How to calculate the number of radiator sections

There is a simplified way to do this quickly. To do this, we need the standard power required to heat one square meter of a room. We present three options.

- If the ceilings in the room have the usual height (from 2.5 to 2.7 meters), the wall to the outside is one, the window is one. Regulatory power - 100 watts.

- If the ceilings are the same, there are two walls outside, one window. Rated power - 120 watts.

- If the height of the ceilings is the same, there are two walls outside, two windows. Rated power - 130 watts.

Now we multiply two quantities - the standard power for our option and the area of \u200b\u200bthe room. Having higher ceilings or a larger window (for example, if it is with a bay window), we additionally multiply by a correction factor of 1.1. As a result, we get the radiator power (total).

In the passport of the radiator, the thermal power is indicated for its one section. The resulting total power must be divided by it. Rounding up decimal numbers.

For example: The room has an area of 16 square meters, it has one outer wall and one window with a bay window. Battery FARAL Green HP 500 (section thermal power - 180 watts).

We multiply 100 watts by 16 square meters and by a factor of 1.1.

100 x 16 x 1.1 = 1760 (watts).

To calculate the number of radiator sections, divide this number by 180.

1760 / 180 = 9.778 (pieces).

Rounding up - we get 10 sections.

Updated: 20 December 2016

If you notice a mistake in the text, please highlight it and press Ctrl+Enter

Popular

Copyright 2017 — SRBU.RU Reprint of materials is prohibited!

Login to the site using:

Or enter your username and password:

Other Options

Aluminum radiator in the interior of the room

Weight matters when choosing fixtures for a heater.

The passport indicates the mass of one section. To determine the total weight of an unfilled radiator, this parameter must be multiplied by the number of sections. Depending on the dimensions, the weight of one section can be from 1 to 1.47 kg.

The volume of water in the radiator is also calculated from the parameters of one section, which must be multiplied by the number of sections.

The capacity (internal volume) of a section depends not only on its dimensions, but also on the thickness of the shell. The average capacity of one aluminum section is in the range of 250 - 460 ml. The internal volume of the radiator is taken into account when calculating heating systems and has the most direct impact on the volume of coolant required to fill them.

The maximum allowable coolant temperature for aluminum radiators is standard and is 110 degrees.

Which aluminum heating radiators are better - choose a model from well-known manufacturers.

A large selection of design solutions for vertical heating radiators allows them to be installed even in rooms without windows. Photos of interesting models.

Advantages and disadvantages of an aluminum heater

Aluminum products have a number of positive qualities that are the reason for the popularity of this product.

- Aluminum radiators weigh relatively little. which facilitates their transportation and allows you to do the installation yourself.

- Such batteries look attractive and can not only heat, but even decorate various rooms.

- Features of the material and well-thought-out design of the batteries cause high heat transfer. Aluminum batteries can significantly save heating costs. by reducing the volume of coolant in each section.

- Such batteries quickly respond to changes in the coolant supply. almost instantly cool and cool down. This allows you to warm up the premises in a short time and increases the efficiency of thermostats, which is also the reason for reducing heating costs.

- Powder coating simplifies battery care. there is no need for periodic painting.

- There are models that can withstand high pressure.

- All this is combined with a relatively low price.

How to maintain a constant temperature in the room with a thermostat for heating radiators?

What are the advantages of electric heating. Types of boilers, installation and connection with your own hands.

But such products also have several disadvantages. Things to know before buying:

- In prefabricated devices, rubber sealing elements are used, which makes it impossible to use antifreeze as a coolant.

- Low protection against corrosive processes. To extend the operating period, it is necessary that the water has a neutral acidity and does not contain abrasive particles that can damage the protective film.

- Air can accumulate inside the heater. to bleed which it is necessary to equip the battery with an air vent.

- The weak point of such a battery is threaded connections.

Nevertheless, for the most part, the properties and features of aluminum heaters make them ideal for heating systems.

