Technological process of PP welding

Welding of polypropylene pipes is based on the ability of this type of plastic to soften when heated to a certain temperature, acquiring a state similar to soft plasticine. With close contact between two melted parts, the process of mutual penetration (diffusion) of materials occurs, resulting in a strong connection, which is not inferior in durability to a holistic structure.

There are two main ways to connect polypropylene pipes: butt and coupling. In the first option, the ends of the parts are heated at the same time with a special disk soldering iron, after which they are connected together; this technology is widely used when joining large-diameter pipes in industrial construction.

When used in the construction industry for laying water and heating networks of polypropylene pipes of small diameters (up to 63 mm), the butt method is absolutely unsuitable for the following reasons:

- welding of polypropylene pipes of only one diameter can be realized;

- after docking, a convex seam is formed inside the pipeline, which reduces the cross section of the passage channel - this significantly increases the hydraulic resistance of a small diameter pipeline and reduces the efficiency of its use, increases the likelihood of blockages.

- the connection has less strength than the coupling.

The technology of soldering with the use of couplings consists in the use of a transition piece for joining pipes (a segment of a conventional single-layer PP pipe) with an inner diameter corresponding to the outer diameter of the pipe segments to be connected. To carry out work with a special soldering iron, the outer surface of the pipe and the inner transition sleeve are simultaneously heated, after which the parts are quickly connected manually. A similar procedure with heating the sleeve and the outer tubular sheath is carried out with the second joined segment. It is clear that after insertion into the coupling, the ends of both pipe sections are almost joined end-to-end without a convex seam, and if an adapter with different diameters is used, then pipelines of any size can be joined.

Rice. 5 Soldering plastic pipes - a technological process

What is the service life of polypropylene pipes, what temperature can they withstand

Polypropylene pipes have proven themselves in heating systems. They have become a worthy replacement for metal heating pipelines.

The service life of polypropylene pipes is not less than the service life of metal pipes.

PP pipes are not afraid of corrosion, resistant to chemicals that are used in everyday life, in addition, when water freezes, they do not collapse. Therefore, polypropylene pipes can be used in heating systems for 25 years, and in cold water pipelines for about 50 years.

The strength and reliability of a polypropylene water supply system is also ensured by the method of their connection. It is carried out by welding. This provides solidity and strength. During operation, there is no need to constantly tighten the connections, as is the case with metal pipelines.

What temperature can polypropylene pipes withstand?

Many people are still distrustful of polypropylene pipes in heating systems. Let's see what temperature they can withstand, what is the service life of polypropylene pipes and whether it is possible to use them for home heating.

The material that is taken for the manufacture of pipes is obtained by polymerization of polypropylene with the participation of metal catalysts. Polypropylene softens at +140C, this material melts at +175C.

It becomes obvious that prolonged exposure to high temperature and excess pressure will lead to deformation of the pipeline.

Manufacturers guarantee the normal operation of polypropylene pipes in the heating system at temperatures up to + 95C. But there is still a margin of safety, which allows a short-term increase in the temperature of the coolant to a temperature of + 140C. But frequent jumps in temperature to this value will lead to a reduction in the life of the pipeline, although it will not melt itself.

When buying polypropylene pipes, you need to pay attention to their marking. For a cold water supply system, pipes made of polypropylene PN10 to PN25 are used

PN20 pipes can be used up to +60C, and PN25 pipes can be used if the coolant temperature is up to +95C.

What pressure can polypropylene pipes of different types withstand?

Many buyers who decide to install a polypropylene pipeline for cold water supply or for heating are interested in how much pressure they can withstand. The service life of polypropylene pipes will depend on this. This question is very important. Since the pressure in the plumbing system or in the heating system, which polypropylene experiences throughout the entire period of its use, affects the service life of the product. If the pipeline has a constantly high temperature, but low pressure (or vice versa), then the pipe will last a long time. But if there is both high pressure and high temperature in the system at the same time, then the service life will be drastically reduced.

In order for the pipeline to serve the 50 years promised by the manufacturer, it is necessary that the pressure in the system be 4-6 atmospheres, and the temperature of the coolant does not exceed 75 degrees.

Polypropylene pipes in the heating system

Polypropylene pipes are now quite a popular material for installing a heating system. They are resistant to deformation, abrasion, and are characterized by low oxygen permeability. In addition, they perfectly withstand temperatures with a minus, are not afraid of freezing water.

But, when choosing them, you need to consider such points:

Polypropylene pipes are rigid, do not bend. To create contours or turns, you need to use corners, which is not always convenient.

For polypropylene pipes, fittings are produced with a large cross section when compared with fittings of other elements of the system, for example, radiators. This circumstance negatively affects the appearance of the system.

Polypropylene stretches strongly when heated

If the system is made in an open way, then it looks ugly due to sagging pipes.

