3 Terms and definitions

In this standard, the following terms are used with their respective definitions:

3.1 autoclaved cellular concrete: An artificial stone material with a porous structure, made from a binder, finely ground silica component, a blowing agent and water, and subjected to heat and moisture treatment at elevated pressure.

3.2 technological documentation: A set of documents that define the technological process of manufacturing products and contain data for organizing the production process.

3.3

|

required strength of cellular concrete: The minimum allowable value of the actual strength of concrete in a batch, determined by the laboratories of manufacturers in accordance with its achieved uniformity. |

3.4

|

actual strength of cellular concrete in a batch: The average value of the strength of concrete in a batch, determined by the results of tests of control samples or by non-destructive methods directly in the structure. |

3.5 normalized density of cellular concrete: The grade of concrete specified in the regulatory, technical or project documentation for average density

3.6

|

required density of cellular concrete: The maximum allowable value of the actual density of concrete in a batch, determined by the laboratories of manufacturers in accordance with its achieved uniformity. |

3.7

|

actual density of cellular concrete in a batch: The average density of concrete in a batch, determined by the results of tests of control samples or by the radioisotope method directly in the structure. |

3.8 class of cellular concrete in terms of compressive strength: The value of the cubic strength of concrete in compression with a security of 0.95 (normative cubic strength).

3.9 actual thermal conductivity: The average value of the thermal conductivity coefficient of cellular concrete in a batch, determined from the results of testing control samples

3.10

|

input control: Control of the supplier's products received by the consumer or customer and intended for use in the manufacture, repair or operation of products. |

3.11

|

operational control: Control of a product or process during or after the completion of a manufacturing operation. |

3.12

|

acceptance control: Product control, based on the results of which a decision is made on its suitability for supply and (or) use. |

Note - The decision on the suitability of products for supply and (or) use is made taking into account the results of incoming and operational control, as well as acceptance and periodic tests.

3.13

|

acceptance tests: Control tests of products during acceptance control. |

3.14

|

periodic tests: Control tests of products, carried out in the volumes and within the time limits established by the regulatory and / or technical documentation, in order to control the stability of product quality and the possibility of continuing its production. |

3.15 equilibrium humidity: The actual average moisture content of cellular concrete over the thickness of the wall of the structure and cardinal points for the heating period after 3-5 years of operation.

Note - The equilibrium weight humidity in the outer walls of cellular concrete of buildings with dry operation in dry and normal climatic zones of humidity and buildings with normal operation in a dry climatic zone is assumed to be 4%. In the rest of the outer walls of cellular concrete, the equilibrium moisture content is assumed to be 5%.

Annex 1

Table 4. Control scheme A.

