Interior partitions designs and materials

Partition structures are divided into two groups:

- single layer;

- multilayer.

Single-layer walls separating the interior space of the house are made of various dense homogeneous building materials, which are rigidly bonded to each other with mortar. It can be brick, blocks, tongue-and-groove slabs, expanded clay concrete. The soundproofing parameters of each material depend primarily on the mass, and in order to provide the desired level of this indicator, the wall thickness can be increased. However, this approach increases the load on the ceiling and foundation, reduces, albeit slightly, the area of \u200b\u200bthe room.

If we recall physics, then sound waves, propagating, encounter an obstacle (partition) in their path and are reflected or refracted. Porous structures are able to absorb a wave that is scattered in the bowels of the material. Therefore, preference is often given to multilayer partitions, consisting of at least two or three layers.

In this design, materials of different structure alternate: dense and light. They largely differ in characteristics and are not rigidly connected to each other. The former, for example, represented by brick or plasterboard, have a high reflection coefficient and perform a soundproof function, the latter are soft (mineral wool) and perform sound absorption. Such a union is effective and creates optimal conditions for protecting the premises from noise, since one layer of the structure reflects the sound wave, the other absorbs it.

To compare the characteristics of different materials, an indicator such as the sound insulation index of partitions is used. SNiP regulates the sound insulation of interior partitions in one apartment. This parameter is at least 43 dB.

However, as practice shows, the number of powerful noise sources has recently increased significantly: home theaters, air conditioners, hoods and other household appliances. An increase in background noise does not contribute to comfortable living, and it is desirable to equip interior partitions, bringing the sound insulation index of the structure to at least 50 dB.

Application of new developments

Competition in the construction market forces manufacturers to look for ways to improve product quality. For this, work is being done in the following directions:

- creation of acoustic drywall;

- the use of a special filler with noise-absorbing properties for partitions;

- elastic pads under the frame, reducing the sound from impacts;

- filling partitions and creating false walls;

- spraying cellulose fibers inside the partitions.

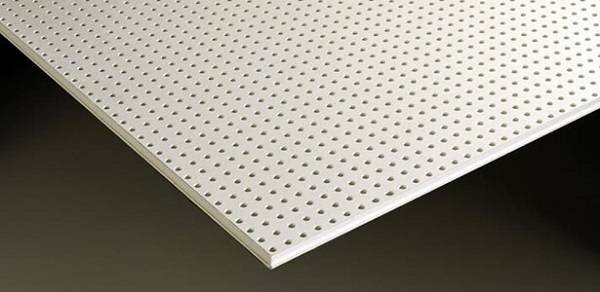

Acoustic drywall

The Knauf and Aku-Line companies have mastered the production of acoustic drywall, which reduces the noise level when finishing interior partitions and when facing walls. Increased sound insulation of the partition is achieved due to the large number of holes that create a reflection of the transmitted sound wave directed at the wall surface. In addition, a sound-absorbing non-woven fabric is glued to the cardboard on the wrong side.

Noise-absorbing filler inside the partitions

Sound insulation of plasterboard partitions also provides for the presence of sound-absorbing filler between them. The same companies are developing it. Expanded polystyrene is widely used - a thermoplastic foam made of fused granules with air cavities. The material also successfully copes with the function of thermal insulation. The addition of a flame retardant can improve the fire resistance of expanded polystyrene. Judging by customer reviews, domestic polystyrene foam is a very poor heat insulator.

Mineral wool slabs have high protective properties against sound propagation. Knauf manufactures a wide range of stone wool acoustic slabs, among which 4 cm thick products are often used for soundproofing walls. For effective dispersion of sound waves, the uniformity of the plates, which Rockwool acoustic mats have, is of great importance.

Materials for partitions with improved soundproofing properties are more expensive than conventional ones, but with their help they achieve complete soundproofing. In addition, thinner filler can be used, which will reduce costs and loss of room volume.

High-quality noise absorbers are membranes made of thin cloth with a fleecy coating. The layer can be from 2.5 to 12 mm thick.

Polyester or polyurethane foam panels are used for internal filling and for creating false walls. Some of them may be flammable due to the content of flammable substances.

