What is included in the maintenance of gas equipment

MINIMUM LIST OF WORKS TO BE PERFORMED (SERVICES PROVIDED) ON MAINTENANCE AND REPAIR OF INDOOR HOUSE

AND (OR) INDOOR GAS EQUIPMENT

in accordance with Decree of the Government of the Russian Federation of 14.05.2013 No. 410 (as amended by Decrees of the Government of the Russian Federation of 15.04.2014 N 344, of 04.09.2015 N 941, of 09.09.2017 N 1091, of 06.10.2017 N 1219, as amended by Decision of the Supreme Court of the Russian Federation dated December 10, 2013 N AKPI13-826)

Name of the serviced object

1. Visual inspection of the integrity and compliance with regulatory requirements (inspection) of in-house and (or) in-house gas equipment

in-house and (or) in-house gas equipment

2. Visual check of the availability of free access (inspection) to the house and (or) house gas equipment

in-house and (or) in-house gas equipment

3. Visual check of the state of painting and fastenings of the gas pipeline (inspection)

4. Visual check of the presence and integrity of the cases in the places of laying through the external and internal structures of apartment buildings and households (inspection)

5. Checking the tightness of connections and disconnecting devices (instrument method, soaping)

in-house and (or) in-house gas equipment

6. Checking the functionality and lubricating the disconnecting devices

disconnecting devices installed on gas pipelines

7. Disassembly and lubrication of taps

domestic gas equipment

8. Checking the operability of devices that automatically turn off the gas supply when the controlled parameters deviate beyond acceptable limits, its adjustment and adjustment

safety fittings, gas control systems

9. Adjustment of the gas combustion process in all operating modes, cleaning of burners from contamination

domestic gas equipment

10. Checking the gas pressure in front of the gas-using equipment with all burners running and after stopping the gas supply

individual cylinder installation of liquefied hydrocarbon gases

11. Replacement of cylinders for liquefied hydrocarbon gases

group and individual cylinder installations of liquefied hydrocarbon gases

12. Checking the presence of draft in the smoke and ventilation ducts, the condition of the connecting pipes with the smoke duct

smoke and ventilation ducts

13. Instructing gas consumers on the safe use of gas to meet household needs

Drywall box

Creating an ergonomic interior in the kitchen is a realistic task if you sew up the gas pipe with drywall. This solution has both advantages and disadvantages.

Drywall box as a means to hide flaws

Positive sides:

- the development and implementation of the project can be carried out not only with the help of a specialist, but also independently;

- materials for creating a structure are available for purchase at a building profile supermarket;

- the cost of the necessary components of the structure is within reasonable limits and affordable for everyone;

- plasterboard box can harmoniously fit into any interior with the help of appropriate decoration.

Negative sides:

- closing gas pipes with drywall is unacceptable from the point of view of the safety of people living in the house, because. at the same time, access to them is completely or partially blocked;

- the design “eats up” the usable volume of the kitchen, which is important for cramped spaces;

- it is also not recommended to close the gas pipes in the kitchen because when repairing or replacing gas communications, the structure will have to be dismantled.

The technical side of the issue

If, when repairing a kitchen, the “pluses” of masking a gas pipe with drywall outweigh the “minuses”, pay attention to the recommendations on how to install the box. After installation is completed, the box should be plastered

After installation is completed, the box should be plastered

- We make measurements and determine the size of the future structure.

- We prepare the amount of materials and tools necessary for work: moisture-resistant drywall, a metal profile or a wooden block, a screwdriver and self-tapping screws, a hacksaw.

- We form the frame of the structure from metal or wooden rails.

- We specify the dimensions in place, cut drywall sheets and cut out the resulting details.

- Using self-tapping screws, we fix the blanks on the frame.

- When gaps or chips form, be sure to carefully mask them with mounting foam or putty.

- We produce the final design of the surface with materials that are in harmony with the idea of \u200b\u200bthe interior of the room.

Which plastic pipes are suitable for gas

It would be great in general to understand the order of prices for such work, so that you can either get involved in it (and write time off at your own expense) or understand that the “calamity of the disaster” is unbearable and put it off in order to accumulate funds.

During the installation of gas pipelines, special fittings (threaded) can also be used on these pipes, the second option is the installation of pipes by welding.

I have such a question, we live in Kalmykia in a village in the yard, we have a meter and a kitchen already with gases, but there is a house nearby in the same yard and we decided to connect gas there, where to start how much money will it take? There is already a house on the project, they just didn’t connect the gas there !!

The very first step in solving the problem of gasification of a private house will be to obtain the appropriate technical conditions. They are provided by the gas service department at the place of registration of the house. The term for the provision of technical specifications from the date of application, in accordance with applicable law, is no more than 10 days. This service is provided free of charge.

