Introduction

It is known that during the start-up of heating systems, air pockets remaining inside and solid particles or sludge circulating in the flow cause great problems. The presence of air cavities and plugs automatically means a high concentration of dissolved gases in the water, which can cause increased corrosion and erosion processes, problems with cavitation, and a decrease in the efficiency of pumps, fittings and heat exchangers. The presence of gases, in turn, stimulates the appearance of solid particles in the coolant. Settling in places with the lowest speed, layers of particles sharply reduce the efficiency of heat transfer. Getting into pumps and control valves, they quickly disable equipment. Corrosion processes under a layer of deposited sludge are difficult to slow down. If we take into account that during the periodic shutdown of systems for preventive maintenance, tons of particles settle at the bottom of pipelines, this process each time creates new sources of pitting corrosion.

Currently existing methods and equipment are directed to a greater extent to the treatment of water entering the system /1/

At the same time, it is sometimes not taken into account that systems cannot be perfectly sealed, gas flows into systems can be quite large even in closed systems, and degassing of large and complex systems can take a long time. In this case, as in the case of start-up, problems can occur even if the quality of the make-up water is normal.

It may also be noted that in the event of design or adjustment errors, areas of negative pressure may appear in some areas of the systems. In this case, conditions are created for the emergence of stable gas flows into the system.

It is generally accepted that in most cases the installation of a sufficient number of air vents will ensure the degassing of systems during operation. To evaluate the effectiveness of their application, we recall that the gases in the system are in three states: in the form of cavities, bubbles and microbubbles, and in a dissolved state /2/. The work of air vents is mainly associated with the first form, because. only the appearance of a significant volume of gas in the upper part of the air vent activates the mechanism for its removal. The main mass of bubbles and microbubbles going in the stream simply does not have time to rise into the air vent chamber. Therefore, air vents should be placed at the highest points of the system, at local elevations and on radiators. In complex systems, it is necessary to install a large number of these devices. At the same time, the air vent, along with the expansion tank, is one of the most vulnerable elements. Almost all differences in designs and prices are associated with varying degrees of reliability and protection of air vents from blocking them with bubbles or depressurization when dirt particles get inside the trigger mechanism.

In complex systems with a large number of air vents installed in hard-to-reach places, it is difficult to check the quality of their work. The low price (and sometimes quality) of air vents often does not compensate for the laboriousness of maintenance and losses from emerging problems. Air cavities not removed in time can be reabsorbed by water when the operating mode of the system is changed, further stimulating corrosion. Leaking water or getting air inside when the air vent is depressurized can quickly disable any system. Automatic float air vents remove air pockets and bubbles as they appear in automatic mode /3/. Air vents of this type provide better tightness and are better protected from blocking and depressurization when dirt enters them.

Mud collectors installed inside the system circuit, as a rule, are equipped with grids with large cells. Otherwise, they quickly become clogged and the circulation flow can be completely blocked. Thus, we can assume that inside the system, as a rule, there are no devices that perform the processes of fine cleaning of the coolant from sludge and its amount can grow as a result of chemical reactions or exfoliation of deposits.

Purpose

The purpose of installing a hydraulic distributor in a heating system is to separate the coolant flows, as well as to protect boiler equipment.

Consider the main specific situations in which this device can be useful in the heating system:

- When it is required to create two or more heating circuit circuits with different coolant flow rates. For example, a docked circuit requires a higher flow rate than the main one from the boiler. In this case, there are two ways to solve the problem: increase the power and circulation of the main circuit, which will not be economically justified and will lead to a rapid depletion of the equipment resource. Another way is to install a hydraulic arrow that will regulate the flow.

- In heating circuits, including boilers, underfloor heating and several circuits, a hydraulic separator will help to avoid the negative influence of these systems on each other. When turning on and off any of the elements, the overall balance of the system will not be disturbed.

- If there are several circuits (from one boiler), each of which has its own circulation pump. The hydrogun does not allow their opposition to each other. The devices work gently, the coolant is distributed evenly and in sufficient quantities in all circuits.

- There are several boilers that are combined into a single heating circuit. You can't do without installing a hydraulic gun.

- Maintainability is another plus that appears when installing a hydraulic valve. The device makes it possible to maintain the operability of all circuits, except for the one that needs to be turned off.