The cheapest filler for drywall walls is foam. It reduces noise to some extent, but its efficiency is low.

Spraying sound-absorbing coatings

Spraying cellulose fibers with an adhesive composition is often used due to its low cost and the possibility of mechanizing the process. The method is used to correct acoustics inside entertainment and public spaces.

Finished coatings "Sonaspray" have a texture like plaster under a fur coat. It can be coarse or even, depending on the size of the cellulose flakes. Since the coatings look spectacular, dyes of a wide variety of shades are introduced into the composition of the solution. Coloring of a covering can be made after its drawing.

The possibility of spraying a foamed solution of cellulose on the surface of walls and ceilings made of building materials eliminates the need to create a frame that is used to hold sheet cladding from GKL. The manufacturability and cost-effectiveness of the process allows a team of specialists to provide a productivity of 300 m² per day.

With the right equipment, the soundproofing of a drywall interior partition can be improved by applying cellulose from the inside.

Installation and soundproofing of plasterboard partitions

Protection against the penetration of extraneous sounds into the room during the construction of hollow and frame partitions increases significantly with an increase in the density and mass of the material used for sheathing, in our case it is GKL, as well as the sound-absorbing qualities of the layer and the width of the air space between the sheathing.

- The construction of a false wall begins with marking on the floor or lower floor. With the help of a plumb line or a laser level (level), the lines are transferred to the ceiling and walls.

- According to the dimensions calculated during marking, the frame elements are cut.

- The guides of the frame of the structure are attached to the ceiling and floor, the fasteners are made with dowels, which are located in increments of no more than 100 cm. The frame is attached to the walls in the same way. To prevent the transfer of sounds and noises to the partition, an elastic strip, for example, polyurethane or cork tape, is laid between the surface of the ceilings and walls.

Such popularity is due to the presence of polymer inserts in suspensions, which dampen sound upon contact between metal parts.

- In the guide starting profiles (ceiling, floor), transverse racks are mounted and fastened with self-tapping screws, the step is not more than 60 cm. or 300 mm.

- Above the door openings, as well as at the joints and joints of the plasterboard, additional frame racks are installed. A prerequisite - the joints of the sheets are always placed on the profile. To give the necessary rigidity to the structure, the racks around the door frame are reinforced by installing a wooden block inside the metal profile.

- Over the entire area of the sheet, with self-tapping screws, the sheathing web is fastened to the profile, a step of 25 cm. With a multilayer structure, the fastening step must be increased, but not more than up to 60 cm, in this case, the joints of the plates should be located in a run. The minimum allowed approximation of the location of the screws to the edge (joint) of the web is 10 mm.

- When placing fasteners (self-tapping screws, screws), it is necessary to ensure that they are screwed into the gypsum board only at a right angle, while penetrating into the metal racks by at least 10 cm.

- In order to allow the drywall sheet to expand and/or contract freely with changes in humidity or temperature, it is recommended to leave technological gaps:

- ceiling and edge of the canvas - 5 mm;

- floor and sheathing - 10 mm;

- between 2 blades with a straight edge - 6 mm;

- the folded edge of the canvas - without gaps.

As a result, the gaps, depending on the size and location, are puttied or covered with a reinforcing mesh and again covered with putty.

- After the installation of the casing is completed on the one hand, the necessary communications are carried out in the internal space of the frame and soundproofing is placed between the racks of the crate. If the thickness of the mineral wool or plates is less than the width of the profile, then its edges are inserted into the grooves of the racks, where they are additionally fixed with liners. When soundproofing drywall partitions, sound absorption boards can be glued to the inside of the frame.

- All communications, including wiring, must pass through the GKL sheathing only in special elastic sleeves, for example, made of porous polyethylene or a similar material. This is done in order to exclude the possibility of the formation of through cracks due to displacement of pipes due to temperature changes. All pipes passing through the interior of the false wall must be covered with the selected sound absorber on at least one side.

- The final stage is the installation of the second side of the false wall.

In this case, the surface of the floating floor will be in contact with the wall structure only through the soundproofing elements. Due to this, the floor will not only serve as a kind of barrier from various sounds, but also will not transmit impact noise to adjacent rooms.

