Furnace departments

Any stove, be it Russian, Dutch, Swedish or a bathhouse, consists of several main sections. For each of them, the material should be selected separately, since certain characteristics are important that are necessary specifically for a particular part of the focus.

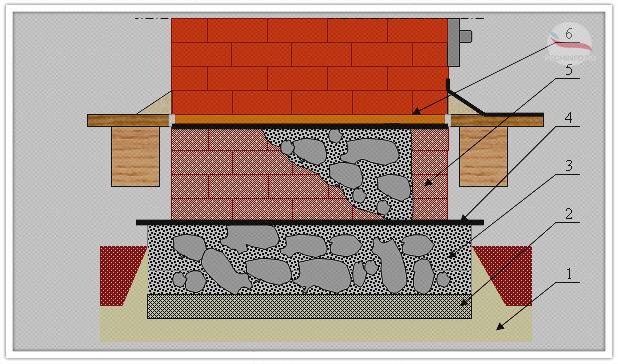

Foundation

The foundation is built first. Since the structure is usually located on the ground floor, the proximity of the ground must be taken into account. Therefore, as the first layer, a concrete slab is usually laid, and below the floor level, and a layer of waterproofing is applied on it.

Thus, we get a layer that will withstand the mass of our future structure, and also will not allow moisture and cold that come from the soil to affect it. On top of the waterproofing layer, continuous brick rows are usually laid, there can be from two to four.

This is the second part of our foundation. For it, as a rule, clinker material is used. This is due to the fact that it has a very high strength, it is not afraid of loads, so such a base can easily withstand the weight of the entire stove.

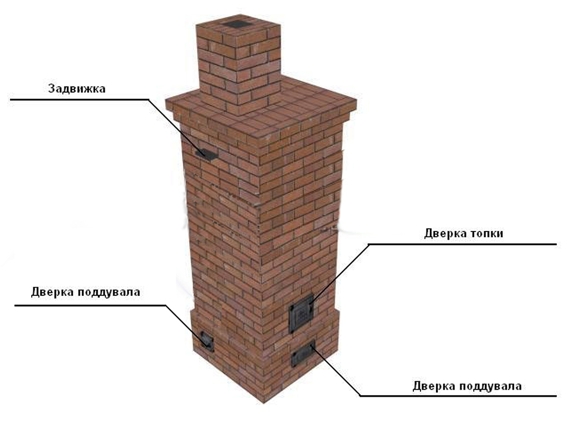

Firebox

Another design department that raises the most questions about the selection of material is the firebox. This is the place where firewood is laid and where a fire is made. The bricks in the firebox are directly exposed to the flame for a long time, and this happens over many years. Therefore, they are subject to appropriate requirements.

As a rule, fireclay blocks are used to lay out the firebox. They have the highest fire resistance of all possible options, so they calmly perform their functions throughout the entire life of the hearth.

In principle, the entire structure can be folded from fireclay. But this is very expensive. In addition, the firebox lined with cream-colored fireclay blocks looks very advantageous surrounded by red brick blocks, so this solution is optimal in terms of not only functionality, but also design.

Chimney and pipe

The chimney does not come into direct contact with the fire and does not carry a particularly high load. However, it also has certain requirements.

Firstly, from the inside it is affected by aggressive chemicals released during combustion.

They adversely affect the condition of the building material from which the inside of the chimney is lined, therefore, special attention should be paid to the stability of these bricks in various destructive factors.

Secondly, the part of the chimney that is located above the surface of the roof of the house - that is, the pipe - is also subject to attacks from the external environment. Rain and snow, frost, wind, sudden changes in air temperature - all this largely undermines brick blocks.

Experienced craftsmen recommend using two different materials for this section of the furnace. Clinker, as the most resistant to aggressive chemicals, is used for laying out the inner layer. And outside, an ordinary ceramic brick is perfect, which perfectly tolerates the effects of the external environment. not in vain, because many different structures are being built from it, including residential buildings.

Foundation Foundation

The Dutch oven, despite its light weight, needs a foundation. You can equip the foundation in two ways - from cement mortar or from bricks. Both options have their own characteristics.

In turn, the Dutch brick foundation will be noticeably more expensive, but at the same time it is much easier to make.

Formation of the cement foundation

Consider the method of forming a cement foundation for a Dutch oven.

You need to do the following:

- Prepare a pit, the depth of which is at least 50 cm. The area of \u200b\u200bthe base to be formed must be larger than the size of the planned furnace.

