Heating with conventional wood

Firewood has been used for heating for a very long time; it is a high-quality fuel for home and baths, barbecues and barbecues. The environmental friendliness of firewood will always be at the level of 100%, and this fuel has plenty of other advantages. We note the main advantages of firewood, without deeply delving into this topic:

- First of all, I would like to say that the process of harvesting, drying and storing firewood is understandable to everyone. From an early age, we know how to look for firewood, collect and kindle it.

- It is not difficult to kindle wood,. Some varieties of trees can burn at high humidity, giving off heat.

- The cost of firewood is small, even if you do not go through the entire harvesting cycle, but buy ready-made poles or logs. (However, until the time of comparing the prices of various types of fuel, it will not be argued which is more profitable.)

- Firewood is not afraid of mechanical damage and can be completely different.

- From an aesthetic point of view, firewood burns perfectly. They create a beautiful fire and soulful crackling, and when some varieties are burned, a characteristic pleasant aroma appears. For open fireplaces, where the appearance of what is happening is important, such fuel is considered optimal.

- The substances released during the combustion of firewood have a beneficial effect on a person, they calm the nervous system, and heal the respiratory organs.

Strategic forest reserve for the winter

We will also highlight the disadvantages of natural fuel:

- In order to obtain a high heat output, the firewood must be well dried under natural conditions, which requires an extremely long time, for example, 1 or 2 years. The best firewood is considered to be wood that has lain in a dry barn for a couple of years.

- With long-term storage, wood loses some of its qualities, especially fragrant varieties of trees.

- Firewood takes up a lot of space; for their normal storage in the proper amount, it is necessary to build an appropriate structure.

- When using firewood, there is always a lot of garbage (wood chips, bark, wood dust, sawdust).

Having got acquainted with the main features of the two types of fuel, let's make a comparison.

Note

- Calorific value measurement in Kcal/kg. It is well known that 1 (one) calorie is the amount of heat required to heat one gram of water by one degree. The meaning of this physical quantity is completely understandable and it is already easy to imagine how much heat is needed to heat a bucket of water 4,500 Cal / kg. (4,500 Cal/kg) is the calorific value of a kilogram of our fuel in Calories.

- Calorific value measurement in MJ/kg. System international thermal unit. Its physical meaning can only be expressed in terms of calories. 1 calorie is equal to 4.19 joules. (4.500 Kcal/kg. * 4.19 Joules = 18.855 MJ/kg.) is the calorific value of a kilogram of our fuel in Joules.

- Calorific value measurement in kWh. In the energy sector, it is customary to measure electrical and thermal energy in kWh. 5.238 kW hour / kg. - the heat of combustion of a kilogram of our fuel, measured in "electrotechnical units." How did you get this value? If a kilogram of this fuel is burned in an hour, then it is not difficult to calculate how much energy was released every second, that is, what thermal power was generated in this case. Divide 18.855.000 J (see point 2) by 3600 seconds and get 5238 J/sec. those. 5.238 kW

In particular, the following advantages of this type of biofuel can be distinguished:

- Low price. Compared to any other energy sources, especially hydrocarbons, this fuel is much cheaper. Accordingly, it is possible to solve the issue of heating and heating more economically. Moreover, the solution is relevant both for a country house (organization of a heating boiler) and for industrial facilities (preparation of water at the required temperature and heating of workshops). Another important factor is the lack of pressure on the market price of the international factor.If Kiev buys pellets exclusively at the internal price, formed on the basis of internal supply and demand, then coal and gas are supplied to the consumer at prices dictated by the world market.

- Favorable physical and chemical properties of the material. Wood pellets have a high calorific value, which makes it possible to achieve high boiler performance with low fuel consumption. In addition, when burning pellets, little ash is formed, therefore pellet boilers are not too capricious and require a minimum of maintenance.

- Efficient fuel structure from the point of view of combustion physics. Since pellets are a mound of individual elements, they burn very well, because the best catalyst, air, is contained directly in the structure of the bulk material. Accordingly, the fuel can be considered universal, it does not require any additional processing before use. Such fuel is no worse than gas or coal.

- Wood pellets are an almost unlimited resource. If oil is equated with black gold and gas is the cause of international scandals, then low-grade timber, as well as waste from the woodworking industry, is in abundance. Therefore, this resource is always available on the market without any problems.

- Ecological purity. Burning pellets does not lead to emissions of any harmful substances, fully complies with the most stringent standards for emissions of carbon dioxide, as well as any other gases into the atmosphere. Accordingly, pellets are not only profitable, but also green technology.

