Installing a water pump in a private house

The process of connecting a station to resources depends on the type:

- good or well;

- centralized water supply.

- disconnection of the water supply;

- the free end of the city pipe with a pipe or a piece of pipe is connected to the battery;

- all nodes of the station are connected and located;

- checking system performance.

First start-up connection The first start-up of the pumping station is carried out to test the composite system.

For this you need:

1. Fill water through the dedicated plug or pump opening and all connected piping. Charging the pump must be carried out at the very top so that all the air is released.

second

Connect the pressure side of the system to the entire piping distribution in the house. Close the filling port of the pump if it is full. Check the air pressure in the tank. If it is below the value specified in the instructions, start the air using a conventional pump for the pump. In case of excess pressure in the threshold, bleach the air to the nominal value.

3. Connect the power supply through the socket. Water will begin to fill the highway and the battery.

The pump automatically switches off when it reaches a pressure of approximately 3 atm.

4. After the pump stops, open any cord in the house. The pressure must be reduced as indicated by the pressure gauge. If the meter readings differ from these parameters in the instructions, adjust them as recommended.

The cost of connecting the water supply system by third-party experts

- Placement in the basement or pallets;

- Laying pipes in a ditch from a well or from the end of the connection to the central water supply of the house;

- Battery storage;

- Installation and configuration of the automation system and electrical equipment;

- System health check.

Labor costs depend on the need to find a trench and the complexity of installing equipment.

For example, installation with attachment of equipment starts from 2500 to 3000 rubles.

The final assessment can be assessed comprehensively if the scope of the proposed services includes container installation, automation testing, pumping station piping. In this case, the total labor costs for the Moscow region are 7,000 rubles:

- suction in the central water supply network - 2,000;

- mandatory - 3,000;

- tank installation - 1,500.

Automatic systems and elements that ensure control and reliable operation of the pumping station system

It is necessary to say in more detail about modern systems as part of pumping stations that will ensure uninterrupted water supply to your home, as well as guarantee long-term operation of the pump.

So, when implementing a pumping station of any type, it is necessary to implement the following automation systems: - Protection against dry running of the pump (“Protection against “dry running” for a well pump using a pressure switch and level sensors.

Electrical circuit for protecting the pump from "dry running");

- The use of a pressure switch or electrocontact pressure gauge (signaling) to maintain pressure in the water supply system (“Water pressure switch (installation, characteristics, design, configuration)” and the article “Electrocontact pressure gauge (signaling) (principle of operation, application, design, marking and types) for water supply systems”.

In addition, if you are assembling a pumping station, which is said from A to Z, then information on choosing a receiver “Hydraulic receiver (hydraulic accumulator) for a house water pumping station (selection, design)”, as well as information on pipe installation “ Installation of metal-plastic (metal-polymer) pipes with threaded fittings”, “Do-it-yourself soldering of plastic (polypropylene) pipes”.

Now, having already a certain amount of information, and, accordingly, knowledge, we hope that the selection of components, as well as the assembly and connection of your pumping station will take place more deliberately, faster, and also with minimal deviations and errors.

The problem of water supply is at the forefront of creating a comfortable living environment in the country. This most often helps to solve the problem of connecting the pumping station to the water. Communications to provide a home is not just a banal plumbing facility with liquid Gander, after all, a complete home water supply system.

The need for an independent water supply, the basic needs of rural dwellers, leads to the constant use of water for cooking, sanitary and domestic use, as well as refrigerants in the heating system.

Household pumps are not always faced with such a variety of work functions.