- Make a pillow 10-1 cm thick out of gravel and gently tamp it down.

- Install the formwork and put a reinforcing frame made of metal rods, the thickness of which is 1 cm.

- Prepare the cement mixture and gradually pour the reinforcing structure.

- Cover the foundation with cement powder.

And now the solution.

High-quality laying of a Dutch oven with a stove requires the preparation of a clay solution. The quality of the solution depends on the strength and heat resistance of the Dutch, its tightness during operation.

The ratio of binders in the composition of the clay solution depends on its purpose:

- for masonry work or

- for finishing the stove with a stove.

The hardened mixture should have a high level of rigidity. Masonry mortar of the correct consistency will be plastic and viscous, it will not crumble and will not be liquid.

Preparation of masonry mortar.

This process includes the following steps:

- The clay is placed in a trough where some water is added to it.

- After that, the clay soaks for 6-48 hours.

- During the soaking of the clay, the material is thoroughly mixed, if necessary, trampled in rubber boots.

- Sifted sand is added to the solution.

This completes the preparations, you can start laying the Dutch stove with a stove.

Type of material for the project

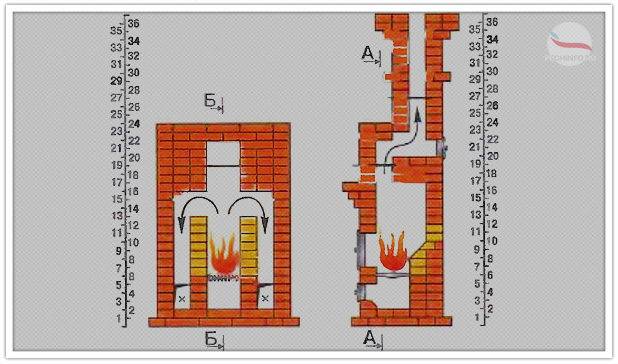

Scheme of laying the rows of the furnace.

The outer layer of the project is usually laid out from ceramic bricks. Such material lends itself well to processing and has sufficient thermal conductivity.

When buying, carefully inspect its surface. Quality stones of this type have no differences in color over the entire surface, there are no cracks and chips, the geometry meets the standards.

The furnace furnace needs a special refractory brick that can withstand high temperatures and is highly durable. The latter property is both an advantage and a disadvantage at the same time, since it complicates its mechanical processing.

Refractory bricks are made in various forms. Moreover, it has no voids. This type of artificial stone can withstand temperatures of +1400 ... +1600 ºС. It differs from the usual form in its composition and characteristic metallic ringing upon impact.

It is made from special refractory clay in industrial furnaces at very high temperatures. Such material has clear edges, which makes it possible to perform precise geometric constructions from it. But refractory bricks have a rather high cost. Therefore, it is recommended to divide the building into external and internal decoration.

This allows you to significantly reduce project costs without compromising its safety and thermal conductivity.

Calculation of the furnace dimensions

The stove planned for construction should provide a comfortable temperature in the house. To calculate the size of the furnace, you must first find out the heat loss of the building. This can be done mathematically and empirically. Let's take a closer look at the second method:

There should be no sun outside and a strong wind is desirable. Turn off all electrical and heating equipment in the house. Windows, doors and ventilation must be well closed. After 24 hours, take a room thermometer reading.

We turn on the electric heater, with a power of 1 kW. After 24 hours, the temperature should be recorded again.

You can conduct the experiment at any time of the year. The main thing is that there is no sun, which will give a large error. Find the average temperature with and without a heater. We consider their difference and divide by the set power of the heating device. The resulting number indicates how many degrees a 1 kW heater adds.

Determine the comfortable temperature in the room. We find the difference between the desired room temperature and the minimum outdoor temperature in winter. The result is divided by the value obtained earlier. Get the power needed to heat the house.

Preparation for the arrangement of the furnace

Before installing the stove, you need to carry out a number of preparatory work:

If a gas main is connected to the house, then the location of the stove must be coordinated with the gas and fire service so that the structure can be used absolutely legally

In addition to the location, you also need to pay attention to the features of the furnace - for example, it can be built into a wall or located in close proximity to combustible materials.

For the stove, it is necessary to calculate and make a separate foundation. The perimeter of the foundation should protrude beyond the contours of the stove by at least 5 cm on each side

For pouring the foundation, you can use both reinforced concrete and ordinary silicate brick. In the latter case, the rows of the foundation must be reinforced with a mesh so that the structures do not deform. The soil under the foundation must be well tamped, and on it to equip a sand cushion with a thickness of 5 cm or more.

