Penoplex or mineral wool

Physical indicators of mineral wool:

- density - varies widely and can be from 10 to 300 kg / m3;

- thermal conductivity (at a density of about 35 kg / m3) - 0.040-0.045 W / m * K;

- moisture absorption - more than 1% (depending on density);

- vapor permeability - 0.4-0.5 mg / h * m * Pa;

- maximum holding temperature of 450 C and above.

An analysis of these values shows that the worst thermal conductivity of mineral wool is compensated by better vapor permeability, high temperature resistance and incombustibility. Min. cotton wool is justified precisely in those conditions where the listed parameters are important.

The use of glass wool insulation is advisable to use in garages, workshops, industrial facilities, wherever there is an increased risk of fire. Wet rooms, such as saunas, baths and swimming pools, are also better insulated with mineral heaters, so in this case the vapor permeability of the insulator is important.

The environmental safety of insulation based on polystyrene and mineral wool depends on the conditions of use. Polystyrene derivatives can support combustion in case of fires, while emitting toxic smoke. Mineral heat insulators are resistant to high temperatures and do not decompose, but over time they can age and release dust, in the form of microfibers that make up the material. The external method of wall insulation using basalt wool, in this regard, is safe.

The insulation design must take into account the possible impact of water. Mineral materials are subject to a greater accumulation of liquid, while their thermal conductivity will be increased.

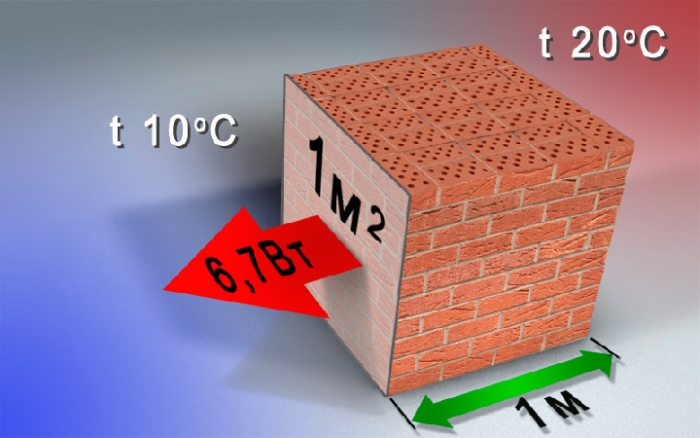

Features of thermal conductivity

This can be seen if you take, for example, a piece of foam. 1 meter thick and 1 square meter. Heat one side and leave the other side cold. The difference between the temperatures will be tenfold. To obtain the coefficient of thermal conductivity, it is necessary to measure the amount of heat that passes from the warm part of the sheet to the cold.

People are used to being constantly interested in the density of polystyrene foam from sellers. This is because density and heat are closely related. To date, modern foam does not require checking its density. The manufacture of improved insulation involves the addition of special graphite substances. They make the thermal conductivity of the material unchanged.

Comparative analysis of the main technical characteristics of basalt wool and expanded polystyrene

fire resistance

Compared to expanded polystyrene, basalt wool has a higher fire resistance. Basalt wool fibers are sintered at a temperature of about 1500 degrees. However, the maximum allowable temperature for the use of this heat-insulating material in the form of mats and slabs is limited due to the binders that were used in the formation of finished products. At a temperature of about 600 degrees, the binders are destroyed, and the basalt slab or mat loses its integrity. It should be noted that expanded polystyrene without any consequences can withstand temperatures that do not exceed 75 degrees.

combustibility

Equally important are such an indicator as combustibility - the ability of a material to burn. Modern building materials are usually divided into:

- non-combustible (NG) - able to withstand exposure to very high temperatures without ignition, loss of strength, structural deformation and changes in other properties.

- combustible (G) - the degree of flammability is determined by such indicators as flammability, smoke-generating ability, flame propagation, toxicity.

It is important to note that if materials of class NG are not only completely fireproof, but also prevent the spread of fire, then class G materials always pose a fire hazard.

The combustibility of basalt wool, which is based on inorganic materials that by their nature cannot burn, is determined depending on the amount of organic binders used in the manufacture of insulation. High-quality basalt wool (for example, the Beltep trademark) contains no more than 4.5% binders, therefore it is assigned the NG group. In the case of a higher content of organic substances, the flammability group of basalt wool changes to group G1 (low combustible materials) or G2 (moderately combustible materials).