- In some situations, the equipment may be subject to temperature fluctuations. A sharp supply of cold liquid to a heated element of the system can lead to cracks and failure. Cast iron heat exchangers, radiators, etc. are especially sensitive to such differences. This happens when heating is started, during repair work, emergency shutdown, etc.

These are the main functions that the hydraulic gun performs. During the operation of the device, in its lower part there is an accumulation of sediment from impurities contained in the coolant (scale, rust, sand, and other dirt).

A special valve is installed here to remove sediment, and many attribute this to the additional benefits that a hydraulic distributor provides.

After all, cleaning the liquid from impurities favorably affects each element of the system and prolongs their service life.

In addition, the device is equipped with the ability to bleed the air dissolved in water. If it accumulates in radiators, it leads to a decrease in heating efficiency. So the hydraulic separator is also an air vent.

In the warranty card for some types of equipment, you can read that the manufacturer is responsible and is ready to accept faulty equipment only if there is a hydraulic separator in the system.

Hydro arrow for heating principle of operation, purpose and calculations

In a traditional heating system without the use of special units, certain disadvantages may be present. Its functioning without important improvements and adjustments will become unbalanced. Correctly mounted hydraulic arrow for heating helps to remove imbalance

It is important to use this unit to reduce the level of thermal fluctuations inside the boiler and to create a coordinated operation of the circulation pumps.

In the current conditions, the demand for a hydraulic arrow is manifested in most heating systems. Functionally, it is a compensation chamber that provides communication between independent heating circuits.

- The need for hydroelectric equipment

- What does a hydraulic separator look like?

- The principle of operation of the node in the system

- Additional functions

- Carrying out calculations

- Special conditions

- How to properly combine a manifold with a hydraulic gun

The principle of operation of the hydraulic gun

Let's analyze the principle of operation of the hydraulic separator. Since there is nothing inside the device pipe, it is clear that the regulation of the coolant is carried out due to physical laws. How it works:

When the equipment is just starting up, the temperature of the coolant is not yet sufficient to somehow heat the room, and the circulation pumps are already dispersing it through the batteries. Water, reaching the hydraulic arrow, goes down and rotates in a small circle and the boiler works for itself, raising the temperature of the coolant faster.

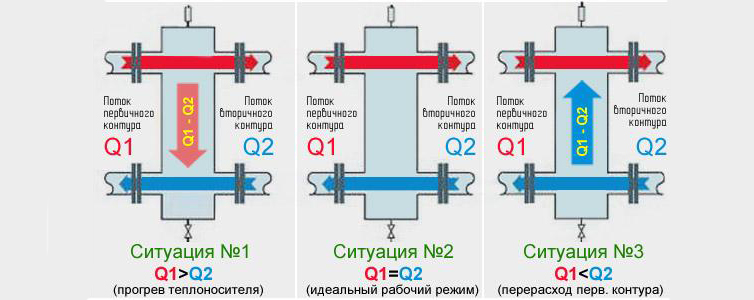

Hydraulic processes occurring in the hydraulic gun

After the balance in the supply and return temperatures is restored, the flows practically do not mix, and the hydraulic gun performs only the functions of collecting impurities and air from the liquid. But in practice, such a balance is practically not achievable and short-term, so the presence of a hydraulic gun will always be justified.

If for some reason the flow rate of the system increases, and the ducts in the boiler are of smaller diameter and simply cannot provide a higher flow rate. Then the water in the hydraulic arrow is mixed (the required volume of liquid is added from the return to the supply) and each element of the system receives as much as it needs - the boiler is smaller, the pipeline branches are larger.

Long-burning heating boilers are especially in dire need of installing a hydraulic arrow, since they have several firing modes (from ignition to damping) and at each stage of operation it is required to create stable pressure and temperature conditions.

Separators for degassing and sludge removal

Fig.1 Separator

The separators that appeared in recent years in the Russian Federation began to be produced in Europe more than 30 years ago and have become a standard element for degassing and removing sludge from heating and water supply systems. In addition to removing plugs, separators remove microbubbles and sludge particles from the water stream and combine the functions of air vents, filters and deaerators. Separators do not require consumables, energy and maintenance, operate for several decades, have a simple and reliable design without moving parts.