|

The coefficient of variation VP, % |

KT, % of normalized strength, at nequal to |

|||||||

|

1 |

2 |

3 |

4 |

6 |

10 |

30 or more |

||

|

5 |

74 |

73 |

73 |

73 |

72 |

72 |

72 |

|

|

6 |

76 |

75 |

75 |

75 |

74 |

74 |

73 |

|

|

7 |

79 |

78 |

77 |

77 |

76 |

76 |

75 |

|

|

8 |

81 |

80 |

79 |

79 |

78 |

78 |

77 |

|

|

9 |

84 |

82 |

81 |

81 |

80 |

80 |

79 |

|

|

10 |

87 |

85 |

84 |

83 |

83 |

82 |

81 |

|

|

11 |

90 |

87 |

86 |

86 |

84 |

84 |

83 |

|

|

12 |

93 |

90 |

89 |

88 |

88 |

87 |

86 |

|

|

13 |

96 |

93 |

92 |

91 |

90 |

89 |

88 |

|

|

14 |

99 |

96 |

95 |

94 |

93 |

92 |

91 |

|

|

15 |

103 |

100 |

98 |

97 |

96 |

95 |

94 |

|

|

16 |

107 |

103 |

101 |

100 |

99 |

98 |

97 |

|

|

17 |

111 |

107 |

105 |

104 |

103 |

101 |

99 |

|

|

18 |

115 |

111 |

109 |

108 |

106 |

105 |

103 |

|

|

19 |

120 |

115 |

113 |

111 |

110 |

108 |

106 |

|

|

20 |

125 |

119 |

117 |

116 |

114 |

112 |

110 |

|

|

21 |

130 |

124 |

122 |

120 |

118 |

116 |

114 |

|

|

22 |

Region |

129 |

126 |

125 |

123 |

121 |

118 |

|

|

23 |

invalid values |

130 |

128 |

126 |

123 |

|||

|

24 |

variations |

131 |

128 |

|||||

Table 5. Control scheme B

|

The coefficient of variation Vn, % |

KT, % of normalized strength, at nequal to |

||||||||||

|

2 |

3 |

4 |

6 |

10 |

15 |

30 |

50 |

100 or more |

|||

|

5 |

82 |

77 |

76 |

74 |

73 |

73 |

72 |

72 |

72 |

||

|

6 |

86 |

80 |

79 |

77 |

76 |

75 |

74 |

74 |

73 |

||

|

7 |

92 |

84 |

82 |

80 |

78 |

77 |

76 |

76 |

75 |

||

|

8 |

98 |

88 |

85 |

82 |

81 |

80 |

78 |

78 |

77 |

||

|

9 |

105 |

92 |

89 |

85 |

83 |

82 |

81 |

80 |

79 |

||

|

10 |

113 |

97 |

93 |

89 |

86 |

85 |

83 |

82 |

82 |

||

|

11 |

122 |

103 |

97 |

92 |

89 |

87 |

86 |

85 |

84 |

||

|

12 |

109 |

102 |

96 |

92 |

91 |

88 |

97 |

86 |

|||

|

13 |

115 |

107 |

101 |

96 |

94 |

91 |

90 |

89 |

|||

|

14 |

123 |

113 |

105 |

100 |

97 |

94 |

93 |

92 |

|||

|

15 |

119 |

110 |

104 |

101 |

98 |

96 |

95 |

||||

|

16 |

127 |

116 |

109 |

105 |

101 |

99 |

98 |

||||

|

17 |

Region unacceptable values variations |

122 |

114 |

109 |

105 |

100 |

101 |

||||

|

18 |

129 |

119 |

114 |

109 |

107 |

105 |

|||||

|

19 |

125 |

119 |

113 |

111 |

108 |

||||||

|

20 |

125 |

118 |

115 |

112 |

|||||||

|

21 |

124 |

120 |

117 |

||||||||

|

22 |

129 |

125 |

122 |

||||||||

|

23 |

127 |

||||||||||

GENERAL PROVISIONS

1.1.The stability of such characteristics of cellular concrete as strength and density depends mainly on the quality of raw materials, the well-established equipment, the stability of the technological process and other factors:

strength - from the stability of density indicators, the fineness of grinding of the binder and silica component, the accuracy of dosing components, autoclaving modes, etc.;

density - on the speed and temperature of lime slaking, the accuracy of dosing of the blowing agent, the viscosity and temperature of the cellular concrete mixture, etc.

1.2. Systematic control of the strength and density indicators of cellular concrete is carried out by sampling, manufacturing and testing of control samples with processing of the results by the method of mathematical statistics.

1.3. In accordance with the "Guidelines for the design of concrete and reinforced concrete structures made of cellular concrete" (M., Stroyizdat, 1977), the main indicator of the standard resistance of concrete is its standard cubic strength Rн, determined by the formula

(1)

where - design strength (grade) of concrete in compression, MPa, with a security of 95% *;

VR — coefficient of variation of concrete strength.

______________

* Such security means that in 950 cases out of 1000 the actual values should be higher than the standard Rн. This is possible provided that the average strength of concrete is equal to the design one, and the coefficient of variation is no more than 18%.