Expanded polystyrene, regardless of the type of material, always belongs to class G. At the same time, the combustibility group of this heat-insulating material can vary from G1 (low combustible material) to G4 (highly combustible material).

Water absorption

Basalt wool has an open porosity, therefore it is able to absorb moisture (up to 2% by volume, and up to 20% by weight). And since water is an excellent conductor of heat, when moisture enters, the thermal insulation characteristics of basalt wool deteriorate significantly (up to complete unsuitability). And although manufacturers treat basalt wool with water-repellent additives that prevent moisture absorption, experts recommend that this heat-insulating material be reliably protected from moisture by vapor and waterproofing barriers.

Unlike basalt wool, expanded polystyrene has a closed closed porosity, therefore it is characterized by high resistance to capillary water absorption (up to 0.4% by volume) and diffusion of water vapor.

Strength

Under the strength characteristics, we mean such indicators as the strength of the material for peeling off layers, compression at 10% deformation, shear / shear, bending, etc.

For basalt wool, the strength characteristics depend on the density of the material and the amount of binders. For expanded polystyrene, these indicators depend solely on the density of the material. At the same time, expanded polystyrene is characterized by higher compressive strength at 10% deformation than basalt wool with a lower density (for example, the compressive strength at 10% deformation of expanded polystyrene with a density of 35-45 kg / m3 is about 0.25-0.50 MPa, while for basalt wool with a density of 80-190 kg / m3 this indicator ranges from 0.15-0.70 MPa). Note that for basalt wool with a density of 11-70 kg / m3, not strength characteristics are measured, but the compressibility value under a load of 2000 Pa.

Thermal conductivity

One of the most important indicators of any thermal insulation material is its thermal conductivity. Studies have shown that both materials we are considering have almost the same thermal conductivity: for basalt wool - 0.033-0.043 W / m • ° C, for expanded polystyrene - 0.028-0.040 W / m • ° C.Note, moreover, that air has the lowest thermal conductivity (0.026 W / m • ° C), and one and the second heat-insulating material is an effective heater.

Thermal conductivity concept and theory

Thermal conduction is the process of transferring thermal energy from warm parts to cold parts. Exchange processes occur until complete equilibrium of the temperature value.

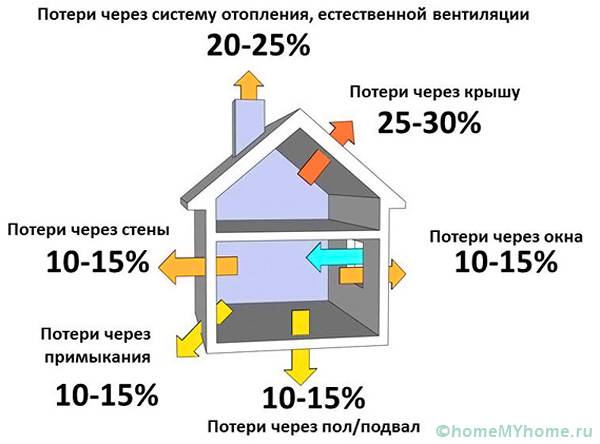

A comfortable microclimate in the house depends on high-quality thermal insulation of all surfaces

The heat transfer process is characterized by a period of time during which the temperature values are equalized. The more time passes, the lower the thermal conductivity of building materials, the properties of which are displayed in the table. To determine this indicator, such a concept as the coefficient of thermal conductivity is used. It determines how much heat energy passes through a unit area of a certain surface. The higher this indicator, the faster the building will cool down. The thermal conductivity table is needed when designing the protection of a building from heat loss. This can reduce the operating budget.

Heat loss in different parts of the building will be different

The thermal conductivity of foam from 50 mm to 150 mm is considered thermal insulation

Styrofoam boards, colloquially referred to as polystyrene foam, are an insulating material, usually white. It is made from thermal expansion polystyrene. In appearance, the foam is presented in the form of small moisture-resistant granules; in the process of melting at high temperature, it is melted into one piece, a plate. The dimensions of the parts of the granules are considered from 5 to 15 mm. The outstanding thermal conductivity of 150 mm thick foam is achieved through a unique structure - granules.