- Convenient burning process. Modern pellet boilers have a high degree of automation, which allows switching to this type of fuel without any technical difficulties. A pellet boiler requires no more attention than a coal-fired boiler.

- When burning 1.9 tons of pellets, approximately the same amount of heat is released as when burning one ton of fuel oil, while the cost of pellets on the domestic market is three times cheaper. Thus, heating with pellets is 40% cheaper than fuel oil.

Where pellets burn

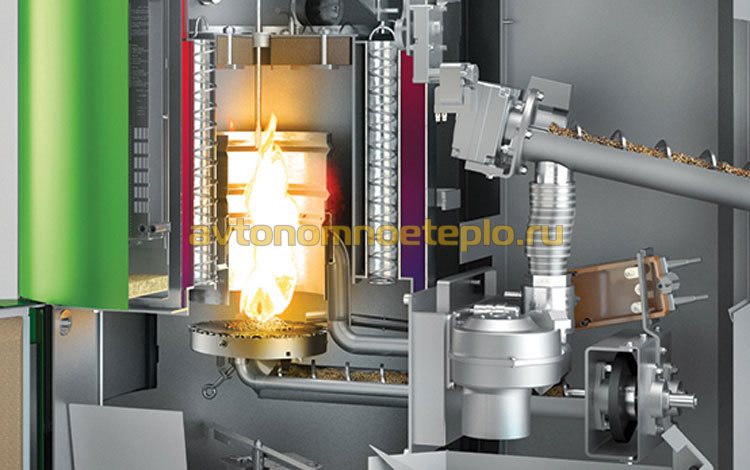

Heating boilers on pellets belong to the class of solid fuel boilers. They have a robust housing with a combustion chamber and a heat exchanger. The combustion of fuel pellets leads to the release of hot combustion products, which, passing through the heat exchanger, give it (and it is the coolant) heat.

"Born" back in 1947, pellet boilers have grown significantly in terms of efficiency and "intellectual" development. Pellet boilers today are fully automated systems that can “free” a person from the duties of a stoker for quite a long time (up to a month or more). It all depends on the size of the bunker or warehouse for storing pellets. The self-cleaning function allows you not to "get stuck" in the life of a high-quality boiler for the entire heating period.

An important factor in the spread of fuel boilers on pellets is their high environmental friendliness. After all, pellets are recycled wood, and the process of their combustion occurs with minimal release of harmful by-products. In fact, this is a non-waste "production".

Pellet boilers, having a high efficiency, a long period of operation, autonomy (from a person), also have a high cost. But the cost of pellets over several years compensates for investments in the boiler. The consumption of pellets for heating can be determined from the ratio: to obtain 5 kW of heat, it is necessary to burn 1 kg of pellets. A house with an area of 100 square meters will require 20-25 kg of pellets for its heating.

If necessary, such boilers can also be fired with wood, coal, wood chips, straw waste, etc.

The reverse application is also possible. If you have a ready-made stove or fireplace, you can heat them with pellets. Remembering the analysis of the properties of fuel pellets, it can be argued that a pellet stove will have a higher efficiency than when fired with wood.

Pellets history of creation

The word pellet is of English origin and literally means granules. For those who still do not quite understand what is at stake, I will explain: pellets are small cylindrical granules made from waste from the woodworking industry and agriculture. They are used as solid fuel in direct combustion systems or gas generator units.

The first person who came up with the idea of “compressing” firewood and giving it a more convenient form for transportation was the Bavarian Rudolf Gunnerman, who later launched the production of the first pellets in the United States. The products turned out to be very profitable, especially since free raw materials such as peat, sawdust, shavings and other waste from the woodworking industry, as well as straw, corn and sunflower stalks, husks and other plant mass could be used for the production of fuel pellets. In America, they began to show interest in this type of fuel, since, in addition to its efficiency, it presented a number of advantages, one of which was ease of transportation and high bulk density. These advantages have retained their significance today. For example, the same peat, due to its low density, does not make sense to transport more than 100 km from the development site, since in this case the transportation costs will exceed the cost of the fuel itself. If the peat is compressed 5-7 times, as it happens in the process of pellet production, then transportation over long distances becomes justified.

To date, more than 80 large enterprises are engaged in the production of fuel pellets in America. Annual production volumes are more than 1 million tons, which are absorbed mainly by the US domestic market. In addition, the United States purchases about 40% of the consumed volume of pellets from abroad (mainly in Canada). The popularity of fuel pellets in America has led to the development of efficient pellet combustion technologies. To date, more than 20 American companies are engaged in the production of equipment operating on pellets, which also supply their products for export.