Crimping pressure

Pressure testing of the heating system

Before the start of the heating season, the central system is checked for leaks - that is, they are pressure tested. This operation consists in supplying the coolant under pressure exceeding the working pressure by 1.5 - 2 times.

Standard values of crimping pressure are from 20 to 30 atm.

If the radiator is not designed for such pressure, it may fail during testing of the heating system.

If you have central heating in your home

be sure to pay attention to this parameter when buying a battery: according to the passports of many models, it is only 18 atm. Such models are only suitable for autonomous heating systems.

4 Completeness

5.4.1 Assembly of radiators at the manufacturing plant should be carried out according to the customer's specification; delivery of radiators on 4—8 sections, and also separate sections is allowed.

5.4.2 Each radiator must be equipped with two blind plugs with a left-hand thread, two through plugs with a right-hand thread and gaskets.

At the request of the consumer, blind plugs with a right-hand thread and through-hole plugs with a left-hand thread with a threaded hole with a diameter of G 1/2-B or G 3/4-B are additionally supplied.

5.4.3 Radiators shipped to the consumer in one transport unit according to one accompanying document must be accompanied by a passport.

5.4.4 The passport must contain:

- name or trademark and address of the manufacturer;

- the number of radiators in the batch;

- the number of sections (blocks) in one radiator;

- nominal heat flow of one section (block) in kW

—■ manufacturer's warranties;

— date of issue or shipment;

- OTK stamp.

When delivered to a distribution network, a passport must be attached to each radiator.

Design features of bimetallic radiators

Bimetallic heating batteries are made of steel and aluminum. Internal collectors and vertical pipes are made of stainless steel, as it is resistant to the aggressive effects of hot coolant. The body of the device or casing with ribs is made of aluminum, which heats up quickly and has a high thermal conductivity. The tubes and body are joined together by injection molding or spot welding.

There are two types of bimetal appliances:

- Sectional. Separate sections are interconnected by nipples with heat-resistant rubber gaskets. The junction of the sections is vulnerable to leakage. The advantage of this variety is the ability to add or remove sections in order to adjust the thermal power of the heating unit. Also, if one section fails, it can be easily replaced. Service life reaches 30 years.The maximum working pressure is 25 bar, and the thermal power of the section is a maximum of 200 W.

- Also on sale are monolithic bimetal batteries. In the manufacturing process, a welded one-piece collector is first made of steel or copper. Then it is placed in a special form and filled with aluminum under pressure. The disadvantage of this model is that in the event of a breakdown or leakage, the device will have to be completely replaced. These units will last up to 50 years at operating pressures up to 100 bar. In terms of thermal power, they are not inferior to the previous version.

Do not confuse the following types of designs:

- Bimetallic structures have a casing made of aluminum. This metal does not interact with the liquid coolant and acts as a heat exchanger. These models can be used in autonomous and centralized heating networks. The core can be made of steel or copper.

- Semi-bimetallic devices have internal channels made of different materials. So, vertical channels are made of steel pipes, and horizontal channels are made of aluminum. It can also be the other way around. These heaters are not suitable for installation in a centralized system, since a low-quality coolant with an alkali content circulates here. In contact with such water, aluminum tubes are susceptible to corrosion.

Semi-bimetallic options are cheaper and outwardly very similar to real bimetallic radiators, but they are much inferior in strength, durability and corrosion resistance.

Advantages and disadvantages

Having considered the device of bimetallic heating radiators, it is worth listing the advantages:

- The main advantage is the high heat transfer of bimetallic radiators. In this parameter, they are 3 times superior to steel batteries.

- Due to the smooth inner surface, the batteries are free of lime deposits and rust.

- Radiators with a copper core or stainless steel tubes are not subject to corrosion after draining the coolant.

- Since aluminum does not come into contact with the hot coolant, the service life of the device is quite long.

- Resistance to high pressure and water hammer allows the use of units in centralized heating systems.

