Battery connection methods

Batteries in such a design as a single-pipe heating system of a two-story house (a photo of such equipment is clearly shown on the page) can crash using any of the currently available technologies. The connection diagram is:

- Lower. In this case, the "supply" and "return" pipes are connected to the battery from below.

- Diagonal. With this scheme, the pipes are connected to the radiator from above and below from opposite sides.

- vertical. In this case, the trunk is connected at the top and bottom on one side.

In order for the air both in the rooms farthest and in the rooms closest to the boiler to warm up evenly, radiators are connected to the pipe, usually on the bypass. Thus, a simplified analogue of a two-pipe system is created. With a bypass, it is easy to adjust the amount of flow through the radiator.

Pipe laying methods

Along the perimeter of the house, the highways in such a system, both on the first floor and on the second floor, are usually carried out under the floor. Such a "hidden" system does not spoil the appearance of the premises. However, it should be borne in mind that with such a gasket, most likely, you will have to use the lower method of connecting radiators. And with this tie-in method, unfortunately, the batteries do not work at full capacity. The solution may be to use a bypass of a special design.

In this case, a metal-plastic segment of a length equal to the height of the battery is cut into the “supply” pipe in front of the radiator. Connection to the highway is made through it, in the upper part of the section. A short vertical segment is welded to the "return" pipe. The radiator joins it at the lowest point of the opposite section.

Underfloor heating speed

According to their characteristics, heating systems can be divided into two types:

- Water, where the function of the coolant is performed by water, antifreeze or ethylene glycol solutions;

- Electric, where carbon rods, electric cables or infrared film act as a coolant.

Each system has its own advantages and disadvantages. The heating time of such floors depends on the design of the heat carriers and the depth at which they are laid.

To heat one square meter of surface with a screed depth of 5 - 6 cm, an average of 1.5 - 2 hours is required.

Water floor heating rate

Water heated floor warms up for a long time. The heating time can be 20 - 30 hours, for the legs the temperature rise will be noticeable after about 5 hours. Most of the time and energy is spent on warming up the screed, which, on average, reaches a thickness of 5 cm. Only after it has been heated is heat released into the room. After switching off, the comfortable temperature of the surface and the room can be maintained throughout the day. As a rule, the total heating and cooling time depends on the thickness of the tie elements. A significant disadvantage of such a coolant is the complexity of installation.

Electric floor heating speed

Electric floors warm up quite quickly compared to water floors. Electric coolants heat up instantly. It takes them no more than 6-8 minutes. The rest of the time is occupied by uniform heating of the screeds around the entire perimeter of the room. The warm-up time to the set values takes on average from 12 to 24 hours, depending on the area of the surface, for the legs the effect will be noticeable after a couple of hours. When the power is turned off, the cable floor will be able to maintain the selected thermal regime for a long time. A thermostat is connected to the design, which, when the heat drops by 2 - 3 degrees, will automatically regulate the heating force.

Heating rate of infrared film and rod floors

Rod and film infrared floors are considered innovative and fastest in heating.Their peculiarity lies in the fact that heat transfer occurs due to direct radiation. Already in the first hours, a general increase in the air temperature in the room becomes noticeable. Heat transfer to the air occurs directly without excessive heating of the screeds and the main coating. In addition, such floors have the smallest thickness of screeds. After the first switching on, it takes 10 minutes for the elements to reach the nominal mode and start heating the room.

Since the human body temperature is 6 degrees higher, there is no significant effect at first. However, comfortable conditions for the legs appear already in the first hours of operation of the system.

Forced circulation heating system

The circulation of the coolant is carried out using a circulation pump. This solves the problem of low return temperature by adding hot water from the supply line. Also, more comfortable heating conditions are achieved, thanks to the possibility of adjusting the temperature in the heaters. However, there are also significant disadvantages:

- The chance of overheating increases if the room heaters are set to low heat consumption.

- In the absence of power supply, the circulation pump will no longer be able to perform its function, and therefore the movement of the coolant will stop. This can also lead to overheating.

For example, in order to reduce the risk of an emergency increase in temperature in the heating system, Trayan solid fuel pyrolysis heating boilers are equipped with external or built-in emergency heat exchangers.