Algorithm for arranging sound insulation

Before proceeding with the arrangement of drywall sheathing with soundproofing properties with your own hands, it is worth preparing the surface of the walls.

They need to be carefully examined for the presence of cracks, cracks and other violations in the design. All old finishes are removed without fail, and defects are eliminated

It is important to restore or restore dilapidated and destroyed areas.

The next step is to mark the walls for mounting the frame base. Using a laser or hydro level, mark the lines on the floor and ceiling where the frame guide profiles (UD) will be laid

The distance from the wall is beaten off in such a way that mineral wool slabs can be laid in the resulting space.

According to these marks, a damper tape is mounted, and the guide rails of the future frame are laid on it.

A soundproof membrane is mounted on the wall, fixing it to plastic dowel umbrellas.

Along the lines where the guides will be installed, 3-4 vibration suspensions are attached.

The number of racks is calculated by 3-4 pieces per sheet of drywall. They are arranged in such a way that adjacent panels are joined on the extreme rails.

All metal parts are connected with small self-tapping screws, bugs, vibration hangers are also bent to the racks and fixed using two screws on each side.

At the end of the assembly of the base, the selected sound insulator is laid in it, for example, mineral wool slabs, which, in turn, is covered with a vapor barrier film.

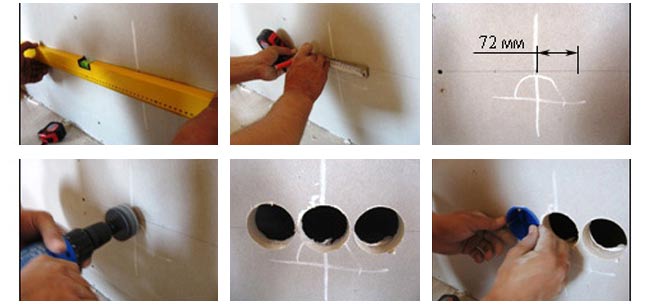

The next step in the frame is electrical wiring with leads for sockets, switches and, if necessary, lighting fixtures. The cable is enclosed in a plastic flexible corrugated pipe, which is attached either through the racks of the frame (if holes are provided), or to the base parts with brackets or ties.

When everything is ready, you can begin the installation of drywall sheathing. It is mounted according to standard technology, providing fixation with black self-tapping screws.

An important condition for creating the soundproofing properties of a plasterboard wall will be the sealing of the joints between the sheets with an elastic tape.

When everything is ready, you can start finishing the drywall surfaces with putty and decorative materials.

The final chord will be the installation of electrical equipment - sockets and switches

They should also be given special attention when there are openings in the load-bearing wall for their installation. At the same time, the sockets are dismantled (previously de-energized), and a washer made of absorbent material (preferably thick cardboard or pressed mineral wool) is inserted into the hole for the socket.

Having made such a lining, the opening is plastered. The same procedure is carried out with junction boxes. All equipment will be re-mounted in a plasterboard wall. The video shows the process of soundproofing a wall under drywall.

Methods for effective soundproofing

It is possible to achieve the maximum result when carrying out soundproofing of plasterboard partitions only if the requirements that are not directly related to the structure itself are met. In particular, indispensable conditions for creating favorable conditions in the room are:

- installation of a window equipped with at least two-chamber double-glazed windows;

- wall decoration with noise-absorbing materials (plaster mixtures, drywall, etc.)

This will reduce the noise level coming from the street or from a neighboring apartment.

As for the plasterboard partition itself, reliable sound insulation for it is created by alternating hard building materials with soft products. This is the only way drywall will not let noise through, and soundproofing materials will become a barrier to neutralize various sounds. Good sound insulation will be obtained when the following conditions are met:

- installation of two separate frames was carried out, which serve as the basis for plasterboard sheets;

- all elements and fasteners are fixed using noise-absorbing gaskets;

- the absolute tightness of the partition is ensured (there must be no cracks, holes and other deformations).