- The service life of monolithic models reaches 50 years.

- The thermal power of sectional models can be adjusted by adding or reducing the number of sections.

- The technical characteristics of bimetallic radiators do not deteriorate during operation.

- The external attractiveness of the batteries allows you to harmoniously fit them into the interior of the living space.

- The power of bimetallic radiators can be regulated by a thermostat. Thanks to this, the room maintains the optimum temperature and saves energy for heating the coolant.

- If you need to choose accessories for heating radiators, bimetallic devices are compatible with elements made of different materials.

The only drawback of bimetal units is associated with their high cost, which is due to the peculiarities of the technological process. However, this price will pay off during the long-term operation of the battery, as well as its good heat dissipation.

How to choose and install an aluminum radiator

- if you still decide to install an aluminum battery in a house with central heating. it is better to dwell on reinforced products designed for a pressure of at least 16 atmospheres;

- for private houses, radiators of a standard (European) type are quite suitable.

You also need to take into account a number of nuances:

What is the coolant temperature.

Pipe connection method. which can be unilateral or bilateral. In the first case, the number of battery sections should not exceed 8-10 pieces. Otherwise, the distant compartments simply will not warm up.

In order to achieve optimal operation of the heater, the minimum distances to obstacles must be observed. 3 cm from the wall, 10 cm from the floor and from the window sill.

At the point of entry and exit of the pipeline, it is necessary to install shut-off valves. including thermostats.

It is also important to install an air release valve.

Under no circumstances should copper piping be used. Regarding the boiler with a copper heat exchanger, there is an opinion that it is far from the battery, so it should not lead to corrosion.

In high pressure systems, pipes are recommended to be made of metal

but aluminum cannot come into contact with cast iron and steel surfaces without processing.

- pliers;

- screwdriver;

- drill with impact mechanism;

- hydraulic level.

After all the preparatory work, you can install the batteries in stages:

- assemble the sections into a single radiator;

- connect shut-off and control valves, as well as air valves to it;

- drain the coolant from the system;

- install brackets for the battery on the wall and fix the heater to them;

- connect the radiator with pipelines according to the selected heating scheme;

- check the heating system.

The video shows the process of assembling an aluminum radiator with your own hands:

If you have doubts about your abilities, it is better to entrust the installation to professionals. Only with proper installation will it be possible to fully appreciate all the positive qualities of aluminum radiators.

You should also refuse to purchase and install if you live in an apartment building and are not sure about indicators such as operating and pressure pressure in the heating system and the quality of the coolant.

Also read with this article

- Choosing a quality electric oil heating radiator

- How to bleed air from a heating radiator: remove air plugs correctly

- Bimetallic heating radiators: types of batteries, which is better to choose?

- Decorative screens for radiators: how to choose and install

- How to calculate the number of sections of bimetallic heating radiators for a house

- Table for calculating the heat transfer of heating radiators

- Which radiators to choose for heating a private house: we take into account every little thing

- Do-it-yourself septic tank made of concrete rings: volume calculations and a simple assembly scheme

3 Requirements for raw materials, materials and components

5.3.1 Sections (blocks) of radiators and radiator plugs must be cast from gray cast iron with lamellar graphite according to GOST 1412, nipples - from ductile iron grade not lower than KCh30-6F according to GOST 1215.

It is allowed to manufacture nipples from steel grades 08kp or 08ps according to GOST 1050.

5.3.2 The outer surface of the radiators must be coated with primer GF-021 in accordance with GOST 25129 or GF-0119 in accordance with GOST 23343.

5.3.3 The quality of the ground coating must be at least class VI according to GOST 9.032.

5.3.4 Gaskets used in the assembly of radiators must be made of materials that ensure the tightness of joints at a coolant temperature of up to 423 K (150°C).

