Fitting connection methods

Depending on the types of fittings, the following methods and methods of fastening can be distinguished:

- Threaded connection. This type is most often found when connecting pipes and other metal structures. A particular advantage in this case is that the cutting process itself is completely uncomplicated. So, each developer will be able to make a threaded connection on their own, without anyone's help. As for the disadvantages, in the case of a threaded connection, this is poor tightness. It should also be noted that when the thread is exposed to sufficiently high temperatures, corrosion can develop, and this, in turn, affects problems during the dismantling of the structure.

- Solder capillary. It is used exclusively when mounting metal pipes. In this case, a wire is pulled between the fitting and the pipe. When heated, it straightens out, which allows you to completely fill the gap between the connecting elements. Capillary soldering is considered one of the most reliable and durable fastening methods. However, for doing it yourself at home, this method is quite complicated.

- compression method. For fixing, a compression ring is used, which is fixed to the pipe with a fitting. The advantage of this method is that it can be used on pipes made of absolutely any material. It is also quite convenient in terms of accessibility to pipes (great even in cases where access to pipes is limited). But this method also has one significant drawback - it is very poor reliability.

- The pressing method differs from the compression method in that special pressing fittings are required for its implementation. In this case, a huge disadvantage is the factor that you have to use additional equipment. However, with regard to reliability, the pressing method is much higher than that of the compression method. The pressing method also has excellent advantages, it can be used when connecting plastic pipes, while soldering is completely unacceptable.

- Self-locking fittings. Such connecting elements have special rings on the inner surface. When the pipes are connected to each other, due to the large number of teeth on the ring, fixation occurs. This mount is good and secure. It should also be noted that the design is assembled and disassembled very easily.

Now, knowing the basic connection methods, you can choose the one that suits you exclusively. If you are going to install a heated towel rail yourself, you should not choose a connection method that you do not understand or do not know how to do. It is better to give your preference to a simpler method, but do it well and efficiently.

Ways to connect heated towel rails

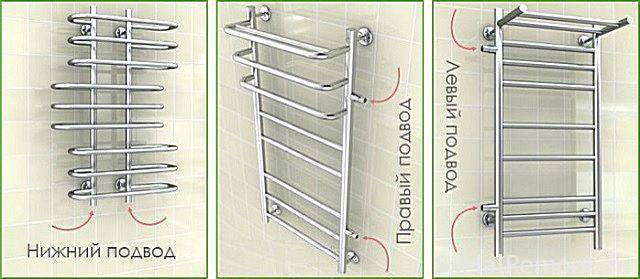

Depending on the design of the water heated towel rail, the ways to connect it to the system can be as follows:

- lower - inlet and outlet pipes are located at the bottom of the heater and in the same plane with it;

- lateral - branch pipes are located on the side of one side of the dryer and are rotated by 90 degrees relative to its plane;

- central - connection is made to the branch pipes located in the middle of the lower part of the device;

- diagonal - “connectors” for connecting to the system are located at diagonally opposite points of heated towel rails; found in "ladder" models.

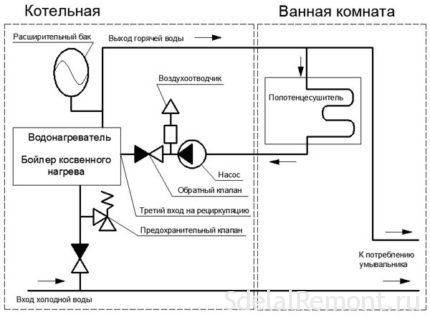

DHW or heating

Since traditional heated towel rails use hot water as a heat carrier, the most obvious way to connect them is to tie into an existing hot water supply system.But, unfortunately, this method is far from always available, and much more often you have to do it differently: connect to a central heating system. Unfortunately, because as a result of such a connection, the work schedule of the heated towel rail becomes rigidly tied to the heating season - and in the warm season, the dryer turns from a heater into a simple towel rack ...