Each granule has a huge number of thin-walled micro-cells, which in turn increase the area of contact with air many times over. It is safe to say that almost all foam plastic consists of atmospheric air, approximately 98%, in turn, this fact is their purpose - thermal insulation of buildings both outside and inside.

Everyone knows, even from physics courses, atmospheric air is the main heat insulator in all heat-insulating materials, it is in a normal and rarefied state, in the thickness of the material. Heat-saving, the main quality of the foam.

As mentioned earlier, the foam is almost 100% air, and this, in turn, determines the high ability of the foam to retain heat. And this is due to the fact that air has the lowest thermal conductivity. If we look at the numbers, we will see that the thermal conductivity of the foam is expressed in the range of values from 0.037W/mK to 0.043W/mK. This can be compared with the thermal conductivity of air - 0.027 W / mK.

While the thermal conductivity of popular materials such as wood (0.12W / mK), red brick (0.7W / mK), expanded clay (0.12 W / mK) and others used for construction is much higher.

Therefore, the most effective material of the few for thermal insulation of the outer and inner walls of a building is considered to be polystyrene. The cost of heating and cooling residential premises is significantly reduced due to the use of foam in construction.

The excellent qualities of polystyrene foam boards have found their application in other types of protection, for example: polystyrene foam also serves to protect underground and external communications from freezing, due to which their service life is increased significantly. Polyfoam is also used in industrial equipment (refrigerators, cold rooms) and in warehouses.

The main characteristics of heaters

To begin with, we will provide the characteristics of the most popular heat-insulating materials, which you should first of all pay attention to when choosing.Comparison of heaters in terms of thermal conductivity should be made only on the basis of the purpose of the materials and conditions in the room (humidity, the presence of open fire, etc.)

We have arranged further in order of importance the main characteristics of heaters.

Comparison of building materials

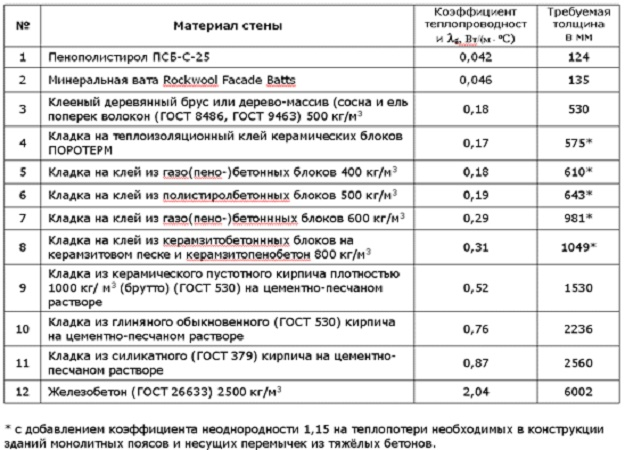

Thermal conductivity. The lower this indicator, the less a layer of thermal insulation is required, which means that the cost of insulation will also be reduced.

Moisture permeability. The lower permeability of the material to moisture vapor reduces the negative impact on the insulation during operation.

Fire safety. Thermal insulation should not burn and emit toxic gases, especially when insulating a boiler room or chimney.

Durability. The longer the service life, the cheaper it will cost you during operation, since it will not require frequent replacement.

Environmental friendliness. The material must be safe for humans and the environment.

Comparison of heaters by thermal conductivity

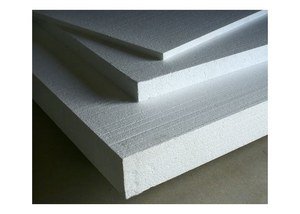

Expanded polystyrene (styrofoam)

Expanded polystyrene (styrofoam) plates

This is the most popular heat-insulating material in Russia due to its low thermal conductivity, low cost and ease of installation. Styrofoam is made in plates with a thickness of 20 to 150 mm by foaming polystyrene and consists of 99% air. The material has a different density, has low thermal conductivity and is resistant to moisture.

Due to its low cost, expanded polystyrene is in great demand among companies and private developers for the insulation of various premises. But the material is quite fragile and quickly ignites, releasing toxic substances during combustion. Because of this, it is preferable to use foam plastic in non-residential premises and for thermal insulation of non-loaded structures - insulation of the facade for plaster, basement walls, etc.

