Advantages and disadvantages of installing VIN

As mentioned earlier, induction boilers, in comparison with their predecessors, are characterized by greater efficiency. The monetary costs of heating with induction heaters are not only lower than in the case of using a heating element, but also do not change during operation. The automatic control system controls the air temperature in the room and, if necessary, turns off the heater, so the boiler's operating time per day is no more than 8 hours. The efficiency of tubular heaters subsequently decreases significantly and increases the cost of electricity.

Economics of using VIN

Economics of using VIN

VIN belong to devices of the 2nd class of electrical safety, having reinforced insulation. The induction boiler does not require grounding, as well as additional ventilation in the room. Fire safety is ensured by the absence of connecting sections and electrical contacts exposed to high temperatures.

Not only water can act as a heat carrier, but also any liquid non-freezing materials that do not need to be removed from the system with the onset of cold weather. This is true for rooms that are not used during such a period - the boiler can simply be turned off. Additional technological preparation of the carrier is not required. In addition, even when using "hard" process water, there is no scale problem, since magnesium and calcium ions do not settle on the pipe walls due to the action of powerful eddy currents, but are removed with a stream of hot water.

The installation of VIN does not require special approvals from regulatory authorities (Rospotrebnadzor), unlike gas heaters. The design is easily integrated into the existing heating system.

The main disadvantage of induction boilers is their high cost. Their use is also not possible in open heating systems. It is also not always possible to mount the heater on the wall.

Unlike a heating element, an induction boiler will last for 30, and when used in a residential area - 40 years, or more than 100,000 hours. The equipment does not require inter-seasonal checks, and preventive maintenance is kept to a minimum. When carrying out work on the installation of boilers, there is also no need to involve qualified workers. In addition, induction boilers are silent during operation.

Durability, compactness, autonomy and no need for frequent maintenance make VIN a profitable alternative to uneconomical tubular heaters and gas-fired boilers that require high initial costs.

Equipment options

Almost all manufacturers offer induction boilers in the power range from 3 to 80 kW in two types of configurations:

- standard. It includes equipment for controlling the boiler (a cabinet measuring 20x40 cm and a remote control that provides contactless control) and a temperature sensor.

- improved (VIP). In addition to the standard set, it contains a coolant flow sensor, a circulation pump and shut-off and control valves. The kit includes a boiler safety group - structural elements that protect against excess pressure in the system. Most often, this is a system of a pressure gauge, a valve for releasing excess coolant and an air vent.

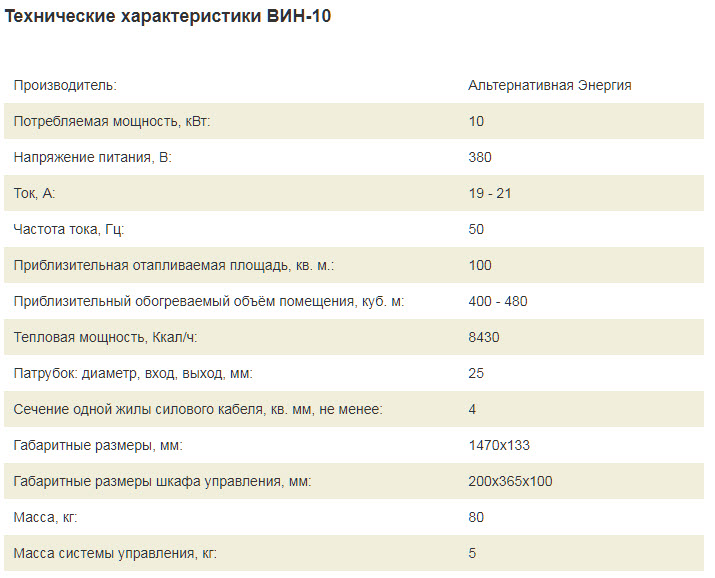

Specifications

The induction boiler is universal and is connected to a conventional 220 V power supply supplying alternating current (frequency 50 Hz). There are models that operate on a 380 V network.

Thermal performance depends on the power of the heater and varies from 2500 to 67400 Kcal/hour for various configurations. An increase in power, and, consequently, in the potential size of a heated room, affects the price of VIN.Boilers with a power of over 7 kW are a system of three heaters in series.

Dimensions for single heaters (VIN-3, -5, -7 / 220 V) are most often indicated as the height of the structure x diameter. A typical boiler with a diameter of 13.3 cm has a height of about 62 cm. The mass of the device is 25-30 kg. More powerful boilers can weigh up to 185 kg, which imposes certain restrictions on their wall placement.

The diameter of the inlet and outlet pipes is the same and, depending on the characteristics of the VIN and the manufacturer, is 23-32 mm.

The device and scheme of operation of VIN

Induction boilers have a three-layer design:

- an outer metal layer that protects the device from external influences;

- heat-insulating layer, excluding overheating of the boiler;

- inner layer (core).

The core is the key element of the VIN. It is a metal tube in the form of a cylinder, toroidally wound with the wire of an induction coil (inductor). The pipe, otherwise called a heat exchanger, is made of a ferrimagnetic material (steel). The winding is impregnated with a special composition, which makes it possible to classify the insulation of the structure as heat resistance class H (limiting temperature - 180°C).

Alternating current from the source enters the wires of the coil, generating an alternating magnetic field. Under the influence of a magnetic field in an electrically conductive substance (water, antifreeze) that fills the heat exchanger pipe, eddy induction currents occur. This leads to heating of the material and the release of thermal energy into the atmosphere. Heat losses in this process are about 1-2%, the efficiency of the boiler during operation remains constant (98%).

Thus, cold water, rising through the heat exchanger, quickly warms up due to electromagnetic induction and is fed into the outlet pipe of the boiler already hot. The heating time is several minutes. At the same time, the temperature of the winding remains no higher than 140 ° C, which makes the induction boiler fireproof. The temperature difference between the metal surface of the heater and the coolant does not exceed 30°C.