Welding guide

Installation of polypropylene pipes

Welding plastic pipes is a simple event that you can handle on your own. It is enough to go through each step of the guide step by step.

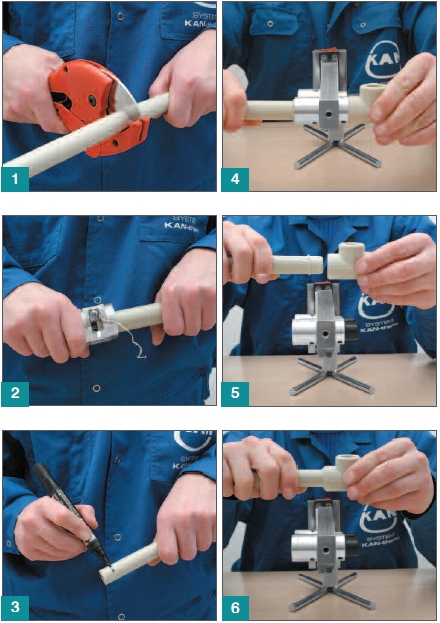

The first stage is the preparation of parts for welding

Start by preparing the elements to be joined. Cut pipes according to the requirements of pre-prepared wiring diagrams. Lay out all the cut elements in the order in which they will be connected using a special soldering iron. So you avoid the risk of incorrect connection of the elements of the pipeline system.

cut pipes

The second stage is setting up the tool for welding

Plastic Pipe Welding Machine

The design of the soldering iron assumes the presence of a temperature controller. Set the regulator to the limit recommended by the manufacturer in accordance with the attached instructions. To understand that the soldering iron has heated up to the set temperature, you can by the extinguished bulb of the temperature controller.

The third stage - heating the elements

Heating elements

Before starting welding, all the constituent elements of the future pipeline must be heated. Refer to your soldering iron manual for recommended conditions and optimal preheating times. Be sure to check it out.

To heat the parts, you must insert them into the connectors of the welding device. You can also find information on how to do this correctly in the manufacturer's manual for your soldering iron.

How to solder polypropylene pipes

The fourth stage - the connection of elements

Compound

Properly heated parts connect very quickly and evenly. During the connection process, no distortions and rotations of the elements should be allowed. When connecting two pieces of plastic pipe, strictly maintain the cut angle - only in this way will the seam you create be tight and reliable.

Fifth stage - cleaning connections

Let the seam cool and carefully clean it. A file can be used for cleaning.

Thus, there is nothing super complicated in self-welding of plastic pipes. Use high-quality tools, follow the recommendations received in everything, and very soon you will be able to use your own plumbing or heating system.

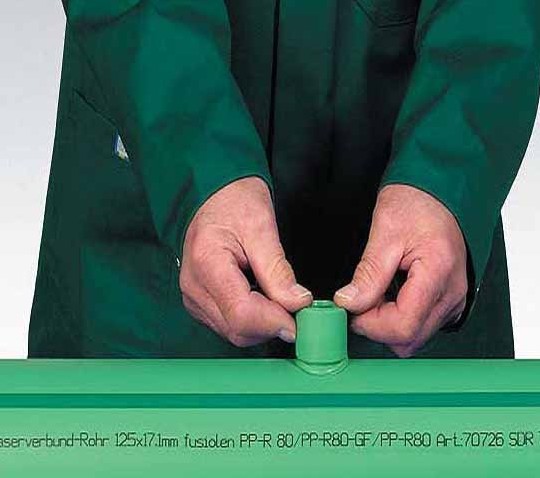

Welding instructions for welding saddles

After drilling, the welding machine is installed

Weld-in seat installation

Successful work!

How to choose pipes

Line diameter

When choosing pipes made of polypropylene, one must proceed from the characteristics of the room and the functional purpose of the piping system. For a water main with hot and cold water, pipes of small diameter are required. For sewerage and heating, you need to purchase pipes of large diameter. Along with this, it is necessary to measure the area on which the installation will be carried out, as well as take into account the length of the entire pipeline. Also, welding polypropylene pipes with your own hands will require special knowledge and skills.

When choosing the type of polypropylene pipes for a particular pipeline, you need to take into account, take into account the degree of complexity of their installation, as well as how to cook polypropylene pipes in each case. You need to determine exactly whether you can independently cope with the upcoming front of work on your own, or you still have to turn to professionals.

Types of polypropylene pipes

Functional purpose

It should be noted that for heating, hot water supply and for water supply systems that are designed for cold water, there are different types of polypropylene pipes that differ in their technical indicators. Therefore, welding of PP pipes or other types of pipes will also depend on the functional purpose of the entire piping system.