Note. When ensuring under production conditions the design strength of cellular concrete in compression, the difference in the actual values of the coefficient of variation VRwill lead to unequal provision of normative resistance of concrete to compression: at low values VR safety margins will be excessive, and at high they may be insufficient, which under operating conditions can lead to an accident (see appendix).

1.4. To ensure the normative resistance of cellular concrete compression, its average strength in the production process should be taken depending on the value of the coefficient VR (according to GOST 18105.0-80 and 18105.1-80).

1.5. The spread of values of the density index is characterized by the coefficient of variation Vg and controlled during the production process.

The limiting value of the coefficient of variation in a batch according to SN 277-80 (“Instructions for the manufacture of products from cellular concrete”, M., Stroyizdat, 1981) and GOST 25485-82 should be taken equal to Vg = 5 %.

1.6. Systematic statistical control of the strength and density of cellular concrete under production conditions is carried out based on the results of testing a series of control samples for each batch of products produced during the analyzed period (GOST 18105.1-80), which allows you to assign the required strength RT and her average Ryfor a controlled period, as well as to regulate the required density gT of cellular concrete.

1.7. Statistical control of the strength of cellular concrete is carried out for a batch of products according to two schemes:

Scheme A - using the results of the control of batches of concrete for the previous period;

Scheme B - based on the results of the control of this batch.

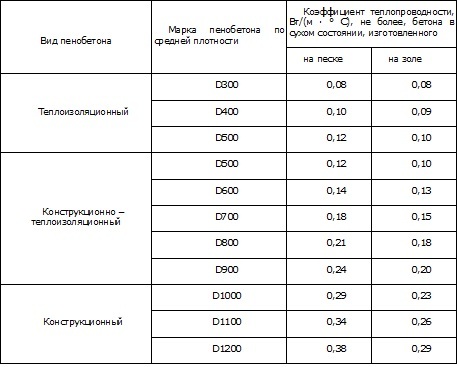

Density and mass of foam blocks

Foam concrete can have different densities.

It is denoted by the Latin letter D, after which there are numbers from 300 to 1200 in increments of 100 units. The higher the density, the greater the mass and strength, but the lower the thermal insulation characteristics. Therefore, according to the area of \u200b\u200buse, foam blocks are divided into three categories:

from D300 to D500 - heat-insulating blocks of foam concrete. They are used as a heater (for example, when insulating a balcony or loggia), they are not able to withstand any significant load. Price of one of the firms. Cut blocks are more expensive, but it is much easier to work with them from D600 to D900 - structural and heat-insulating blocks.

They are also often called construction. They withstand some load, while they have good heat retention properties. These are usually used in the construction of private one-two-story houses.

The best choice is D600 and D700.The thickness of the wall when using blocks of this density is only 35-45 cm (for central Russia), and without the need for additional insulation. from D1000 to D1200 - structural blocks.

Able to carry significant loads, but the thermal conductivity is low. Additional insulation required. Little is used in private construction.

The density of foam blocks affects its mass. In fact, the brand also displays the mass of one cubic meter of material. For example, a cubic meter of D400 brand foam blocks will weigh about 400 kg, a cube of D700 density blocks has a mass of about 700 kg.

How much does a cube of foam blocks weigh depends on the density of the material

Why "about", because the manufacturing process allows for some error. A little more weight is considered normal - in the range of 10-15%.

But at the same time, you need to make sure that there are no extraneous inclusions. Some manufacturers mix broken bricks or crushed stone to reduce costs. Because of this, the mass becomes a little larger, which is generally uncritical.

But these additives greatly reduce thermal conductivity, which is not good at all. And this is no longer foam concrete, but incomprehensible building blocks with unknown characteristics and it is not clear how they will behave during operation. So when buying, be sure to be interested in the mass, and if possible, break a couple and see what's inside.