To meet the last criterion for the design, all existing seams are subject to puttying using a shock-absorbing mesh. When laying electrical wiring and other communications, the joints are treated with silicone sealant.

What distinguishes gypsum fiber from drywall

According to the previously viewed qualities of gypsum fiber, it is enough

it is difficult to say something about the difference between it and drywall. When comparing

characteristics of these materials, it can be confidently stated that they are somewhat

are similar. If the house is being renovated, then you can use any of the materials, the main thing is that it

matched the quality and cost.

Due to the high level of stability of GVL material, its

can be used in the construction of sports halls and industrial

premises. As for less demanding buildings, for them the optimal

drywall is the solution.In the manufacture of complex building structures

it is better to choose gypsum fiber with increased mechanical strength

loads.

Both can be used to level walls and ceilings.

material, however, in most cases, preference is given to drywall, so

how the loads in such structures are small and there is no need to apply more

thick panels.

Theoretical basis

Before installing insulating layers, it is necessary to understand the nature of the functions they are supposed to perform, as well as some basic terminology.

Soundproofing is a set of measures and technical solutions aimed at reducing the level of noise coming from outside.

The noise itself is conditionally classified into three groups:

- Percussion - arise due to mechanical impact on the surface and initially propagate in a solid medium (shocks, knocks, squeaks, etc.)

- Structural - formally, they are a kind of percussion, but due to their specifics, they stand out in a separate group. They arise due to the relative mixing of structural elements relative to each other, which is typical, for example, of frame houses. Structural noises include, in particular, the creaking of parquet.

- Acoustic - the most common group, which includes all sounds coming from external sources and falling into the structure of walls and partitions from the air. Examples of acoustic noise are human voices and music.

In practice, both of these phenomena are inextricably linked with thermal insulation as a way to prevent heat loss as a result of heat exchange with the external environment.

Therefore, the modern building materials market includes many combined products that provide comprehensive sound and heat insulation of surfaces, although there are also “highly specialized” substances. You can learn more about them and other insulating materials from the next section.

Do-it-yourself soundproofing drywall wall step-by-step sequence of actions

Having collected all the necessary components, you can start marking for the future drywall wall. It is drawn with an ordinary pencil on the surface of the walls and ceiling. In this case, all lines are additionally checked against the level and the principal plan. The marked room allows you to see exactly where the new wall will be installed, and what place it will take in the apartment.

The process of forming a frame structure with further sound insulation and finishing is carried out according to the following scheme:

- First, lay the soundproof sealing tape in two layers around the entire perimeter on the floor and ceiling.

- A UD-type guide profile is screwed to the floor and ceiling, which will set the direction for all subsequent racks. They are fixed with self-tapping screws, which are screwed in every 40-50 cm.

- Racks prepared in advance and cut to size, formed from a CD-type profile, are inserted into the rails fixed at the top and bottom, and mounted on hangers. The number of racks directly depends on the required structural strength, since the more there are, the more reliable the wall will be.

- The optimal distance between the profiles is 55-60 cm. The profile is inserted into the rails and fixed with self-tapping screws. To increase the load-bearing qualities of the system, the vertical racks are connected by jumpers made of CD-profile with a step of 60 cm.

- Mineral wool is laid in the interframe space, which acts as sound insulation.Moreover, it is necessary to lay it as tightly as possible, completely filling all the voids and carefully joining the seams. It is laid from the floor itself to the ceiling until the entire area of \u200b\u200bthe wall is completely covered with insulation.

- A soundproof membrane is stretched over the mineral wool. If possible, it should contain as few seams and joints as possible so that the canvas is as solid as possible. The joints are formed with an overlap of 15-20 cm and glued with reinforcing tape. The membrane itself covers both sides of the partition, creating a kind of cover for the insulation.

- Drywall is applied to the frame and fixed with metal screws. Their caps are slightly recessed into the surface of the GKL, and the edges are joined as tightly as possible. The finished wall will have a slightly unusual appearance, since the surface of the acoustic drywall is perforated.

- The finishing of an insulated wall consists in filling the joints of drywall, into which putty and reinforcing tape (serpyanka) are placed. No further action is taken with acoustic gypsum plasterboard, since the perforation must remain open. Otherwise, it will lose its properties and will not be able to dampen sound vibrations.