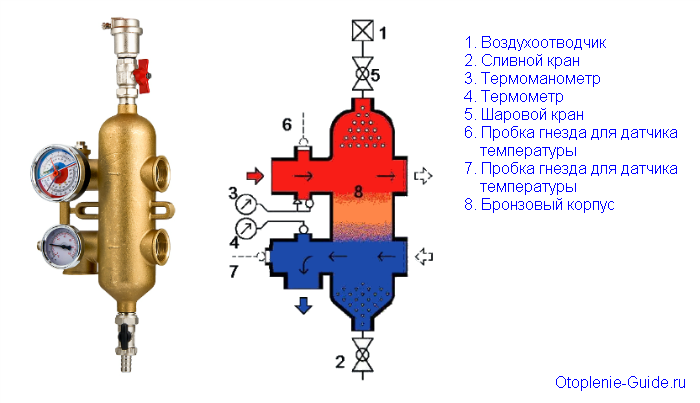

The universal separator is a metal cylinder with an air vent at the top, a sludge discharge valve at the bottom and a fixed mechanical separating element inside (Fig. 1). An element inside the separator ensures rapid transport of microbubbles to the top and settling of insoluble particles at the bottom as the water flows through the separator. The separator's automatic float-operated air vent vents the air accumulating at the top, and periodic sludge removal is carried out manually using a ball valve at the bottom of the separator. In both cases, the system will not depressurize. When the system is initially filled with water, large air bubbles are quickly removed using a special valve in the air vent housing. Separators are installed vertically.

Separators of different companies, as a rule, differ in different types of separating elements. In separators Pnevmateks (Switzerland), as such an element, a petal spiral (spirals) with a profiled surface made of stainless steel is used, installed vertically along the axis of the separator (Fig. 1). The mechanisms for extracting gases and solid particles can also be different. As a rule, the gravitational mechanism of particle settling and bubble sublimation is used in this case.To enhance the effect, the flow velocity inside the separator is reduced (cross-sectional increase), the flow is laminarized. Some models use centrifugal effect to spin the flow inside the separator. When using working elements with a large area, the mechanism of sorption of microbubbles on the surface is switched on with their further merging into larger bubbles and ascent.

The range of application of separators is quite wide.

For example, Pneumatex industrial separators (sizes DN 50 – 600 mm) are capable of handling flows in the range of 5 – 2000 m 3 /h. Cases of industrial separators are made of steel.

Brass separators for small objects (sizes DU 20 – 40 mm) handle flows up to 5 m 3 /h. All brass separators are assembled from basic elements and are easily transformed.

Separators for heating systems

Devices made of anti-corrosion brass and stainless steel;

Rapid removal of dirt particles and air pockets;

Options for any engineering systems, including those with high temperatures and pressure;

Various connection options;

Ability to work in an aggressive environment;

Prevent cavitation and corrosion;

The ability to significantly increase the service life of heating, water supply and cooling systems.

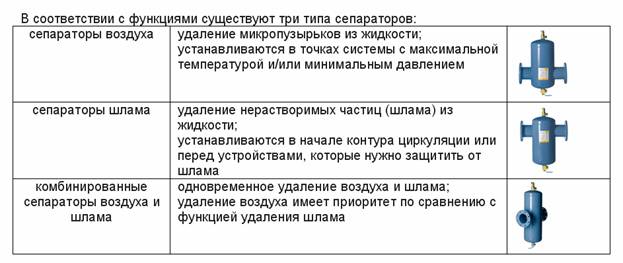

Gas/air micro bubble separators, sludge separators, gas/air micro bubble separators and sludge separators are divided into three types.

Simply separator of micro-bubbles of gas/air - removes micro air bubbles from the heating system.

Sludge separator - the smallest particles with a size of 5 microns (=0.005 mm) are separated and removed, but at the same time the pressure in the heating system does not drop, even with a large accumulation of dirt.

Separator of micro-bubbles of gas and sludge - removes both air and particles of contaminants.

Separators are made with different types of connection, usually small diameters with threaded connections, and from 50 mm already with flanges or for welding.