In what cases is it necessary to transfer the gas pipe

There are only two ways of external laying of gas pipelines: underground and air (on supports). Surface highways often require relocation. There may be several reasons for this:

- critical subsidence of soil under the supports, threatening the integrity of the pipe;

- the existing gas pipeline interferes with the construction of a new building;

- after redevelopment of the site, the air highway blocks the entrance to the territory or interferes with the organization of a recreation area.

Inside a residential building, it is also often necessary to move gas pipes:

- the dimensions of the new household appliances are incompatible with the existing location of the internal wiring;

- redevelopment of the kitchen requires a rearrangement of the gas stove or boiler.

Preparation for the transfer of the gas pipeline

Gas is an extremely explosive and volatile substance. Therefore, any actions with the main supplying blue fuel to the building are prohibited without the permission of the local gas supply organization.

When planning a visit to this company, prepare documents that will confirm your ownership of the house. Together with them, you need to bring permits issued during the initial laying of the gas pipeline.

The plan of the site and the house with gas networks applied to them and the proposed location of the pipe to be transferred will also be required by gas specialists. Based on the listed papers, they will develop specifications. Without them, it is impossible to make a project, obtain permission and carry out work.

- the gas pipeline should not pass through living rooms. The entry point and piping may only be done in the boiler room;

- laying the line through doorways, windows, on the floor and in ventilation shafts is prohibited;

- the minimum allowable distance from the gas pipe to the electric cable is 25 cm, and from the electrical distribution panel - 50 cm;

- stationary equipment and household appliances installed in the kitchen should not interfere with the inspection of the gas pipeline and its repair;

- pipe routing is allowed to be performed at a height of at least 220 cm from the floor;

- gas risers and horizontal pipes at intersections with building structures must pass through steel protective "sleeves".

What to do next

Having handed over all the collected documents to the gas service, you need to wait for the visit of the master of this organization. You will be notified of the deadline once the transfer application and accompanying documentation have been reviewed and accepted.

An employee of the gas office will conduct a technical examination and draw up a conclusion based on its results. It will state:

- the possibility of transferring the gas pipe according to the presented project;

- calculation of consumables required for the work and an estimate of the estimated costs.

Having paid the amount declared by the contractor, you can prepare for the meeting of the installation team.

Sequence of work

Removing the old and installing a new section of the highway is performed in the following sequence:

- The shut-off valve that supplies gas to the site is closed.

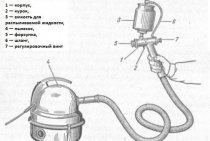

- The disconnected "branch" is blown through by a compressor to remove gaseous fuel residues from the pipe.

- The removed section of the highway is cut out by a grinder. The holes at its ends are tightly welded (jammed).

- New holes are cut out in the supply pipe and a portable segment of the line is welded into them.

When performing these works, observe the distances established by the norms:

- from the foundation of the house to the low pressure gas pipeline line must be at least 2 meters;

- between the medium pressure gas pipe and the buildings on the site, it is necessary to ensure a gap exceeding 4 meters;

- The “security zone” for the gas pipeline is designated in accordance with safety rules and is 2 meters on each side.

The placement of the pipe on the outer wall of the building is regulated by two points:

- Distance from door and window openings is at least 5 meters.

- The distance from the roof is at least 2 meters.

Having completed the transfer of the highway section, the performers draw up an act of work performed. Its signing is preceded by the start-up of gas and the control of all welded and threaded joints. Their tightness may only be tested with soapy water and never with an open flame.

After making sure that the work performed is in full compliance with gas standards, the head of the installation team, together with the customer, signs the acceptance certificate. In this case, a corresponding mark is made in the gas log of home ownership.

The main reasons for the transfer

The placement of a gas pipeline in multi-apartment and individual houses is provided for at the design stage, choosing the best option for this. Typically, the gas riser runs close to the windows in such a way as to ensure ventilation of the area next to the gas stove. At the same time, the gas outlet should not be located too far from the water supply - this will lead to inconvenience when installing the kitchen set.

From the above norm it follows that it is forbidden to use a flexible piping of a greater length and if the rated distance between the shut-off valve and the gas consuming installation is exceeded, it will have to be compensated by lengthening the steel pipe.

If the owner needs to move the gas pipe, most often he does this for the following reasons:

- Installation of new equipment to replace old or additional equipment. If a water heater is installed in the room (for example, in the bathroom of an apartment), you will have to pull a pipe from the kitchen to another room to supply gas.A similar situation may arise in an individual cottage when placing new or additional appliances: gas boilers, cooking stoves, columns.

- One of the common reasons for the transfer is related to regulatory requirements, for example, if the consumer previously had a single-entry stove, then when placing a separate hob and oven, each appliance will need its own supply. To provide two entrances, you will have to change the configuration of the pipe with cutting in the connecting fittings and performing operations equivalent to transfer.

