Selection Guide

And it seems to me that aluminum and bimetallic heating radiators will gradually replace cast iron ones. They began to be used not so long ago, so they are still wary. But they have already proven themselves well and more and more people prefer them. I installed aluminum radiators in my apartment 3 years ago. They look very nice, no need to paint and the house has become warmer.

Considering that in the old days there was no particular choice among radiators (as a rule, most of them had classic cast-iron radiators), then at present there is a wide range of products on the radiator market. In my case, when choosing a radiator, “there was room to turn around”, since the heating system is closed and created in my own house

On the advice of familiar installers, he paid attention to bimetallic radiators and did not lose. For several years now I have not bothered with the painting process, as in the case of cast iron ones, radiators do an excellent job of their functions and the house is always cozy and comfortable, regardless of the outside temperature

The only thing that had to be done additionally to protect the radiators from deposits was to install a system for deeper cleaning of the coolant.

I would not at home and I do not advise anyone to install an aluminum or bimetallic radiator in their apartment. Bimetal in those regions where there are serious problems with water treatment - such a battery will have to be changed after one heating season. Aluminum and bimetal are assembled by hand by a craftsman and the build quality depends on the professionalism of the person. Steel, for example, is assembled in fully robotic factories. Austrian radiators, in addition, have insurance against damage for 1 million and a guarantee for the entire device, and not a section like bimetal and aluminum. With it, you can block the entire window opening, providing an even flow of heated air to the window. This eliminates the formation of cold air currents on frosty days.

I completely agree with you Sergey. Bimetal and aluminum in an apartment is a risky undertaking; it is not possible to avoid contact of the coolant with the metal and there is a threat of an explosion. The quality of a steel radiator is much easier to determine, here are the signs of a quality device: the uniformity of welds, gaps, painting and the availability of guarantees and insurance. And do not be too lazy to consult with your master or HOA!

Bimetal has higher operating pressure characteristics - they can be safely installed in high-rise buildings (the pressure in them usually does not exceed 6 atm). The working pressure of bimetallic radiators is 10 atm, and some can withstand 16 atm. It is advisable to take a little promoted brand - the factory always makes the first order well.

From the section of the article on steel radiators: “Steel radiators do not withstand water hammer and pressure increased to 25 atmospheres, so it is better not to use them in heating systems for city apartments.” From the section of the article on bimetallic radiators: “It turns out that the bimetallic radiator combined the best properties of steel and aluminum heating devices. From steel he took. resistance to pressure drops (withstands up to 40-50 atmospheres). Where is the truth?

A steel radiator using "German" technology served a little more than 10 years. At one fine moment, a needle-thin stream appeared at the point of spot welding. For a battery, this is not a term. Soviet cast-iron batteries last half a century or more. Now I'm wondering which one to buy. The quality of modern technology is deliberately spoiled. You buy a cat in a poke.

Compatibility of the radiator with the heating system

The modern assortment of batteries is diverse - cast iron, aluminum, steel, copper, bimetallic devices - it is only important to understand which heating radiators will better "fit" into a particular heating system of your home. What is meant by this? This refers to the extent to which the technical parameters of the heater - the permissible temperature of the coolant, its pressure and composition, as well as heat transfer and inertia correspond to the indicators of your heating system

When buying a radiator, its appearance, durability, and, of course, the price are also important. It should be borne in mind that there are nuances in the selection of heating batteries for open systems (apartment buildings) and closed systems (individual houses). In the event that the indicators declared by the manufacturer do not correspond to the characteristics of your heating system, then rapid wear and even failure is possible.

Technical specifications

Paying attention primarily to the appearance and cost of the radiator, however, do not forget that the technical and operational characteristics of the device should come first. Not every heating battery, both imported and domestic, will withstand the operating conditions in existing domestic heating networks

The centralized heating system, which we inherited from the Soviet Union, is characterized by: fluctuations in pressure and temperature, as well as poor quality of the coolant (water). The design temperature for a single-pipe open domestic system in high-rise buildings is 105 degrees Celsius, the pressure is 10 atmospheres. However, these parameters sometimes go off scale when starting the heating system after the summer period, which leads to water hammer, which some heating devices from foreign manufacturers are not designed for.

Not every heating battery, both imported and domestic, will withstand the operating conditions in operating domestic heating networks. The centralized heating system, which we inherited from the Soviet Union, is characterized by: fluctuations in pressure and temperature, as well as poor quality of the coolant (water). The design temperature for a single-pipe open domestic system in high-rise buildings is 105 degrees Celsius, the pressure is 10 atmospheres. However, these parameters sometimes go off scale when starting the heating system after the summer period, which leads to water hammer, which some heating devices from foreign manufacturers are not designed for.