It is important not to overheat the pipes during installation, as the passage may decrease when the pipes are inserted into the fittings. Such an installation error will lead to poor performance of the heating system.

It is not recommended to use polypropylene pipes when piping boilers. In boiler rooms, the temperature of the pipes often changes, while polypropylene is not a suitable material for such conditions.

Given all the negative points described above, then polypropylene pipes for heating systems are a good option.

What temperature can polypropylene pipes withstand?

To determine the purpose of a polypropylene pipe in appearance, there is a special marking. In addition to the manufacturer and brand name, the generally accepted classification is applied to the pipe.

- name of polypropylene modification;

- standard proportional ratio;

- nominal outer diameter and wall thickness;

- nominal pressure;

- manufacturer's standards.

The maximum temperature of PP pipes is 95 ° C. This is perhaps the only drawback of polypropylene, it does not withstand high temperatures. At t 140° the material becomes soft and easily deformed, and melts at 175°.

The temperature in heating systems is also not designed for such indicators, so PP pipes are quite suitable for using them for heat pipelines.

Short-term increases in temperature indicators rarely lead to failure, but it is important to consider that when pipes are operated at temperatures of 100 °, their service life is significantly reduced. The 50 years declared by the manufacturer can actually turn into a year and a half, because the durability depends not only on its technical characteristics, but also on the operating conditions

The 50 years declared by the manufacturer can actually turn into a year and a half, because the durability depends not only on its technical characteristics, but also on the operating conditions.

Nuances when soldering polypropylene pipes

Soldering propylene pipes requires certain skills and experience; when carrying out work, inexperienced installers should take into account some of the nuances:

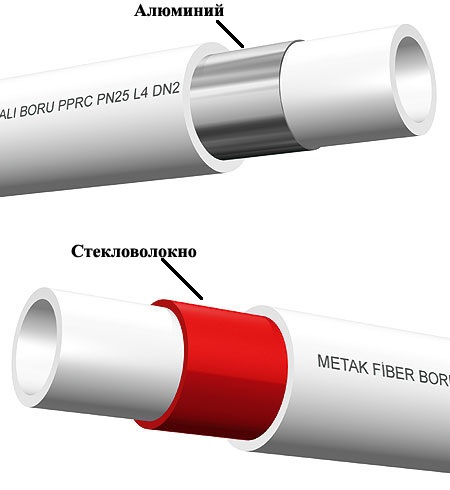

- Polypropylene pipes reinforced with an inner aluminum shell require a slightly longer heating time, which can be determined experimentally by conducting experiments on joining short cuts.

- PP pipes reinforced with aluminum located under a thin outer shell of polypropylene require preparation for soldering, it is necessary to remove this aluminum layer to the depth of the connection with the fitting so that the foil does not interfere with soldering. To do this, use a special device for stripping - a shaver, produced in several versions: manual and for a drill. If you have to deal with the installation of aluminum-reinforced PP pipes in large volumes, it is better to purchase a nozzle for a drill (screwdriver) - the removal of the aluminum layer when using it is faster and with higher quality than that of a perforating model.

- If the aluminum reinforcement is located in the middle between the inner and outer pipe walls, usually experienced welders do not clean the pipe. But, if experience is not enough, then it is recommended to use strippers for internal reinforcement - trimmers. Their design differs from the shavers mentioned above by the presence of a knife that cuts the foil from the inside from the end of the pipe.

Rice. 13 Sequence of soldering of PP-pipes reinforced from above with foil

- They do not clean the pipe shell of the joined parts from dirt - this error leads to poor diffusion of polypropylene and further depressurization of the joint.

- Cannot handle 90 degree cut. The error leads to the fact that when the pipe sections are inserted into the heating nozzles, they are not completely immersed and, during installation, too much clearance is formed between their ends - this weakens the connection and leads to the accumulation of dirt in the formed groove.

- The pipes in the coupling are joined too tightly or not deep enough, in the first case, an internal shaft is formed at the junction, which reduces the diameter of the passage channel. If the pipes in the coupling are placed too far apart from each other, an internal groove will form and the strength characteristics of the connection will deteriorate.

- Do not observe a right angle when joining parts. In the absence of a control tool, it is rather difficult for a novice installer to maintain a right angle, or rather the alignment of the connection, distortions adversely affect the quality of the joints and make it difficult to install long sections into pre-cut straight grooves.

- Underheated or overheated parts. In the first case, diffusion will be insufficient, the joint will later delaminate and a leak will appear, when the pipe shells are overheated, a surfacing narrowing the through hole will appear inside.

- Rotate or correct the position of the parts during the welding process. This violation of technology leads to further depressurization of the connection.

- Do not observe time intervals when soldering, docking. Deviations from the recommended table values lead to defects in the form of overheating or underheating of the pipe shells, their delamination and, accordingly, to poor-quality connection of parts.