In finished form, a do-it-yourself insulated drywall wall will have an extraordinary appearance and be highly durable. At the same time, no noises and conversations can penetrate through it, which will inevitably affect the atmosphere of the room and its comfort.

Watch this video: the process of soundproofing drywall walls.

The procedure for performing soundproofing work

Photo: mineral wool slabs

First of all, you must understand that you can even cope with the construction of this partition yourself, i.e. even the owner of a country house, whether it is wooden or brick, will be able to do all the work with his own hands.

You need to start with marking and fastening the profiles around the perimeter, constructing a frame from them, on which drywall will subsequently be attached. To do this, you need to cut off the desired sections of the profile with metal scissors and simply drill them to the walls, ceiling and floor.

When the frame is ready, on one side you need to attach drywall sheets, but so that they fit snugly (without the slightest gap to each other). All joints are puttied and laid on the inside with a layer of mineral wool, then sheets are attached on the reverse side. Thus, you will get a dense partition, closely stuffed with mineral wool from the inside.

Such soundproofing of interior partitions will serve you for many years and will allow you to really protect yourself from noise coming from the neighboring part of the room. However, there are cases when these measures are not enough, then it is possible to strengthen this partition with special materials. In building the frame, you can also use wooden beams, but this will only be a waste of money, and such a frame will take much more time.

Soundproofing materials

In addition to standard gypsum boards, it is possible to use special soundproof sheets for the construction of partitions.

Manufacturers present several types of fillers:

- Acoustic mats are stone wool panels.

- Mineral fiber glass wool. Available in slabs and rolls.

- Polyurethane panels and foam fillers.

- Expanded polystyrene from the made foam plastic received by method of melting of granules.

- Polyurea is a popular type of foam filler with corrosion and thermal insulation properties.

The incombustibility and environmental friendliness of mineral fillers, combining heat and sound insulation properties, should be highlighted:

- basalt wool;

- mineral wool;

- glass wool.

Sprayed, foam components are used, however, when exposed to temperatures, it is possible to release toxic specific gases harmful to human health.

What not to do

In the absence of experience, mistakes can be made that can significantly spoil the sound insulation of walls made of plasterboard. The first mistake is inappropriate materials, such as polyurethane foam. It is not intended for soundproofing equipment and also does not meet fire safety standards. Styrofoam is also not very suitable for the device of a noise-absorbing layer. This material is an excellent heat insulator and is intended primarily for insulating the walls of the facade of a building.

It's from the side of the street. Using expanded polystyrene inside an apartment or house, you can provoke a transfer of the dew point inside under the plasterboard sheathing, as a result, mold may form, since water vapor will condense in this place.

It's from the side of the street. Using expanded polystyrene inside an apartment or house, you can provoke a transfer of the dew point inside under the plasterboard sheathing, as a result, mold may form, since water vapor will condense in this place.

Roll materials, membranes or mineral wool are mounted only with an overlap, they should not form gaps at the joints between individual panels.

Sound insulation of partitions from plasterboard

Gypsum plasterboard (gypsum plasterboard) structures are gradually replacing other non-load-bearing partitions. When solving the problems of dividing rooms into zones, sound insulation of interior partitions should always be provided. With a complex solution of problems, the costs for this will be minimal.

GKL partitions themselves have soundproofing, but it can be significantly increased by simple measures:

- the use of special soundproof materials;

- wall cladding using special technology;

- the use of soundproof fasteners for the frame;

- use of a special profile;

- increasing the distance between the racks;

- the use of a frame with a greater thickness;

- increasing the thickness of the cladding;

- the use of special materials as a frame filler.

The plasterboard partition is made in the form of a sandwich: the outer shell is made of plasterboard, and the filler is placed inside.

Sheathing of partitions can be done with special acoustic drywall. Additional sound absorption inside is created by a layer of non-woven material glued to the sheets. If the price for them does not suit you, you can get out of the situation at the expense of the filler. The porous slabs in the partition wall are the main means of absorbing noise.

