Spring tube benders for bending copper pipes

The design of spring devices is extremely simple. The active element in them is a very strong steel spring with coils that fit snugly together. The stiffness of the spring will prevent the copper pipe from slipping off, deforming or breaking inside the equipment. When the pipe is bent at a certain angle, the steel spring will turn out, moving to another free place.

The main condition that ensures even bending is the correspondence between the dimensions of the spring and the pipe.

The main advantages that a spring manual pipe bender has:

The tool is lightweight and versatile.

They can work in confined spaces. If you want to change the path of a part of the pipeline, it is not necessary to dismantle the part of the system in order to transport it to the machine. The spring pipe bender will be able to mold the part on the workbench. The spring manual pipe bender can give any shape to the copper pipe without restrictions, while keeping the product from bending into an acute angle. The device molds the pipeline elements very gently.

Disadvantages of spring pipe benders:

- It is convenient to work with this device only for short pipeline lengths. There are no marks with degrees, bending is done “by eye”.

With a spring of suitable diameter, the copper pipe can be bent quickly and without damage.

Manual lever pipe bender for copper pipes

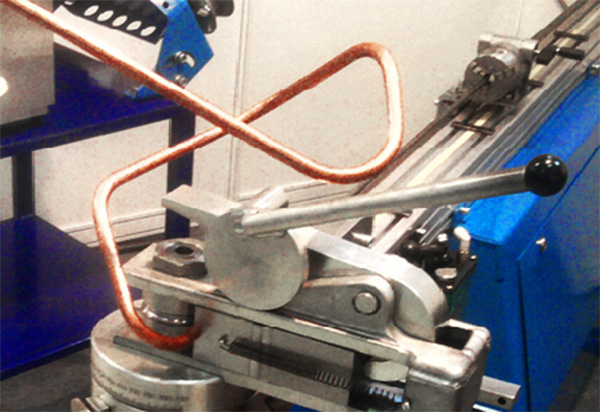

The next type of tool, a lever pipe bender for copper pipes, has two levers in its design. On one of them there is a shoe, and the second is equipped with a bending template. Both levers have bending marks, thanks to which the bending angle can be adjusted.

To place the pipe in the lever tool, it is necessary to move the handles apart.

After making sure that the pipe lies exactly in the grooves of the template, it should be fixed with a bracket. The lever with the shoe is laid so that the zero marks on it and on the template coincide. With a smooth movement, the lever turns to the desired bending angle.

Benefits of Lever Copper Pipe Bender:

- Light weight, compact and affordable price. Allows you to bend a copper product without much physical effort. The maximum bending angle is 180 degrees, which is quite enough for domestic needs.

Disadvantages of a lever pipe bender:

- A manual pipe bender is useless when working with large-sized products. The tool cannot be used to bend pipes of other diameters.

How to make a pipe bender yourself

If necessary, you can make an effective manual pipe bender with your own hands.

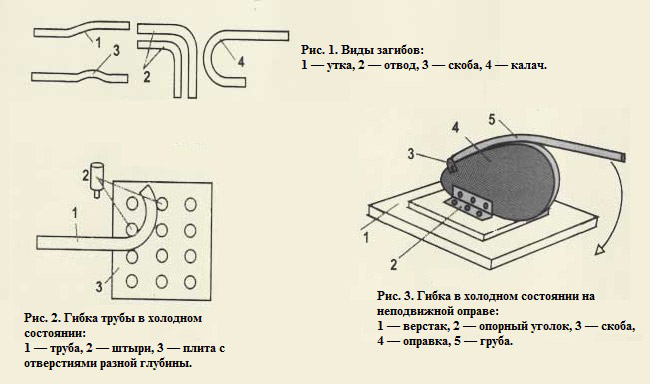

The simplest device is easy to manufacture on the basis of a concrete slab. Additionally, you only need a puncher and a certain number of steel pins. On the plate, markings are made in the form of a grid with cells of 4x4 or 5x5 cm. Deep holes are drilled in the nodes of the grid, after which the pins are fixed in them. Pipe bender is ready.

Next, the copper pipe is placed between the pins and gently bent in the desired direction. By moving the product between the pins, you can change the bending radius.

The next device is structurally more complicated and already looks like a real pipe bender. First of all, a base is made, for which a strong rectangular iron pipe with a wall thickness of at least 3 mm is best suited. Stepping back from one edge 2-3 cm, a hole is made. Its diameter must match the size of the main pulley.