5.3.5 Pipe threads on radiator parts must be made in accordance with GOST 6357.

5.3.6 Threaded holes of sections or blocks of radiators must be made with a diameter of G 1 1/4-B or G 1-B.

5.3.7 Radiator plugs must be made with right and left threads with a diameter of G 1 1/4-B or G 1-B without a hole (blind) and with a threaded hole (through) for connecting the radiator to the heating system. The diameters of the threaded hole of the through plugs are taken equal to G 3/8-B, G 1/2-B or G 3/4-B according to the customer's specification. If not specified in the specification, the grommets must be supplied with a G 1/2-B tapped hole.

5.3.8 Radiator nipples must be manufactured with external right and left threads with a diameter of G 1 1/4-B or G 1-B.

Qualitative characteristics

Before purchasing a heater, you should also study the qualitative characteristics of various models, showing the design features and manufacturing technology.

Heat carriers

The technical passport for the product must indicate with which coolants it is allowed to operate. The permissible range of values of the hydrogen index (pH) of the coolant can also be specified.If an aluminum radiator is supposed to work with non-freezing liquids (antifreezes), special intersectional gaskets are used in its design.

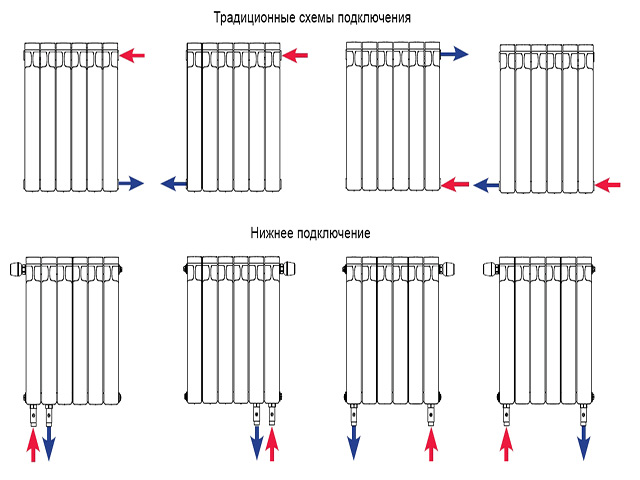

Connection diagrams for aluminum radiators.

Connection methods

The standard section of the aluminum radiator has a top and bottom manifold that allows one of the known side connection methods. Some models of heating appliances are equipped with a manifold with a lower connecting pipe, which allows for a lower connection that is convenient when installing a collector heating system.

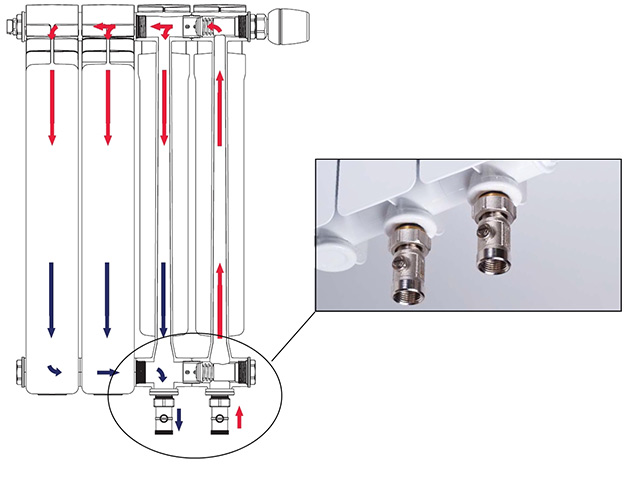

Scheme of the movement of the coolant at the bottom connection.

Manufacturing method

Sections can be made by injection molding or extrusion. Extrusion is a pressure treatment method that results in a preform of increased density. Radiators made by this method have higher strength, which allows them to withstand increased pressure.

