Termite.

Comrades, I noticed here that on most real objects, Thermite is needed to @#$%^&^%$#@#$%^ and so on .. Well, here's a little reference on it for you:

Thermite mixture (termite) (chem., tech.) (from the Greek therme - heat, heat) - a powdered mixture of aluminum (less often magnesium) with oxides of various metals (usually iron).

When ignited, it burns intensively with the release of a large amount of heat (it has a combustion temperature of 2300-2700 ° C). The mixture is set on fire with a special fuse (a mixture of BaO2, Mg, Na). The quantitative ratio of the components of the mixture is determined by the stoichiometric ratio. The most common iron-aluminum thermite (containing calcined scale or rich iron ore) is used for welding rails and for casting large parts. The ignition temperature of such thermite is about 1300 °C (priming mixture 800 °C); the resulting iron and slag are heated up to 2400 °C. Sometimes iron cut, alloying additives and fluxes are introduced into the composition of iron thermite. The process is carried out in a magnesite crucible. Thermites are available for welding telephone and telegraph wires, as well as wires for power lines. In military technology, thermite is used as an incendiary composition. In the production of ferroalloys, thermite with the addition of fluxes is called charge.

If you can buy buy it. I bought it under the name soldering rod.

But many complain that it is simply not on sale and do it themselves:

The basis of a home-made "electrode" is a piece of wire made of ordinary carbon steel of the lowest quality (carbon content is less than 0.22%). The wire diameter (2-5 mm) depends on the thickness of the parts to be welded. Thermite itself consists of 23% aluminum filings (silumin is not suitable!) And 77% iron scale, the particle size of which should not exceed 0.5 mm. Aluminum files are completely replaced by aluminum powder to obtain silver paint. Scale and sawdust (powder) are bound with glue (BF-2, "Moment"). On one side of the thermite pencil, a seed is applied that acts as sulfur on ordinary matches. It consists of 2 parts of Bertolet salt (KClO3) and 1 part of fine aluminum filings (parts are taken by weight). The binder for Bertolet salt and aluminum filings is the same as for electrode thermite. To form a thermite pencil, all three components - scale, sawdust and glue - are mixed well in a glass or earthenware bowl, after which the resulting creamy mass is evenly applied to the prepared piece of wire with an ordinary stick or the wire is rotated over the dishes, gradually “winding” the thermite composition on it . here's the termite.

Interior designs

Functional and beautiful shelves, racks, tables, racks and other interior elements are easy to make from construction board THERMIT SP. This material is easy to process and install, weighs little and is highly durable.

Plate surface THERMIT SP can be painted, plastered, glued mosaic, tile. Unlike drywall or MDF, which are traditionally used in the interior for the manufacture of structural elements, building boards THERMIT SP have absolute moisture resistance, which allows them to be used in wet rooms. And the installation of structures does not require a frame, due to the rigidity of the plates.

Building boards can be easily rounded by making notches along the radius of the rounding. Ease of processing and installation allows you to build a design of unique complexity in a dry repair, without the use of complex tools and expensive building materials.

From building boards THERMIT SP can be made:

- Shelves

- Cabinets

- Shelving

- Racks

- Exhibition stands

- steps

- box

- columns

- tables

Between building boards THERMIT SP are glued together with glue or silicone sealant, and for fixing to the wall, glue and additional fixing with dowels with a pressure disk are required.

Finishing window and door slopes

Sandwich panels coated with PVC sheet or paper laminate are most widely used for finishing slopes when installing PVC windows (“double-glazed windows”). Most often, the white color of the coating is used, however, in the design of a modern interior, it is possible to use a color coating, drawing, silk-screen printing, film stickers.

Finishing window and door slopes with sandwich panels THERMIT SP coated with PVC sheet prevents freezing of slopes, thanks to the heat-insulating properties of the filler (extruded polystyrene foam), it is free from the risk of mold and condensate. The surface is hygienic and aesthetic, it is very easy to clean. Application of sandwich panels THERMIT SP facilitates installation: the panels are light, they are easy to process and adjust to size, there is practically no waste left, no additional finishing is required.

Application of sandwich panels THERMIT SP With an extruded polystyrene core and a PVC sheet covering, it meets all the requirements of indoor hygiene. Sandwich panels THERMIT SP widely demanded due to ease of processing and durability.

Thermal insulation of a pitched roof

Insulating a pitched roof saves on the heating of the entire building, especially if the space under the roof is used as a living space (mansard roofs). At the same time, in summer, thermal insulation made of extruded polystyrene foam THERMIT XPS keeps under a roof a coolness, protecting internal rooms from heating from a roof, hot under the sun.

On a pitched roof, wooden rafters with high thermal conductivity are "cold bridges" and lead to significant heat loss. Therefore, extruded polystyrene foam boards THERMIT XPS it is best to lay in a continuous layer on top of the rafters for new construction or major repairs of the old roof. Only if this method is technically impossible, extruded polystyrene foam boards THERMIT XPS laid between the rafters, taking plates of greater thickness.

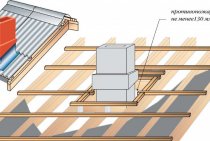

Installation of heat-insulating plates THERMIT XPS over the rafters

1. Inner lining; 2. Rafter; 3. Rail-limiter; 4.THERMIT XPS; 5. Vapor barrier; 6. Lath of the counter-lattice; 7. Lathing batten for fixing roofing material; 8. Roofing material.

Description of the installation sequence

- Install pitched roof rafters. The pitch of the rafters is 600–1200 mm, the section is 50 * 150 mm, or other calculated values.

- At the bottom of the roof, a limiter rail is attached to prevent the plates from THERMIT XPS slide down.

- Plates THERMIT XPS laid on top of the rafters in a checkerboard pattern, starting from the limiter rail.

- A vapor barrier layer is laid on top of the plates, and then fixed with longitudinal rails on nails or self-tapping screws every 30 cm. The height of the rail must be at least 4 cm to ensure ventilation. It is recommended to make holes in each rail so that the rail does not crack.

- On top of the longitudinal rails, transverse (for fixing tiles) or solid flooring from OSB or boards (for mounting rolled roofing materials) are attached.

Insulation of a pitched roof under the rafters

1. Roofing material. 2. Lath battens. 3. Lath of the counter-lattice. 4. Rafter. 5.THERMIT XPS. 6. Vapor barrier. 7. Rail for fastening the skin. 8. Inner lining material

In recent years, low-rise houses with attics have been in demand, and old houses are built on attic floors. For effective insulation of the attic or attic when turning them into a living space, it is recommended to mount plates THERMIT XPS under the rafters over the entire surface. In this case, it is necessary to ensure good ventilation of the room.

If the attic or attic is not heated, then a competent solution for insulating a pitched roof is thermal insulation not of the roof slope, but of the uppermost floor. Otherwise, through an unheated attic, heat will leave the building, and this is a waste of energy.

Construction of an insulated blind area

The blind area is a horizontal waterproof strip along the perimeter of the outer walls of the house, designed to protect the foundation from rain and flood waters and perform a decorative function.

In addition to protection from water, the blind area serves to insulate the foundation and basements. To do this, it is based on plates of extruded polystyrene foam. THERMIT XPS. The insulated blind area is an aesthetic option for warming the soil around the foundation, and also performs a moisture-proof function. Such a blind area will last a long time without cracks at the junction with the building, caused by frost heaving of the soil.

The thermal insulation layer under the blind area is laid at a depth of 20-30 cm with a slight slope from the structure. Width at least 1 meter. Such a blind area device will additionally divert groundwater from the base.