Turbocharged boiler device and specifics of work

Before installing a turbocharged gas boiler, it is advisable to get acquainted with how it works and on what principle it operates.

The device can be used for heating apartments, cottages and country houses. He freely "pulls" to heat a dwelling of any size. Designed for use in a heating system, which provides for forced circulation of the coolant using electric pumps.

According to their functionality, turbocharged boilers are as follows:

- single-circuit (only for space heating);

- double-circuit (for heating the room and providing hot water at the same time).

The gas double-circuit turbocharged boiler has the following performance characteristics:

- small dimensions;

- noiselessness and lack of vibration;

- light weight;

- compact and simple chimney system;

- high level of security.

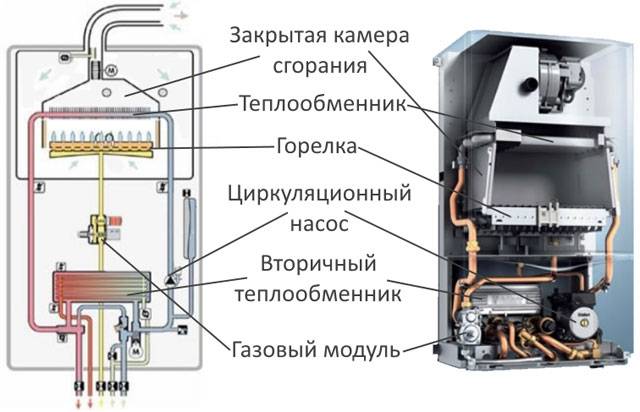

Standard gas turbine boilers are equipped with the following structural elements:

- closed combustion chamber;

- electric pump;

- turbine;

- expansion tank;

- electronic automation;

- valve for gas supply;

- heat exchanger.

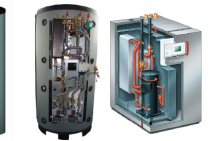

Turbine boilers are distinguished by the form and method of placement:

- wall;

- floor.

Technological methods of installation of 2-circuit boilers

The installation of such expensive equipment as a double-circuit gas boiler must be approached carefully. Further successful work and the number of possible problems will depend on the installation of equipment.

To avoid them during operation, you need to pay attention to the following details:

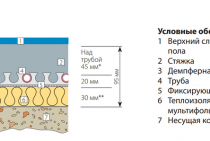

- Is there a slight slope in the chimney. The slope should be about 2 degrees so that the condensate that forms can be freely discharged to the outside.

- Is it possible to provide a separate connection to the heating network and water supply. The connection sequence is very important.

- Are the pipes interchanged? Through which water and natural gas are supplied. Sometimes this can happen during the installation process.

- Is electrical safety ensured? The socket must be grounded. It is possible to use a voltage stabilizer.

In addition to the above, make sure that the automation is configured correctly. The formation of condensate depends on its operation, the excess of which can disable the system.

How to choose a gas turbo boiler

- Selection according to specifications.

- Manufacturer.

- Costs.

Selection by power and functionality

- Performance - accurate calculations are performed after an audit of the heated premises for heat loss. There is a formula for calculating the average performance value, 1 kW = 10 m². Calculations using the above formula are not suitable for boilers with a separate heat exchanger (two-circuit), as well as for rooms where the ceiling height is more than 2.7 m. Boiler equipment with a bithermic heat exchanger is calculated taking into account the required power reserve (+ 15%) and additional capacity required for water heating (+15%).

- The number of heating circuits - if there is an urgent need for hot water, choose a boiler with two heat exchangers. In other cases, a heat generator with one heating circuit is suitable. A modern 2-circuit gas turbo heating and hot water boiler operates in the Winter / Summer mode. After the end of the heating season, the primary circuit is switched off. The boiler continues to operate as a conventional instantaneous water heater.

- Heat exchanger material - the primary circuit is made of cast iron and steel. Secondary heat exchanger, copper or aluminium. Each material has its own parameters of thermal conductivity and duration of operation.The material of the circuits affects the cost of the boiler.

- Automation - the device of a double-circuit turbocharged gas boiler includes conventional or weather-dependent automation. Modern models are equipped with a remote control unit, at the request of the customer, they are additionally equipped with a remote notification module. The more functions the automation has, the more economical the boiler consumes gas.