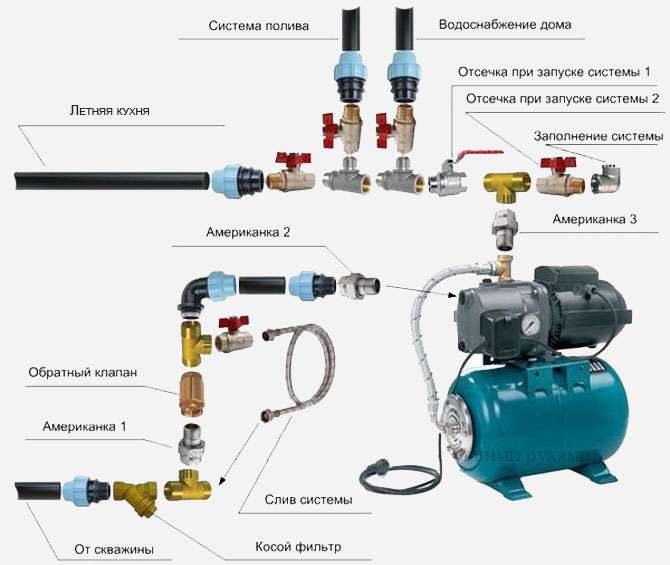

In addition, installing a pumping station in a private home allows evacuation and supply of water to increase system pressure if the existing pump is not strong enough to deliver liquids to the right place on the surface, in the garden, in the garden or at home. It offers various models on the market, but only a few components for a sufficient distribution of the base model, which is reflected in each pump installation system:

- storage tank;

- pump;

- control relay;

- non-return valve that does not allow leakage;

- filter.

A filter is needed, otherwise the grain of the grains will lead to rapid abrasive wear of machine parts.

Equipment location

The installation and operation of the pumping station ensures long-term reliable operation of the equipment, subject to the following conditions:

- when installing the station in a bunker, it is placed below the level of soil freezing in winter, which is at least two meters;

- The place where the station is installed (basement or casson) must be heated in winter;

- When assembling the connection plan by hand, it is necessary to prepare a stand, which is then installed on the station in order to prevent groundwater floods.

It is important!

Do not touch the equipment with walls so that the mechanical vibration of the operating mechanism does not affect the room.

Assembly and connection of a pumping station with a suction pump

We will begin the description of the assembly and composition of the first version of our pumping station with a station with a suction pump. This solution has its pluses, which, upon closer examination, automatically become minuses.

Let's try to "dig" to those and others, having examined in more detail all the features of a station with a suction pump. The first significant plus of such pumping stations is their wide distribution and the ability to meet "ready-made solutions".

By "ready-made solutions" we mean pre-assembled kits consisting of a receiver, a pump, a piping between them, a pressure control switch, a pressure gauge. Such kits are good in that you will not need to collect an already certain part of the plumbing and elements to provide water supply. The second advantage of such a station is that the pump and all the main elements of the system are above the ground, which greatly facilitates their maintenance and replacement.

The disadvantages of a pumping station with a suction pump will be that the characteristics that are already included in the pre-assembled pumping stations may turn out to be unacceptable for you. So, for example, the receiver will be small or the pump will not provide the proper suction lift. In addition, the suction pump will require high tightness from the suction pipe, and a check valve will also be needed to keep the water column from the well to the pump.

Otherwise, you will need to constantly add water to the nozzle to prevent air build-up and keep the pump running.

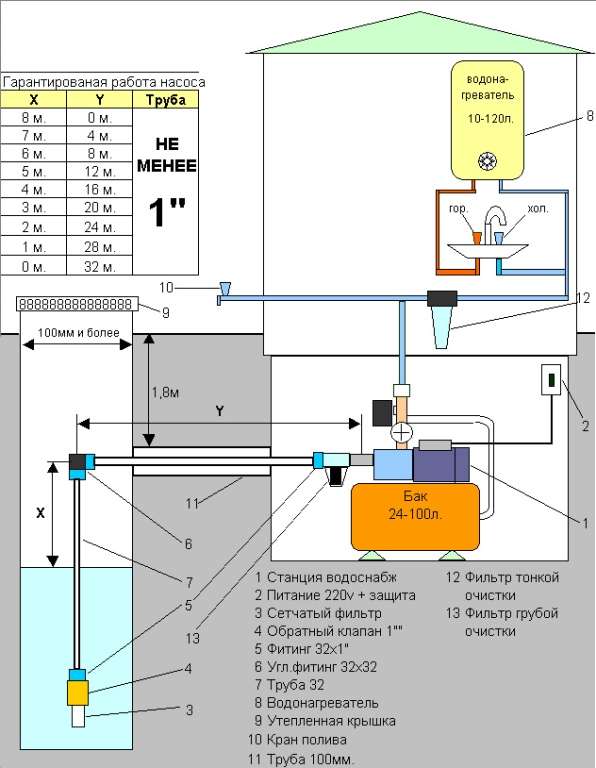

The assembly (diagram) of a pumping station with a suction pump is carried out according to the following principle