The room must be equipped with high-quality ventilation. Even if gas is not supplied to the house, ventilation is still needed - thanks to it, the stove will have good draft. The lack of high-quality ventilation causes a vacuum in the room, due to which the stove noticeably “pops” during operation.

Calculation of the number of bricks

Regardless of the type of brick block, they all have the same standard dimensions. This makes it possible to use several varieties at once in one masonry, without having to puzzle over trying to align the rows.

Bricks are characterized by the following dimensions:

- single (standard) - 250 × 120x65 millimeters;

- one and a half - 250 × 120x88 millimeters;

- double - 250 × 120x138 millimeters.

There are also other options, but these are usually European standards that are not applied in our country.

For furnace construction, as a rule, a single brick is used, sometimes one and a half. Double does not work in this case. The fact is that it is usually hollow, that is, it has a large number of holes in the structure. This is done in order to reduce its mass.

We need only full-bodied blocks. Hollow ones accumulate heat much worse and are destroyed faster under the influence of various aggressive factors.

Let's go directly to the calculations. For them, we need only two indicators: the number of bricks from which the lowest solid row is laid out, that is, the base, as well as the number of rows. All this is easy to calculate, knowing the dimensions of the blocks that you are going to use.

After calculating the amount of material in the base, multiply it by the number of rows of which the furnace will consist. In this case, only those departments that go to the chimney are taken into account. Subtract a third from the resulting work, and you will have the required number of bricks.

Calculations for the chimney are made separately. There you take the number of bricks in one row, multiply by the number of rows and subtract nothing.

That's all. It remains to sum up the results. Now you know how many bricks you need to build a hearth. Do not forget to add about 5% in case of replacement of blocks broken during the construction process. Good luck and warmth in the house!

What are the ovens

The classic Dutch model is purely heating. The rectangular model has a single brick wall. Subsequently, furnaces appeared in the form of a triangle, a trapezoid, a round shape.

They can be heating, with a fireplace, with a stove, a container for heating water. It's easy to create them yourself. You need to choose the appropriate option and get to work.

A small stove for a summer residence will take up very little space. Its perimeter is about 50 cm. At the same time, it is able to heat several not very large rooms. You can lay it out of ceramic bricks. For the manufacture of the firebox, fireclay refractory type is used.

A Dutch woman with a stove is a rather rare option; it is often used not only for heating, but also for cooking.It is easy to fold it with your own hands using a full-bodied ceramic brick. For the firebox zone - fireclay bricks.

A three-turn stove is laid using red ceramic solid bricks. Fireclay is suitable for the firebox zone.

The round stove was quite often used for heating hospital buildings, shelters, that is, where there were no funds for full-fledged stoves. Usually it was laid out in one brick, and covered with a steel casing on top. This Dutch stove seems simple, but it is quite difficult to perform, so it is better to entrust its manufacture to an experienced craftsman. It is unlikely that it will be possible to lay it out with your own hands.

Scheme of a Dutch oven with a stove.

Scheme of a Dutch oven with a stove.

For a house in which they constantly live, it is necessary that the stove can store heat for a long time.

This largely depends on its mass and, as a result, the amount of material spent on construction. The efficiency factor is important, on which its efficiency depends.

To give, where the owners are only visits, the stove should heat up quickly. This is a lighter, more economical option that will use little material. The ideal option in this case would be Dutch.

How to calculate the number of bricks

The amount of this material depends on the size of the Dutch oven. If there is a finished project, then it usually indicates the amount of building materials. Experienced furnace specialists also know how much material is required for a furnace of one size or another. But if you plan to lay a Dutch woman with your own hands, there is a universal formula for counting the number of bricks. It should be noted that the amount here is also calculated inaccurately, conditionally.

It is necessary to calculate the number of bricks necessary for laying out the bottom row, provided that they are laid solid. Then calculate how many rows you plan to lay out in height, given that the height of one row is approximately 7 cm. Multiply these two numbers and subtract 1/3 from the result.

//www.youtube.com/watch?v=apKtactWkqo

Let's say the base of the oven is 3 by 4 bricks. It turns out that in the first continuous row 24 pieces will be laid. Then you need to calculate the height of the future furnace. If the height of the house inside from floor to ceiling is 2 m 40 cm, from this number you need to subtract the height of the cutting - about 30 cm. You get 2 m 10 cm. Given the row height of 7 cm, you get 30 rows in height. Then subtract a third of this number. 30 is divided by 3, it will be 10. 10 is subtracted from 30, you get 20 rows. Then you need to multiply 20 by 24. You get 480 pieces. It will take about 50 pieces to cut, in the end it will turn out that 530 bricks will be needed for such a furnace.