It is necessary to pay attention to the permissible temperature and pressure of the coolant in the heating system, which are indicated in the passport of the heater. Aluminum panel radiators with anodized coating allow operation in systems with increased pressure and do not require paintwork

Another fundamental parameter for a heating battery is its heat transfer. This characteristic affects the efficiency of heating the air in the room and depends on the material used in the design. It is well known that the heat transfer of steel is lower than that of aluminum, and copper is better than cast iron in this indicator. But, based on any one technical parameter, it will not be entirely true. It is necessary to comprehensively evaluate all the pros and cons of each type of heating device in order to opt for the best option.

What are flat radiators

It is necessary to start talking about flat radiators from their depth size. There is no exact indicator that would indicate the subtlety of the device.It is mostly determined by eye. For example, a cast-iron radiator can be taken as a standard - this is a common design. Anything that is less than half its depth can be attributed to flat heating radiators.

If we make an overview of all existing models, then only steel panel batteries are suitable for this standard. We will consider them. Why does it happen that panel structures have a small thickness? It's all about the technology of their manufacture.

How can I flush the heating battery

These are devices made of steel stamped sheets. The form is based on a solid sheet with a fairly large area of penetration. That is, this is not a sectional structure, but flat over the entire area of the heater itself. This is what is achieved by increasing the heat output. But at the same time, the depth of each panel is not very large, and, accordingly, the volume of coolant used in the heating system in the flattest radiator will be small. This ratio has a definite plus - a small fuel consumption for heating the coolant. That is, these two quantities are directly proportional.

Manufacturers have gone further. They did not focus on devices with a purely panel form, because, as mentioned above, this form has a reduced power. To increase this indicator, additions were made to the structure itself in the form of a finning system, the so-called convection ribs. They are welded over the entire area of the battery by spot welding. The main shape of the ribs is trapezoidal.

Types of flat radiators

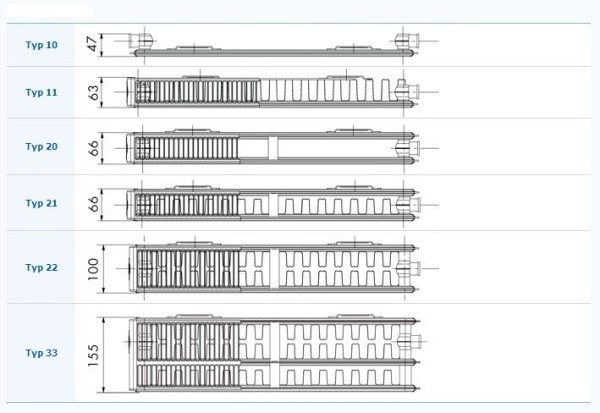

The classification of flat radiators for all manufacturers is the same. There are five types in total: 10, 11, 12, 22 and 33. How do they differ from each other?

- Type 10 is just a stamped panel with no frills. If we talk about the category "the thinnest heating radiators", then this type is the basis of this category. You won't find thinner on the market. Let's look at the type using the example of Kermi radiators. So type 10 has a depth of 46 mm.

- Type 11 is one panel with one layer of finning system. The depth of this model is 59 mm. Calmly and it can be classified as "flat".

- Type 12 - these are two panels, between which convection ribs are installed. Its thickness is 64 mm.

- Type 22 is a design consisting of two panels and two fin systems that are located between the planes of the panel. Depth - 102 mm.

- Type 33 is three panels. Two layers of ribs are installed between the first two, and one layer between the second and third. Depth 157 mm.

For other manufacturers, the depth size may vary in the same range with slight deviations in one direction or another. The deviations are insignificant, so the dimensions of the Kermi heating radiators can be taken as the basis for our analysis.

Attention! All types of steel panel radiators, except type 10, are supplied with protective side walls and a top grate. This improves the appearance of the device, but increases its cost.

And one more thing, the convection fins are a real dust collector, which is very difficult to clean.

And now let's choose from this type those heating devices that can enter the category of "flat". Let's start with the fact that the depth of the cast-iron radiator ChM-140 is 140 mm. This is what we will deviate from.

You can immediately determine that the first three types, and these are 10, 11 and 12, are thin. But 22 and 33 are not included in this category. That is, it turns out that not all steel panel heating radiators can be considered flat.

Characteristics of sectional types of heating batteries and their comparison

- Cast iron sectional radiators. Considering the types of heating batteries, it should be noted that it is cast iron appliances that have been known to consumers for a long time, since the days of the Soviet Union.In those years, they were installed everywhere - in residential, industrial and public buildings.

The structural solution of cast-iron sectional radiators allows them to be heated to high temperatures. Due to the peculiarities of cast iron as a material for the manufacture of batteries, they give off heat for a long time and therefore they were assigned leading positions among heating devices in those years, the heat transfer of cast iron radiators is quite good.

