Components of a brick chimney.

|

Pipe parts. A brick chimney consists of the following main parts: 1. Fluff 2. Chimney in the attic. 3. Otter. 4. Comm. |

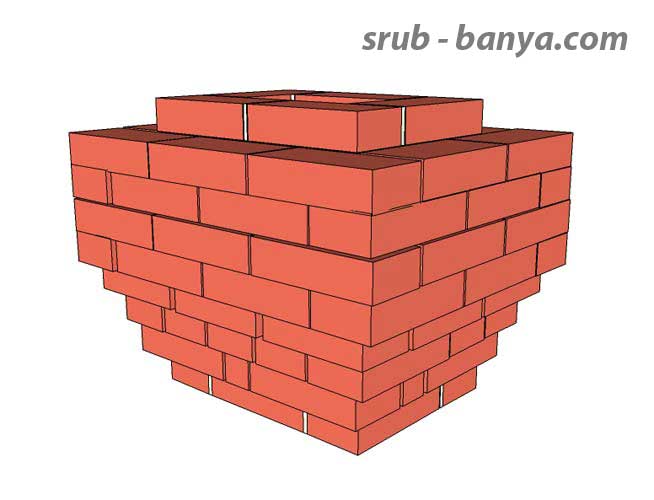

Fluff.

|

Fluff. The fluff is designed to provide fire safety All parts of the pipe that are above the fluff are placed on the (masonry) mortar. |

|

Fluff order. Fluff can be considered both part of the furnace and part of the chimney. I mention it here to show the fluff order. |

Chimney in the attic.

|

Chimney in the attic. Plastered chimney in the attic. Photo. An attic chimney is a pipe that runs through the attic. Placed on (masonry) mortar. In order to avoid the penetration of sparks through the lack of masonry density, the pipe in the attic must be plastered and covered with whitewash. I plastered the pipe with an outdoor stucco mix, to which I added 30% crushed stone wool. |

|

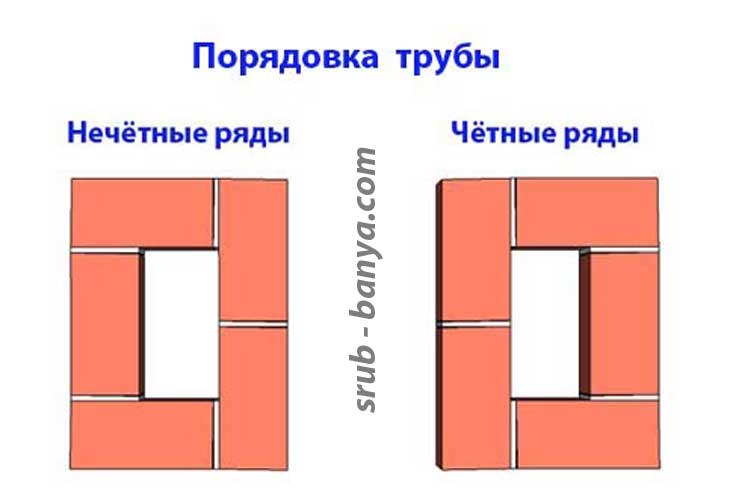

Chimney stacking. The ordering of the chimney consists of alternating two layers. |

Otter.

|

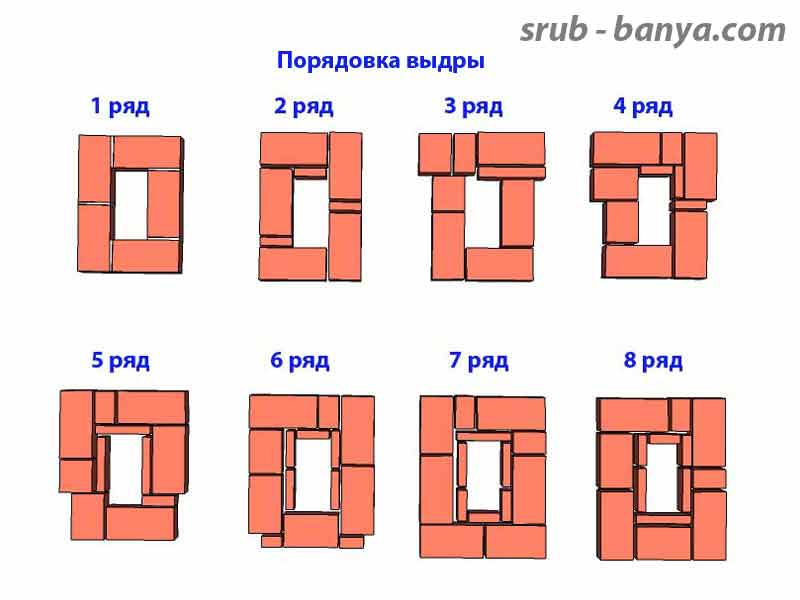

Otter.