Rice. 2 Ways to connect gas-consuming equipment

- Redevelopment. The gas stove is transferred if, for some reason, the kitchen plan is changed, partitions are demolished or completed, the kitchen area is increased by attaching a balcony or loggia to it. When implementing the latter option, the slab is sometimes taken out to an insulated balcony, leading a pipeline to it (an option that is not very acceptable from the point of view of legality and safety standards).

- Plate transfer. Sometimes the decisions of designers on the placement of the gas pipeline do not always coincide with the vision of the owners of the arrangement of the kitchen space, for example, they decided to make a cooking zone in the middle of a large kitchen. In this case, the gas pipes have to be moved or hidden to provide a convenient aesthetic gas supply to the hob.

- Acquisition of a kitchen set with built-in gas equipment. The gas pipeline riser in all city apartments is designed to connect one stove in a certain place, if the owners purchase cooking appliances built into the kitchen furniture, with a high probability the standard position of the riser outlet will not work for them - it will have to be moved.

- To enhance the aesthetic appearance. Mild steel gas pipes, painted in a light color that turns yellow over time, spoil the look of many modern kitchens, where the owners want to achieve a high decorative effect. If it is not possible to hide the gas pipeline in the upper cabinets of the kitchen set, consider one of the rare options for placing pipes in the strobes (channels) of the walls under easily removable decorative panels.

- Changing the location of the gas meter. A gas meter is a rather voluminous device that takes up a lot of space on the wall. If it creates inconvenience or violates the aesthetic appearance of the kitchen too clearly, it is not possible to place the appliance in a kitchen wall cabinet, consider moving it to another place (usually downstairs) along with a pipe connection.

Rice. 3 Pressure characteristics of gas pipelines for various purposes according to SNiP 2.04.08-87

What SNIP warns about

The gas pipeline, which is carried out in the floor or inside any room, must be at a certain distance from sewer pipes, plumbing, heating and other technological equipment. This rule proceeds from the fact that during the operation of the gas system it will be necessary to periodically inspect, and, if necessary, repair and perform various types of maintenance.

Between the gas pipeline, wired broadcasting and communication system passing through the wall, the minimum distance is set in accordance with safety regulations. And between the gas pipeline and power supply communications stretched inside the premises, the permissible distance and the possibility of their intersection are determined by the requirements established by the PUE.

The laying of the gas pipeline in buildings should be located at a height of at least 2 m. 20 cm from the floor level to the bottom touch with the gas pipe, if it is covered with insulation, then to the bottom of the insulating layer.

Gas pipes are attached to walls, ceilings or columns by means of hangers, clamps, hooks, brackets, etc.The distance between the fasteners of the gas pipeline is set in accordance with the rules defined in SNIP No. 2.04.12-86.

Installation of gas pipes that transport liquefied gas must be carried out with a 3% slope of the system. If a meter is installed in the building, then the slope should go from it.

Vertical gas pipes at their intersection with building structures must be wrapped in a special case. The space between the case and the gas pipeline is filled with any soft materials (tarred tow, rubber bushings, etc.).

The end of such a cover should protrude above the floor by at least 3 cm, and its diameter should be set so that there is an annular gap of at least 5 millimeters between the case and the pipe, if the pipe diameter is not more than 32 mm, and protrude by at least 10 mm, if the diameter of the gas pipeline exceeds the specified size.

Household gas appliances and other gas burner devices are attached to the system using rigid connectors.

During any manipulations with gas lines, it should be remembered that the possibility of gas leaks, which can lead to accidents, is not ruled out. Therefore, if the transfer of the gas pipe is planned in order to give the room aesthetics, it is necessary to consider other options for alterations without affecting the gas supply system. If you decide to reconstruct, then it is necessary to carry out work with specialists, removing family members from the premises.

Decor in the matter of masking pipes

The easiest way to disguise a gas pipe in the kitchen is during repairs, replacement of old furniture and kitchen equipment. Taking into account the style of the future interior and its other features, you can use several proven methods.

The preferred option to remove the gas pipe in the kitchen is to hide it behind furniture. With the help of pencil cases, it is easy to hide the riser in the kitchen, and horizontal pipes will not be visible behind wall cabinets with a missing back wall and specially made slots. You can just as easily close the gas meter in the kitchen.

The obvious positive aspects of this method of closing the gas pipe in the kitchen are the ability to remove the faucet for the gas stove and the gas water heater from your eyes, hide the gas meter in the kitchen and at the same time provide free access to them so as not to violate safety requirements.