Extruded polystyrene foam

Penoplex (extruded polystyrene foam)

Extrusion (technoplex, penoplex, etc.) is not exposed to moisture and decay. This is a very durable and easy-to-use material that can be easily cut with a knife to the desired dimensions. Low water absorption ensures minimal change in properties at high humidity, the boards have a high density and resistance to compression. Extruded polystyrene foam is fireproof, durable and easy to use.

All these characteristics, along with low thermal conductivity in comparison with other heaters, make Technoplex, URSA XPS or Penoplex slabs an ideal material for insulating strip foundations of houses and blind areas. According to manufacturers, an extrusion sheet with a thickness of 50 millimeters replaces 60 mm foam block in terms of thermal conductivity, while the material does not allow moisture to pass through and additional waterproofing can be dispensed with.

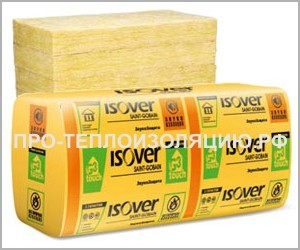

Mineral wool

Izover mineral wool slabs in a package

Mineral wool (for example, Izover, URSA, Technoruf, etc.) is made from natural materials - slag, rocks and dolomite using a special technology. Mineral wool has a low thermal conductivity and is absolutely fireproof. The material is produced in plates and rolls of various stiffness. For horizontal planes, less dense mats are used; for vertical structures, rigid and semi-rigid slabs are used.

However, one of the significant disadvantages of this insulation, as well as basalt wool, is low moisture resistance, which requires additional moisture and vapor barrier when installing mineral wool. Experts do not recommend using mineral wool for warming wet rooms - basements of houses and cellars, for thermal insulation of the steam room from the inside in baths and dressing rooms. But even here it can be used with proper waterproofing.

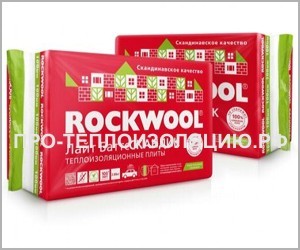

Basalt wool

Rockwool basalt wool slabs in a package

This material is produced by melting basalt rocks and blowing the molten mass with the addition of various components to obtain a fibrous structure with water-repellent properties. The material is non-flammable, safe for human health, has good performance in terms of thermal insulation and sound insulation of rooms. Used for both internal and external thermal insulation.

When installing basalt wool, protective equipment (gloves, a respirator and goggles) should be used to protect the mucous membranes from cotton wool microparticles. The most famous brand of basalt wool in Russia is materials under the Rockwool brand. During operation, the thermal insulation slabs do not compact and do not cake, which means that the excellent properties of low thermal conductivity of basalt wool remain unchanged over time.

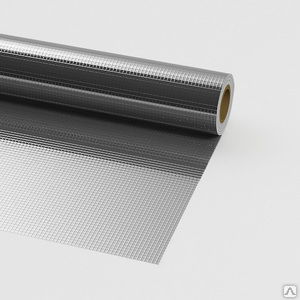

Penofol, isolon (foamed polyethylene)

Penofol and isolon are rolled heaters with a thickness of 2 to 10 mm, consisting of foamed polyethylene. The material is also available with a layer of foil on one side for a reflective effect. The insulation has a thickness several times thinner than previously presented heaters, but at the same time it retains and reflects up to 97% of thermal energy. Foamed polyethylene has a long service life and is environmentally friendly.

Izolon and foil penofol are light, thin and very easy-to-use heat-insulating material. Roll insulation is used for thermal insulation of wet rooms, for example, when insulating balconies and loggias in apartments. Also, the use of this insulation will help you save usable space in the room, while warming inside. Read more about these materials in the Organic Thermal Insulation section.

Distinctive features of PPE insulation

Specifications

Foamed polyethylene thermal insulation is a product with a closed-cell structure, soft and elastic, having a shape corresponding to its purpose. They have a number of properties that characterize gas-filled polymers:

- Density from 20 to 80 kg/m3,

- Operating temperature range from -60 to +100 0C,

- Excellent moisture resistance, in which moisture absorption is no more than 2% of the volume, and almost absolute vapor permeability,

- High sound absorption even at a thickness greater than or equal to 5 mm,

- Resistant to most chemicals

- The absence of rotting and fungus damage,

- Very long service life, in some cases reaching more than 80 years,

- Non-toxic and environmentally friendly.

