a checkerboard pattern. Not recommended for use in small spaces.

- Mounting at an angle to the direction of the light allows you to hide irregularities and visually lengthen a small room.

Pay attention to lighting when laying

This is a rather complex design scheme.

Heating system of a private house.

It is good if the house has a good wooden floor.

But to make a wooden floor now is both expensive and troublesome, and there are other technologies.

Therefore, they make a screed under the laminate.

Therefore, it makes sense to make a warm floor, because it is not as expensive as it might seem.

Here is the cost of the mixing unit with the collector: “Estimate of the sanitary equipment of the central control unit for TIM water heated floors”.

It makes sense to make a water-heated floor.

An electric underfloor heating will not be much cheaper, the required electrical power will not always be provided and electricity is expensive.

The temperature of the warm floor under the laminate.

On the most common laminate you come across, you can find that it is suitable for underfloor heating and that the temperature of the warm floor should not exceed 28 degrees.

It may seem that this temperature is too low to heat anything.

But it is not.

In one room I have no batteries and the warm floor rarely turns on - no more than 10 minutes.

During this time, the temperature rises from 21.5 to 23 degrees and the floor is turned off.

The experience of operating an electric heated floor under a tile in a bathroom showed that the floor does not feel cold at a temperature of 23 degrees.

At a temperature of 26 degrees, the tile feels warm.

In the bathroom, the electric underfloor heating is controlled exactly according to the floor temperature in order to ensure the required sanitary conditions.

In all other rooms with a water-heated floor under a laminate, the temperature of the floors is not measured.

The experience of operating a water-heated floor under a laminate in one room showed that it makes no sense to control and limit the floor temperature with water-heated floors.

It is enough to supply the coolant to the underfloor heating circuit of the required temperature.

And the regulation is carried out by opening the directions of the warm floor according to the temperature sensor in the room.

Regulation with electric heads on the underfloor heating manifold is the most reliable and cheapest.

And if you look at the versions of thermostats, you can see that it is rare that thermostats designed to control water-heated floors (load 3A) are equipped with external sensors.

Thus, it makes sense to listen to the recommendations of the laminate manufacturer.

But 28 degrees on the laminate does not mean that the coolant should be supplied with a temperature of no more than 28 degrees.

There is a heat transfer coefficient between the pipes and the floor, the floor and the laminate through the substrate, and there is heat transfer from the laminate to the room air.

This means that the temperature of the supplied coolant can be higher.

32 degrees can be served safely. Perhaps more.

The temperature of the heat carrier supplied to the warm floor.

|

I consider the use of a pump-mixing group to be mandatory for water heated floors.

The thermostatic head included in the kit allows you to set the maintained temperature of the coolant. The thermometer allows you to visually control the temperature. |

It would be tempting to keep the temperature of the floor so that it is always warm to the touch.

In order for the temperature of the laminate to be 26 degrees, for example, it is necessary to supply a coolant of 32 degrees.

And let's always supply a coolant of 32 degrees and do not regulate anything.

But this is unreal.

If the floor temperature is 26 degrees, the room temperature will quickly become 25 degrees. And it's already hot.

Yes, and it is impossible to heat only with a warm floor - there will be condensation on the windows.

It is necessary to install, albeit small and barely heating, but radiators are another additional heat release into the room.

That is why I do not see the point of adjusting the floor temperature. What's good is that the floor is warm to the touch if the room is hot.

Another option is to supply water to the floor with a temperature slightly higher than that required in the room, for example, 24 degrees.

But here we fly with the possibility of adjusting the floor.

Indeed, if the climate outside changes and you need to additionally provide energy to the room, this will be problematic with a barely warm warm floor.

The transfer of energy between bodies whose temperature difference is small is very slow.

It turns out that the coolant must be supplied two degrees more than the limit on the laminate.

32 degrees just right.

As a result, the laminate to the touch is simply not cold.

There will be a slow response to a change in climate conditions or a change in the set room temperature.

For example, in the evening the temperature dropped from -1 to -10 and the wind started, and / or the temperature setting in the room rose from 22 to 24 (manually or according to the schedule) - in this case, at a coolant temperature of 30 degrees, the temperature in the room will reach 24 degrees for a long time .

The response time to a change will be the shorter, the higher the coolant temperature.

Then why not set the coolant supply temperature to 35 degrees? Or 40?

What is the limitation imposed by the laminate manufacturer to us - where 28 is there and 35.

I tried setting 40.

Floor temperature fluctuations of 22 - 35 degrees seemed unpleasant, although this may be a bias.

Plus to it - inertia. The floor with a warmer coolant continues to heat even after the circulation is turned off. That is, winning in inertia at the start, we lose in braking.

Since the inertia at the start in my heating system is smoothed out by radiators dependent on underfloor heating.

Together with the warm floor, heating with radiators starts.

Thus, immediately after the start of heating, as the temperature drops, the radiators begin to heat the room, while the warm floor is still swinging.

As I understand it, if not for this, then we would have to supply a coolant, with a temperature of 40 degrees.

Well, a little hysteresis also helps. For some reason, the minimum hysteresis for thermostats is 0.5.

Operating in one room at the first stage, a cheap Chinese thermostat with separate “start” and “stop” temperature settings (in fact, an arbitrary hysteresis) found out that a hysteresis of 0.3 would be optimal for a water-heated floor.

Optimal labeling of laminate for underfloor heating

laminate classes.

Each type of material has its own unique marking, focusing on which you can find out the degree of its strength and purpose. Not every type of laminate has the necessary compatibility with underfloor heating.

Sheets made using conventional technology have a rather low heat transfer, which is very important when designing a warm floor. In order for high-quality floor heating to warm the floors as much as possible, many flooring manufacturers have developed their own manufacturing technologies for this material, which are marked as a special marking

Optimum operating conditions 28-30°C

In order for high-quality floor heating to warm the floors as much as possible, many flooring manufacturers have developed their own manufacturing technologies for this material, which are marked as a special marking. Optimal operating mode 28-30°C.

The optimal sheet thickness should not exceed 8-10 mm, the use of a thicker material is fraught with overheating of the floor system or the lower part of the coating.

When choosing a material for covering floors, it is necessary to pay close attention to these important indicators, otherwise the heating efficiency will decrease during severe cold weather or some important floor elements will deteriorate. This must be taken into account in order to obtain the required effect from underfloor heating.

Inertia.

The accuracy of maintaining the temperature in the room is directly proportional to the rate of change in the floor temperature, which, in turn, is inversely proportional to the inertia.

In his heating system with underfloor heating, he deliberately made an excess thickness of the screed with pipes in order to increase the inertia in case of a power failure.

It turns out that heating radiators smooth out the inertia during heating, accelerating the heating of the room.

An increase in the temperature of the coolant also levels out the inertia, but is undesirable, again, because of the inertia.

But I chose inertia, radiators and low coolant temperature.

Some aspects of installing underfloor heating

Scheme of the device of a heat-insulated floor.

Such a heating system is not suitable for installation in every residential area.

Many experienced specialists do not advise making the described heating system within an apartment, because it involves the installation of special pumps and decent containers for running the system fluid.

They occupy a significant amount of living space. There is always a risk of a pipe breaking inside a given heating system, and the water released as a result of force majeure can permanently ruin relations with neighbors from below.

Therefore, it is advisable to install such an advantageous combination of high-quality underfloor heating with durable laminate in private houses or cottage and country buildings. Before you start covering the floors with laminate, you need to find out some features of its installation in order to avoid various problems in the process.