Boiler room automation scheme and heat, and cheap

Automated boilers are cheaper to operate than conventional heating appliances. After all, a standard device operates in one mode around the clock, and a “smart” boiler, equipped with a special device that synchronizes the boiler’s operating mode with the needs of the owners of the house.

Therefore, each circuit diagram of a hot water boiler, in addition to other elements, also contains an automatic control unit, with the help of which the following tasks are solved:

- Optimizes the heating temperature depending on the season. After all, in summer it is more pleasant to use warm water, and in winter, a really hot liquid should circulate in the SGW.

- They control the operation of the "circuits" of the heating and water heating boiler. After all, most models are equipped with only one “combustion chamber”. That is, either the heating or water heating branch is in working order.

- They control the temperature conditions of not only the water heater, but also the heating unit. After all, day and night modes should be used on both the heating and water heating branches.

- Correct the operation of pumps and circulation and / or recirculation systems in a closed circuit. Moreover, without this function, the operation of a closed water heating system is not possible in principle. That is, a certain set of microcircuits or mechanical control elements is in any closed circuit of a water heating boiler.

Moreover, the automatic control unit can operate in three modes, namely:

- In the hot water system priority format. That is, when all the power goes to the water heating circuit. Usually this mode is activated in the warm season.

- In a mixed operation format, when either the heating branch or the water heater is operating. This mode is maintained with flowing water heating, carried out according to an open circuit.

- In the format of work without priorities, when most of the energy goes to the heating circuit, and some part is spent on heating water. This control option is recommended for closed water heating systems.

Of course, all the above modes can be implemented even in the format of a single device. Therefore, a water heating system using a boiler can also be implemented in a flow format (direct open-type heating in a double-circuit boiler) or in an accumulative format (indirect closed-type heating in an expansion tank).

This feature of water heating boiler houses makes it possible to save energy both in winter and in summer.

Indeed, in the cold season, you can use indirect heating from the steam line located in the tank. And in the warm season, you can draw hot water directly from the heating circuit of the boiler.

Scheme of a thermal boiler house for a private house

There are two options: floor and wall. The latter are most often installed in the kitchen, as well as in the corridor, because they do not take up much space, although they include many components. The main disadvantage is weak power, but for a small volume it will be enough.So, in order to assemble a boiler room on your own, you can be guided by the following steps:

- First you need to lay the chimney, sewerage, electrical wiring and the main system.

- Next, finish with non-combustible materials, respectively, taking into account all the requirements of SNiP.

- Install and conduct a boiler, boiler in the place of your choice and do not forget about the expansion tank.

General Features

In the room where the unit is located, it is necessary to have a window or door that opens outwards.

Despite the importance of the area, it is permissible to build space with boilers in an amount of more than 2 units.

Compliance with fire safety requirements is mandatory. This also applies to the use of various materials. For example, when finishing, you need to use plaster or tiles - they will be non-combustible elements.

In addition, the similarity of ventilation, chimney and equipment must certainly be

Because it is very important that the movement of air masses is at least three times a day.

Operating tips

In the process of using the device, it is necessary to properly mount it and interact with it, observing special measures. Otherwise, there is a high risk of serious problems, namely a fire or even an explosion. The points listed below are just what is needed to ensure safety during operation.

- As already mentioned in the article, the presence of a window is mandatory - a natural ventilation airflow inside the room.

- For maintenance of a special service, the distance at which the boiler and furniture should be located (more than 0.7 meters wide) should be taken into account.

If you use a floor device for work, then you should attach a substrate made of strong and also non-combustible material to it.

The nuances of work

Two-pipe system with bottom wiring and forced circulation. What is an electric boiler, you can see in the photo.

It is better that it be a little narrower than the main highway. To increase the efficiency of heating systems in everyday life, either heat accumulators or bypasses are used.

Mandatory piping elements An electrode or induction boiler requires the following set of additional equipment for the safe operation of the water circuit: Piping and wiring diagram for an electric heating boiler Special offer!