Most Advanced separation and deaeration systems for heating systems developed in Europe, companies such as Spirovent (Spirovent) Netherlands - Holland and Flamco (Flamco) Netherlands, are leaders in production and sales separators, non-blocking air vents, automatic make-up systems and deaerators of various types for heating systems, hot water supply and cooling systems. A distinctive feature of the products is reliability, service throughout Russia, price-quality ratio at the highest level. And the payback of this equipment is guaranteed, even if you do not notice it!

Heating and hot water systems have "invisible enemies". This micro air bubbles and sludge particles, destroying pipes from the inside. Tracking their appearance is like looking for a needle in a haystack. However, there are special automatic devices for this - gas and sludge separators.

How are separators arranged?

Each gas microbubble separator has a metal case with a ventilation valve and an eyelet for fastening. Inside there is an air chamber, separating drum, as well as an output device for cleaning or washing.

They act as follows - the flow, passing through the separator slows down. As a result air bubbles rise up. They enter the air chamber and from where they are brought out by a special non-blocking air vent. Non-blocking air vents very reliable and durable, because the work depends on their work the separator of micro-bubbles of gas/air and sludge.

Sludge separator works on a similar principle, only the accumulation of deposits occurs in the lower separator parts and is completely removed by washing. Moreover, having a sufficiently large volume separator does not create additional resistance heating system or DHW, even with a large accumulation of dirt. This is due to its special design.

Advantages:

These devices are made of materials resistant to corrosion, mechanical damage and oxidation.

100% tightness - a virtue that everyone has separators. Buying them means protecting yourself from leaks.

Often buyers ask the separator is not clogged, if the coolant contains large particles of sludge. Most modern models do not know such a problem. The most successful of them (separators brand Spirovent) able to remove foreign bodies from 5 microns in size and of course all large particles!

Separators does not require maintenance and constant monitoring. Most models are fully automatic.

These devices can be considered "quick response" devices. It only takes a few seconds to remove an air lock or sludge!

Modern separators work silently.

To start the device, you do not need to slow down the entire system.

Any separator Easy and quick to install and long lasting.

Buy separator gas can everyone - its price is reasonable and accessible to most buyers.

So if air locks and dirt are frequent guests in your pipeline, we recommend installing gas and sludge separators, deaerators and non-blocking air vents.

Everyone can buy them in the Teplostock store - even if you live in the most remote regions. After all, this is not a reason to endure inconvenience and constantly change pipes!

We are always ready to help you make a choice and organize supply of separators directly from European factories!

Do-it-yourself hydraulic arrow for heating

Calculations of the dimensions of a hydraulic arrow for heating begin with the diameter of the pipe, which is suitable for a particular system.

For calculations, you need data:

- Boiler power (kW) - W.

- The difference between the flow and return temperatures is ΔT.

By substituting the data, the formula can be used to calculate the minimum internal diameter (D) in mm.

Between the nozzles, 2-3 internal diameters of the device should “fit”.

But not everything is as simple as it seems. To make an arrow yourself, you need the skills of a welder. The services of a hired specialist will cost a lot. It is not always easy to find high-quality pipes with even threads, then you have to resort to the services of a turner. As a result, the combined cost of materials, labor, and time may even exceed the cost of purchasing a finished factory device.

There is one more point in which homemade products are inferior to factory counterparts. Because they don't have a heat shield, the spacer radiates heat where it's not intended by the owner.

Device

So, what is a hydraulic arrow in a heating system. A hydraulic arrow is a hollow pipe (the cross section can be both round and square), from which branch pipes come out. Usually they are located in pairs on opposite sides, but there are options (see "Types of hydraulic separators").

The materials from which the device is made:

- Steel (stainless steel or low carbon).

- Copper.

- Polypropylene.

Plastic models are suitable for systems from 13 to 35 kW. They are not used in combination with solid fuel heat generators, and the temperature in the system must not exceed 70 °C.