We hide from the eyes the excess in the closet

Another good idea to get rid of pipelines in a conspicuous place is decorative pipe boxes. Its implementation will cost less than buying new furniture. This method is really good for people who know how to craft on their own. To make a box in the kitchen for pipes, you must first enclose the gas riser with a frame made of wooden bars or a metal profile. Then fix any decorative panels made of plastic, glass, chipboard or wood on it. Such a box for a gas pipe in the kitchen, if equipped with a door and shelves, can be used to store useful little things.

The same materials are used to close the gas meter in the kitchen by building a special cabinet. The method is justified when it is impossible to close the gas meter in the kitchen using the general design. This situation arises because of its isolated position. The output will be a separate locker made of the same materials. Home craftsmen will make a box for a gas meter with their own hands.

We decorate our interior with trinkets

If there is not enough space for the construction of extra bulky structures, you can get out of the situation if you beat the gas pipe in the kitchen with the help of decor, turning it into an independent element of the interior. For example, bright magnets will add color to an unsightly gas riser. People with artistic inclinations, having made the painting with a bizarre pattern, will turn the pipe into an exotic snake, a tropical liana, a fragment of brickwork or a floral border.This element of the interior, decorated using decoupage technique, looks beautiful.

- When funds are limited, use a cheap masking method - paint the pipe with paint so that it blends in color with the general background of walls or furniture. For this purpose, heat-resistant paint for a gas stove, matched to the color of the equipment, is suitable.

- The most common, economical and aesthetic method to hide a gas pipe is to cover it with drywall. Let's take a closer look at the pros and cons of this option.

Features of cutting and replacing gas pipes in the apartment

Who to contact if you plan to replace the gas pipeline?

If there is a need to replace gas pipes or connect new devices, the best solution would be to contact a specialized organization that supplies gas to the apartment. Representatives of the gas service have special equipment, performers are trained in safe working methods.

A service representative who arrives will inspect the system and determine the life of the gas pipes. In addition, he will check the premises for compliance with the requirements for the safe operation of gas equipment, and carry out the measurements necessary to determine the amount of materials. Based on the data obtained, an estimate of the cost of the pipeline replacement work will be drawn up.

Replacement of the gas pipeline in the apartment must be carried out in compliance with all safety requirements, gas does not tolerate neglect.

Before cutting the gas pipe, the gas supply to the section to be replaced must be shut off and purged. The gas-air mixture should be removed outside the apartment, while ventilation should be carried out in the room.

The release of the mixture into the general house ventilation ducts is not allowed.

Only after all safety measures have been completed, dismantling can begin. How and how to cut a gas pipe is known to many. There are no special differences with the dismantling of other pipelines, so it is best to use an ordinary grinder for cutting. Of course, this can be done with a hacksaw, but it will take more time.

The tie-in into the gas pipe is carried out using gas welding, the valves are mounted on threaded connections.

Start-up work

First of all, a visual inspection of the integrity of the pipeline is carried out, all the necessary plugs are installed, and the connection of gas appliances is checked.

In the gas-air mixture after purge, there should not be more than 1% oxygen, and this is precisely what determines the duration of the purge. The composition of the mixture should ensure even (without pops) burning of the flame in gas appliances.

During the day after the start of gas, it is necessary to ensure enhanced control of the operation of all equipment.

Insertion into the gas line

Residents of new buildings, especially owners of private housing constructions, often have to deal with such a problem as tie-in to a gas pipeline and installation of new wiring around the premises. This procedure is much more difficult than conventional repair work.

It is necessary to prepare a whole package of documents:

- Technical passport for the construction and its certified copy.

- Topographic plan of the land plot with drawing of all types of communications. This document will need to be certified in Gorgaz.

- Permission to connect to the gas pipeline (permission to tie into the gas pipeline).

- Technical documentation for all gas equipment that is planned to be operated indoors. This list includes certificates, expert opinion that the equipment can be operated indoors.

- The act of inspection of chimneys and ventilation ducts.

Getting permission

The developed project must necessarily be agreed with the technical department of the gas service.

After agreement, an agreement must be drawn up for technical supervision of the tie-in work and an estimate for their implementation

One of the basic rules of how to crash into a gas pipe is to carefully read the contract and other documentation, pay attention to the warranty obligations of the installer

If you have all the documents, you can start inserting and connecting gas equipment. A package of technical documentation must be drawn up for the performance of work. The gas network and equipment must be commissioned by a special commission, which includes representatives of the gas service and the installation organization.

After payment of all official payments, representatives of Gorgaz carry out sealing of the control equipment, a contract is concluded for the supply of gas and maintenance of the equipment.

In many cases, the entire range of work is carried out by employees of the gas service. This approach may cost a little more, but it avoids many of the problems associated with obtaining permission and project approval. Therefore, preparations for tie-in to the gas pipeline should begin with a visit to Gorgaz.