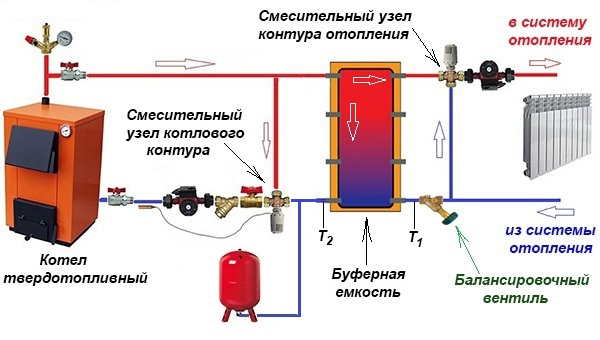

The inclusion of storage tanks in the piping scheme allows you to accumulate excess heat and, if necessary, give it to the heating system. This solves several problems:

- In case of low heat consumption, excess hot heat transfer fluid is stored for later use.

- With low heat consumption, the solid fuel boiler still operates at rated power.

- Allows you to use devices with higher power.

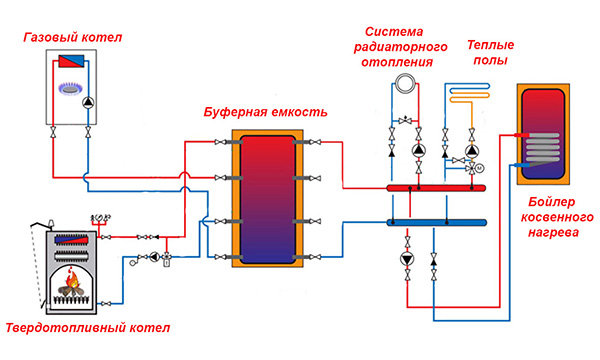

The figure shows the piping of a solid fuel boiler with a heat accumulator and a circulation pump:

Photo 4: Piping according to the forced circulation scheme

Photo 4: Piping according to the forced circulation scheme

Many owners of private houses designing a heating system are interested in the question, is it possible to tie a solid fuel boiler with polypropylene? The use of polypropylene pipes imposes certain requirements on the temperature of the coolant. When using polypropylene pipes in a heating system, experts advise that the first 1-1.5 meters of the supply line be made of metal, as well as use a larger pipe diameter and a thermostatic valve. Naturally, overheating of a solid fuel boiler should be avoided in every possible way.

When performing this type of piping, it should be borne in mind that the cost of additional equipment can be equal to and even exceed the cost of the solid fuel heating device itself. This is not suitable for those who decide to buy a TT boiler for home heating, focusing on its relatively low price.

Established standards for surface temperature of underfloor heating

In the reference book of Building Norms and Rules (SNiP), strict regulations are established on the account of what the floor temperature should be. According to paragraph 44-01-2003, the maximum and minimum temperature of the warm floor should be in the range of 26 and 35 ° C.

The minimum point of 26°C should only be set if the room is permanently occupied. If visitors rarely enter the room, then the optimum temperature should be at around 31 ° C. This value is usually set for bathrooms, pools and bathrooms, where a comfortable temperature for the feet is most needed. The main limitation is that the temperature along the heating axes should not exceed the allowable 35 ° C, a higher temperature will cause unwanted overheating of the system and flooring.

For a parquet surface, the maximum value is 27 °C. This is due to the characteristics of the material and its thermal properties, overheating of such a floor covering can lead to its deformation.

For a comfortable stay in the room, 22-24 ° C is enough. This temperature is pleasant for the feet and evenly heats the air in the room. Unlike classic batteries, the air temperature will be maximum over the entire height of the site. In practice, a coolant value of 30 °C is rarely achieved.

As a rule, all parameters are calculated at the stage of designing a heated surface. Before installing water and electric heating systems, their tasks and indicators of heat loss in the room should be taken into account.

Joint connection of two boilers

To increase the comfort of heating a private house, many owners install two or more heat sources that operate on different energy carriers. At the moment, the most relevant combinations of boilers are for:

- natural gas and firewood;

- solid fuel and electricity.