Otter and comin. Photo. The otter is part of the chimney above the roof. It is a ledge from which precipitation water rolls onto the pipe collar without penetrating into the attic. The pipe collar is made of galvanized iron. |

|

Otter order. Otter order. |

|

Bevel on the otter to drain water. In order to prevent the protruding upper row of the otter from getting wet from precipitation, we perform a bevel for water drainage with masonry mortar. |

Komin.

Comin - part of the pipe above the otter.

The higher the pipe, the better the traction.

In accordance with the requirements for fire safety:

The elevation of the top of the chimney above the ridge of the roof must be at least 50 cm, with a distance of the chimney to the ridge of less than 3 m.

If the distance from the pipe to the roof ridge is more than 3 m, then the top of the pipe should be located in relation to the roof ridge at an angle of no more than 10 degrees to the horizon (See the diagram in the topic

fireproof oven).

The height of the comin is regulated by the number of rows of masonry.

In my case, 7 rows were enough to meet the height requirements.

|

The order of the top of the comin. The order of the top of the comin. |

|

Komin. The penultimate row of a quarter of a brick stands for the dimensions of the pipe. We make a bevel with cement mortar to give the top of the pipe the aerodynamic properties of the wing. The wind blowing from the side creates a rarefaction above the top of the pipe, which improves traction. |

As I said, the fluff lies on a clay-sand mortar. It is also desirable to lay the first two layers of the pipe above the fluff on a clay-sand mortar. This may be necessary if you have to hang a pipe to repair the furnace.

We put all other overlying layers on a cement - masonry mortar.

Advice for beginner bakers:

Don't bother with all kinds of round pipes and sandwiches - leave them to the metalheads. The brick chimney provides excellent draft, is very easy to join with the stove, and, with careful masonry and plastering, is absolutely fireproof.

Remember that if you use a pipe made of a different material with a brick oven, then the junction of the pipe and the oven will always be a source of increased fire danger!

It is much easier and faster to lay a chimney than a stove, since there is no brick grinding operation and only the inner channel needs to be smooth and even.

Types of paint

For a brick pipe, only heat-resistant or enamel coloring compositions are suitable, which, when properly applied to the surface, ensure the durability of the coating for 10 years.A variant is possible with the use of a special varnish, the protective decorative properties of which are less and amount to 3-4 years. Each type of coverage has pros and cons, for example:

How to choose?

For high-quality painting of a brick chimney, which should retain protective and decorative properties for a long time, it is necessary that paintwork materials meet the following requirements:

- They had a high level of adhesion (adhesion of surfaces of dissimilar solid and liquid bodies) - the coloring composition must be absorbed by the structure of the brick, providing protection from fluctuations in temperature and humidity.

- They were vapor and water permeable - they removed excess moisture from the surface, but at the same time they did not allow drying.

- They were resistant to ultraviolet rays - they retained their color for a long time, did not fade in the sun.

So, for example:

- The mass fraction of non-volatile substances should not exceed 17%.

- The optimal index of conditional viscosity at air temperature from 0 to +20 °C should be 36 s.

- Important points are the duration of drying, the interval in operating temperatures, the shelf life.

home remedies

The chimney can also be processed with self-made dyes. For example, a brick is ground into small crumbs, sieved in a sieve until a homogeneous mass is obtained. Then it is mixed with homemade milk, country milk and egg whites. The solution should be similar to liquid sour cream. It is applied with a wide brush, covered with drying oil on top or, if a shiny surface is needed, with varnish. Forms a heat-resistant and stable coating of brick color. To prevent the painted brick from getting dirty, it is recommended to apply a layer of whipped protein. This heat-resistant paint protects brickwork from moisture and dirt.

How to paint a brick chimney?

The quality and durability of the lacquer coating is greatly influenced by the appropriate surface preparation. The coloring composition should cover only the repaired areas put in order. First of all, old pipes are damaged. The reason is the effect of water, wind, time. In addition, the solution that holds them together becomes unusable.

Basically, only plaster is enough to treat the destroyed surface, but it may be necessary to restore the damaged masonry. Thus, the bolted connections on the clamps can loosen, since the chimneys are high-rise structures that are subject to vibrations. As a result, the barrel tilts and destruction is possible, to prevent which these connections must be tightened.