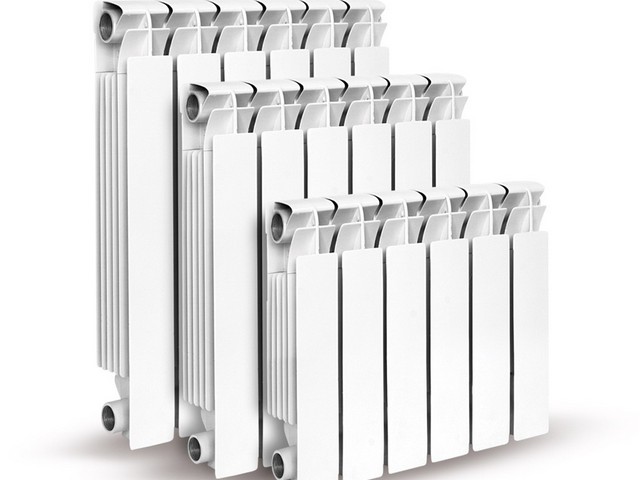

Aluminum radiators of various standard sizes.

Aluminum sectional radiators have proven themselves well in individual heating systems, when the homeowner has the opportunity to independently choose the type of coolant and control its quality. Such devices are characterized by high thermal performance, outperforming bimetallic models due to their lower cost. The technical characteristics of aluminum heating radiators give the buyer the opportunity to choose the best model among a number of analogues.

Which aluminum or bimetal heating radiators are better?

Installing a heating radiator - process description, features

Painting cast iron radiators at home

Popular manufacturers. What to look for when buying a radiator

There are representatives of Italy, Hungary, Russia and China in this category of goods on the Russian market. The most qualitative and popular - "Italians". Hungarian products are slightly inferior to Western European counterparts, but their price-quality ratio is ideal.

Domestic goods are produced on modern equipment, so their quality is also worthy of attention. If you decide to opt for Chinese products, then you should not chase the low price.

Below is a table that gives a general description of the products of some of the most popular manufacturers.

When buying radiators, especially those made in China, carefully check the quality (wall and fin thickness), and also pay attention to the warranty period. A few years ago I bought radiators for a cottage under construction, I was looking for not too expensive ones and only aluminum ones, I did not consider bimetallic ones

As a result, he acquired Italian firms Radena

A few years ago I bought radiators for a cottage under construction, I was looking for not too expensive ones and only aluminum ones, I did not consider bimetallic ones. As a result, he acquired the Italian firms Radena.

In a severe frost, there was a power outage and the house “froze through”, on the top floor some batteries burst, they had to be scrapped. I bought the same ones, the system works perfectly, the pressure is stable, although some of them had ice then. I thought that over time, "thawed" will begin to leak, but no.

Satisfied with the choice, I advise everyone.

In order not to miscalculate with the purchase and installation, you also need to correctly calculate how many sections you need to heat the room. After all, you don’t want to freeze or spend extra money.

Tall radiators

When radiator sizing is limited due to lack of space for a standard appliance, tall and narrow coils are preferred as these models have limited width.

Cast iron radiators. Unlike domestic cast iron products of standard dimensions, among foreign products you can find designer appliances, the height of which is unusual for Russian consumers. For example, the Demrad Retro line of cast-iron radiators.

Their sizes are as follows:

- the height of the section with a width of 76 millimeters varies between 661 - 954 millimeters;

- depth - 203 mm.

Working pressure - 10 atmospheres, they are tested at 13 atmospheres.

In the largest sections, the thermal power reaches 270 watts. At the same time, narrow heating radiators can have height dimensions of 2400 millimeters. Working pressure is limited to 6 atmospheres. The high height contributes to the solid heat transfer of the heating radiator. at a delta of temperatures equal to 70 degrees, it reaches even more than 433 watts.

Aluminum radiators. Usually, for tall aluminum radiators, the piping is placed at the bottom to make the pipes invisible.

Bimetal radiators. Basically, the models of tall and narrow bimetallic radiators are original design designs, and, accordingly, all their sizes are non-standard. Basically, these products are rarely sectional - they are usually monolithic.