To calculate the length of the base, it is necessary to determine the maximum bend radius that the pipe bender will be capable of, and add 5 cm to this indicator. We cut off the excess part of the pipe. The stopper for bendable pipes will be made in the form of a hairpin. At one end there will be a nut, at the other - a T-shaped element.

Next, we proceed to the manufacture of the pipe bender handle. For this, iron plates with a thickness of 4 mm or more are perfect.The width of the plates must match the dimensions of the base.

After preparing all the elements of the future pipe bender, you can begin to assemble the device. The base is firmly clamped in a vice, the pulley is inserted into the hole made, the handles are fixed.

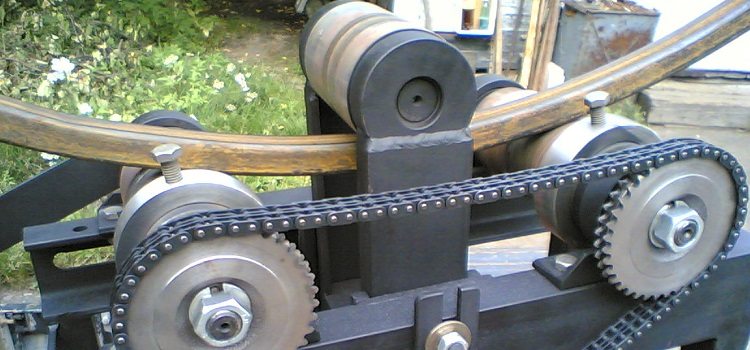

Some craftsmen independently assemble complex and functional hydraulic installations. For this, a hydraulic car jack, rollers, an iron channel, a shoe and steel fasteners are used. The most important point is the choice of rollers, since this part will ensure the correct fit of the pipe and, as a result, the quality of the bend.

Features of copper pipes and their application

Copper pipes are widely used in everyday life and in many areas of the national economy. This is due to an impressive list of advantages that distinguish this material from plastic or iron counterparts:

- Good resistance to mechanical stress, shock, bending.

- Long service life, measured in tens of years.

- Resistant to the growth of pathogenic microorganisms, which makes copper piping the best option for supplying drinking water.

- Ease of installation and maintenance.

- Resistant to the formation of plaque on the inner walls of the pipeline. During operation, the clearance of the pipeline does not decrease, blockages are not formed.

- Wide operating temperature range.

- Small coefficient of thermal expansion.

- Resistance to corrosion.

In the construction of pipeline networks, two types of copper pipes are used:

- Annealed.

- Unannealed.

Annealed products are widely used, they are easy to bend, have good resistance to high temperatures, pressures or chemicals. But in terms of strength, such a pipe will lose unannealed.

Unannealed products are more difficult to bend, while the bending radius should not be less than three pipe diameters.

What are pipe benders

Pipe bending devices differ in their design and intended purpose. They are mechanical and portable manual.

For bending tubes of small diameters, the latter option is quite suitable. A manual pipe bender for copper pipes can cope with thin-walled products with a diameter not exceeding 50 mm (according to DU - two-inch pipes). To give the desired shape, the fold has to exert physical effort, which is the main drawback of the design. However, consumers are attracted by its affordable price and light weight.

Separately, electro-hydraulic or electric machines with CNC (computer numerical control) can be distinguished. One of the program control functions will be the bending of copper tubes, including those of small diameters. Of course, it is not worth buying such a machine for the sole purpose of bending pipes.

According to the bending mechanism, pipe benders can be divided into three groups:

Crossbow manual pipe bender.

The equipment has the shape of a crossbow weapon, and the bending itself takes place according to the principle of pulling the bowstring. The desired angle is attached to the section of the copper pipe using a template included in the kit of the crossbow device. Templates (forms) are completed only in a single copy, designed for a pipe of a certain diameter.

It will no longer be possible to bend a pipe with a diameter different from the template. This type of equipment will not be able to bend an angle exceeding 90 degrees. A manual pipe bender is suitable only for small pipes, with a diameter of 10 mm to 22 mm. Segment pipe benders.

The pipe is pulled out using a special segment. Visually, the device resembles a small machine for bending pipes with a diameter not exceeding 42 mm. The maximum bending angle for a segmental machine is 180 degrees.