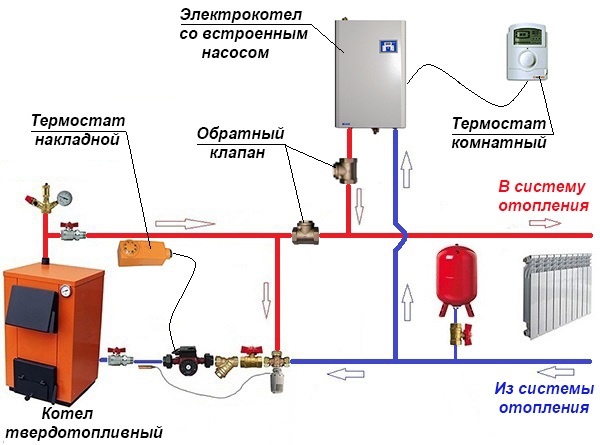

Accordingly, a gas and solid fuel boiler must be connected in such a way that the second one automatically replaces the first one after burning the next portion of firewood. The same requirements are put forward for piping an electric boiler with wood burning. This is quite simple to do when a buffer tank is involved in the piping scheme, since it simultaneously plays the role of a hydraulic gun, which is shown in the figure.

As you can see, due to the presence of an intermediate storage tank, 2 different boilers can serve several heating distribution circuits at once - batteries and underfloor heating, and in addition load an indirect heating boiler. But not everyone puts a heat accumulator with a TT boiler, since this is not a cheap pleasure. In this case, there is a simple scheme, and you can mount it yourself:

Note. The scheme is valid for both electric and gas heat generators operating together with solid fuel.

Here the main source of heat is a wood-burning heater. After the firewood load burns out, the air temperature in the house begins to fall, which registers the room thermostat sensor and immediately turns on the heating with an electric boiler. Without a new load of firewood, the temperature in the supply pipe decreases and the overhead mechanical thermostat turns off the pump of the solid fuel unit. If after some time it is ignited, then everything will happen in the reverse order. Details about this method of joint connection are described in the video:

Tying with the method of primary and secondary rings

There is another way to jointly tie a solid fuel boiler with an electric one to provide a large number of consumers. This is a method of primary and secondary circulation rings, which provides for hydraulic separation of flows, but without the use of a hydraulic arrow. Also, for reliable operation of the system, a minimum of electronics is required, and the controller is not needed at all, despite the apparent complexity of the circuit:

Theoretically, any number of heat sources and secondary rings can be included in the main circuit. The main thing is to choose the right pipe diameters and the performance of pumping units. The actual performance of the main ring pump must exceed the flow in the most "gluttonous" secondary circuit.

To achieve this, it is necessary to perform a hydraulic calculation and only then will it be possible to choose the right pumps, so an ordinary homeowner cannot do without the help of specialists.In addition, it is necessary to link the operation of solid fuel and electric boilers by installing shut-off thermostats, as described in the following video:

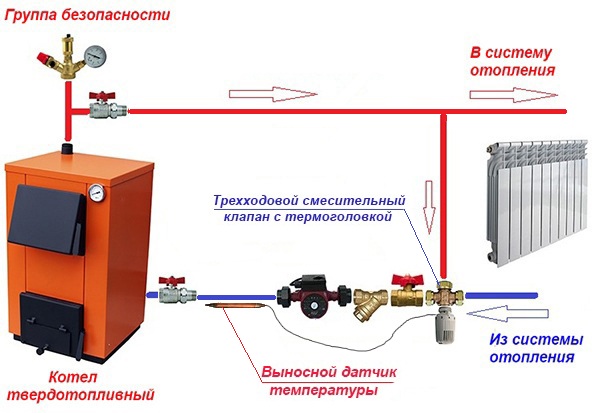

How to connect a solid fuel boiler

The canonical scheme for connecting a solid fuel boiler contains two main elements that allow it to function reliably in the heating system of a private house. This is a safety group and a mixing unit based on a three-way valve with a thermal head and a temperature sensor, shown in the figure:

Note. The expansion tank is conventionally not shown here, since it can be located in different places in different heating systems.