Cranes

To control the operation of the heated towel rail, two shut-off valves with a cross section corresponding to the main pipes are installed in front of it. The design and arrangement of these valves does not matter much - both two-position (open / closed) ball and multi-turn products are equally suitable. True, if an air lock is accidentally formed in the towel dryer, leading to a sharp decrease in the efficiency of the heater, it will not be possible to remove it through such taps. Initially, air can be bled through the nuts, but if they are often twisted, the seals will quickly become unusable.

Valves usually have a threaded connection - therefore, if there are no threads on the main pipes, it must be cut or welded on the appropriate fitting.

Fittings and their types

When installing a towel dryer, special attention should be paid not only to the choice of material for the structure itself, but also to the methods of its fastening. After all, not only beauty depends on them, but also the functionality and general practicality of the entire drying system.

Moreover, if you manage to choose the right fittings for the dryer, the design can serve you much longer.

Those who are assembling the design of towel dryers for the first time may not know what fittings are. So,

The best option is when the entire structure (pipes and fittings) are made of the same materials. In stores you can find these types of fittings:

Detachable extension. This view will help you adjust the distance from the heated towel rail to the wall to which it will be attached. They are used as a kind of support, for the connection of which at least two fasteners are required. Extension fittings are connected exclusively in front of pipe bends. This type of connector has one minor drawback - the thread is too long. However, dealing with this problem is very easy. Excess thread can easily be cut off or simply sharpened.

Polymer winding. This type of fitting allows you to save yourself from the play that appears on the adjustment joints. If you manage to wind the winding correctly, it will be able to take the form that is required of it. You should also take into account the fact that this part will not be compacted over time.

The crane is angular (corner). It is designed for direct connection of the heated towel rail to the central heating pipe. Depending on the size of your pipes, you can choose either the standard options for the corners, or you can choose more convenient options. Angle fittings will help you change the direction of the pipes.

Tee. This unpretentious connector will rush to the rescue if you need to make several branches from the central system, in different directions. This fitting can also directly connect the heated towel rail and the riser. This also takes the bypass into account. Bypass allows you to turn off the heated towel rail as unnecessary and at the same time without creating obstacles to other heating grids.

Cross fittings. With their help, you can branch the system in only two different directions.

Fitting American.An American is a kind of crane with which you can dismantle the structure at any time. The convenience of this fitting is simply incommensurable, because you do not have to completely turn off the system. It will be enough just to turn off this valve, unscrew the nut and remove the structure. In this case, there are several main types of connection: a. nut-fitting; b. nut-nut (with an intermediate fitting); c. fitting-fitting (with an additional nut or coupling);

Coupling coupling. Performs almost the same functions as the American. The coupling helps to quickly disassemble and assemble all connections. This part has one feature - it has different diameters from different sides, which in turn helps to connect pipes of various sizes. The turnbuckle can have both internal and external threads.

Reflectors. This fitting does not allow moisture to penetrate to the mount.

Plugs, caps, plugs. They completely seal the pipes

When buying chrome fittings for a heated towel rail, you need to pay attention to the quality of the thread

If the threads are uniform, then the quality of the fittings is high.

It is also important to know that non-chrome metal joints are very easy to corrode. The most correct option is to buy fittings along with a heated towel rail

So you can save yourself from searching for the right ones or exchanging those that already have, but inappropriate parts.

Design and main types

The classical water heated towel rail is made of a metal pipe inside which the heat carrier flows. Hot water is not required for the operation of the electric towel dryer, it can operate all year round. The design of this unit consists of several elements:

- Electrical cable for connecting the device to the network.

- Serpentine where things are placed.

- Thermostat to maintain the desired temperature.

- Wall mount with which the device is mounted.

It is customary to distinguish between "dry" and "wet" types of units, each of which has its own advantages and disadvantages. In devices of the second type, a coolant heated with the help of heating elements circulates through the pipes. One of the main advantages of an oil heated towel rail is the ability to retain heat for a long time after being disconnected from the mains. The maximum heating temperature of this device is 70 degrees.