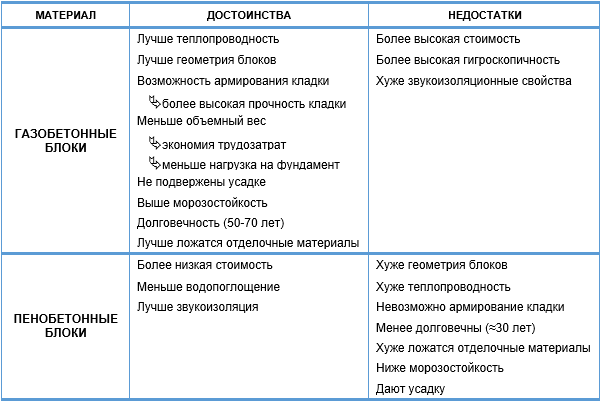

Aerated concrete block and foam block what is the difference

Foam concrete, being cellular concrete, is inferior to aerated concrete in several characteristics:

- the dimensions of aerated concrete blocks are completely standardized; for foam concrete there are no uniform standards for all products;

- shrinkage of aerated concrete is ten times less than that of foam concrete, the indicator for aerated concrete products is 0.5 mm / m, while for foam concrete it varies from 1 to 3 mm / m;

- due to the use of foaming agents, the environmental friendliness of foam concrete is worse;

- the strength of aerated concrete products is higher due to uniformity.

Foam concrete products are not inferior to aerated concrete in some characteristics:

- fire resistance;

- frost resistance;

- ability to keep warm.

Foam block dimensions

The production of cellular concrete blocks is regulated by GOST 215 20-89. It defines the characteristics and standard sizes, but there is also a note that it is allowed to change the parameters by order of the consumer.

By appointment, foam blocks are wall and partition. Wall used in the laying of load-bearing walls. They usually have a size of 600*300*200 mm.

Some firms produce blocks with a length of 625 mm. The rest of the parameters remain the same. In that case, the size of the most popular foam block looks like this 625 * 300 * 200 mm.

The dimensions of the foam block can be not only standard

In any case, for a wall 30 cm wide, it is enough to lay one block. Moreover, if you use the brand D600 or D700, it is quite possible to work alone. One block does not weigh that much - from 21 kg to 26 kg (21 kg - less dense, 26 kg - more).

Foam block dimensions D 300D 400D 500D 600D 700D 800600*300*200 mm10.8-11.3 kg14.0-14.8 kg18.0-19.0 kg21.5-22.4 kg25.0-26.4 kg28.6-29 .8 kg600*300*250 mm13.5-14.9 kg18.0-19.9 kg22.5-24.5 kg27.0-28.4 kg31.5-34.6 kg36.0-39.6 kg600 *300*300mm16.2-17.4kg21.6-23.7kg27.0-29.7kg32.4-35.6kg37.8-41.6kg43.2-47.5kg600*300* 400 mm21.6-23.7 kg28.8-31.7 kg36.0-39.6 kg43.2-47.5 kg50.4-55.4 kg57.6-63.4 kg

There are wall blocks of different formats. Here are the main dimensions of the foam block, which is used for laying load-bearing walls and partitions:

- 600*300*200 mm - the most popular size of foam blocks; 600*300*250 mm; 600*300*300 mm; 600*300*400 mm.

With a density of D600 or D700, it is quite possible to work alone with foam blocks 200 mm wide, 250 mm wide. Their weight is 20-35 kg.

You can handle it alone. Even larger ones, with a width of 300 mm and even more so 400 mm, are already work for two. It is even possible to use a lifting mechanism.

There are large-format block panels.

You can work with them only using lifting equipment - at least a winch. But the construction is progressing very quickly. The dimensions of the large format foam block are as follows:

- 1000*600*600mm;1000*600*500mm;1000*600*400mm;1000*600*300mm.

That is, blocks with a width of 300 mm and 400 mm are stacked in one row during the construction of a building in central Russia. Since their height is 60 cm, there will also be few rows.