After restoring the brickwork, it is worth cleaning the outer surface of the pipe (damp, household sink) using special equipment, and sometimes manually, to remove dirt, soot, soot, and ash. Loose layers of paint are effectively cleaned off with a sandblaster or an acid solvent. The better this work is done, the smoother the new coating will lie and last longer.

The cleaned surface is covered with a primer. Coloring compositions are superimposed on top of it. To ensure saturation in color, stable and long-term preservation of the flooring, the paint must be applied twice. For structures such as a brick pipe, devices are used that can operate in high pressure mode, and rollers are also used. Paints and varnishes are applied by spraying onto the surface.

Paint selection

The choice of coloring composition primarily depends on what material the chimney is made of, because brick paint will not be able to fully protect the metal from adverse conditions. Therefore, before purchasing a paint and varnish product, you should carefully read its characteristics, find out for which materials it is intended. But there are uniform requirements for all paints and varnishes:

- Drying time.A very important parameter for outdoor work, because with a long drying time, the applied coating can be damaged by weather conditions.

- temperature range. It is necessary to take into account the approximate temperature of the gases passing through the pipes and the minimum temperature drop in the region.

- Conditional viscosity. The optimal indicator will be 36 conventional degrees.

- Validity. It is determined how long the protective qualities of the dye remain.

If all indicators are chosen correctly, then a dense heat- and moisture-resistant film is formed on the pipe surface, which will last for a long time.

Popular paints and varnishes have the following properties:

- resistance to degradation caused by oxidation;

- resistance to aggressive atmosphere;

- low surface tension;

- water repellency;

- corrosion resistance;

- heat resistance.

The term of maintenance-free operation increases up to 15 years due to these indicators. It is for this reason that paintwork materials are used to protect many objects:

- household and industrial heat exchangers;

- pipelines with superheated steam;

- chimneys;

- collectors.

All heat-resistant paints and varnishes in liquid form have increased toxicity, and when applying them, you need to use protective equipment (respirator, gloves and clothing covering the skin).

A good composition for strengthening the surface are organosilicon materials with high water-repellent properties, which also have good adhesion to various building materials.

To paint the outside of chimneys, the following coatings are suitable:

- The best option for priming the surface is gray enamel KO-8111, which has increased heat resistance.

- For bright signal coloring, OS-12-03, red and white paints are usually used.

Paint KO-8111 perfectly withstands temperatures up to 620 ° C, so it is often used when painting pipes of boiler houses and other industrial facilities. It is ideal for external anti-corrosion work on heating and water supply pipelines. This enamel is also used for painting steam pipelines and other technological pipes.

Enamel KO-8111 has good moisture resistance, and it is also resistant to temperature extremes. As the degree rises, the paint applied to the surface even becomes stronger.

For a bright signal painting of pipes, red and white paint is applied to a dried, primed surface. This composition is applied in two or three layers, and the paint layer is obtained with a thickness of 35-55 microns, at a consumption of 125-160 g/m2 per layer.

Silicone paint products are also considered a suitable material for painting. They have a lot of advantages:

- Synthetic polymers have high endurance and resistance to damage and abrasion.

- The use of this material guarantees increased durability of the coating, since silicone paints are unique in their heat resistance. They are able to endure long-term operation at temperatures up to 720 °C.

- This coating material has a low surface tension. It forms a coating that has high weather resistance as well as reduced dust and dirt retention.

These materials are painted:

- automobile mufflers, various parts of motors and even nozzles of jet engines;

- heat exchangers, collectors and pipelines;

- metal and brick pipes of furnaces in houses, saunas.

After the silicone paint dries, a very durable coating is formed. It is fire resistant and has many other protective properties.

Now there is an abundance of silicone paints and enamels for metal and brick pipes.

When choosing paintwork materials, it is important to understand their protective capabilities.

How to prepare clay mixes for kiln masonry

The mixture is used for construction inside the building.It cannot be used for chimneys on the roof. The optimal proportions are considered to be the following: the ratio of the shares of clay and sand as 1:1 or 1:2, and the volume of water as 1:4. In practice, everything determines the fat content of clay.

One of the tests is used to check the raw materials. For example: a kind of dough is kneaded from 500 g of clay and rolled into balls with a radius of 20–25 mm. The ball is placed between two dies and squeezed until cracks appear on the lump of clay. A ball of lean clay that falls apart even with slight pressure. From the poor - with a decrease in volume by ¼ or 1/5. Normal gives cracks when reduced to 1/3 of the diameter, and oily - at ½.

To obtain a solution with your own hands, take the following steps.