However, "wet" structures, unlike "dry" ones, consume more electricity. In addition, their service life is shorter, since the heating elements in the liquid wear out faster. On average, a “dry” heated towel rail works 3-5 years longer. However, it should be remembered that much here depends on the quality of the materials used in the manufacture of the device.

Features of connection in houses with centralized heat and water supply

Technologically, “cutting” a heated towel rail into a heating system is a procedure that requires stopping the heating operation and removing the coolant from the system. Therefore, in apartment buildings, it is best to do this in the summer, during the “dead” heating season. In the midst of winter, it is very difficult to persuade public utilities to even temporarily turn off heating, but the reaction of neighbors, in the event of positive results of persuasion remaining without heat for several hours, is not at all difficult to predict ...

However, when carrying out work in the summer, not everything is so simple: the heating system must be empty, without a coolant. In the case of centralized heating of an apartment building without the help of public utilities, it is very difficult to make sure that the water from the pipes is completely drained; in addition, the "feeding" of the system should be blocked - and this, again, is under the jurisdiction of the housing and communal services.

We remove the old

Work begins after the complete "dehydration" of the system to which it is connected.The dismantling of an old heated towel rail is usually done by a “grinder” - even with a threaded connection, nuts and couplings most often “stick” to the pipes tightly and cannot be unscrewed. If this did not happen, the old dryer is simply unscrewed and removed from the brackets.

The need for a bypass

A bypass is a piece of pipe that serves as a jumper between the “supply” and “return”, to which a heated towel rail is connected, mounted BEFORE the taps that control the operation of the device. Its purpose is to ensure the operability of the system when one of the elements (in this case, the dryer) is removed from its composition: if there is a bypass in the system, the circulation of hot water in it will not stop. In its absence, in which case it will be necessary to completely shut off the water ...

Connection specifics

Lateral connection is used for hidden installation of hot water or heating pipes. The process of joining is relatively time-consuming - but the result is worth it! The bottom connection is used in models of heated towel rails designed for installation in open systems, and is most often used in houses of an old housing stock. If necessary, it can be converted into a side one without much difficulty (but not vice versa!) - it is enough to connect 90-degree corners to the "input" and "output" of the dryer. But the appearance of the finished structure will not be very attractive ...

When choosing a heated towel rail model, it should be taken into account that devices with a side connection are slightly (about 10%) more powerful than products with a bottom connection to the system.

Some useful tips for connecting heated towel rails

- If the diameters of the pipeline and the nozzles of the dryer do not match, the connection is made through adapters, the working section of which should not be less than the same parameter of the pipes of the system. In case of non-compliance with this condition, there is a high probability of excessive pressure in the system, leading to a violation of its performance.

The layout of the DHW or heating system and the axial dimensions (the distance between the geometric centers of the nozzles) of the heated towel rail must be “linked” to each other. Otherwise, during installation, you will have to use various adapters and fittings, which does not improve the appearance of the assembled system at all.

The more additional adapters are used when assembling, the higher the likelihood of leakage at the joints. Therefore, you should not save on sealing joints with winding or special compounds.

When selecting taps and fittings for connecting a heated towel rail to the system, their electrochemical compatibility must be taken into account. Some metals in physical contact with each other form a galvanic pair, which leads to their rapid mutual corrosion. For example, brass and steel are bad neighbors.

The chrome-plated models of heated towel rails have the longest service life and the highest heat dissipation. True, and they have a corresponding price ...

Connection options

Water heated towel rails can have a different scheme for connecting to hot water, therefore, when purchasing such a device, this factor must also be taken into account to make it easier to install it. So, according to the installation method, these accessories may have:

- Bottom connection.

- Top connection.

- Corner water supply.

- Side connection (left or right)

The most practical and optimal is the lateral connection, since models with this design can be adapted to any installation location. This installation option will help make the connection node almost invisible, so the type of connection will not spoil the interior design.It is imperative to clarify the center distance between the pipes for connecting to the hot water supply, if it is not planned to re-pipe. Usually this parameter is 500 mm, but there are exceptions. This must be taken into account when going shopping.