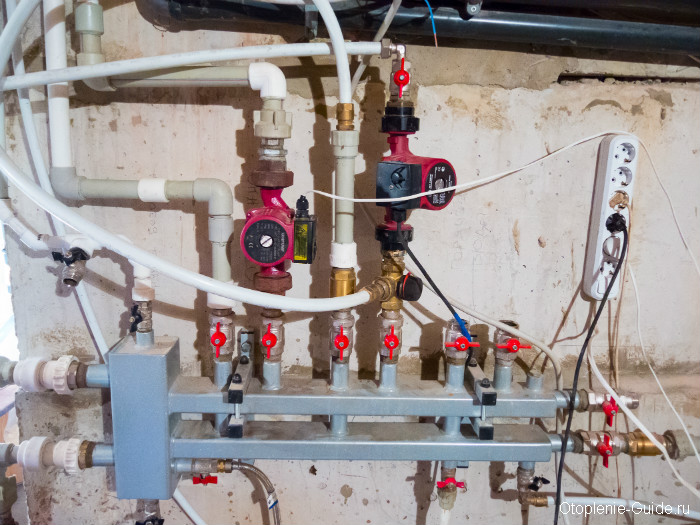

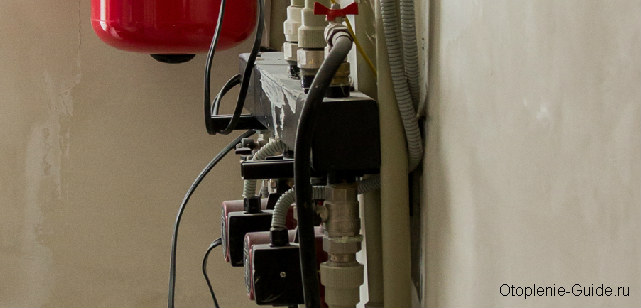

Heating system with hydraulic arrow

An automatic air vent is installed at the top point. A drain cock is usually connected to the hole pointing downwards to remove dirt. But it is possible to connect an expansion tank to this pipe.

Separators with magnetic traps

Pneumatex separators with magnetic traps (DN 20 - DN 400 mm) trap insoluble iron impurities in water much more efficiently than conventional separators.The rod(s) with a powerful magnet is inserted from the bottom outside into the separator sleeve and removed before the operation of washing out the sludge without violating the tightness of the system. The magnetic rod is separated from water by the walls of the sleeve and does not require cleaning or corrosion protection. The sleeve is made of non-magnetic material, so the magnetic particles quickly settle down and then the sludge is washed off through the valve. For efficient flushing, the valve is offset from the center (creating a vortex effect). Separators with magnetic traps also contain conventional separating elements and have all the degassing and non-magnetic particle removal properties of conventional separator models.

Design, purpose and principle of operation of the hydraulic switch

The hydraulic arrow for heating consists of a bronze or steel body with two pipes for connecting to the boiler circuit (supply pipe + return pipe), as well as several pipes (usually 2) for connecting heat consumer circuits. An automatic air vent is mounted in the upper part of the hydraulic separator through a ball valve or shut-off valve. at the bottom of the drain (drain) valve. A special mesh is often installed inside the body of factory hydraulic arrows, which allows you to direct small air bubbles into the air vent.

The design of the Valtec VT model. VAR00.

The hydraulic arrow for heating performs the following functions:

- Maintaining the hydraulic balance of the system. Turning on / off one of the circuits does not affect the hydraulic characteristics of the remaining circuits;

- Ensuring the safety of cast-iron heat exchangers of boilers. The use of a hydraulic arrow allows you to protect cast iron heat exchangers from sudden temperature changes (for example, during repair work, when the circulation pump is turned off, or when the boiler is turned on for the first time). As you know, a sharp change in the temperature of the coolant adversely affects the cast-iron heat exchangers;

- Air vent. The hydraulic arrow for heating performs the functions of removing air from the heating system. To do this, in the upper part of the device there is a branch pipe for mounting an automatic air vent;

- Filling or draining the coolant. Most of both factory-made and self-made hydraulic switches are equipped with drain valves through which it is possible to fill or drain the coolant from the system;

- Cleaning the system from mechanical impurities. The low flow rate of the coolant in the hydraulic separator makes it an ideal device for collecting various mechanical impurities (scale, scale, rust, sand, and other sludge). Solid particles circulating in the heating system gradually accumulate in the lower part of the device, after which they can be removed through the drain cock. Some models of hydraulic arrows can be additionally equipped with magnetic traps that attract metal particles.