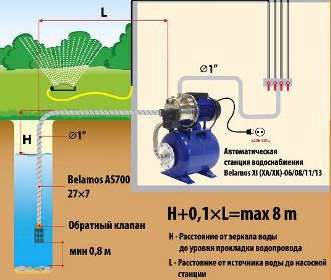

Please note that when calculating the length of the suction pipe, one vertical meter equals one horizontal meter (1:4). That is, when calculating the suction height, when choosing a pump (pumping station), it is necessary to take into account the length of the suction pipe, both vertically and horizontally. The characteristic of the ascent depth is given conditionally (8 meters), for your station this indicator may be different

See the specifications in the passport for the pumping station or pump. I would also like to additionally note the presence of a tap to fill the suction pipe with water

The characteristic of the ascent depth is given conditionally (8 meters), for your station this indicator may be different. See the specifications in the passport for the pumping station or pump. Also, in addition, I would like to note the presence of a tap to fill the suction pipe with water.

This system is not shown in the picture above, but is shown in the photo below. (yellow funnel - pipe - tap on a tee)

Naturally, all connections must guarantee maximum tightness, and all shut-off and control valves of the water supply system must be in good order.

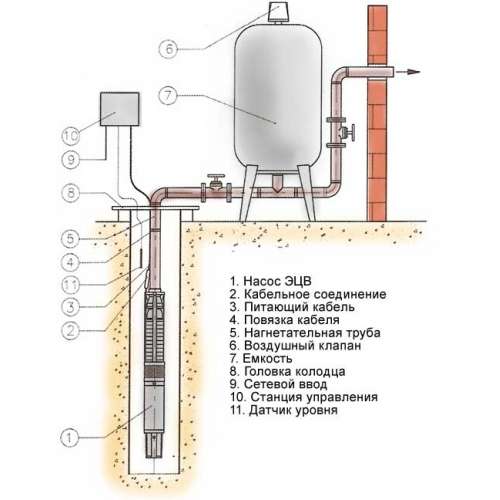

Assembly and connection of a pumping station with a submersible pump

The submersible pump in the pumping station system at home is mainly applicable in cases where the height of the water rise is much greater than the suction pump can provide.

Also, another advantage of a submersible pump, as part of a pumping station, is the lower requirements for the tightness of the pipe from the well to the receiver. When using a submersible pump, the system is not afraid of airing, since water is supplied by the pump directly from the well, which means that it is able to displace all air plugs on its way.

The assembly (diagram) of a pumping station with a submersible pump is carried out according to the following principle

When water is supplied to the house, then the same pipeline decoupling scheme is used as in the previous case.

(not shown in the figure).

The disadvantages of a pumping station with a submersible pump are that the pump will be replaced already from the well, that is, most likely on the street, and not indoors (usually a basement).

The installation requirements for all components and assemblies of the pumping station are the same as for the case with the suction pump. This means that all fittings and components must be in good working order, and the connections must be tight, but we repeat that if the performance of the supply pipeline from the well to the receiver decreases (the inability to hold the water column), such a station will still ensure its full performance without prior preparation.

In the case of a suction pump, you will first need to fill the suction pipe if a static column of water leaves it.

Installation and connection of a pumping station in a private house

Then the station must be connected to the electrical network for a soft start and the pressure and automation must be checked. At first, water goes with air - air plugs come out, which formed during the filling of the pumping station.

When the water flows in an even stream without air, your system has entered the operating mode, you can operate it. The station should not be started very often, otherwise the engine will overheat. The rate of launches in one hour is up to 20 times (the exact figure should be indicated in the technical data sheet of the system). Then, during operation, it is necessary to control the air pressure in the accumulator (1.5 atmospheres).

Comments

Water in our house is one of the main criteria by which it can be called comfortable.

If you remember that without water a person can live the least, only less without air, then the importance of water supply to your home becomes paramount.

Unfortunately, the water from our wells is no longer always applicable for use as drinking water, but the need for washing dishes, floors, washing clothes, washing yourself, as well as using water for other technical needs, you still will not disappear anywhere. Moreover, water consumption can turn out to be so large that it will be very difficult to supply it to your house in the old proven grandfather way, using a rocker and buckets, and besides, it will take you a lot of time.

Fortunately, progress does not stand still.