The dimensions of the foam block are selected depending on the type of building and wall

There are also smaller blocks.They are usually used for insulation, in some cases for the construction of walls - if the partition is needed with a small thickness, or they decided to build from small foam concrete blocks. The dimensions of the foam block of small thickness are as follows:

- 600*300*100mm; 600*300*150mm.

It is easy to work with them, since the mass is small, especially if they are used as heat-insulating ones. The density of foam concrete is then 300 or 400 units, so that the weight of one foam block does not exceed 10 kg.

https://youtube.com/watch?v=UqtqzN5CY1Qrel%3D0%26controls%3D0%26showinfo%3D0

- www.avtobeton.ru

- stroy-expertiza.ru

- ostroymaterialah.ru

- stroychik.ru

Do not confuse foam concrete and aerated concrete

There are two porous building materials of artificial origin on the market - aerated concrete and foam concrete. Their composition is similar.

It is a mixture of cement and sand with the addition of water and a foaming agent. As a result, the mixture acquires a porous structure, which increases thermal conductivity and reduces weight. These are the main advantages of materials of this type.

But not everyone understands the difference between foam concrete and aerated concrete.

It is not surprising: they are very similar in appearance, even they have a common GOST. The difference is mainly in the features of the technology. The characteristics of both materials are very close and they belong to the same group - cellular concrete.

Foam blocks and gas blocks visually do not differ too much

Classification

In accordance with GOSTs, aerated concrete is classified according to several criteria:

- by appointment;

- structural;

- structural and heat-insulating;

- heat-insulating.

Hardening method:

- autoclave;

- non-autoclave.

GOST 25485-89 divides aerated concrete into grades in accordance with their average density.

This characteristic is determined in the dry state of products and corresponds to the following grades of aerated concrete:

- D300;

- D350;

- D400;

- D500;

- D600;

- D700;

- D800;

- D900;

- D1000;

- D1100;

- D1200.

Grades from D300 to D500 are classified as heat-insulating concretes. They have non-standardized frost resistance and a reduced strength index. This applies to both autoclaved and non-autoclaved concretes.

Concrete under the D500 brand is transitional and when used as a structural material, a frost resistance characteristic is added for it, which has a grade from F15 to F35.

Aerated concrete grades from D500 to D900 are of mixed type. Compared to previous concretes, they have a higher strength index, but lower frost resistance. They are assigned grades in terms of their relationship to low temperatures from F15 to F100.

D1000, D1100, D1200 are grades of structural type concrete. Blocks of them are used mainly for the construction of load-bearing structures. The strength index of these grades is much greater than that of previous concretes.

According to GOSTs, aerated concrete products must have the following dimensions:

- dimensions of the U-shaped block - 600x200x200-400 mm;

- block dimensions - 625x250x100-400 mm.

Specifications by brand:

| Brand | Thermal conductivity, W/(m•°С) | Strength, kgf/cm2 | Density, kg/m3 | Vapor permeability, mg / mchPa | Shrinkage, mm/m | Humidity, % no more |

| D300 | 0,072 | 4,3 | 300 | 0,26 | — | 8 |

| D350 | 0,084 | 6,42 | 350 | 0,25 | — | 8 |

| D400 | 0,096 | 9,69-14,3 | 400 | 0,23 | — | 8 |

| D500 | 0,12 | 9,69-24,5 | 500 | 0,20 | — | 8 |

| D600 | 0,14 | 14,3-33,7 | 600 | 0,16 | 0,5 | 8 |

| D700 | 0,17 | 19,4-46,9 | 700 | 0,15 | 0,5 | 8 |

| D800 | 0,19 | 19,4-70,4 | 800 | 0,14 | 0,5 | 10 |

| D900 | 0,22 | 33,7-91,8 | 900 | 0,12 | 0,5 | 10 |

| D1000 | 0,24 | 70,4-107 | 1000 | 0,11 | 0,5 | 10 |

| D1100 | 0,26 | 91,8-117 | 1100 | 0,10 | 0,5 | 10 |

| D1200 | 0,28 | 107-117 | 1200 | 0,09 | 0,5 | 10 |

Weight of standard blocks by brand (kg):