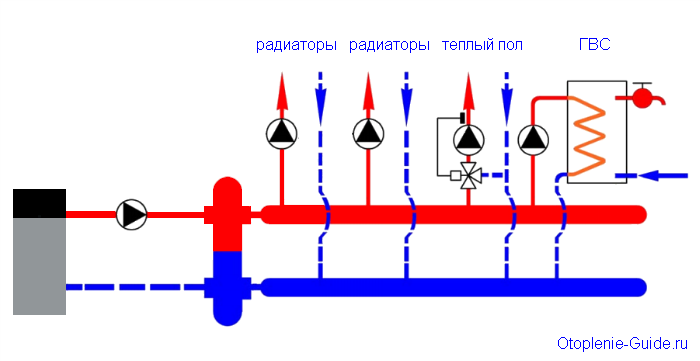

Scheme of a heating system using a hydraulic separator.

Advice! It is recommended to install the magnetic trap before filling the system with coolant, otherwise, when installing the trap, it will be necessary to drain the water from the hydraulic separator.

The process of removing mechanical particles through the drain valve:

- Turn off the boiler and circulation pumps;

- After the coolant has cooled down, we block the section of the pipeline where the drain valve is located;

- We put on a hose of a suitable diameter on the drain tap, or, if space permits, we substitute a bucket or any other container;

- We open the tap, drain the coolant until clean water flows without contaminants;

- We close the drain valve, after which we open the blocked section of the pipeline;

- We subscribe the system and start the equipment.

Why Should You Use a Hydraulic Arrow

Section of the heating system with a hydraulic arrow.

From a different angle.

In heating systems where there are two or more heating circuits (radiators, warm water baseboard, warm floor, hot water), as a rule, the circuits are interconnected by a common collector. In this case, the presence of a common collector can lead to the following problems:

- The circulation pumps of each of the circuits influence each other (especially if the pumps differ in power). To overcome the effects of a larger pump, a smaller pump must be pushed to its limits, consuming more electricity than is required under "normal" conditions. At the same time, working at the limit of their capabilities, the pumps fail earlier. In addition, under such conditions, the pump cannot always provide the required performance;

- Even if the circulation pump of one of the boilers was turned off, its radiators will still heat up (under the influence of the other pumps, the circulation of the coolant in the disconnected circuit will remain);

- Difficulties in calculating the power of pumps for both the boiler and heating circuits. The power of the boiler pump must be selected taking into account the total power of the heat consumer pumps.

All of the above problems can be solved by a hydraulic arrow.

Arrow side view.

Note! In the hydraulic separator, the speed of the coolant is sharply reduced (by about 9 times), this is due to the fact that at the entrance to the separator, the flow diameter increases several times (usually 3 times). Due to this, pressure drops in the system are excluded.

Where can I buy

Among the domestic enterprises engaged in the production of ready-made hydraulic guns is the Novosibirsk company TMK Gulfstream.

Here, hydraulic distributors are manufactured from high-carbon steel with a thickness of 3 mm.

Simple devices with 4 nozzles cost from 3.1 thousand rubles. (up to 50 kW). A similar device up to 100 kW will cost almost 4 thousand rubles.

There are models combined with a collector. Such a kit for three circuits will cost 6.8 thousand rubles. Five-circuit - 9.3 thousand rubles. Among the products there is also a powerful boiler equipment. For example, a DN100 arrow designed to operate up to 500 kW will cost 25 thousand rubles.

You can contact the organization by phone +7 913-953-16-80.

Many other manufacturers are also engaged in the production of hydraulic distribution equipment (only the prices are much higher):

- Italian firm Immergas;

- Ariston;

- Meibes and others.

Conclusion

A hydraulic distributor in a powerful or “branched” heating system is a necessary thing. Attempts to run such systems without a hydraulic arrow led to the fact that the warm floor overheated during the off-season, the radiators sometimes lacked power, and the circulation pump experienced overloads and quickly failed. Therefore, saving is not appropriate here. Moreover, domestic equipment of good quality can be purchased at a very modest price.

Even if you entrusted the installation of the heating system to specialists, it is advisable to understand the main intricacies of its arrangement. And if you decide to do the installation of heating systems with your own hands, all the more you should study this issue in detail. The article provides information about the main stages of installing the system.

For a diagram of the simplest design of a thermostat for an incubator, see this topic.