But the most important characteristic of polyethylene foam materials is their very low thermal conductivity, due to which they can be used for thermal insulation purposes. As you know, air retains heat best, and there is plenty of it in this material.

The heat transfer coefficient of polyethylene foam insulation is only 0.036 W / m2 * 0C (for comparison, the thermal conductivity of reinforced concrete is about 1.69, drywall - 0.15, wood - 0.09, mineral wool - 0.07 W / m2 * 0C).

INTERESTING! Thermal insulation made of polyethylene foam with a thickness of 10 mm can replace a 150 mm thick brickwork.

Application area

- To reduce heat transfer by convection and heat radiation from walls, floors and roofs,

- As a reflective insulation to increase the heat transfer of heating systems,

- To protect pipe systems and highways for various purposes,

- In the form of an insulating gasket for various cracks and openings,

- For isolation of ventilating and air-conditioning systems.

In addition, polyethylene foam is used as a packaging material for transporting products that require thermal and mechanical protection.

Is polyethylene foam harmful?

Supporters of the use of natural materials in construction can talk about the harmfulness of chemically synthesized substances. Indeed, when heated above 120 0C, polyethylene foam turns into a liquid mass, which can be toxic. But in standard living conditions, it is absolutely harmless. Moreover, polyethylene foam insulation materials are superior to wood, iron and stone in most indicators. Building structures with their use are light, warm and low cost.

Thermal conductivity of expanded polystyrene in comparison

If we compare polystyrene with many other building materials, we can draw colossal conclusions.

The thermal conductivity index of the foam leaves from 0.028 to 0.034 watts per meter / Kelvin. If the density increases, the thermal insulation properties of extruded polystyrene foam without graphite additives decrease.

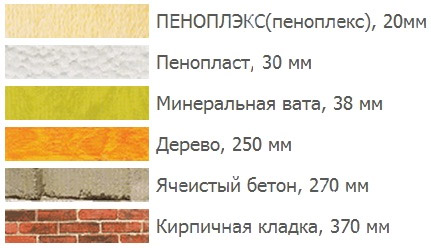

A 2 cm layer of extruded foam is able to retain heat like a layer of mineral wool 3.8 cm, like a regular foam plastic, a layer of 3 cm, or like a wooden board, which is 20 cm thick. For a brick, these abilities equate to wall thickness of 37 cm. For foam concrete - 27 cm.

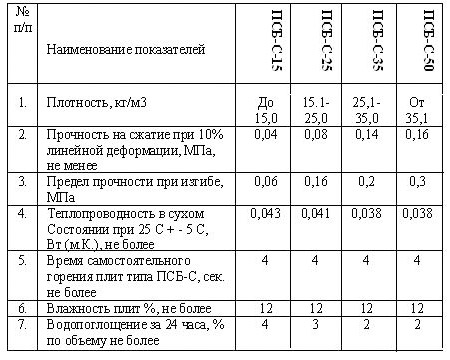

Indicators for different grades of expanded polystyrene

From the above simplified formula, we can conclude that the thinner the insulation sheet, the less effective it is. But in addition to the usual geometric parameters, the final result is also influenced by the density of the foam, albeit slightly - only within 1-5 thousandths. For comparison, let's take two plates that are close in brand:

- PSB-S 25 conducts 0.039 W/m °C.

- PSB-S 35 at a higher density - 0.037 W / m ° С.

But with a change in thickness, the difference becomes much more noticeable. For example, for the thinnest sheets of 40 mm at a density of 25 kg / m 3, the thermal conductivity index can be 0.136 W / m ° C, and 100 mm of the same expanded polystyrene pass only 0.035 W / m ° C.

Comparison with other materials

The average thermal conductivity of PSB lies in the range of 0.037-0.043 W / m ° C, and we will focus on it. Here, foam plastic, in comparison with mineral wool from basalt fibers, seems to win slightly - it has about the same performance. True, with twice the thickness (95-100 mm versus 50 mm for polystyrene). It is also customary to compare the conductivity of heaters with various building materials necessary for the construction of walls. Although this is not very correct, it is very clear:

1. Red ceramic brick has a heat transfer coefficient of 0.7W/m⋅°C (16-19 times that of foam). Simply put, in order to replace 50 mm of insulation, you will need masonry about 80-85 cm thick. Silicate and you need at least a meter at all.