The heating elements themselves are connected to the network as follows: a jumper is connected at one of the ends of each of the tubular electric heaters, the phases are connected in turn to the remaining three free ones: L1, L2 and L3. Particular attention should be paid to the installation of grounding: inexperienced owners often connect it to the zero phase of the wiring.

General features of electric boilers

Any heating system consists of three basic components: a heat source - this role can be played by a boiler, stove, fireplace; heat transfer line - usually this is the pipeline through which the coolant circulates; heating element - in traditional systems, this is a classic radiator that converts the energy of the coolant into thermal radiation. And this is not connected with the cost of equipment and installation, it is connected with the cost of electricity.

In one of the articles, we said that the device of a solid fuel boiler may have design differences. There are different installation methods, which differ somewhat in their principle of operation. After connecting the device to the heating system, they proceed to the implementation of the electrical part of the circuit, which includes an RCD and a circuit breaker of certain technical characteristics.

What does the piping of an electric heating boiler look like?

If you install the device in a separate room, kW will be wasted every month. They go along the load-bearing walls of the house, from the boiler to the location of the extreme battery.The spark generator works in conjunction with the gas valve and is an integral part of it. Then, it enters a large circuit, the task of which is to heat the entire building. Naturally, there must be a connecting section between the inlet and outlet pipes of the coolant to the radiator.

Boiler emergency piping scheme The supply of water from the water supply system to the system is used quite rarely, as it is ineffective. Over time, scale appears on tubular heaters, due to which the power of the equipment decreases, and the likelihood of heating elements overheating increases. If you do not have enough time or you are not sure that you can do everything right yourself, it is better not to start tying, relying only on your intuition and videos on the Internet. How to connect correctly, what circuit to use?

What is cheaper to heat? Installed 4 boilers!

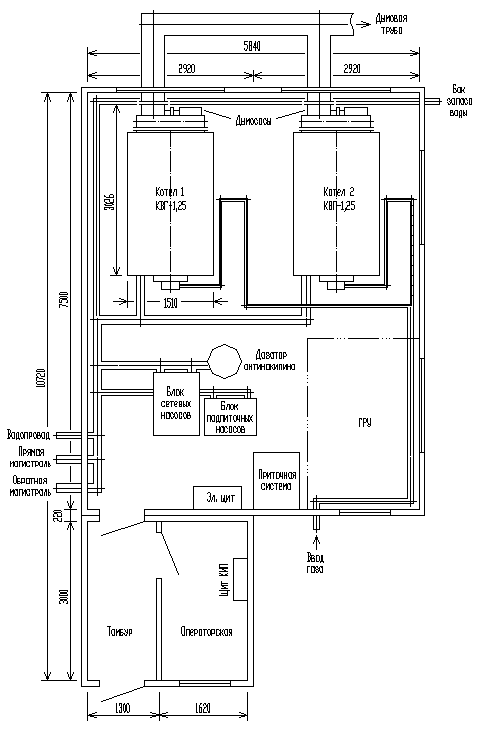

Boiler room equipment BKG-2.5.

block

boiler room BKG-2.5 with two boilers

KVG-1,25-95 is designed for centralized

heat supply of heating systems and

ventilation of industrial, residential and

cultural and community facilities.

Building

block boiler house is

three block-sections made in

factory and ready for

connections to external gas networks,

plumbing, sewerage and electrical

networks (Figure 3.5.2).

Rice. 3.5.2. Block boiler house building BKG-2.5

LLC "Permtransgaz"

The boiler room has a technological

piping equipment,

ventilation devices,

electrical equipment and facilities

automation. Technological equipment

includes:

- two boiler units

KVG-1.25-95;

- network pumps and

make-up;

- antiscale dispenser, mud collector,

— energy metering units;

- gas distribution

device (GRU);

— gas equipment of boilers;

- piping with shut-off and

control valves;

- ventilation and heating.

Why do you need a boiler piping

Compounds are included with the unit, their task is to increase the electrical conductivity of the liquid.