| D300 | D350 | D400 | D500 | D600 | D700 | D800 | D900 | D1000 | D1100 | D1200 | |

| Block | 4.5 | 5,25 | 6 | 7,5 | 9 | 10,5 | 12 | 13,5 | 15 | 16,5 | 18 |

| U-block | 9 | 13,5 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | 33 | 36 |

How to choose the desired density of foam concrete blocks

As we have already found out, the density of the foam concrete block is directly related to its thermal insulation characteristics and bearing capacity. The warmer, the weaker, the stronger, the colder. So a compromise needs to be found.

In general, there are not so many options.

In most cases, builders use foam blocks with a density of D600-D700 as an independent (structural and heat-insulating) wall material. Such blocks are able to withstand the load from monolithic ceilings without an armored belt, or finished floor slabs (but with an obligatory armored belt around the perimeter of the slabs). Of course, all types of wooden floors are also applicable in houses made of foam blocks of this density.

As alternative solutions, builders create multi-layer structures. Where low-density foam blocks are used only as a heat-insulating material, and the role of load-bearing elements goes to bricks, sand concrete blocks or monolithic concrete.

It is desirable to make all combined structures using foam blocks in the form of shell contours.

That is, if there is a brick wall, then it must be completely lined with foam concrete blocks, and not done in pieces or some separate elements. A few years ago, builders who did not particularly trust foam concrete used mixed structures, when the corner elements of the building were laid out from sand concrete blocks, and the gap between these vertical “column-corners” from sand concrete blocks was filled with foam blocks. An armored belt was cast along the perimeter (a monolithic concrete tape that distributes the load from the floor slabs to the walls of foam blocks) and ready-made floor slabs were placed.

The undoubted disadvantage of such a solution is the presence of cold corners and walls in the form of concrete pillars-corners and armored belts. Modern builders are unlikely to use such structures, but it was, and many still suffer from what it was.

Especially cold in winter, when frost and mold appear inside the house, on the corners and under the ceiling. I hope that I helped you a little to understand the grades, densities, thermal conductivity and other important characteristics of the materials you buy. For all unexplained foam concrete questions, write to eduard@avtobeton.ru With warm and strong frost-free greetings, Eduard Minaev.

The expert measured the propagation velocity of ultrasound in foam concrete structures to determine the average compressive strength, class and grade of foam concrete (see Appendix No. 1, photo).

Measurements were made by ultrasonic tester UK1401, according to GOST 17624-87 “Concrete.

Ultrasonic method for determining strength. The number and location of controlled sections on structures are established taking into account the requirements of GOST 18105-86 “Concrete. Strength control rules.

According to the measurements performed, calculations of the average strength of concrete were made, the grade and class for the compressive strength of foam concrete were determined.

The results are listed in Table No. 1.

Table #1

No. of the measuring section Velocity of propagation of ultrasound in the sections The closest class of foam concrete in terms of compressive strength Grade of foam concrete in terms of average density m/sV 2.5D 600 2.31860 m/sV 2.5D 600

ASSIGNMENT OF STATISTICAL CHARACTERISTICS OF cellular concrete FOR THE CONTROLLED PERIOD

7.1. The assignment of the average strength level and tolerances for the density of cellular concrete for the controlled period is based on the statistical indicators obtained for the analyzed period (scheme A).

7.2. Average strength level of cellular concrete Ry is assigned for each controlled period and is determined by the formula

where RT - the required strength of cellular concrete for the analyzed period;

KMP - coefficient taking into account inter-batch variation, and determined from Table. (See Appendix 1 to GOST 18105.1-80).