2. Solid wood is better in this regard compared to brick - here it is only 0.12 W / m ° C, that is, three times higher than that of polystyrene foam. Depending on the quality of the forest and the method of building walls, a log house up to 23 cm wide can become the equivalent of a 5 cm thick PSB.

It is much more logical to compare styrenes not with mineral wool, brick or wood, but to consider closer materials - polystyrene foam and Penoplex. Both of them belong to expanded polystyrenes and are even made from the same granules. That's just the difference in the technology of their "gluing" gives unexpected results. The reason is that styrene balls for the production of Penoplex with the introduction of blowing agents are simultaneously processed by pressure and high temperature. As a result, the plastic mass acquires greater uniformity and strength, and air bubbles are evenly distributed in the body of the plate. Styrofoam, on the other hand, is simply steamed in a form like popcorn, so the bonds between the expanded granules are weaker.

As a result, the thermal conductivity of Penoplex, an extruded "relative" of PSB, also improves markedly. It corresponds to 0.028-0.034 W / m ° C, that is, 30 mm is enough to replace 40 mm of foam. However, the complexity of production also increases the cost of XPS, so you should not count on savings.By the way, there is one curious nuance here: usually extruded polystyrene foam loses a little in efficiency with increasing density. But with the introduction of graphite into Penoplex, this dependence practically disappears.

Prices for foam sheets 1000x1000 mm (rubles):

What you need to know about the thermal conductivity of foam

The ability of a material to transfer heat, to conduct or retain heat flows, is usually estimated by the coefficient of thermal conductivity. If you look at its dimension - W / m∙С o, then it becomes clear that this is a specific value, that is, determined for the following conditions:

- The absence of moisture on the surface of the plate, that is, the coefficient of thermal conductivity of the foam from the reference book, is a value determined in ideally dry conditions, which practically do not exist in nature, except perhaps in the desert or in Antarctica;

- The value of the thermal conductivity coefficient is reduced to a foam plastic thickness of 1 meter, which is very convenient for theory, but somehow not impressive for practical calculations;

- The results of measurements of thermal conductivity and heat transfer are made for normal conditions at a temperature of 20 ° C.

According to a simplified method, when calculating the thermal resistance of a foam insulation layer, it is necessary to multiply the thickness of the material by the thermal conductivity coefficient, then multiply or divide by several coefficients used in order to take into account the actual operating conditions of the thermal insulation. For example, strong watering of the material, or the presence of cold bridges, or the method of mounting on the walls of a building.

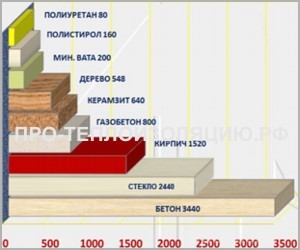

How the thermal conductivity of foam plastic differs from other materials can be seen in the comparison table below.

In fact, not everything is so simple. To determine the value of thermal conductivity, you can make it yourself or use a ready-made program for calculating the parameters of insulation. For a small object, this is usually done. A private trader or self-builder may not be interested in the thermal conductivity of the walls at all, but lay foam insulation with a margin of 50 mm, which will be quite enough for the most severe winters.

Large construction companies performing wall insulation on an area of tens of thousands of squares prefer to act more pragmatically. The performed calculation of the thickness of the insulation is used to draw up an estimate, and the actual values of thermal conductivity are obtained on a full-scale object. To do this, several foam sheets of different thicknesses are glued onto a wall section and the actual thermal resistance of the insulation is measured. As a result, it is possible to calculate the optimal thickness of the foam with an accuracy of several millimeters, instead of the approximate 100 mm of insulation, you can lay the exact value of 80 mm and save a considerable amount of money.

How beneficial is the use of foam in comparison with typical materials can be assessed from the diagram below.

Using thermal conductivity values in practice

The materials used in construction can be structural and heat-insulating.

There are a huge number of materials with thermal insulation properties.

The highest value of thermal conductivity is in structural materials that are used in the construction of floors, walls and ceilings. If you do not use raw materials with heat-insulating properties, then to save heat, you will need to install a thick layer of insulation for building walls.

Often simpler materials are used to insulate buildings.

Therefore, when building a building, it is worth using additional materials. In this case, the thermal conductivity of building materials is important, the table shows all the values.

In some cases, insulation from the outside is considered more effective.