The presented diagram shows how to connect the unit correctly and should always accompany any solid fuel boiler, preferably even a pellet one. You can find various general heating schemes anywhere - with a heat accumulator, an indirect heating boiler or a hydraulic arrow, on which this unit is not shown, but it must be there. More about this in the video:

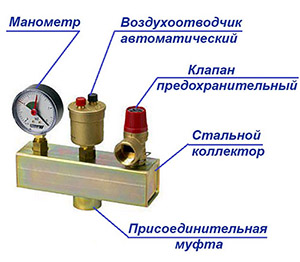

The task of the safety group, installed directly at the outlet of the solid fuel boiler inlet pipe, is to automatically relieve the pressure in the network when it rises above the set value (usually 3 bar). This is done by a safety valve, and in addition to it, the element is equipped with an automatic air vent and a pressure gauge. The first releases the air that appears in the coolant, the second serves to control pressure.

Attention! On the section of the pipeline between the safety group and the boiler, it is not allowed to install any shut-off valves

How the scheme works

The mixing unit, which protects the heat generator from condensate and temperature extremes, operates according to the following algorithm, starting from kindling:

- Firewood is just flaring up, the pump is on, the valve on the side of the heating system is closed. The coolant circulates in a small circle through the bypass.

- When the temperature in the return pipeline rises to 50-55 °C, where the external sensor is located, the thermal head, at its command, begins to press the three-way valve stem.

- The valve slowly opens and cold water gradually enters the boiler, mixing with hot water from the bypass.

- As all the radiators warm up, the overall temperature rises and then the valve closes the bypass completely, passing all the coolant through the unit heat exchanger.

This piping scheme is the simplest and most reliable, you can safely install it yourself and thus ensure the safe operation of the solid fuel boiler. Regarding this, there are a couple of recommendations, especially when tying a wood-burning heater in a private house with polypropylene or other polymer pipes:

- Make a section of the pipe from the boiler to the safety group from metal, and then lay plastic.

- Thick-walled polypropylene does not conduct heat well, which is why the overhead sensor will frankly lie, and the three-way valve will be late. For the unit to work correctly, the area between the pump and the heat generator, where the copper bulb stands, must also be metal.

Another point is the installation location of the circulation pump. It is best for him to stand where he is shown in the diagram - on the return line in front of the wood-burning boiler. In general, you can put the pump on the supply, but remember what was said above: in an emergency, steam may appear in the supply pipe. The pump cannot pump gases, therefore, if steam enters it, the circulation of the coolant will stop. This will accelerate the possible explosion of the boiler, because it will not be cooled by the water flowing from the return.

Way to reduce the cost of strapping

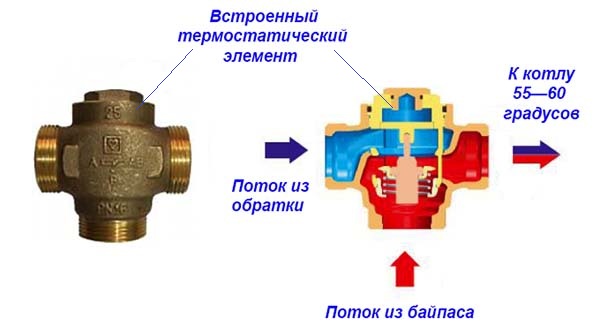

The condensate protection scheme can be reduced in cost by installing a three-way mixing valve of a simplified design that does not require the connection of an attached temperature sensor and a thermal head.A thermostatic element is already installed in it, set to a fixed mixture temperature of 55 or 60 ° C, as shown in the figure:

Special 3-way valve for solid fuel heating units HERZ-Teplomix

Note. Similar valves that maintain a fixed temperature of the mixed water at the outlet and are designed for installation in the primary circuit of a solid fuel boiler are produced by many well-known brands - Herz Armaturen, Danfoss, Regulus and others.

The installation of such an element definitely allows you to save on piping a TT boiler. But at the same time, the possibility of changing the temperature of the coolant with the help of a thermal head is lost, and its deviation at the outlet can reach 1–2 °C. In most cases, these shortcomings are not significant.

