Advantages of copper pipes

Copper has been used for hundreds of years to manufacture water storage vessels and water reservoirs. Therefore, pipelines made of this material are considered elite. A large selection of pipes and fittings makes it possible to use copper for heating systems. Copper pipes in an apartment are ideal for any engineering system.

With the correct connection, parts of the system can be mounted in walls and floors. Another advantage is that after the reaction of chlorine in water with copper, tenorite is formed, which only increases the life of the systems.

Copper is completely impermeable to oxygen, which is important for the heating system. The only limitation is that it is not advisable to use aluminum radiators (this does not apply to steel and bimetallic ones)

Pipes are made from copper grade CU-DPH according to DIN 1412, containing 99.90% copper and 0.015-0.040% phosphorus

When purchasing, you should pay attention to the presence of a stamp of 0.015-0.040%, indicating that the product complies with the DIN standard. The part of the system located outdoors must be insulated with plastic casings.

Another option is to purchase pipes in a casing

The main properties of pipes made of copper:

- density - approximately 9-10 g / cm3, but it can be more or less, this indicator does not affect the quality of the system;

- thermal conductivity is very high (394 W / m * K), which is a strong argument in favor of a copper heating system;

- melting temperature - about 1000 degrees - the temperature in the pipes never reaches such a level;

- thermal expansion - a five-meter-long copper pipe at a temperature of 90 degrees lengthens by about 0.5 cm, that is, a linear expansion coefficient of 0.017 mm / m * K;

- small roughness coefficient - Ksh = 1.5. 2) * 10 ^ -6 m, that is, almost perfectly smooth, which increases the throughput and makes it possible to use pipes with a small diameter.

When is it appropriate to use copper pipes

Copper pipes provide high resistance to temperatures over 100˚C, existing in central heating systems that operate on solid fuel boilers.

It is possible to lay pipes on the wall without losing the aesthetic appearance.

If the heating and water supply system has many branches and involves the installation of a large number of fittings, then this reduces the cost of installation with all the advantages of copper pipes and makes their use more expedient compared to other materials.

The durability of copper pipes is comparable to the life of the house, so if there are no financial restrictions, the installation of such pipes will be justified.

How to paint copper heating pipes

When choosing a paint, the following subtleties should be taken into account: it should not change color at high temperatures, protect from external influences, and should not exfoliate. In order for the paint to lay down more evenly, it is necessary to treat it with a primer for non-ferrous metals. Red lead primer 81 will do.

Moreover, it must be taken into account that the paint is not absorbed, and it is required to spread it with a brush carefully. But to achieve more or less even painting is possible only after applying two layers. It is a little easier to work with paint in spray cans: it lays down more evenly.

You can paint copper pipes, but you will have to apply several thin layers

Oil paints cannot be used for copper pipes - they darken from temperature, and in heating systems it is considerable. The following paints are suitable: PF enamels - 115, 156, 167, 187, 223 and 519, alkyd, polyurethane and GF enamels - 0119. The use of varnishes is allowed: VL-51 or ethinol varnish, in which aluminum powder is added in a ratio of 9k1.

Installation of copper heating pipes

When assembling the pipeline, two types of connections are used: using fittings and welding. Pipes with heating devices are joined through collapsible or press fittings. Installation is also possible for connecting / branching pipes, but welding is more often used for these purposes. When using annealed pipes in the right places, they can be bent, reducing the number of joints. For bending, a special device is used - a pipe bender. which allows you to get different angles without reducing the lumen of the pipe and without impairing the patency of the system. It is almost impossible to bend copper pipes by hand: although the material is plastic, it is impossible to bend it manually without reducing the clearance. So it is better not to use this method.

To bend a copper pipe, special equipment is used - this cannot be done by hand, as the pipe clearance decreases and circulation worsens

No special equipment is required to install compression fittings: the pipe is inserted into the corresponding groove until it stops, and then it is twisted with a nut, pressing the pipe material against the fitting body. For a snug fit, two keys may be needed - tighten until completely sealed. This is all the required equipment. But the specificity of crimp connections is such that constant monitoring of tightness is required: from time to time they begin to “drip”. Therefore, such connections cannot be walled up.

Press fittings are installed using special press machines. They are not cheap (including rent). But the connection is tight and reliable, but one-piece.