True, cast-iron radiators need to be heated to the desired temperature for a longer time, and this requires a larger amount of fuel or energy carrier. In order to save money, not all consumers choose cast iron products for installation.

The appearance of modern cast iron radiators has undergone minor changes with the same technical characteristics. One section is able to heat about two "squares" of the area. On sale you can even find designer models that can decorate a room.

Since cast iron appliances require a large amount of fuel to heat, they are not installed if they plan to use expensive energy sources, such as electricity. Choose more economical heating radiators, including aluminum batteries.

Aluminum sectional radiators. These appliances are considered a modern alternative to cast iron appliances because they weigh less and have less heat capacity. Aluminum sectional products give off heat no worse than cast iron and quickly warm up to the desired temperature (for more details: “How to choose aluminum heating radiators: technical specifications“). Thanks to their aesthetic and neat appearance, they fit perfectly into modern interiors.

One aluminum section heats one "square" of the room. If you install such batteries yourself, you can handle the installation without any problems on your own, since they are much lighter than cast iron products. According to experts, if we compare heating batteries for a private house, then aluminum sectional radiators have now become clear leaders.

Bimetal radiators. Outwardly, such heating batteries are similar to aluminum appliances. Bimetallic heating radiators in the section can be seen in the photo. They combine elements of steel and aluminum. Due to the manufacture of two alloys, these devices are called bimetallic.

When you look at a bimetallic heating radiator in a section, you can see a stainless steel heat-conducting channel inside it. Thanks to this design, the strength of the devices has increased significantly. And the thermal conductivity of bimetallic radiators is greater than aluminum. These heating products can be installed with economy class coolant. One section of such a radiator supplies heat to 1.4 "squares" of area. Bimetallic radiators are lightweight, and their installation is similar to the installation of aluminum batteries.

For different types of modern heaters, the sections may differ in size. Therefore, when choosing radiators, you should specify the power of the section. Based on this parameter, you can calculate the number of sections, taking into account the area of \u200b\u200bthe room.

We disassemble flat radiators

Anyone who has visited a specialized store selling heating equipment at least once can appreciate the whole variety of heating devices offered on the market. This is actually a huge assortment that allows you to make a choice to the taste of the consumer. No wonder they say that demand creates supply. So, this postulate is directly related to modern heating radiators. But the topic of our article is flat radiators. Why are they called that, and why are they needed at all? We will answer these and other questions.

Let's start with the second question, which determines the purpose of the flat design. There are several positions here:

- Reducing the size of the heater - increasing the free space of the room. This is especially true for the windowsill. With flat heatsinks, its width is drastically reduced. Good or bad, everyone decides for himself, but the designers are delighted with this. There is an opportunity to experiment.

- The heating battery itself is a kind of dust collector. By reducing the width of the device, we reduce the plane on which the dust settles.

- We add that flat batteries are the owners of a presentable appearance. In any case, they differ significantly from sectional models.

And now the most important question related to the heat transfer of this type of radiators. How much is this decrease? After all, it is no secret that the size of the heating battery affects the amount of heat output. To thoroughly understand this issue, you need to understand what flat heaters are.

Installation

Flat heating radiators are most suitable for rooms with a closed heating system. An expansion tank is a must.

The heating process consists of the following steps:

- The pump acts on the coolant

, which in turn begins to circulate through the pipeline. - Then it goes through the valve

. - At the next stage, it ends up in the radiator.

- After that, it moves along the air carrier.

- Moves to the return pipeline until it reaches the expansion tank with a membrane

.

If you decide to install flat radiators for open heating systems, then remember that in this case they will not last long, because. will not be able to resist corrosion processes.

Do not purchase thin radiators for installation in rooms with high humidity.

Overview of flat products

Production features

If we are talking about flat models, then most often we mean not the surface topography, but the depth of the radiator. At the same time, the term “flat” can be interpreted in different ways, because this category very often includes all batteries whose depth is less than that of a standard cast iron product.

Aluminum products with shallow depth

Almost all devices that belong to this type are steel panel heaters. No, in principle, you can find both a flat oil cooler and an aluminum structure, but the main niche in this market segment is occupied by steel.

The following radiators are produced using mixed technology:

- The basis of the product is a stamped steel sheet, which is subjected to mechanical processing and forms the internal contour of the heater.

- Due to stamping, a profile is formed, which provides an increase in the heat transfer area.

- Trapezoidal convection ribs are sometimes welded to the base sheet to improve work efficiency. When passing through the fins, the air is heated and then distributed throughout the room. (See also the article Repair of heating pipes: features.)

Appearance of the flat panel model

As a result of all these operations, a flat steel radiator is obtained, which combines compact dimensions with fairly good heat dissipation. Of course, in this parameter it will be inferior to full-size models, but if it is the form that is important for us, then we will have to put up with some heat losses.