Sweden became a popularizer of pellets and a kind of Columbus that brought American technologies to Europe, in 1985 it launched the production of fuel pellets from woodworking industry waste. With the advent of the nineties, the pellet boom covers all of Europe and by the end of the century they are already being produced in England, Italy, Norway, the Netherlands, France, Finland, Denmark and Germany. Today, most of the waste from European woodworking enterprises goes to the production of pellets.

A significant role in the popularity of fuel pellets was played by the high environmental friendliness of this type of fuel. As with wood burning, pellets release exactly as much carbon dioxide into the atmosphere as the plant has absorbed during the growth process. However, imported fuel is always tested for the content of harmful impurities in it, since this type of fuel can only be considered environmentally friendly if the wood or agricultural waste grew in environmentally friendly areas. So, in 2009, Italy found an increased content of cesium 137 in a batch of pellets from Lithuania, after which all 10,000 tons were returned to their “homeland”. Meanwhile, pellets from Ukrainian manufacturers are successfully sold in Europe, despite the Chernobyl disaster. Today, 15 enterprises operate in this country, and almost all of their products are exported. For Russia, with its wood reserves and the number of woodworking enterprises, the production of pellets is undoubtedly a profitable prospect, but so far this industry is at the development stage. China saw great prospects in the production of fuel pellets and has already set a course for their production, planning to reach the level of 50 million tons per year by 2020. This is about ten times more than today's annual production of Russian pellets.

The main advantages of fuel briquettes include

- Fuel briquettes obtained from vegetable raw materials are an environmentally friendly product. The material of the fuel briquette in full is natural raw materials. The binder is a natural "living" lignin - a substance contained in the cells of dead plant material.

- After heat treatment of raw materials during the production process, eurofirewood is not affected by fungi.

- In comparison with natural firewood - eurofirewood, due to its greater density, burns longer. Therefore, putting briquettes into the oven (boiler) can be 2-4 times less often.

- Due to their convenient shape, eurofirewood is very convenient to store and use.

- They have high calorific value. Eurowood gives on average 2 times more heat than conventional firewood. Their calorific value is comparable to that of coal.

- During combustion, a constant temperature is ensured at each stage of combustion due to an even flame.

- The ash content after combustion of briquettes is within 1-3%. For comparison: ash content after combustion of coal: 30-40%, combustion of natural firewood: 8 -16%, wood chips: 11 - 18%. For this reason, those working on eurowood are cleaned once a year. At the same time, ash can be used as an environmentally friendly fertilizer.

- When burning fuel briquettes, poisonous carbon monoxide is not released and other harmful substances are not formed.

- When using eurofirewood, heating costs are lower than in the case of using coal or natural firewood.

There are 3 types of fuel briquettes:

- RUF briquettes. RUF-briquette is a briquette in the form of a large rectangular brick.

- NESTRO briquettes. NESTRO briquette is a cylindrical briquette. May be with a radial hole inside.

- Pini&Kay briquettes. Briquette Pini-Key is a briquette having 4, 6 or 8 faces with a longitudinal radial hole inside.

Firewood traditional fuel

First of all, firewood harvested from trees of various species is suitable for heating. They differ in structure, ability to give off heat. The performance of the boiler will depend on this. The calorific value of firewood, depending on the type, varies:

- 1600-3200 kilocalories, with an average humidity of up to 12 percent.

- If this indicator of humidity is higher, from 40 to 50 percent, then the calorific value decreases.

Moreover, fuel with high humidity will have to be dried beforehand. This can be done by placing the harvested fuel in special rooms with good ventilation.

Firewood is expensive. For example, in the Moscow region per cubic meter will have to pay at least 2 thousand rubles

. If the firewood is split and well dried, then their cost is in the range of 4-5 thousand. It should be noted that when burned, firewood gives a large percentage of ash.

How to make money on pellets

This is not the topic of this article. But still, we want to note that for the organization of cost-effective production, access to wood waste in large quantities and a line with a pellet capacity of 2000 kg / h are required. The money invested in such a line will pay off on average 1-3 years.

But, as they say, nothing is impossible. You need to think, count and do!

1. Fuel loading

A wood-burning stove must be constantly looked after and logs should be added in a timely manner. In a harsh winter, with long nights, at least (and very likely), you will have to get up a couple of times. Pellet boilers are equipped with a special bunker. It is enough to load the pellets into it, and you can not approach the heater for several days, or even weeks (depending on the model) - the automation independently feeds the pellets into the furnace as they burn out.

2. Climate control

The level of automation of wood-burning boilers is zero. Pellet analogs, depending on the set temperature, maintain it themselves in the room, dosing the supply of pellets to the furnace.