- Clay is laid on a flooring of boards with dimensions of 1.5 * 1.5 m. It is necessary to apply in layers and moisten with water.

- If you need to add sand, then it is laid in a layer on top of the wetted clay.

- As soon as the clay gets wet, it is mixed and raked into a ridge about 30 cm high. Then the ridge is cut into plates with the edge of a shovel, the edges and lumps are crushed. Then they are again collected in a ridge.

- Stirring is repeated 3–5 times until no clots remain in the resulting mixture. The finished solution slides off the iron shovel, but does not spread. A sample can be seen in the photo below.

How to prepare a lime mixture for a chimney

Lime mortar is required for roof structures. Its components are sand, water and lime paste. The latter is prepared by slaking lime.

- The preparation method depends on the quality of the lime. If quick-extinguishing lime is used, then in a special container a box - a quenching box, water is poured - 1/2 of the height, and then lime is added. When steam is formed, it is intensively mixed, and after quenching is completed, it is filtered through a sieve with mesh sizes of 5 * 5 mm.

- Medium extinguishing is poured into a box at 1/4 height and half filled with water, when steam appears, it is mixed. Water is added in small doses until complete extinction.

- Slow-extinguishing is poured into a box at 1/4 height and wetted with water. After the appearance of cracks, mixing begins with the gradual addition of water in small portions until the consistency of the mixture reaches the state of milk of lime.

- The substance is poured into the creative pits, where it is stored under a layer of earth of 50 cm. It is recommended to keep the substance before use for about a month.

- The resulting lime dough is filtered with their own hands through a sieve with smaller cells - 3 * 3 mm, and mixed with sand. If necessary, diluted with water.

The finished composition should be held on a wooden oar with a layer of 2–3 mm.

https://youtube.com/watch?v=tKemktKq940

The video takes a detailed look at the process of making mixes for roof chimneys.

Colored painted chimneys

The Specialist company offers to buy colored double-circuit chimneys (modular, insulated, sandwich chimneys). The outer pipe of such a chimney is painted in any color of your choice. In order for the new chimney to harmonize with the elements of the facade of your house and the surrounding landscape, our company offers to choose a color according to the RAL (Classic) standard samples, which includes more than 200 different shades:

The color coating is applied not only to pipes, but also to all other components of the chimney (tees, elbows, plugs, etc.), as well as fasteners, support, insulating and fire protection elements and other elements of the configuration of your chimney to achieve the perfect appearance finished product:

The coating of a colored chimney is a resistant polymer composition that performs all the tasks of protecting the structure from destructive atmospheric influences. It does not fade, does not emit toxic substances, does not become thinner, does not crumble, and retains its protective and aesthetic properties for many years, not inferior in terms of strength characteristics to external stainless steel pipes.

Painted sandwich pipes are suitable not only for the actual chimneys of heating systems, they are great for installing natural ventilation in a building (cottage, country house, utility house or bathhouse).Also, for natural ventilation, colored single-circuit pipes are offered, which will continue the chosen color scheme indoors or in places that do not require insulated elements.

Terms of production and assembly of colored chimneys are 7-14 days, depending on the workload of the line, the selected color, the seasonality of the order. When ordering chimneys before the main season (until June), you will receive a chimney in a shorter time.

We can also offer you delivery options and professional chimney installation. (For more details, call: +7 (916) 490-98-99).

The cost of colored sandwich chimneys largely depends on the material and thickness of the inner pipe, however, a colored sandwich is significantly cheaper than chimneys with an external stainless pipe, and differs from a sandwich with a galvanized outer pipe by less than 20%.

For more detailed prices for all products, see the full price list. Marking of colored chimneys in the price list - Ral or Ral p / o.

Thus, at a very affordable price, you get not only a reliable and durable chimney, but also the opportunity to additionally decorate your home, emphasizing its modernity and novelty.

Metal chimneys

The option is most often settled in buildings and boiler rooms, as it is relatively light. In production, the product is less common, since its cost is high, and the height of industrial pipes can be very significant.

metal chimney

- Painting of the chimney of the boiler room is carried out by climbers. For repair work, the product is equipped with brackets according to the norms, but given the height of the structure, only a specially trained person can paint. In the photo - the coloring of the chimney by climbers.

- Used for work compositions that can provide corrosion protection. Silicone coatings are most suitable for this. This option noticeably affects the overall repair estimate, but it withstands very high temperatures - from 330 to 700 C, is absolutely insensitive to moisture and the action of acids and alkalis. The coating is smooth, so it even has a dirt-repellent effect.

- Painting of metal chimneys is carried out in accordance with the GOST standards established for the boiler house or enterprises.