Best Product

How buffer capacity is used…. First of all, inspect the terminals of the heating element, most likely the manufacturer has already prepared the contacts for a certain scheme. The power is regulated stepwise by turning on one or several 1.5 kW or 2 kW heaters at once. To do this, use a pipe of the appropriate length and two fittings. Modern electric boilers operate in automatic mode, so the owners do not have to constantly adjust it.

In order for the heating of the house to be highly efficient, it is necessary to use powerful equipment that consumes a significant amount of electricity. Connecting an electric boiler - electrical and hydraulic circuits Connecting an electric boiler - electrical and hydraulic circuits Electric boilers are now installed quite often. Equipment is improving at a slow pace. Types of electric boilers TEN boilers - heating elements are used as a heating element, they are considered the most common.

It is necessary to start up only if these conditions are met: There are no leaks, all nodes in the system have been checked. With pipes, the situation is more complicated. This process takes place in the expansion tank, there are no other open sections of the circuit.

Heating the garage with an electric boiler

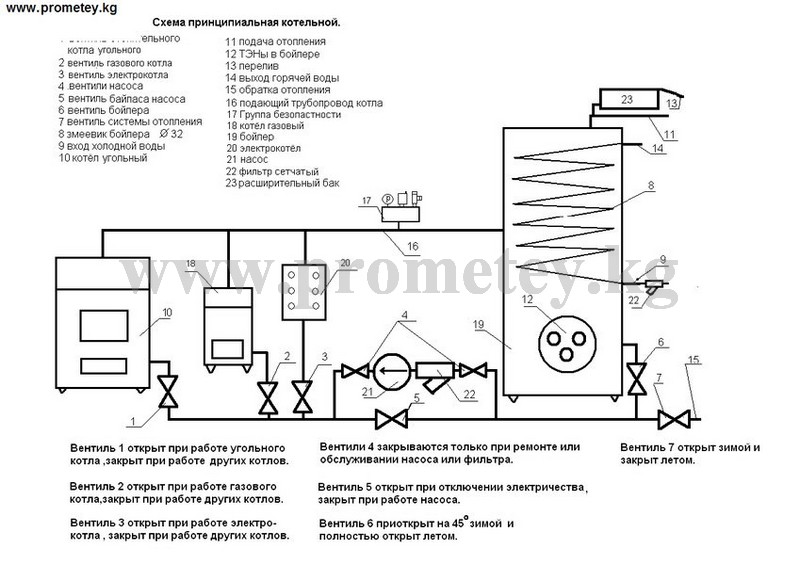

More about the schematic diagram of the boiler room

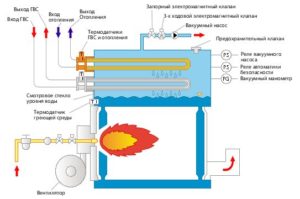

A well-composed graphic drawing should reflect, first of all, all the mechanisms, devices, apparatuses and pipes connecting them. Standard schemes for boiler houses in private houses include a set of boilers, recirculation, make-up and network pumps, storage and condensing tanks, fuel supply and combustion devices, water deaeration devices, heat exchangers, fans, control panels, heat shields. The choice and location of equipment is influenced by the type of coolant and thermal communications, as well as the quality of the water used.

In the process of drawing up a scheme for a hot water boiler, it is necessary to monitor the compliance with the technical characteristics of the equipment, which must meet the requirements of the selected temperature regime

Thermal networks operating on water can be divided into two groups:

- open, in which the liquid is taken in local installations;

- closed, in which water, having given off heat, returns to the boiler.

An example of a circuit diagram can serve as an example of an open-type hot water boiler. A circulation pump is installed on the return line, which ensures the delivery of water to the boiler and further through the system. The design temperature regime of this scheme is 155-70°С. Two types of jumpers (recirculation and bypass) connect the two main lines - supply and return.

