Wood burning stove design

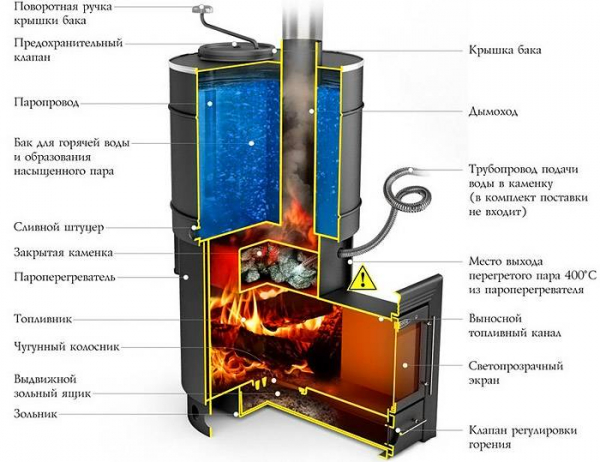

Let us consider in more detail the design of a wood-burning stove using the example of the structure of a cast-iron boiler-heater. The name boiler refers to various furnace units, the walls of which are not made of brickwork.

The design of the bath heater consists of two main compartments:

- Combustion chamber (furnace);

- Stone filling chamber.

The chamber with the buried stone is open inside the steam room. The stones are heat accumulators that heat the air inside the steam room. Their temperature in the heated space can reach 600 ºC. Water is poured onto hot hot stones to form steam.

A cast-iron wood-burning stove gives good steam only during the heating process, after it is finished, it starts to cool down and high-quality steam is not obtained.

Heating of stones is carried out through a surface of a pig-iron fire chamber. The geometric shape of the internal space of the furnace is made with a dome-shaped top, this ensures the rise of heated air masses upwards, circulation and transfer of heat to the walls of the furnace. The size of the internal space of the combustion chamber determines the capacity of firewood and the heating rate of the bath.

The exit from the chamber, where firewood is burning, is arranged in a rest room or in a utility room. Such a structure is called an elongated firebox, it eliminates the possibility of carbon monoxide poisoning, the formation of smoke in the interior of the steam room. The chimney is brought up, its height provides traction and the quality of combustion of firewood inside the firebox.

At the bottom of the firebox is a cast-iron grate through which ash spills. One door closes the space of the firebox, firewood is thrown through it, the second one closes the ashpit (ash collection places under the grate of the combustion chamber).

Additional arrangement of a stone chimney in the wall of the bath, with one or more surfaces opening into the interior of the steam room, will heat the steam room. Radiation of heat by heated stones will provide the main heating of the bath.

A convenient addition to the two main chambers can be an equipped water heater, it will heat the water for the shower.

A beautiful spectacular addition, a living decoration of the bath will be a firebox door made of heat-resistant glass. Glass material will allow you to admire the fire and burning wood.

The modern construction market provides a wide selection of designs of cast iron stoves of various designs. The best models of sauna stoves are made from cast iron material.

Comparative market analysis

The following table shows data for different types of ovens.

Table 1. Comparison of ovens of different types

| "Swede" | brick | 140 — 160 | 40 000 — 60 000 | Suitable for heating and cooking. |

| fireplace stove | brick | 145 — 175 | 42 000 — 63 500 | Open firebox. |

| Two-level | brick | 240 — 250 | 110 000 — 180 000 | Heats two floors. |

| "Russian" | brick | 145 — 165 | 90 000 — 250 000 | Equipped with a bed. |

| "Chevron" | steel | 50 | 9 000 — 10 000 | Compact model weighing about 9 kg. |

| "Indigirka" | steel | 50 | 50 000 — 55 000 | Equipped with thermoelectric generator (12 V, 60 W) |

| "Hydraulic engineer" | steel | 670 | 30 000 — 32 000 | Boiler for connecting water heating. |

| Ferlux LAWA | cast iron | 250 | 38 000 — 42 000 | Decorated with elements of artistic casting. |

Luxurious ceramic oven is expensive

Classification of stoves for wood-fired cottages

The distribution of products into groups makes it difficult to diversify them. Above is a description of a wood-burning stove that is equipped with a hob.

A tank with water, a device for generating steam, and other specific elements are added to the design of the day of the bath

In practice, the following solutions are also used:

Not far from the firebox, in a common array of bricks, a cavity is created, which later performs the functions of an oven, a dryer for mushrooms, vegetables, and fruits.

Combining several heat treatment methods

- With the help of special channels, air flows are directed in such a way that the heat of hot smoke is used as efficiently as possible.

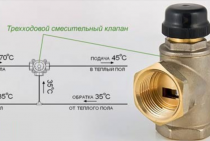

- In the design of stoves for heating wood-fired cottages, heat exchangers are built in. They are connected to standard systems with radiators, a pump, an expansion tank, monitoring and control devices.

Connecting the oven to the general heating system

The heated walls of the furnace are used to generate electricity. Appropriate factory-made generators operate on the principle of the appearance of EMF in a conductor connected to two Peltier elements. The power of such household-class devices reaches 40-60 watts.

This unit is used to generate "free" electricity

Classic designs of brick ovens for wood-fired cottages

If you choose this option, you should expect increased costs. It will take sufficient time and significant financial resources to build a structure of complex shape and internal structure on a solid foundation. You will need decorative cladding, the cost of which can be comparable to previous costs.

For finishing use tiles resistant to high temperatures

But the following advantages should be noted:

- Solid and effective appearance.

- High heat capacity of the building. It helps to maintain a comfortable temperature for a long time after the completion of the wood burning processes.

- Durability. This parameter, as well as the real efficiency of a brick oven for wood-fired cottages, will largely depend on the correct implementation of building technologies.

Modern design

What are the differences between cast iron stoves for wood-fired cottages

You won’t be able to create such a design yourself if you don’t organize your own metal casting section. This is not required, because there are a large number of high-quality models made in factory conditions on the market. Responsible manufacturers ensure the unity of parameters in each product lot. They develop and release new products with improved performance and provide official warranties.

Such products decorate the interior

The following factors should also be positively evaluated:

- Relatively small dimensions.

- Possibility of displacement when installed with the use of corrugated chimney parts.

- Not difficult installation. It can be done independently, without paying for the services of a specialized team.

- This equipment can be called conditionally stationary. Moving it to another location will not involve significant difficulties and costs.

Steel furnaces

Pay attention to the parameters of wood-fired stoves for summer cottages, the prices of which are the most attractive. They are not only cheaper, but also lighter in comparison with the analogues listed above. Some compact models can be transported in the trunk of a car

Commissioning of such equipment will also not be difficult.

A steel furnace can perform several functions at the same time

The main disadvantage of such structures is the small thickness of the steel sheets. It helps speed up the warm-up. But it also cools down very quickly. Numerous cycles of temperature changes have a negative effect on welded joints. If they are created in violation of technological processes, then hidden defects will appear in practice after a short operation.