The amount of material per pipe is calculated separately. 1 line m pipe contains approximately 14 rows. For example, one row of pipe consists of 6 bricks, 6 multiplied by 14, you get 84. This number of bricks contains 1 m of pipe. Let the length of the pipe be 4 m, then 84 is multiplied by 4, you get 336. The result is that 336 pieces will be needed for the pipe.

The formula is pretty simple. Of course, the amount of calculated material is inaccurate. But at the same time, you can already estimate how much brick will need to be purchased and how much it will cost.

The Dutch stove has a simple design, low weight and fits perfectly into a small room. It does not require large financial costs. For a summer residence, you can build a brick rocket stove.

//www.youtube.com/watch?v=I4up-2P_lkc

It heats up quickly and is able to heat the room a few hours after it is kindled. However, this design also has disadvantages. Its efficiency is about 40%, so it is difficult to use it to heat houses where people constantly live. If the view is not closed after heating, the stove will cool down quickly, it has a small heat capacity, so it has to be heated often. These properties make the Dutch woman the most suitable, economical option for heating summer cottages, garden houses and other premises where people do not live permanently.

Types of oven bricks

Furnace brick can be divided into three types:

- Quartz has a small amount of sand in its composition.

- Fireclay is made from refractory clay.

- The main one contains a lot of limestone-magnesian mass.

The outer layer of the stove can be made of ceramic bricks. It is not as resistant to high temperatures, but it also has some advantages: it can be perfectly processed. It can be shaped into any shape with a pickaxe. When choosing such a brick, you should carefully study its appearance: there should be no cracks, and the geometry should exactly repeat the standard. The shade of the product should not differ over the entire surface.

How many bricks to hang in grams

Consider one of the simple and popular calculation methods that allows you to quickly find out how many bricks are needed to build a Dutch oven.

Formula

The following formula is used for calculation:

This formula uses the following parameters:

- B - the planned height of the furnace;

- P - the height of one row;

- O is the number of bricks in the first row.

Let's take a clear example.

For example, it is planned to build a Dutch woman 2.4 m high, at the base of which there are 24 bricks. The height of one row is 7 cm (thickness of one brick).

- From the planned height of the furnace, 0.3 m should be subtracted for cutting. Thus, after subtraction, 2.1 m remains.

- The resulting number should be divided by the height of one row, as a result we get 30 rows.

- We multiply the resulting value by 2/3, that is, subtract 10 rows.

- There are 20 rows left.

- We multiply the resulting number of rows by the number of bricks at the base (24 pieces).

- We get 480 bricks.

- Let's add 50 bricks for cutting.

Arithmetically, it looks like this:

The result is 530 bricks - the required number for the construction of a thirty-row Dutch oven.

Separately, the number of bricks for the construction of the chimney is calculated. It is determined by the height and cross section of the chimney. Thus, the formula should be used:

The following parameters are used:

- Chd - the number of rows in the chimney;

- H is the number of bricks in one row of the chimney.

These simple calculations will allow you to determine how many bricks will be required to build a Dutch oven.

Recommendations for choosing a brick

In order to acquire high-quality material that will not fail even after several years of operation, it is worthwhile to carefully approach the selection procedure. Here are some simple tips to help you do this:

- The fake in its composition has foreign inclusions, such as individual pebbles or pieces of limestone.

- It is desirable to buy the entire amount of material at once from one manufacturer and one batch.

- Brick that has not been fired has a pale appearance and deviations from standard dimensions.

- The above recommendations will help you correctly select and calculate the material for laying the furnace. The process itself will require not only high-quality materials, but also solid experience.

Outcome

Now you know how many bricks you need per oven. It is not difficult to calculate the amount of stone for the construction of the furnace on your own. Errors can only occur in numbers that need to be double-checked several times. Construction work on the construction of the furnace requires not so much the exact amount of material as its good quality. There are a large number of seemingly similar materials on sale, but they all have a different quality.

The described calculation methods are used only in cases where the work is planned to be performed independently. Hired workers will perform all calculations according to their own methods. Do not be afraid to take up a calculator, and then go to the store and purchase the necessary materials in the right amount.