What is the thermal conductivity of the foam Properties and characteristics

Thermal conductivity is a value denoting the amount of heat (energy) passing per hour through 1 m of any body at a certain temperature difference on one side and the other. It is measured and calculated for several reference operating conditions:

- At 25 ± 5 ° С - this is a standard indicator fixed in GOSTs and SNiP.

- "A" - this is how the dry and normal mode of humidity in the premises is indicated.

- "B" - this category includes all other conditions.

The actual thermal conductivity of foam plastic granules pressed into a lightweight board is not as important in itself as in conjunction with the thickness of the insulation. After all, the main goal is to achieve the optimal level of resistance of all layers of the wall in accordance with the requirements for a particular region. To get the initial numbers, it will be enough to use the simplest formula: R = p÷k.

- Heat transfer resistance R can be found in the special tables of SNiP 23-02-2003, for example, for Moscow they take 3.16 m ° C / W. And if the main wall, according to its characteristics, falls short of this value, it is the insulation (mineral wool or the same foam plastic) that should block the difference.

- The indicator p - indicates the desired thickness of the insulating layer, expressed in meters.

- The coefficient k - just gives an idea of the conductivity of bodies, which we focus on when choosing.

The thermal conductivity of the material itself is checked by heating one side of the sheet and measuring the amount of energy transferred by conduction to the opposite surface per unit time.

Features of the production of basalt wool and expanded polystyrene

The production of basalt wool is based on the melt of rocks of the gabbro-basalt group. The melt occurs in furnaces at temperatures above 1500 degrees. The resulting melt is converted into fine fibers, from which a mineral wool carpet is formed. Then the mineral wool carpet is treated with binders and heat treated in a polymerization chamber, resulting in finished products - mats and slabs.

Expanded polystyrene is a lightweight gas-filled material based on polystyrene, which is characterized by a uniform structure consisting of small (0.1-0.2 mm) completely closed cells. Today, the construction market offers two types of this material: ordinary and extruded polystyrene foam. The main difference between these two types of expanded polystyrene is the production technology, and, as a result, the properties of the finished product.

Ordinary expanded polystyrene is formed by sintering granules under the influence of high temperatures.

Extruded polystyrene foam is made by expanding and welding granules under the influence of hot steam or water (temperature 80-100 degrees) and then extruding through an extruder.

The main difference between extruded polystyrene foam and ordinary polystyrene foam is higher rigidity and lower water absorption. Another difference is due to the production technology - the limitation of the thickness of the plates (maximum 100 mm) made from extruded polystyrene foam.

Thermal conductivity of foam

The main characteristic due to which expanded polystyrene has been widely recognized as the No. 1 insulation material is the ultra-low thermal conductivity of the foam. The relatively low strength of the material is more than offset by such advantages as resistance to most aggressive compounds, low weight, non-toxicity and safety during operation. Good heat-insulating properties of polystyrene make it possible to equip the house with insulation at a relatively low price, while the durability of such insulation is designed for a period of at least 25 years of service.

The main types of insulation used to reduce heat loss

For carrying out thermal insulation measures of any kind, the following types of insulators are used:

- extruded polystyrene foam (XPS), refers to polystyrene derivatives (represented by various producing enterprises, has many brands);

- polystyrene, its production also involves the processing of polystyrene, but using a different technology (it has a sufficient number of manufacturers, the breakdown by brand is not clear, it is positioned as “polystyrene”).

- mineral or basalt wool, is fundamentally different from polystyrene products and is the main competitor of expanded polystyrenes (represented on the market of insulating products by a large number of manufacturers).

The number of manufacturing companies, both domestic and foreign, is measured in dozens. When choosing products, it is required to rely on the physical properties of each individual product.

Styrex or penoplex

Physical properties of styrex:

- density - 0.35-0.38 kg/m3;

- thermal conductivity - 0.027 W / m * K;

- moisture absorption, no more than - 0.2%;

- compressive strength - 0.25MPa;

- bending strength - 0.4-0.7;

- vapor permeability - 0.019-0.020 mg / h * m * Pa.

At large deltas of external and internal temperatures, the slightly lower thermal conductivity of Styrex makes this material more profitable, however, with an average difference of 0.003 W / m * K, this will be hardly noticeable.

The production of Styrex brand insulation is located in Ukraine.