Painting an industrial chimney

Painting a concrete chimney

This structure consists of a galvanized or stainless steel inner tube and a thick concrete outer tube.

Brick-based steel chimney

Structures of this kind are usually found in industrial boiler houses, as they are designed for a monstrous load and a large volume of exhaust gases, as well as for a very complex and aggressive composition of the exhaust gas.

- Painting of concrete structures according to the norms of SNiP is also necessary, and is also carried out by climbers - here the height is usually very high.

- The estimate for painting a concrete pipe includes not only the actual work and the cost of the paint, but also the price of additional funds. Concrete is a complex material. After a long service life, its strength and hardness become uneven, the outer layer begins to exfoliate, so when painting, it is necessary to take into account the tendency of the material to deform.

- Heat-resistant enamels are used for coloring, the best option is organosilicon ones. However, primers must be included in the estimate here. This is a necessary element when working with concrete: the material is too porous, instead of providing good adhesion, the top layer simply absorbs the coloring composition, and this will lead to the need for re-painting, which means an increase in costs.

The norms for painting chimneys in accordance with GOST do not regulate the composition and amount of enamel. The only requirement is that it must be fireproof and heat resistant.

Stages of work

Having chosen what you can paint the pipe with, you should not immediately apply paint.It is necessary to carry out preparatory work and select the necessary materials. You may need:

- brush (if the pipe is large, you can use a roller);

- metal hard brush;

- acetone or other degreaser;

- primer;

- selected paint composition.

Further work will vary depending on what the chimney is made of. Chimneys are made from:

- metal;

- bricks;

- ceramics;

- reinforced concrete.

Before starting work, it is recommended, if possible, to stop the gas supply to the chimney and allow the pipe to cool down to ambient temperature. This will not only reduce injuries (the risk of getting burned on a hot surface) and the toxicity of the paint and varnish composition, but will also allow the dye to form a stronger film when it hardens.

metal surfaces

Pipes are made mainly of stainless steel and have recently become the most popular in private homes. They are installed not only on gas boilers and columns, but also mounted on stoves made of bricks. Stainless steel chimneys are durable and comfortable. Their main advantage is ease of installation. But before painting stainless steel, the surface must be prepared. To do this, do the following:

- clean the metal from traces of the old coating, dust and other contaminants with a metal brush;

- thoroughly washed and dried;

- treated with a degreaser;

- an anti-corrosion mixture is applied (if the soil contains anti-corrosion additives, then this step can be omitted);

- after drying, the chimney is covered with 2-3 layers of primer.

Once the primer is dry, you can start painting. Staining is carried out around the perimeter and starts from the top.

Corrosion protection is of great importance for the service life of the chimney. At high operating temperatures and aggressive environments, the protective paint layer must be resistant to these harmful factors. Therefore, painting chimneys is a must.

brick chimneys

Now brick is less popular, but until recently chimneys were mostly made of it. But how to paint a brick? First of all, the design must be prepared:

- tighten the loose bolts on the connecting clamps;

- remove old paint or lime;

- wash from soot, soot and dirt;

- restore the damaged layer of plaster (it is not necessary to change it completely, just apply the mixture to the damaged areas and wait for it to dry);

- apply a primer in at least 2 coats (more allowed).

After the primer dries, you can paint. Paint on a brick is recommended to be applied in 2 layers to ensure greater strength and color saturation.

Ceramic pipes

This is a construction novelty, consisting of a ceramic pipe, a layer of insulation and a foam concrete or metal finish. It is considered the most heat-saving.

The method of painting depends on what the insulating layer is covered with:

- foam concrete is processed using the same technology as brick;

- the metal is painted in accordance with the rules for painting the metal base described above.

When choosing dyes for ceramic pipes, heat resistance does not play a big role, because the insulation layer reduces the heating of the outer surface.

Reinforced concrete

In private houses, reinforced concrete structures are extremely rare, most likely, it will be an industrial pipeline passing through the site, delivering gas or water to the house. You will have to choose a color for it not to your liking, but in accordance with the requirements of the marking color.

The process of protection and finishing is carried out in exactly the same way as when processing and applying paints and varnishes to a metal chimney. The main thing is not to forget about anti-corrosion treatment and degreasing, because the continuity of the supplied utilities depends on the safety of the pipeline.

If the paint is selected in accordance with all requirements and all stages of processing are followed, then after the composition has dried, a durable non-toxic film will be obtained that will protect the structure for 5-15 years. The term of protection depends on atmospheric influences, the internal temperature of the chimney and on the quality of the acquired paint and varnish.