Types of panel radiators

Most manufacturers of panel type radiators use the same product classification. Having understood it, you will be able to determine the depth of the model and its design at a glance - even if you do not have the battery itself in front of you, but only the instructions with the marking.

Note! As a rule, the first number indicates the number of panels, the second - the number of rows of convection fins

Design features of different types

How the symbols are deciphered, we will describe in the table below:

Popular types of heating batteries

If we compare heating radiators, then first of all it is clear that they all differ in design. Based on the fact that they look different, batteries are divided into sectional and panel products.

Sectional radiators. Such devices are divided into three main groups:

- batteries made from cast iron;

- radiators made of aluminum alloy;

- bimetallic products.

From the name it is already clear that the heating device consists of sections assembled into a single structure. For example, many consumers are familiar with cast-iron batteries used for decades, which are a set of a specific number of sections. New aluminum appliances also consist of several sections, but if you look at these heating radiators, the comparison will be in favor of modern products, since they look more aesthetically pleasing (more: "Aluminum radiators - technical specifications, installation").

Panel batteries. They are made only from steel. Outwardly, they are a flat product with bulges. Flat batteries were widely used in the 80s of the last century. Basically they were mounted in panel houses. Modern panel heaters have been modified and their appearance has changed slightly. After that, their heat output increased, and they were once used to heat residential premises. Making a comparison of sectional and panel heating radiators, it can be noted that the former are widely used in heating systems and consumers respond positively to them.

What are heating radiators

Heating batteries, they are also radiators that are installed in residential premises, are mainly water or electric.

Water types of heating batteries heat housing with water, which is used as a coolant (in more detail: "Water heating radiators - types and types"). After the liquid is heated to a certain temperature, it begins to circulate through pipes and batteries, giving off thermal energy to the surrounding air.

Electric heating radiators are only superficially similar to conventional appliances, but their principle of operation is different. They are usually used as an additional source of heat, since high electricity prices make the operation of such heaters economically unprofitable.

True, if there is no possibility to equip water heating, there is nothing left but to use electrical appliances for heating. Suppose that a family goes to a dacha outside the city only on weekends - in this case, an electric convector will be enough, because it will not let you freeze.

What are the types of heating batteries review and comparison

With the onset of the heating season, many residents complain about cold batteries in the apartment. But utilities are not always to blame for the problem of poor heating. Often the reason lies in the fact that the heating radiators are clogged or have already become unusable and need to be replaced with modern types of heating batteries. Before proceeding with the reconstruction of the heating system, it does not hurt to ask what kind of heating batteries are and what advantages and disadvantages they have.

This topic is devoted to this article, which talks about modern heating appliances for apartments and private households. It talks about what kind of heating radiators are.

Radiators and convectors

The types of heaters used in the water heating system are distinguished not only by the material from which they were made, but also by the principle of operation. Since the days of the Soviet Union, radiators and convectors have been used in heating systems. Radiators have higher heat transfer rates than convectors.They radiate heat from their surface and provide constant heating of the room, and convectors move air flows from the bottom up, thus forming a draft.

Outwardly, convectors are also very different from radiators, just look at the photos of these devices, and you can accurately determine which device is a convector and which is a radiator.

The basis of the convector design is a pipe through which the coolant passes. There are thin, sharp steel plates on the pipe.

The advantages of convectors include small size, reliability, low cost. These devices can be built into the floor, into the wall and placed where there is simply not enough space to install a radiator.

The disadvantages of convectors include a low heat transfer coefficient. Therefore, it is unlikely that it will be possible to warm up a large room with the help of these devices; they can only be used as additional sources of heat.

The convection method of heating a room can hardly be called a virtue. Since air convection, or easier air movement, is nothing more than a draft, and you are unlikely to be happy with such a phenomenon in your home. Convectors are often used in office buildings, where a large glazing area makes it impossible to install conventional radiators.

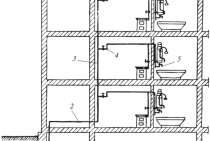

What are the possible types of connection of radiators

The chosen scheme of their installation affects the efficiency of the heating devices.

There are different types of connection of heating radiators:

- diagonal connection. This method of mounting heaters is suitable for long batteries that can warm up evenly. The pipe supplying the coolant is connected on one side to the branch pipe at the top, and at the bottom, a discharge pipe is connected to the branch pipe. If hot water is supplied from below, the battery efficiency will decrease by 10%.

- One-way lateral connection. This is the most common way to install radiators. This connection method, in which the inlet pipe is connected to the upper branch pipe, and the outlet pipe to the lower one, provides the greatest heat transfer.

- Bottom connection. This method of distributing batteries is used only if the heating system is located in the floor.

The service life of the heating system, as well as its functionality, efficiency and reliability, depend on how correctly the type of connection is chosen and how well the radiators are installed in the heating system.