Rice. 14 How not to weld polypropylene pipes

Why do you need pipe reinforcement

To ensure a sufficient level of heat in the apartments, it is necessary to turn on the return pipeline and raise the water temperature to 10 ° C. At close operating temperatures, simple polypropylene pipes begin to lose their properties and, in addition, a linear expansion of their dimensions is possible.

When laying pipelines with high temperatures in a concrete screed, this is especially important.There is a possibility of concrete cracking and breakage of the entire heating system

To reduce this effect and completely eliminate it, polypropylene pipes are reinforced.

Reinforcement is the strengthening of the bearing capacity of the base material of the product with another material having a higher level of strength. Thus, the ability to withstand temperature extremes is increased. Reinforced pipes fully comply with the standards of the heating system, and do not deform when it is significantly increased.

For the reinforcement of pipes made of polypropylene, materials are used:

- aluminum foil applied to the surface;

- the inner layer of aluminum, located along the entire diameter of the pipe, closer to the outer surface;

- fiberglass inner layer;

- an inner layer combining fiber and fiberglass.

Aluminum and fiberglass cost about the same. The price mainly depends on the parameters of the pipe itself and the manufacturer. Nevertheless, fiberglass reinforcement has several advantages over aluminum:

- during installation, cleaning of the edge of the pipe is not required;

- short soldering time of joints (as in non-reinforced pipes);

- there is no internal delamination due to the fusion of glass fiber into polypropylene;

- increases the strength of the product.

There is only one disadvantage of fiberglass - the linear thermal expansion of pipes reinforced with fiberglass is 6% higher than that of pipes reinforced with aluminum.

Soldering polypropylene pipes step by step instructions

One of the main advantages of connecting polypropylene pipes by soldering is the speed of installation work, the process of docking and readiness for further installation of pipes of the most common diameter of 25 mm takes no more than 15 seconds. To do the work without unnecessary time costs, they responsibly carry out all preparatory operations and then mount the pipeline, strictly adhering to the technological process of operations.

Rice. 9 Tool used to weld PP pipes

1. Preparation of tools and accessories

Before soldering polypropylene pipes, components are prepared: pipe segments, tees, elbows, couplings, adapters from plastic to metal, valve shut-off valves.

To carry out the work, you will need a soldering iron and a set of nozzles, as well as auxiliary tools, some of which are included in the device package:

- Pipe cutter, usually for cutting pipes, scissors with a maximum allowable cutting diameter of 40 mm are used, for larger sizes, more powerful scissors or roller cutters are used.

- Tape measure, marker or pencil for marking the length on the tubular sheath.

- Gloves to protect hands from burns during work.

- Level for checking the horizon when installing water outlets.

- Screwdriver or hex wrench to secure the attachments to the heating iron.

Rice. 10 Main stages of PP welding

2. Marking and cutting

For the convenience of work, they free up space in the middle of the room and set the table at a convenient height, all the elements are laid out around the perimeter of the room according to the scheme, after which they begin their sequential cutting with soldering. If the pipeline runs along the perimeter of the room, laying starts from the end wall - it is more convenient to carry out installation. Work is carried out in the following sequence:

- Measure the desired section of the pipe and put a mark on its surface with a marker or pencil, stepping back from the end of the distance, taking into account the depth of heating.

- Cut the pipe with scissors for polypropylene pipes, trying to accurately maintain an angle of 90 degrees. If the tool is sharpened sharply, then there will be no burr on the inner walls and the pipe will retain its geometry.

- If the pipe at the end has small bumps or burrs, then, in principle, this is not a big problem, since when the pipe is heated, they will still melt.

Rice. 11 Soldering PP pipes - main steps

3. Soldering

For soldering polypropylene, soldering irons with a flat iron are mainly used, work is carried out in the following order:

- Connect two parts of the nozzle to the screw with a hex key to the device, connect it to the network and turn on the heating element or both heating elements by pressing the keys.

- The required temperature indicator is set with a thermostat, the standard temperature for soldering polypropylene pipes is usually set at 260 ° C.

- After the indicator changes its color to green, signaling that the heating element has reached the set heating temperature, soldering begins. At first, it is better to carry out trial work on short pipe cuts, after determining the optimal holding time (for this, the table for soldering polypropylene pipes is used), they begin to weld the main pipeline.

- The outer or inner surfaces of the parts to be joined are placed simultaneously from both sides in the heating sleeves, trying to maintain a strictly horizontal position of the parts, to hold the short sleeve, gloves are used that come with the kit. After a certain time, the parts are quickly removed from the soldering iron and connected to each other in a strictly fixed position, trying to keep them on the same axis for the allotted time.

- After the cooling time has elapsed, the assembly is ready for further operation - soldering the second pipe section into the coupling.

Rice. 12 Shavers for removing external reinforcement of PP pipes and an example of their use