Capillary soldering is considered more versatile and reliable. In this way, sections of pipes of the same diameter can be connected directly: one of the ends to be welded is flared - the diameter is slightly increased so that the pipes can be inserted one into the other. To do this, use a special device. The junction is cleaned with a metal brush or special sponges (commercially available). The bonded surfaces are treated with a flux - a special compound that improves the “adhesion” of the metal with the solder. Processed pipes are inserted one into the other. The gap between them should be minimal - fractions of a millimeter. Then the connection is heated using a welded torch. When the material is heated to the melting temperature of the solder, it is brought into the flame and the existing gaps are poured with the molten composition. After the seam is filled, it is cooled. You can just leave it in the air until it cools, or you can lower it into water. In principle, the process is not very complicated, but it requires experience, skill and meticulous execution: both the flaring and the filling process itself require accuracy and accuracy. According to this de scheme, connections are soldered with special copper fittings for soldering.

The process of soldering a copper pipe and the same fitting is well demonstrated in this video, but it is intended to be used in a plumbing system, and therefore tin was used as solder. For heating, other compositions are used that have a melting point of at least 115 ° C. Otherwise, the process is the same.

Rules for choosing brass pipes

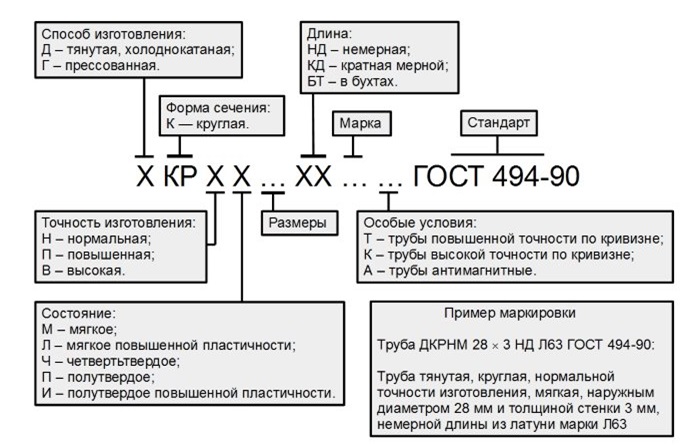

The choice of brass pipes should be based on the determination of the following parameters:

- pipe wall thickness. Brass pipes can be produced by several methods: drawing, pressing and cold rolling. Depending on the manufacturing method, pipes can be thick-walled and thin-walled. Pipes with a larger wall thickness are mainly used for the manufacture of industrial pipelines and pipelines with a high pressure index. Thin-walled are used in everyday life for the construction of water supply systems, heating, and so on;

Pipes with different wall thicknesses

- form. Brass products can have a round, oval, square, rectangular and so on section.A round pipe is used for the construction of pipelines, and a profile pipe (of a shape other than round) is used for the construction of frames, crafts, furniture, and so on;

Round and profile brass tubes

- diameter. Dimensions of brass pipes are made in accordance with GOST 494-90. The diameter can vary from 3 mm to 100 mm, and the length is 1 - 10 m. The most popular in everyday life are pipes 6 m long and 32 mm in diameter, since it is from them that domestic water supply and heating systems are made;

When determining the diameter, it is important to take into account the main characteristics of the pipeline or the level of load in the construction of other forms.

- material condition. Pipes produced by cold rolling and drawing methods can be soft, semi-hard or soft and semi-hard with increased elasticity. It is more expedient to use them for the construction of furniture and other crafts, as well as laying underfloor heating and other similar systems;

- manufacturing accuracy. According to GOST, pipes can have normal, increased and high strength. Products with high strength are used for the manufacture of instruments, and pipes with normal and increased strength are suitable for the construction of pipelines.

The main characteristics of brass pipes are indicated in the marking.

Determination of pipe parameters by marking

Marking and cost

Copper pipes are produced in two types: soft and hard. For heating, solid ones are more often used. The release form is linear segments of 2-5 m long or bays in which segments of 5-10 m are twisted.

Copper pipes are supplied either in lengths or coils

Dimensions. The outer diameter is indicated in millimeters (usually domestic production or from the CIS countries) or inches (imported), and the wall thickness is put through a fraction or “x”: 22x1 mm (22/1mm) - outer diameter 22mm, wall thickness 1mm, which means inner diameter , according to which heating systems are designed, will be 21mm (22-1 \u003d 21). For wiring a household heating system, a wall thickness of 0.8-1 mm is sufficient for a wave.

The outer diameter of the copper pipes is marked, and the wall thickness is set through the fraction

In order not to make a mistake with the choice of diameter when distributing individual heating, it is easier to “dance” from the boiler outlet. This is the diameter of your pipes before the first branch. If the system is small, the entire wiring can be done with one pipe, but if it is large enough, you need to follow the rule: after each branch, a pipe with a diameter one step smaller than the size grid is used. The branch to the heating device (radiator or heated towel rail) also goes one step smaller in diameter. For example, 24mm comes out of the boiler, two branches are separated on the first branch, which are already 22mm pipes, and 20mm goes to the radiators. The "return" is assembled in the same way, but from smaller to larger. If a large area of several floors will be heated, a professional heat engineering calculation is desirable.