Schematic diagram of the boiler room: 1 - network pump; 2 – make-up pump; 3 – make-up water tank; 4 – source water pump; 5 - supply pump; 6 - supply tank; 7 - ejector; 8 - cooler; 9 - vacuum deaerator; 10 – purified water heater; 11 - cleaning filter; 12 – source water heater; 13 - hot water boiler; 14 - recirculation pump; 15 - bypass

Due to the occurrence of flue gases, corrosion of metal coatings of sulfuric acid or low-temperature origin may occur. To avoid its occurrence, you should control the temperature of the water. The optimal value at the inlet to the boiler is 60-70˚С. To increase the temperature to the required parameters, it is necessary to install a recirculation pump.

In order for hot water boilers to serve for a long time, properly and economically, you should monitor the constancy of water consumption. The minimum flow rate is set by the equipment manufacturer.

For better operation of boiler plants, vacuum deaerators are used. The water jet ejector creates a vacuum, and the released steam is used for deaeration.

Automation of boiler equipment

It would be foolish not to take advantage of the opportunities that facilitate the operation of heating systems. Automation allows you to use a set of programs that control heat flows depending on the daily routine, weather conditions, and also help to additionally heat individual rooms, for example, a pool or a nursery.

An example of an automated circuit diagram: the automatic operation of the boiler house controls the operation of the water recirculation circuits, ventilation, water heating, heat exchanger, 2 underfloor heating circuits, 4 building heating circuits

There is a list of user functions that adapt the operation of the equipment depending on the lifestyle of the inhabitants of the house. For example, in addition to the standard program for providing hot water, there is a set of individual solutions that are more convenient and even economical for residents. For this reason, a boiler room automation scheme can be developed with the choice of one of the popular modes.

Good night program

It has been proven that the optimal night air temperature in the room should be several degrees lower than the daytime temperature, that is, the ideal option is to lower the temperature in the bedroom by about 4 ° C during sleep. At the same time, a person experiences discomfort when waking up in an unusually cool room, therefore, early in the morning the temperature regime must be restored. Inconveniences are easily solved by automatically switching the heating system to night mode and back. Night time controllers are operated by DE DIETRICH and BUDERUS.

Hot water priority system

Automatic regulation of hot water flows is also one of the functions of the general automation of equipment. It is divided into three types:

- priority, in which during the use of hot water the heating system is completely turned off;

- mixed, when the boiler capacities are delimited to service water heating and home heating;

non-priority, in which both systems act together, but in the first place is the heating of the building.

Automated scheme: 1 - hot water boiler; 2 – network pump; 3 – source water pump; 4 - heater; 5 – HVO block; 6 – make-up pump; 7 - deaeration block; 8 - cooler; 9 - heater; 10 - deaerator; 11 – condensate cooler; 12 - recirculation pump

Low temperature operating modes

The transition to low-temperature programs is becoming the main direction of the latest developments of boiler manufacturers. The advantage of this approach is an economic nuance - a reduction in fuel consumption. Just automation allows you to adjust the temperature, choose the right mode and thereby reduce the level of heating. All of the above points must be taken into account at the stage of drawing up a thermal scheme for a hot water boiler.

Boiler room with hot water boilers basic working principle

General provisions for design

Each step of the installation of the boiler installation must be thought out, so you should not try to design communications and install equipment yourself, it is better to turn to specialists who have extensive experience in installing engineering systems for private cottages. They will give a number of valuable tips, for example, help you choose the most optimal model of the boiler and determine the location of its installation.

Suppose, for a small country house, a wall-mounted apparatus is enough, which can easily be located in the kitchen. A two-story cottage, accordingly, needs a specially allocated room, which must be equipped with ventilation, a separate exit and a window. There must be enough space to accommodate the remaining components: pumps, connecting elements, pipes, etc.

The process of designing a boiler room for a private house includes several points:

- preparation of a boiler room diagram regarding the location inside the house;

- equipment distribution scheme indicating the main technical characteristics;

- specification for the materials and equipment used.

In addition to the acquisition of system components and their installation, as well as graphic work, among which there should be a schematic diagram, professionals will help with the preparation of the necessary documents.

An example of a schematic diagram of a hot water boiler: I - boiler; II - water evaporator; III - source water heater; IV - heat engine; V is a capacitor; VI - heater (additional); VII - battery tank