Conclusion

3

- those who are accustomed to comfort and value personal time should choose a pellet boiler.

Features of heating with pellets

Pellet combustion indicators:

- Calorific value of pellets: 18 MJ/kg.

- Pellet boiler efficiency: 93-95%.

- Possibility of automation: yes.

- Ash content of pellets: 0.5-3%.

- Humidity pellet: 5-8%.

Just like firewood, this biofuel has its pros and cons.

Advantages of pellets

- Ecological purity.

- Low cost, but higher than firewood.

- Operational safety (absolutely non-explosive).

- Low ash content.

- Ash recycling.

- Ease of storage.

- High calorific value.

- High boiler efficiency.

- Ease of use of pellet boilers.

- There is no need for a large warehouse.

Disadvantages of pellets

More expensive than firewood.

It is much more pleasant to heat with pellets than with firewood. Most modern boilers have a container in which the pellets are filled with a margin. Depending on the model, this stock may be enough for a day, a week, a month or even the whole season. There is no need for combustion control.

Since the ash content of pellets is low, no more than 20 kg of ash burns during the entire season. The boiler is rarely cleaned (once a week or even a month), there will be no problems with the use of such an amount of ash, you can simply fertilize the plot, flower garden, vegetable garden.

The owner of a pellet boiler does not need to take care of fuel preparation, the pellets are completely ready to be fed into the boiler.

Coal grades B, D, G

Due to the high content of volatile substances, such coal quickly flares up and burns quickly. Coal of these grades is available and suitable for almost all types of boilers, however, for complete combustion, this coal must be supplied in small portions so that the released volatile substances have time to fully combine with atmospheric oxygen. Complete combustion of coal is characterized by a yellow flame and clear flue gases; incomplete combustion of volatile substances gives a crimson flame and black smoke.

For efficient combustion of such coal, the process must be constantly monitored; this mode of operation is implemented in the Thermorobot automatic boiler house.

The principle of operation of the wood pellet boiler

- Housing type - the design provides for one or two combustion chambers.

- Reserve heat source - some models have an electric heating element that heats the coolant when the main fuel stops burning.

- The principle of gas generation or pyrolysis - a wood and pellet boiler burns fuel with a limited air supply and high temperature. The creation of such conditions leads to enhanced production of gas, which is afterburned in a separate chamber, which increases the efficiency and thermal efficiency of the equipment.

Combined boiler for wood and pellets, demanding on fuel quality. To start the pyrolysis process, it is necessary that the moisture content of the fuel does not exceed 20%.

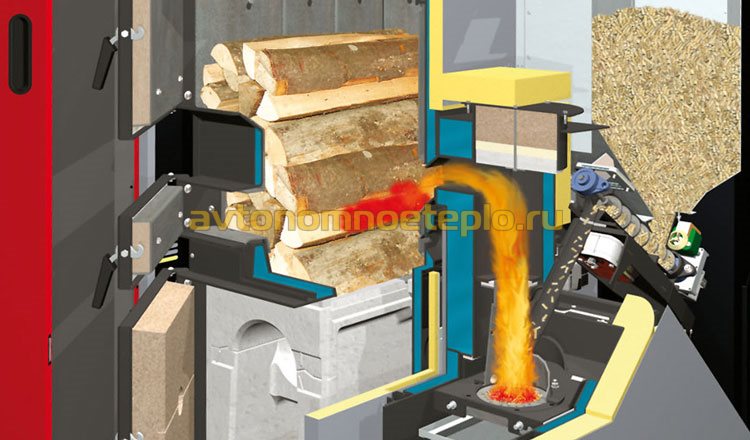

Two-furnace boilers

- There is no need for conversion when switching to firewood or pellets. The burner for fuel pellets is installed immediately. The design has a common heat exchanger, so the heating efficiency does not depend on the type of fuel used.

- Automatic transition to a reserve source of fuel. A two-furnace combined heating boiler for pellets and wood, usually works as follows. Firewood is used as the main source of heating. As soon as the logs burn out and the temperature of the coolant drops, the pellet burner automatically turns on, maintaining heating until the main type of fuel is used again.

Single-furnace boilers

Boilers are distinguished by the following characteristics:

- Less weight - in comparison with two-furnace units, the weight of the boiler structure, even with a cast-iron heat exchanger, is significantly less.

- Difficulties associated with the conversion of the system - in order to convert the boiler to pellets, you will need to install. The conversion, even with the condition of a certain experience, will take about 15 minutes. Automatic transition from firewood to pellets is not provided.