The fittings from the boiler usually come out either copper or brass, but in each case, specify and remember that other materials cannot be directly connected to copper. In order to avoid a chemical reaction, you will have to use brass or bronze fittings or adapters.

There are also annealed and non-annealed pipes. Unannealed pipes have a large margin of safety: they withstand pressure up to 450 MPa, but they do not bend very well: they can only stretch by 6%. To change their characteristics, they are heated to high temperatures, then cooled. The process is called annealing, and the products that came out after it are annealed. The margin of safety has become less - up to 22 MPa, but elasticity has been increased: the material can stretch by 50-60%. Also, the material has become more resistant to temperature extremes, tolerates ultraviolet radiation without problems and is almost insensitive to high humidity. Therefore, annealed copper is used not only in heating, but also in motors and car drives.

One example of soldering copper pipes

The cost of copper pipes for heating is high. We can compare:

- reinforced polypropylene pipes with a diameter of 16mm - from 40 rubles / m;

- metal-plastic pipes with a diameter of 16mm - from 47 rubles / m;

- unannealed copper diameter 10mm - from 280 rubles / m;

- annealed copper diameter 18mm - from 400 rubles / m.

Approximately the same picture will be in fittings: copper fittings are many times more expensive than even those used in metal-plastic systems. As an example, not the most expensive PPR and MP pipes are given, there are more expensive ones, and at times, but copper pipes are also not the most expensive. So roughly you represent the difference.

Advantages and scope of brass pipes

Pipes made of brass are distinguished by:

- strength, which allows them to be used in pipelines with increased internal pressure, as well as for the construction of gas pipeline systems;

- resistance to a number of factors:

- to the formation of corrosion, which is the main factor in the selection of pipes for water supply;

- to temperature fluctuations (domestic and industrial heating systems);

- to the negative impact of aggressive environments (oil and gas industries, chemical production, and so on);

- resistance to mechanical damage and ease of installation, which leads to such applications as the manufacture of building frames, small architectural forms (arbors, greenhouses, and so on), stairs and other types of fences.

Brass plumbing piping

Brass pipe is not inferior in strength to copper products. And the lower cost of brass pipes compared to copper products can significantly expand the scope.

Advantages of copper pipes for heating

What arguments can be given "for" the use of copper pipes in heating systems:

- approximately 80% of heating systems are single-pipe. To get the temperature of the water in the last radiator within 70 degrees, you need its temperature of about 120 degrees at the entrance to the building. According to the regulations, the temperature of the heat carrier in the heating network of the city should not be lower than 70 degrees, and it should not exceed 150 degrees. Polypropylene and metal-plastic products, due to the technical characteristics of the materials, have a temperature limit and are not recommended for use in systems where the water temperature can exceed 95 degrees. Copper pipes can withstand temperatures up to 300 degrees Celsius;

- the ability to withstand pressure from 200 to 400 atmospheres, while soldered joints are not destroyed. The metal-layer can withstand a pressure of only 6 atm. Normal operating pressure in the heating system of high-rise buildings is from 6 to 8 atm;

- and another very important point - copper is not very afraid of freezing. Copper pipe can withstand up to four freezing cycles.

The use of copper pipes in water supply makes it possible to use the bacteriostatic properties of copper, the only material that resists the infiltration of contaminants in urban water networks.

Sanitary copper not affected by chlorine. And if, for example, in Russia, at the request of SanPiN, the permitted level of water chlorination is from 0.3 to 0.5 mg / l, then in Hong Kong this figure is 5 mg / l, the installation of copper plumbing is practiced everywhere, steel pipes are prohibited there according to legislation, and polymer products are used in limited quantities.

The use of copper pipes in a polymer sheath provides reliable protection against stray currents.

Types of pipes

Those who want to buy copper pipes for plumbing should pay attention to their type. Pipes meet. Solid samples are made from more durable copper, it practically does not deform and is really expensive.

This option is appropriate when assembling the central channels of the water supply system, as well as in the case when it is planned to transport a medium under high pressure in the pipe.

Solid samples are made from more durable copper, it practically does not deform and is really expensive. This option is appropriate when assembling the central channels of the water supply system, as well as in the case when it is planned to transport a medium under high pressure in the pipe.

By and large, they are high-pressure pipes, as they have thickened walls and an increased strength class.

The second option is better suited for creating household water distribution. Soft copper pipes have thin walls and are easily deformed. A sample of small diameter can even be bent on its own without using a pipe bender, which is often used by plumbers.

They are cheaper and easier to handle, but they are inferior to competitors in terms of strength characteristics.