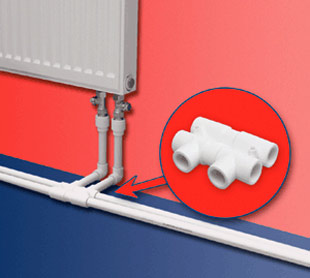

Scheme for connecting propylene pipes to a radiator of a heating system

Do not take pipes for cold water supply for heating systems. They are not suitable for high temperatures and will quickly fail. Pipes for underfloor heating, for heating and for supplying hot water require special technical characteristics. In this case, the technology for welding polypropylene pipes will also have its own characteristics.

To choose the right polypropylene pipes, first of all, you need to choose the right diameter. It should not be too small, as this will affect the water pressure. A large diameter pipe will cost more.

Installation of polypropylene pipes with one's own hand cannot be carried out without the presence of specialized couplings, adapters, corners of various sizes and configurations, as well as special equipment for welding. It will set the required temperature for welding polypropylene pipes, which will ensure the tightness of the connection. When choosing fasteners for pipes made of polypropylene, you need to focus on their diameter and total weight. Fasteners must firmly fix the pipeline segment and withstand its weight in working condition.

Plumbing from polypropylene pipes with fasteners

Equipment preparation

To create a single structure of polymer elements, melting of their end parts is used. After the subsequent fast connection and hardening, a homogeneous one-piece connection is formed. It differs in reliability, tightness. It does not need to be further isolated, protected from external influences.

Tool for soldering polypropylene pipes

To get just such a result, polypropylene pipes are soldered using a special tool:

Tool name/

fixtures

Purpose and main parameters

Important Features

soldering iron

A powerful heating element is installed in a large protruding part

When choosing a device, you should pay attention to its quality characteristics, recommendations of experienced craftsmen in relation to individual models. As standard, there should be a stand, which is used to connect structural elements not “on weight”

nozzles

They insert parts for heating

They are created with a layer of Teflon on the surface to prevent sticking of polymer products when they are melted.

As a rule, manufacturers include nozzles in one set with a soldering iron. It is necessary to check their compliance with the dimensions of the parts to be joined.

Cutter

Tool for creating blanks from pipes of the required length

A special cutter will only be needed for large-scale projects. If relatively small amounts of work are planned, an ordinary hacksaw with a wood blade will be enough

Shaver

This tool is used to remove aluminum from multilayer pipes.

If metal reinforcement is made inside the product structure, or is completely absent, such equipment is not needed.

beveler

Another prep tool. They are chamfered on pipes

It must be suitable for working with polymers. With its help, chamfers are created on the pipes, inclined by 15 ° (45 °), deepened into the product by 2.5 mm (1/3 of the wall thickness). The difference in the above figures is due to the excellent requirements of German and domestic standards. You can follow one or the other rules, but not at the same time

Preparation for work

Before you begin, read a few important guidelines and prepare the necessary tools.

Helpful Hints

-

In the absence of experience in welding plastic pipes with your own hands, first practice a little. Buy fittings and other wiring elements with a small margin. Having gained experience, you will be able to complete the finishing work as quickly and efficiently as possible.

- Before starting work, the mating elements must be properly prepared - cleaned and degreased. Without pre-treatment, it is not necessary to count on a high-quality welded joint.

-

In the process of wiring, you will use not only pipes, but also various additional devices - turn signals, tees, couplings, etc. Remember: pipes must be heated from the outside, and all additional elements from the inside. Do not ignore this rule, otherwise the finished joints will be fragile and short-lived.

- When welding plastic pipes with your own hands, especially if small parts are used in the process, make sure that the internal seams do not reduce the permeability of plastic products.

- Usually such a problem occurs in case of overheating of the pipes - too large influxes of material are formed inside and the holes are clogged. Therefore, it is possible to cook plastic pipes only at permissible temperatures (indicated in the instructions for the soldering iron). After completion of work, be sure to check the pipes for patency. To do this, it is enough to pass water through the product.

- The assembled system can be filled with water not earlier than 1-1.5 hours after the welding of the constituent elements.

Required Tools

Prepare the following fixtures:

-

a special apparatus for connecting plastic pipes;

- nozzles for used pipes;

- pipe cutter or special wire cutters;

-

shaver (for metal-plastic pipes);

-

chamfer tool.

All necessary tools are sold in hardware stores. A soldering iron is quite expensive, so if the work on welding plastic pipes is of a single nature, it will be more profitable to find a company that provides such tools for rent.

Use only recommended equipment. Some home craftsmen try to adapt ordinary household soldering irons for welding plastic pipes, but nothing good usually comes of it.