The segment has the shape of a semi-disk, rotates with a handle. The copper product is bent around the segment body at the right angle. The principle of bending is to create a stress state of uneven compression at the place of deformation.

As a result of this process, the ductility of copper (or any other metal) increases, the natural roughness of the walls decreases, and smooth circulation of the working medium in the pipe cavity is ensured. The machine can be manual, semi-automatic, and sometimes fully automatic. Optimal operation of a manual mandrel is possible when the system is set up correctly. Semi-automatic devices are able to program the angle of deformation, some models independently provide stable lubrication of the mandrel for its movement inside the tube.

The crossbow type pipe bender is a manual fixture

A pipe bending mandrel machine can be made by hand. The most important working elements for him will be a roller die (it is desirable to provide for the possibility of adjusting the diameters), a front clamp corresponding to the diameter of the die, guides, mandrel mandrels and collet clamps for the mandrel.

The basis of the structure will be a standard support frame, which takes all the loads of the process. The drive for work is most often used by a lever, but for more serious purposes, hydraulic drives are used. Drawings of mandrel equipment can be found on the Internet.

Features of bending a copper pipe on a pipe bender

A copper pipe, from the point of view of bending it on a pipe bending machine, has 2 states - soft and hard. Solid and semi-solid copper pipes have greater rigidity. During manufacture, such pipes are subjected to heat treatment in order to increase operational characteristics - strength and ductility. Copper pipes without heat treatment (non-annealed copper pipes) due to their rigidity are extremely difficult to bend even to a 3D radius.

Therefore, when bending copper pipes to bending radii less than 3D, soft pipes should be used, and even better soft pipes with increased plasticity, or hard and semi-solid copper pipes should be subjected to heat treatment - annealing. Annealed copper pipe is more plastic, but has a lower hardness. It is well deformed (bends), but after bending it should be heat-strengthened. Due to the fact that copper does not differ in density from steel, but does not corrode, the wall thickness of pipes very rarely exceeds 1.5–2 mm.

Annealed copper pipes of small diameter (up to 38 mm) can be easily bent on BMK pipe bending machines for small radii (from 1.5 D) even without special equipment.

When bending annealed copper pipes with a diameter of more than 38 mm on pipe benders, it is necessary to select the optimal bending radius with simple equipment, or make complex equipment. For bending such copper pipes, the equipment includes a special bending roller with a straight section, a crease breaker, and a steel flexible mandrel.

After bending on a pipe bending machine, it is desirable to thermally harden products from annealed copper pipes, thus increasing their performance.

All round copper pipes are manufactured in accordance with GOST817-2006 and have the following information in the designation:

The 1st letter determines the method of manufacture (D - cold-formed, drawn or cold-rolled, G-pressed)

2nd and 3rd letters - pipe shape (KR-round)

4th letter - manufacturing accuracy (N, P, I, K, S, U)

5th letter - state (M-soft, P-semi-hard, T-hard, L-soft increased plasticity, F-semi-hard increased strength, H-hard increased strength)

Further dimensions D (diameter) and S (wall thickness), length, etc.

Special conditions for accuracy (T), for curvature (O), tensile requirements (P), requirements for hardness (H), winding conditions in coils (BTH) - free winding, (BU) - ordered winding, (BS) - spiral winding, are defined in GOST 817-2006.

Pipe bender and pipe bending machine for bending copper pipes

LLC "Baltic Engineering Company" produces pipe benders for bending copper pipes and special equipment for them.

Mandrel pipe benders for bending copper pipes with an outer diameter of 3 to 30 mm:

- Programmable mandrel manual pipe bender CM-30 PARTNER in 2- and 3-axis version

- Semi-automatic mandrel bending machine CE-30 PARTNER in 2- and 3-axis version

- Mandrel automatic pipe bending machine CE-30 PARTNER.3X

Mandrel pipe benders for bending copper pipes with an outer diameter of 3 to 51 mm:

- Semi-automatic mandrel bending machine CE-51 MASTER

- Mandrel automatic pipe bending machine CE-51 MASTER.3X

Mandrel pipe benders for bending copper pipes with an outer diameter of up to 80 mm:

- Mandrel semi-automatic pipe bending machine CE-80 PROFi

- Automatic mandrel bending machine CE-80 PROFI.3X

Using pipe bending machines of the PARTNER, MASTER and PROFI series will allow you to make products of any complexity from copper pipes!