Table 3

|

VMP |

KMP |

VMP |

KMP |

VMP |

KMP |

VMP |

KMP |

|

£ 5 |

1,07 |

8 |

1,11 |

11 |

1,16 |

14 |

1,22 |

|

6 |

1,08 |

9 |

1,13 |

12 |

1,18 |

15 |

1,24 |

|

7 |

1,10 |

10 |

1,15 |

13 |

1,20 |

16 |

1,26 |

7.3. The average density of cellular concrete for the controlled period is assigned taking into account the following requirements:

a) the average (for the batch) value of the coefficient of variation for the analyzed period should not exceed: for concrete of the highest quality category - VP = 4%, for the first - VP = 5 %;

b) the deviation of the average (by batch) density of cellular concrete from the standard for the same period should not exceed the values given in Table. .

Production features

When choosing building materials, especially such as cellular concrete, you need to pay attention to even the smallest details. Because it is they who ultimately affect how warm and durable the structure will turn out.

It is these subtleties that we will describe in this section.

Production technology. The production of foam concrete is so simple that it can be made in the garage. It is enough to buy a foaming agent, and the rest of the components are readily available.

The mixture (cement + sand + water) is kneaded in any container, a foaming additive is added. Next, the composition is poured into molds.The ripening of the blocks occurs in natural conditions - in the air.

That is, you can do without special equipment, quality control is conditional - you must adhere to known proportions and technology. But you really want to save money ... Therefore, there are a large number of foam blocks on the market, the qualities of which are far from GOST ones. Foam concrete has a more uniform structure. Aerated concrete is mixed just as easily, but there are two types - autoclave and non-autoclave. The non-autoclave also dries outdoors, but does not have the best performance.

Autoclaved aerated concrete undergoes a hardening process at elevated pressure and temperature. As a result, blocks are obtained with increased strength. They cost more, but they are also much stronger. Accuracy of geometric dimensions. Aerated concrete blocks are produced in two ways.

According to one technology, the composition is poured into finished forms. These blocks have a difference in size up to 3-5 mm. Using another technology, large-format blocks are formed, which are then cut to the specified dimensions.

The difference in the size of such material is minimal. The strength of foam concrete of different densities Foam concrete is poured into ready-made forms. There is no other technology. Accordingly, the difference in block geometry can be significant.

It is corrected by an increase in the masonry joint, which reduces the thermal insulation characteristics of the masonry as a whole.

So when choosing, focus on geometry. If the blocks are almost the same (GOST allows deviations of 1 mm), there is hope that the technology was followed

If we consider these materials from this point of view, then autoclaved aerated concrete with minimal differences in size is more preferable.

Masonry from such material is made using special glue. It is applied in a layer of a couple of millimeters, since the ideal geometry allows this. Since a seam with a wall made of this material is a cold bridge, the wall turns out to be very warm (due to the small thickness of the seam, heat is retained in the building better).

When using foam blocks with a large discrepancy in size, a conventional mortar is used for masonry. Glue is too expensive to be laid in large layers. When using cement mortar, the costs are much less, but the thermal insulation characteristics of the building cannot be compared - they are much lower.

Definition of concrete class

The revealed indicators of the strength characteristics of foam concrete are:

- the nearest class of foam concrete in terms of compressive strength is B 2.5; the brand of foam concrete in terms of average density is D 600.

These indicators indicate that foam concrete is not intended for the construction of load-bearing walls, and carries a heat-insulating character.

Evaluation of work on the construction of a residential building

Examination of the apartment bay - When, in what period (July - September 2008) did the apartment flood occur? Determine the market value of the damage, refurbishment of the apartment from the bay, at the time of the bay and at the date of the examination? Examination of the kitchen - When checking the tile floor with the help of a level, deviations from the plane of up to 5 mm by 2 meters were revealed. The seams between the plates are not worn.