Heating a house without a pump. Two proven options

Until the 90s of the last century, heating a house without a pump was the only one available, since the direction for the manufacture of circulation pumps and their promotion to the masses was not developed. Thus, the owners and developers of private houses were forced to install heating in their houses without a pump.

But when good boiler equipment, pipes and compact circulation pumps began to be brought to the CIS in the 90s, the situation changed dramatically. Everyone started installing heating systems. which do not work without a pump. They began to forget about gravity systems. But today the situation is changing. Developers of private houses again recall the heating of the house without pumps. Since everywhere you can trace interruptions and shortages of electricity, which is so necessary for the operation of the circulation pump.

The issue of quality and quantity of electricity supply is especially acute in new buildings.

That is why today, more than ever, one proverb is remembered: “Everything new is a well-forgotten old!”. This proverb is very relevant today, for heating a house without a pump.

For example, in the past, only steel pipes, homemade boilers and open expansion tanks were used for heating. The boilers were of low efficiency, the pipes were bulky steel, and it is not recommended to hide them in the walls.

Expansion tanks were located in attics. because of this, there were heat losses and the threat of a flood of the roof or freezing of the pipes in the tank. Which in turn often led to an explosion of the boiler, rupture of pipes and human casualties.

Today, thanks to modern boilers, pipes and other heating devices, it is possible to make a smart, economical heating system without a pump. Thanks to modern economical boilers, significant savings can be achieved.

Modern plastic or copper pipes can be easily hidden in walls. The same heating of the house today can be done, both with radiators and with warm floors.

Today, there are two main home heating systems without a pump.

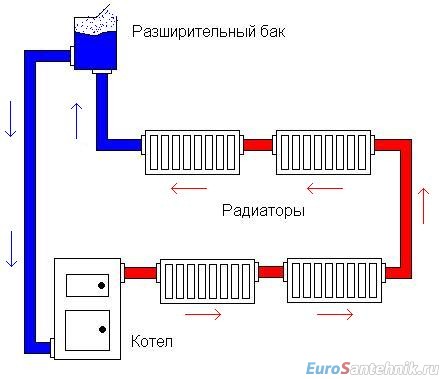

The first and most common system is called Leningradka. or with horizontal spill.

The main thing in home heating systems without a pump is the slope of the pipes. Without a slope, the system will not work. Due to the slope, "Leningradka" is not always suitable, since the pipes run around the entire perimeter of the house. Also, due to the fact that the slope may not be enough, you have to lower the boiler below the level of your floor. The boiler in this case is inconvenient to heat and clean.

Also, when installing a heating system at home without a Leningradka pump, doorways interfere along the route of the pipes. In this case, it is necessary to make window sills with a height of at least 900mm.

This is necessary so that the radiator is mounted and there is enough height for the pipes along the slope. Otherwise, the system is fully functional, with cast iron, steel and aluminum radiators.

The second home heating system without a pump is called the "Spider" or vertical top-spill system.

Today it is the most reliable and practical home heating system without a pump.The main thing is that the "Spider" system is devoid of all the shortcomings of "Leningradka", with the exception of the slope of the return line, due to which the boiler also has to be lowered below the floor.

Otherwise, the Spider system is the most efficient system. Any radiators and underfloor heating can be screwed to the Spider system. It is possible to mount valves under the thermal head on radiators in the “Spider” system and hide pipes in the walls and so on.

Today, it is increasingly necessary to recommend the Spider system to developers, because. today it is an ideal home heating system without a pump.

Thank you for reading this article!

Mounting order

A single-pipe system is assembled as follows:

- In the utility room, the boiler is installed on the floor or hung on the wall. With the help of gas equipment, the most reliable and efficient one-pipe heating system for a two-story house can be arranged. The connection scheme in this case will be standard and will allow you to do all the work, if desired, even on your own.

- Heating radiators are hung on the walls.

- At the next stage, the “supply” and “reverse” risers are mounted to the second floor. They are located in the immediate vicinity of the boiler. At the bottom, the contour of the first floor joins the risers, at the top - the second.

