One of the newest materials for interior wall decoration is laminated drywall. If you take a closer look, this is an ordinary plasterboard, with the only difference being that a vinyl film (PVC film, paper-fabric laminated layer) is applied to its surface on the front side.

This type of material is called differently: LGKL, gypsum vinyl, acrylic, vinyl, colored drywall. Photos of this material can be viewed on the websites of companies involved in its sale. The material is rich in colors, patterns and textures, can imitate various natural materials, such as wood, stone, marble.

The decorative layer of LGKL is reliably protected by a film that protects the material from damage during storage, movement and installation, which is removed only after installation is completed.

One of the most popular brands of gypsum sheets of this type are wall panels "Gipsolam".

Application of LGKL

The scope of this material is quite diverse. With it, you can quickly create an original and durable interior of any room. Most often, laminated drywall is used for the following purposes:

- Installation of interior and zoning partitions.

- Assembly of cabinet furniture of classical or non-standard type.

- Creation of an original and non-standard interior of an apartment or room.

- Sheathing of walls and ceilings.

- Finishing door and window slopes, giving them the desired shape.

- Creation of individual design structures or decor items.

Advantages of laminated drywall

Laminated drywall has a number of advantages.

One of the main advantages of LGKL is the absence of the need for additional finishing or processing of walls covered with laminated material. They do not need to be puttied, sanded and painted, which means that extra time and money are not wasted.

The other undoubted advantages include the following properties of drywall with lamination:

- The ability to install laminated drywall on absolutely any surface, be it concrete, brick, metal or wood.

- A significant reduction in the timing of finishing work inside any room.

- With the help of drywall, you can hide all the existing external imperfections on the walls and ceilings.

- You can fix such drywall on the walls in two different ways: without installing a special frame and in a frame way.

- Surfaces finished with drywall retain heat better. The soundproofing of the room is greatly increased. The levels of these indicators depend on the density of the laminated film on a sheet of cardboard.

- Strength and wear resistance of laminated drywall sheets. It is much higher than normal GKL.

- Large selection of colors, patterns and surface textures.

- Ease of subsequent care - the material can be washed, it does not absorb dirt.

- Refers to environmentally friendly materials.

- The resistance of drywall to external environmental conditions, such as high humidity, sunlight, high temperature.

The price of laminated gypsum boards is quite acceptable and affordable for every buyer.

Mounting Methods

The basis of all types of drywall is absolutely the same (gypsum core). But since the laminated material has a ready-made decorative coating that cannot be damaged by self-tapping screws, its installation differs significantly from the installation of a conventional plasterboard. Let's find out how to properly fix it on the surface.

Frameless installation method

The main condition for the possibility of using this method is a flat and smooth surface.The mounting process itself can be divided into the following stages:

- Surface preparation. They must be cleaned as thoroughly as possible of all possible contaminants and degreased.

- Applying double sided tape to walls. In this case, you must ensure that the tape is pasted evenly. Its stripes should be parallel to each other. Under no circumstances should they break. The recommended spacing between the strips is 120 cm.

- Gluing drywall to the surface. A special glue is applied to the reverse side of the laminated boards. Then they are brought to the base surface so that they hit the tape exactly, and they are pressed tightly.

- Each plate is checked with a level for evenness of installation.

Frame method

This method, compared to the previous one, is more laborious and requires experience. It can be divided into the following steps:

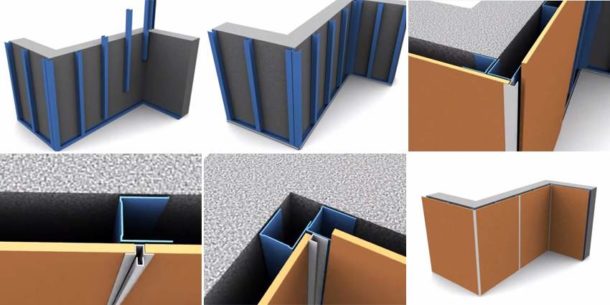

- Marking and forming the metal frame of the future structure. Assembling the frame is not as difficult as it might seem at first glance. They begin to assemble it immediately after carrying out all the calculations and determining the required dimensions of the frame. For assembly, guides and rack profiles are used. The gap between the racks of the frame should be no more than 50–60 cm.

- Attaching double sided tape to racks. This is done for additional fixation of drywall. Adhesive tape is glued immediately before the start of work on the frame sheathing.

- Installation of drywall boards directly on the assembled frame. It starts from the inside corner. The first sheet is fastened with an L-shaped profile, which is attached to the frame post. The distance between fasteners is 40 cm.

- The next sheet is applied, and a special omega profile is inserted between it and the first sheet, which is also attached to the frame. A decorative strip is subsequently placed in it, covering the joint.

- Processing of external corners. It is performed using an F-shaped profile, which is attached before starting the installation of the LGKL.

Important Points

When using any method of mounting laminated drywall sheets, it is necessary to take into account some of its features:

- Laminated GKL is not used for finishing basements and bathrooms and shower rooms. This is due to the high humidity inside these rooms. It is also necessary to take into account the fact that drywall cannot be fixed to walls whose humidity is above 25%.

- When forming and finishing door and window openings, only special waterproof glue should be used.

- When forced to cut a piece of drywall in the corner of the room, the cut is sealed with adhesive tape. The bottom of the cut sheet is treated with waterproof glue.

- Walls and ceiling covered with laminated drywall can be washed. But for this it is necessary to use only liquid detergents and a soft foam rubber sponge. Under no circumstances should scouring powders, petrol or various solvents be used.