An example of such heaters is the Sira RS-800 BIMETALL model radiator, which has the following parameters:

- section height 880 mm;

- depth 95 millimeters;

- length 80 millimeters.

Before calculating the size of a heating radiator, it is necessary to determine the model of a particular heater for a room of a certain purpose and area. It should be remembered that heat transfer is not affected by the size, but by the power of individual sections that are assembled into one battery. The choice, given the size of heating radiators, details on the video:

How to calculate the number of sections

But you can do this calculation yourself according to a simplified scheme. This method is suitable for rooms with a standard ceiling height of about 2.5 m, you only need to know the area of \u200b\u200bthe room.

In most areas of Russia, climatic conditions require that the heating power of each square meter be 100 watts. Therefore, you need to multiply the area of \u200b\u200bthe room by 100. And divide the result by the thermal power of 1 section of the battery model you have chosen.

For example, there is a room of 20 m 2. To heat it, 2000 W of thermal energy is needed. We divide this value by the heat transfer rate of one section of the selected radiator, for example, by 180 watts. If rounded up, you get 12 sections.

For corner rooms with a balcony, you need to increase the resulting value by 1/5, this also applies to the situation when they plan to hide the battery behind the screen. Also, heat transfer losses can be 20% for one-pipe systems, about 12% for a two-pipe bottom connection, 2% for a cross connection.

There are a few more nuances that you need to know when buying and installing radiators.

What requirements must a chimney for a gas boiler meet? Find out from this article.

Technical characteristics of aluminum heating radiators

Before buying an aluminum battery, you need to know the set of parameters that characterize it.

- The pressure that an aluminum device can withstand in operating mode can be from 6 to 20 atmospheres. It all depends on the manufacturer. Crimping (limiting) pressure for these products is about 25 atmospheres. For this reason, aluminum radiators do not always take root in houses with central heating, as there are surges of up to 30 atmospheres in the network.

- The distance between the axes is one of the main dimensions of the batteries, which is the distance between the inlet and outlet pipes. For aluminum radiators, this parameter can range from 20 to 80 cm, but more often there are instances with a distance between the axes of 35 or 50 mm, the height of the battery itself is 10 cm more. Before buying, you need to measure the space under the windowsill. the radiator should not stand back to back, otherwise circulation will be difficult.

- The depth of the battery is 8-11 cm.

- Maximum coolant temperature. which aluminum heaters can withstand can be 110 ° C.

- One of the most beneficial characteristics of aluminum heaters is the ability to give off heat - the heat transfer coefficient, measured in watts. This thermal parameter is indicated by the manufacturer for one section and can be equal to 80-210 W. Due to the special design and low inertia, heat transfer from aluminum radiators is quite high, which allows you to reduce heating costs by reducing the temperature of the coolant.

- Heat carrier volume. which fits in one section, for batteries made of this metal is an average of 0.5 liters.

This is how the main technical parameters of the battery look like.

It is also important for the consumer to know how long the radiator will last, how reliable it is.

Operational period

With regard to susceptibility to corrosion, this was discussed above. To extend the service life of the device, it is necessary to carefully select the coolant, which cannot be done in conditions of centralized heating. A private heating system allows you to do this.

Another factor that can negatively affect the durability is the ability of aluminum to easily crumple upon impact.

Manufacturers set the service life for their products - 5-15 years.

This parameter depends on the production method and assembly methods of the battery.

Production methods and assembly features

These heaters are mainly produced in two ways:

- with the injection method, the radiator is cast as a single piece;

- sections are obtained by extrusion, which are connected to the injection-molded top and bottom of the manifold, and all parts are then fastened together with an adhesive composition.

It is believed that batteries made from virgin raw materials are more durable.

The resistance of aluminum products to corrosion is increased by anodizing.

The subtleties of production that affect the quality of the product: cooling rate, crystallization process, pouring, etc. – may differ from manufacturer to manufacturer.