When tapping the floor tiles, changes in the nature of the sound were revealed. Between the elements of the plinth, voids were revealed. Examination of a residential apartment - Examination of the apartment for compliance with SNiP and GOST, as well as measuring the area of \u200b\u200bthe apartment with an explication of the premises. from silicate bricks.

- Date: 02-04-2015Views: 124Comments: Rating: 49

Density of foam concrete: does this parameter affect construction? Why know him?

Due to their reliability, lightness, strength and environmental friendliness, foam concrete blocks are today considered the most popular building material.

Due to its properties, foam concrete is one of the most popular building materials today.

All its characteristics are based on the value of density, namely its lightness, workability. Working with such blocks, you can immediately see how easy it is to build buildings from them, besides, they contribute to good thermal insulation. And this, in turn, helps not to worry about additional protection of the walls.

What determines the density of foam blocks? Two points influence this characteristic: porosity and the amount of light filler.

As the latter, sand and fly ash are usually used. Since they have their own density, depending on the proportions in the solution, this also gives the density to the material itself. Also important is such a component as a foaming agent.

Technical characteristics of cellular concrete

Cellular concrete belongs to the category of light building materials. However, the method of obtaining it is not based on the addition of light aggregates, as, for example, in the production of cinder concrete, but on the introduction of air bubbles.

The resulting light spongy mass is much lighter in weight, and most importantly, has excellent thermal insulation properties.

How to obtain

- Aerated concrete is an artificial stone in which approximately spherical pores with a diameter of 1–3 mm are evenly distributed throughout the volume and do not communicate with each other. The material is obtained by introducing into a freshly prepared mixture of blowing agents - most often, aluminum powder. They interact with a lime or highly alkaline cement mortar with the release of gas, which foams the hardening concrete.

- Foam concrete is even easier to obtain: a foaming agent - soap or hydrolyzed protein - is added to the mixture and stabilized by mixing. Sometimes it is enough to introduce stabilized foam into the finished solution. The pores are closed, evenly distributed.

- The combination of both methods produces foam-gas concretes. Sometimes, this method is more economical.

Compared to each other, the strength of aerated concrete is higher.

However, the strength of any type of material can be increased by autoclaving.

Bulk density

For cellular concrete, such a characteristic as volumetric mass is important, that is, the weight of a unit volume is 1 cubic meter. m. According to this indicator, both foam and aerated concrete are divided into three categories:

- heat-insulating material - concrete with a bulk density of 300–500 kg / cu. m. It is not used for the construction of a load-bearing wall;

- structural and heat-insulating - with a bulk density of 500–900 kg / m3. it can also be used for supporting partitions;

- the structural material has a bulk density in the range of 1000–1200 kg/cu. m. and, in fact, no longer applies to lightweight concrete.

Thermal insulation material is prepared without fillers. Other options may include fillers - usually fine or ground sand.

The weight of the structure is determined by the volumetric mass of concrete. It is not difficult to calculate it. On average 1 sq. m. wall weighs 300–450 kg if made of foam concrete, and 145–240 if made of aerated concrete.

In addition, the nature of the binder affects both weight and strength: silicate aerated concrete, for example, will be heavier with the same degree of porosity. But the water absorption of silicate options is higher. Therefore, their use in comparison with cement cellular concrete is limited.

Dimensions

The sizes of blocks made of cellular concrete (gas and foam concrete) differ markedly. Depending on the purpose, their dimensions may be as follows:

- smooth base block: width - 200–500 mm, height - 200 mm, length - 600 mm;

- blocks for partitions: width - 75–150 mm with the same length and height;

- jumper blocks: width 250-400 mm, with a height of 200 mm and a length of 500 mm.

In addition, various blocks of complex shape are produced.

It is not difficult to make blocks of a different size from standard modules: cellular concrete is just as obedient in processing as wood and is perfectly connected with ordinary nails. About the application and energy-efficient and other basic properties of cellular concrete, the weight of the blocks and their density, read below.