- Next is the connection to the battery lines. A shut-off valve (on the inlet section of the bypass) and a Mayevsky valve should be installed on each radiator.

- In the immediate vicinity of the boiler, an expansion tank is mounted on the "return" pipe.

- Also on the "return" pipe near the boiler on the bypass with three taps, a circulation pump is connected. A special filter cuts in front of it on the bypass.

At the final stage, the system is pressure tested in order to identify equipment malfunctions and leaks.

As you can see, the single-pipe heating system of a two-story house, the scheme of which is as simple as possible, can be very convenient and practical equipment.

However, if you want to use such a simple design, at the first stage it is important to make all the necessary calculations with maximum accuracy.

13 Signs You Have the Best Husband Husbands are truly great people. What a pity that good spouses do not grow on trees. If your significant other does these 13 things, then you can.

11 Weird Signs That You're Good in Bed Do you also want to believe that you're giving your romantic partner pleasure in bed? At least you don't want to blush and apologize.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don't worry about the shape and length of their hair. It seems that youth was created for experiments on appearance and bold curls. However, already

What is it like to be a virgin at 30? What, I wonder, women who did not have sex until almost reaching middle age.

Why do you need a tiny pocket on jeans? Everyone knows that there is a tiny pocket on jeans, but few have thought about why it might be needed. Interestingly, it was originally a place for Mt.

Never do this in a church! If you're not sure if you're doing the right thing in church or not, then you're probably not doing the right thing. Here is a list of the terrible ones.

Underfloor heating temperature control

To create comfortable conditions, as well as to control the consumption of electricity and other resources, users resort to adjusting the temperature of underfloor heating.

Adjustment of water floors

On water systems, a thermostatic valve or pump-mixing groups with automatic equipment are usually installed.

They prevent overheating of the system and flooring, react to changes in room temperature and open or close valves, maintaining the set modes.

The advantage of such regulators is the simplicity and ease of assembly of the structure.

Regulation of electric and infrared floors

For electric floors, electromechanical, digital and programmable thermostats are used. They are connected in parallel in a circuit and use special sensors that analyze changes in surface heating modes. When the maximum set heating thresholds are reached, they turn off the heat carriers. When the temperature drops a couple of degrees, they again supply power to the electric heaters. Such thermostats allow you to save from 30 to 60% of electricity, significantly reducing the cost of utility bills.

And why "should be 45 ... 55"? And if I heat the house with warm floors and walls? - at 55, you can already boil the eggs (in the crush). What if I have very small (skirting) radiators? - at 45 you will freeze even now.

"45 ... 55" - ordinary stereotypes of thinking, based on the usual scheme of radiators such as "1 knee per 2 m2".

Less is better. However, it will be completely “0” only if there is no heat transfer (heating) at all. The pump can be switched to mode 2 or even 1.

A delta of 20 degrees is considered ideal. But if there is no such delta, and the batteries are hot, then this is also not bad. This means that the battery power is less than the boiler power. And the uncooled water is returned back to the boiler. So in your case, the boiler will turn on less often (hot water comes to it anyway). You can reduce the flow rate. Then the delta will be higher, but the boiler will turn on more often. Strictly speaking, if we neglect the heat losses in the pipes, the efficiency of the system will not change. How much energy the boiler will gobble up, the temperature in the house will rise by that much. What's so what's that.

I have a solid fuel, it does not turn off and will not turn on either)))

Hand kmk less than 20 degrees.

Well, this is when it goes out. Although I can set the electric boiler to 65 degrees. Will warm up

And by the way, why is it not recommended, where to go when it is already completely burned out, turn off the supply to it and wait until it boils.

And below - condensate, and it is very furious near the firewood (sulfur, and as a result, sulfuric acid). Accelerated corrosion of the heat exchanger. For cast iron, it's not so scary. And steel can “eat up” in a season or two (there were posts on SOK). When it has already burned out - no problems - there is no more condensate. But at the stage of kindling - well, it can be a very long time - the boiler itself is cold + the return line is cold. That is why they make protection against cold return in the form of a controlled bypass directly on the boiler piping. It works very simply: until the return temperature reaches +65°C, the water circulates in a small circle (almost like a thermostat in a car). Some manufacturers build a bypass directly into the boiler.