Noise isolation of an interroom plasterboard partition is impossible, if you do not take into account the metal frame, which is an excellent conductor of sound. A sealing tape is placed under the starting horizontal profiles, and all metal connections are made with polymer gaskets. Polymer knots can be used for fasteners.

One side of the frame is sheathed with plasterboard, after which communications are laid, sockets and switches are mounted and connected. Then, a sound absorber is tightly stuffed into the inner part of the partition. There should be no free space between the mats. The layer is closed with a membrane or porous tape. GKL are finally attached on the other side. After everything is closed, small holes and cracks are sealed with sealant.

Sheathing with acoustic plasterboard

To soundproof a partition, it is sufficient to use two materials: a thermal insulator and acoustic plasterboard.However, if these are not enough, there is another additional option. It consists in the installation of a special sound-absorbing film, which is fixed on both sides of the frame. Plasterboard sheathing is the final stage in the construction of the partition.

The sheets themselves are screwed to the profiles with self-tapping screws, the caps of which are slightly recessed. To achieve greater density and uniformity of the coating, the joints can be lightly puttied.

The result of the installation work will be an excellent plasterboard wall, which will differ not only in its aesthetic appearance, but also in its excellent soundproofing characteristics.

What are the advantages of the material and are there any disadvantages

Gypsum fiber sheets, like other material, have their own

Advantages and disadvantages. The main disadvantage of GVL boards is its cost.

This material is currently somewhat more expensive than such materials as:

drywall, plywood, chipboard and MDF boards. Also among the minuses of his canvas

significant weight

When making a frame, it is important to correctly calculate

an indicator of strength, since the mass of the plates is considerable. As for the cons,

this, perhaps, is all

Gypsum fiber has many advantages, which is why this

material is often used in modern construction. Thanks to

hypoallergenic qualities of the finish, it can be used for residential premises and in

particular children's rooms. The microporous structure of GVL sheets allows walls

breathe, which contributes to the protection of the surface to resist fungal

formations and mold.

Due to the hygroscopicity of the composition, the canvas can itself

regulate the humidity of the apartment. If the apartment has high humidity, then

the surface of the GVL absorbs it into itself. In case of increased dryness

gypsum fiber gives off moisture to create optimal climatic conditions. Also

It is worth mentioning the possibility of using GVL panels in rooms with

temperature fluctuations. Gypsum fiber sheet is an ideal finishing material

premises without heating.

Partition walls installation rules

The main point when creating a frame is determining the thickness of the finished wall.

Step-by-step diagram of the installation of partitions.

1. Markup

Mark all dimensions on the drawing. With the help of the building level, the necessary horizontal lines are beaten off. A plumb line is used to measure the vertical plane. Marks and serifs are made with a mechanical pencil, marker, special upholstery thread or chalk. In accordance with the measurements, cutting and fitting of plates will take place.

2. Preparation of elements

Cut a galvanized metal profile of the required length for the vertical racks of the frame. A sealing tape of the same length is cut under each part, which will dampen part of the structural vibration. To beat off the perimeter of the frame, some guide parts will need to be sewn.

3. Frame fastening

Along the marked lines, we mount the guides with sealing tape on the floor and ceiling. After fixing them with plastic fasteners, vertical racks with a given step are installed. Metal consumables (dowels, screws and self-tapping screws) are mounted on a polymer gasket.

4. Filling the frame cells

To install a rolled mineral filler, it is necessary to sheathe the GKL on one plane of the partition. After laying communications and starting filling the cells with mineral wool.

The installed layer is closed with a special membrane, and, if necessary, with waterproofing. It is possible to fix film coatings using a construction stapler.

5. Closing the frame

After the work has been completed, the installation of the second drywall plane begins. The joints of the GKL sheets form figured seams, which are puttied with a special adhesive solution. The internal and external contact angles of the surfaces are reinforced with a reinforcing corner.The cracks that occur at the points of contact of the frame with the floor and ceiling slabs are sealed with sealant.

Subject to the correct selection of high-quality materials and the observance of the technology of finishing work, extraneous sounds will no longer cause you concern.

For advice on soundproofing a drywall wall, see the following article.