- Modest dimensions - boilers operating on wood pellets and firewood have a lower height. Two-furnace and single-furnace units have a built-in pellet bunker for fuel storage. For boilers with one combustion chamber, storage is often installed on top to save usable space.

- Automation - long-burning boilers are easier to control and prevent overheating of the coolant. Automation monitors the air injection, the temperature of the water supply and return. In some models, among other things, a connection to room thermostats is installed.

The efficiency of the boiler, operating on the principle of long burning, reaches 92%. Additional heat is produced by burning the gas produced in the gas generation process.

What is more profitable to use

It is best to start the comparison with the price of fuel, because it worries us the most. If we take average indicators, then 1 cubic meter of fuel briquettes costs about 2 times more than ordinary firewood. As we know, fuel briquettes can be made from different materials, but the price of firewood also depends on the type of wood. If you choose the most expensive fuel briquettes and the cheapest wood, the cost may differ by 3 times.

Note that most often on the market there are products of two types of quality. High-quality briquettes are more dense without cracks and chips, often burned on the outside. Lower quality briquettes have a lower density, they are characterized by a multilayer structure, which is weakly vulnerable to damage. Such briquettes burn faster and release less energy.

Popular fuel for stoves in homes and baths

Let's compare the indicators at work:

- How long fuel briquettes burn - usually 2 hours, while simple firewood is about an hour.

- The heat transfer from fuel briquettes is noticeably higher, since the fire in the furnace is stable throughout the entire burning time. Firewood usually flares up quickly and gives off maximum heat immediately, and then gradually fades out.

- After using firewood, a lot of coal and ash appears in the firebox, while practically nothing remains of eurofirewood.

The main task is heating. They burn for a long time, emit a lot of heat, and at the same time do not take up much space in the house, do not litter, they are also environmentally friendly and safe to use like firewood is common. At the same time, they do not create a full-fledged atmosphere of comfort, do not crack, and often emit a more unpleasant odor when burned. It is not for nothing that the prefix "euro" is present in their name, this type of fuel was created primarily to save on heating.

If you use fuel briquettes for heating a house, then such a replacement for firewood for a stove is quite relevant, but for kindling a bath, such a choice will not always be justified. As well as for a fireplace, the task of which is not only to heat the house, but also to create an appropriate entourage, with which a substitute for firewood clearly cannot cope.

To evaluate the effectiveness of fuel briquettes in each case, experiments should be carried out, too many factors affect their work. Only after you are convinced of the merits of this alternative type of fuel, you can give it some assessment.

Recently, a lot of positive reviews have appeared on the network, indicating that it is more profitable to heat a house with eurowood than ordinary ones. We attribute this to the growing popularity of alternative fuels.

Types and grades of coal

Coal is classified according to many parameters (mining geography, chemical composition), but from a “household” point of view, when buying coal for use in furnaces, it is enough to understand the marking and the possibility of using it in the Thermorobot.

According to the degree of coalification, three types of coal are distinguished: brown, stone and anthracite.The following coal designation system is used: Grade = (brand) + (size class).

In addition to the main grades listed in the table, intermediate grades of hard coal are also distinguished: DG (long-flame gas), GZh (fat gas), KZh (coke fat), PA (semi-anthracite), brown coals are also divided into groups.

Coking grades of coal (G, coke, Zh, K, OS) are practically not used in thermal power engineering, since they are a scarce raw material for the coking industry.

Main European quality standards for fuel pellets

|

Parameter |

||||

|---|---|---|---|---|

|

Germany |

Germany |

|||

|

Diameter (mm) |

||||

|

Length (mm) |

||||

|

Density (kg/dm3) |

||||

|

Humidity (%) |

||||

|

Bulk weight (kg/m3) |

||||

|

Briquette dust (%) |

||||

|

Ash content (%) |

||||

|

Calorific value (MJ/kg) |

||||

|

Arsenic (mg/kg) |

||||

|

Lead (mg/kg) |

||||

|

Cadmium (mg/kg) |

||||

|

Chromium (mg/kg) |

||||

|

Copper(mg/kg) |

||||

|

Mercury(mg/kg) |

||||

|

Zinc(mg/kg) |

||||

|

Fixer, bonding materials (%) |

* "no" - does not mean a value, it may be, there is no information, it is not defined, there is no exact value, etc.

The successful development of the economy of any country is directly related to the growth of energy consumption. However, fossil energy carriers, firstly, are not unlimited, and secondly, their burning leads to environmental pollution and to the greenhouse effect on our planet. The latter is one of the causes of climate change on Earth.