Data. Solid fuel boiler 25 kW on coal. I think lower on wood.

The heated area is 100 sq.m., no insulation of 15 cm of timber; floors and ceilings, though 20 cm of cotton wool each)), not caulked. There are 8 convectors with a total capacity of approximately 12 kW. And the boiler is on. But the DHW is not consumed much, so it does not particularly participate in the calculation (I turn it off altogether when the boiler has cooled down, the boiler cools down too (( )

And I would not say that it is very warm in my large rooms. In the bathroom and in the bedroom do not breathe. But in the hall and the kitchen is so-so, 20 degrees, but I would like 25)) But all the approaches to the convectors are hot.

PS there are suspicions that this heats badly in general.

In the apartment, I would have thrown it out))) but in the country there are 15 of them. It’s unprofitable, but these are quite inexpensive.

Maybe replace it with cast iron, or leave it as is for now.

Something cheap for anyone. I have an average of 1 radiator costs 5 thousand. In total, there are 2 pieces, plus thermal heads and connection, and Td and TP)))

I know Denis, but what's the point, he won't make a 70% discount))))

Steam heating

Heating with a membrane tank

Sometimes steam heating is associated with water-based space heating structures. And here, in fact, there is no mistake, but there is one caveat: steam is water heated to a boil.

Thus, the principle of operation of a steam heating system is that the water in the boiler is heated until steam is formed, and then this coolant enters the heating elements through pipes.

Heating system with coolant in the form of steam, consists of the following structural elements:

- a heat generator, presented in the form of a boiler, which heats water and accumulates steam;

- an exhaust valve that controls the flow of steam into the system;

- main pipes;

- heating radiators.

It is important to know: when installing a steam heating structure, it is strictly forbidden to use plastic pipes. As for the classification of steam heating, it is absolutely similar to water heating heating systems.

As for the classification of steam heating, it is absolutely similar to water heating heating systems.

Binding option with buffer tank

The presence of a buffer tank is highly desirable for the operation of the boiler on solid fuels, and here's why. In order for the unit to function efficiently and produce heat with the efficiency stated in the passport (from 75 to 85% for different types), it must operate at maximum mode. When the air damper is closed in order to slow down combustion, there is a lack of oxygen in the furnace and the efficiency of burning wood decreases. At the same time, emissions of carbon monoxide (CO) into the atmosphere increase.

For reference. It is precisely because of emissions that in most European countries it is forbidden to operate solid fuel boilers without a buffer tank.

On the other hand, with maximum combustion, the temperature of the coolant in modern heat generators reaches 85 ° C, and one laying of firewood lasts only 4 hours. This does not suit many owners of private houses. The solution to the problem is to put a buffer tank and include it in the piping of the TT boiler so that it serves as a storage tank. Schematically it looks like this:

By measuring the temperature T1 and T2, you can adjust the layer-by-layer loading of the tank with a balancing valve

When the firebox burns with might and main, the buffer tank accumulates heat (in technical terms, it is loaded), and after attenuation it releases it to the heating system. To control the temperature of the coolant supplied to the radiators, on the other side of the storage tank, a three-way mixing valve and a second pump are also installed. Now it is not at all necessary to run to the boiler every 4 hours, because after the attenuation of the firebox, the buffer capacity will provide heating for the house for some time. How long - depends on its volume and heating temperature.

For reference. Based on practical experience, the capacity of a heat accumulator can be determined as follows: a private house with an area of 200 m² will need a tank with a volume of at least 1 m³.

There are a couple of important nuances. In order for the piping scheme to work safely, a solid fuel boiler is needed, whose power is enough for simultaneous heating and loading of the buffer tank. So, you need power 2 times higher than the calculated one. Another point is the selection of pump performance in such a way that the flow rate in the boiler circuit slightly exceeds the amount of water flowing in the heating circuit.

An interesting option for docking a TT boiler with a self-made buffer tank (aka an indirect heating boiler) without a pump was demonstrated by our expert in a video: