Sound insulation installation instructions

1 Protector vibration hangers are fixed to the ceiling with M6 bolts using metal anchors. Their number is calculated based on the total weight of the structure and the bearing capacity of the vibratory hangers. Usually they take a suspension pitch of 600x600 mm or 400x800 mm

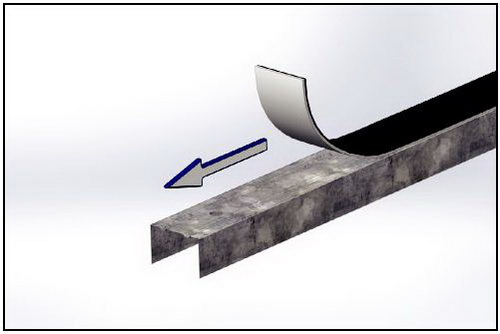

2 Along the entire perimeter, on the SoundGuard Band Rubber damping tape - a guide profile is attached to the walls (the tape serves as a gasket between the profile and the surface on which it is attached to reduce the transmission of vibrations).

3 Then the profile is attached to the walls through the SoundGuard Vibro Washer 8x18 vibration washers with a step of 600mm. 10mm holes are drilled under the dowel-nails. The side wall of the profile, on which the soundproof panels will be attached, is also glued with SoundGuard Band Rubber.

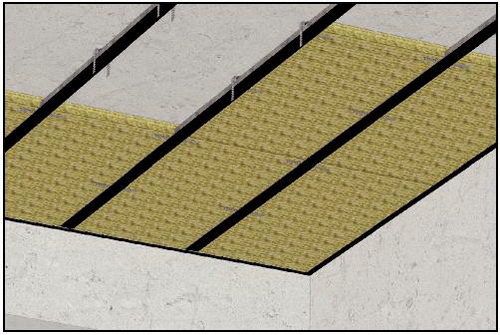

4 Ceiling profiles are installed through Protector vibration hangers at a distance of 400mm or 600mm from each other. Their end side is glued with damping tape SoundGuard Band Rubber 50 mm.

5 The space between the profiles is sealed with absorbent, fibrous material EcoSlab SoundGuard EcoAcoustic or SoundGuard Basalt Sound Absorbing Board.

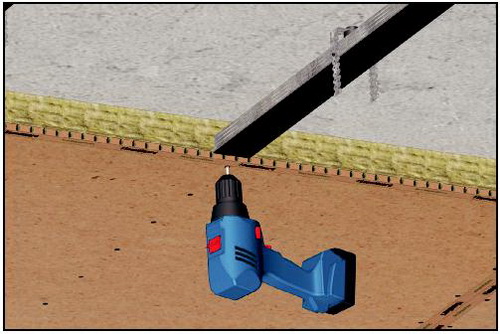

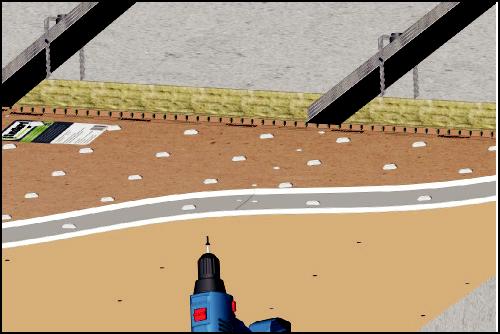

6 SoundGuard EcoZvukoIzol panels are attached to the ceiling profile using self-tapping screws GM 3.5 × 30. At least 21 self-tapping screws are required per panel. The rows of panels are arranged with a slight offset of the vertical joints so that they do not coincide with each other.

7 Be sure to “drown” the head of the self-tapping screw 2 mm deep into the panel and coat it with SoundGuard Seal from above. This is done to avoid direct contact between the self-tapping screw and the GVL (GKL) sheet, which is sewn over the EcoZvukoIzol SoundGuard panels.

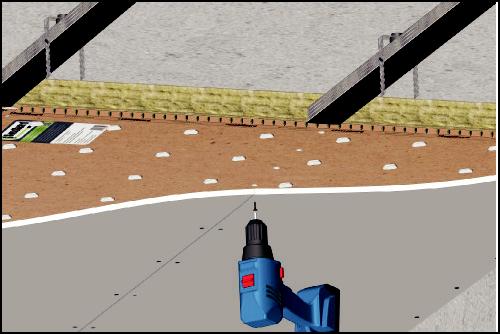

8 The panels are joined tightly to each other and their edges rest against the walls. Such contact will dampen the impact and structural noises that pass through the structure. The joints of the panels and the places where they adhere to the walls are treated with sealant, and then, after it dries, all these joints are glued with SoundGuard Tape. SoundGuard EcoZvukoIzol panels can be easily cut with a regular hacksaw or jigsaw. If you do this carefully, then the mineral filler of the panels spills out minimally and does not affect their soundproofing qualities. The incision site is also sealed with tape.

9 The first layer of GVL (GKL) sheets is fastened through the SoundGuard EcoZvukoIzol panels with self-tapping screws (3.5x35 in size) to the profile!!! framework and through the spot application of SoundGuard Seal. The edge of the plasterboard, which follows the contour of the walls, should not !!! come into contact with them, as this can become a sound-conducting bridge. A gap of 3-5 mm is left there, which is treated with SoundGuard Seal soundproofing sealant.

10. The second layer of GKL sheathing is attached to self-tapping screws (3.5x45 in size), which pass through GVL (GKL) and the profile. Finishing work (puttying, painting, whitewashing, priming, etc.) directly on soundproof panels, without sheathing with plasterboard sheets, leads to deformation of the surface of soundproof panels and the impossibility of their operation.

Soundproofing installation

Preparatory work

Before proceeding with the installation of sound insulation, it is necessary to carry out a number of preparatory work:

- Remove the old wall covering (wallpaper, decorative panels).

- Remove sockets and switches. If there is a wiring junction box on the wall, remove the cover from it. Don't forget to de-energize the wiring first.

- Remove the wires from the box and sockets for the switch and sockets.

- Extend the wires for the switch and sockets to the length of the future insulation.

- Temporarily insulate the bare ends of the wires.

- Fill the nests and the box with cement mortar or mounting foam.

- Inspect the wall and joints between the plates for cracks.

- Seal cracks with cement mortar.

Frame manufacturing

The best way to block sound is the frame method of soundproofing, which is why we will consider it in our article:

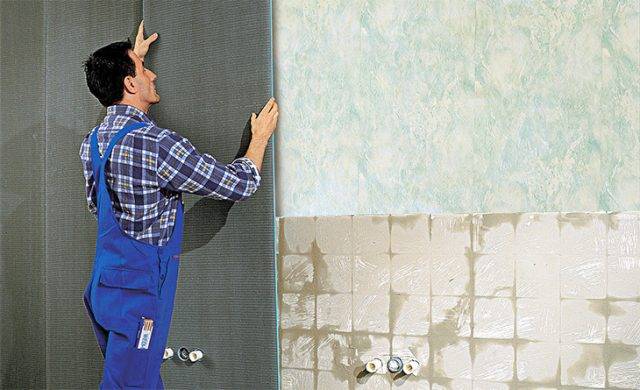

- Stick a thin soundproof membrane over the entire wall area. You can use a self-adhesive membrane or use special glue to fix it.

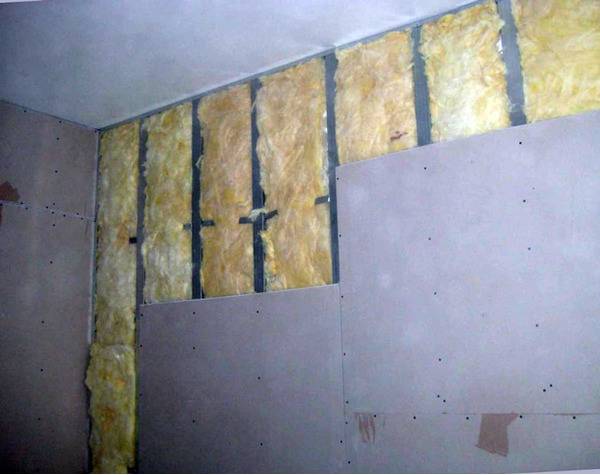

- Make a frame frame, for this, install vertical guides along the edges of the wall, as well as horizontal ones, under the ceiling and on the floor. Use dowel screws to secure the guides.

- Install the vertical guides inside the frame, at a distance of 40-50 centimeters from each other.

- Place sound deadening material between the frame rails. To fix the sound insulation in the frame, you can use glue or bendable metal tape attached to the guide screws.

- Inspect the frame for voids and gaps. There should be no gaps and empty space in the frame.

- Lead the wires of the switch, sockets and wiring through the insulation.

- Install drywall sheets or other finishing boards on the frame. When installing the panels, make holes for the junction box, switch and sockets.

- Seal the seams between the panels.

- Install the finishing wall covering (wallpaper, plaster).

- Install sockets, switch and junction box.

Methods of soundproofing without a frame

In order to save space, many people prefer to use a frameless soundproofing method. This method really allows you to reduce the thickness of sound insulation by 2-3 centimeters, but at the same time, the quality of noise insulation is significantly reduced.

How to make soundproofing without making a frame, you can see in the video:

Whatever method you choose, remember that only comprehensive soundproofing of the apartment, which includes insulation of the floor, ceiling and walls, will provide 100% elimination of noise.

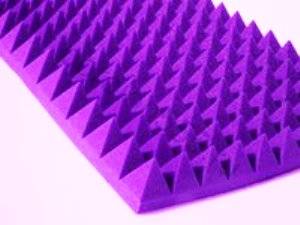

Quality sound recording

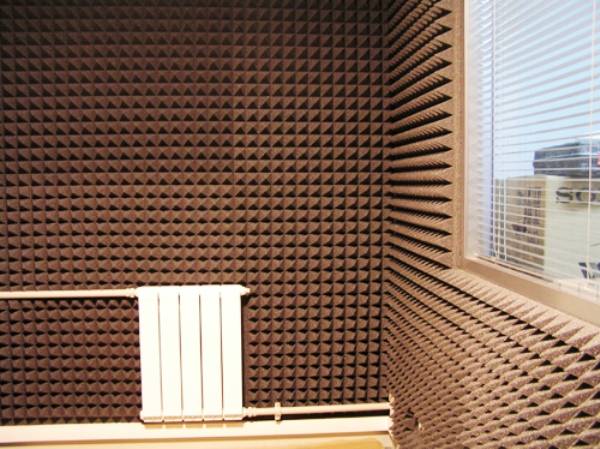

The main field of application of embossed acoustic panels is the premises where rehearsals are held and soundtracks of vocalists' songs are recorded. We are talking about recording studios, where acoustic foam rubber can be placed not only on the ceiling and walls, but also on specialized sound-absorbing screens.

This is due to the fact that great attention is paid to the control of acoustic parameters in such rooms: they are tuned to different frequencies. Acoustic room preparation is an essential element of any serious audio project, whether it's building a home theater or a music lounge.

The fact is that each room leaves its own "acoustic imprint" on the nature of the sound of the equipment, and this imprint in most cases is negative.

Acoustic room preparation is an essential element of any serious audio project, whether it's building a home theater or a music lounge. The fact is that each room leaves its own "acoustic imprint" on the nature of the sound of the equipment, and this imprint in most cases is negative.

The biggest challenge in acoustic room design is optimizing the so-called reverberation time over the widest possible audio frequency band. Reverberation time is the amount of time it takes for the sound pressure level to drop by 60 dB after the sound source is turned off. This parameter strongly depends on the frequency of the sound, the higher it is, the faster the sound vibrations decay, and vice versa.The reverberation time in a good cinema hall should be approximately the same throughout the entire sound range, and this is extremely difficult to achieve.

At low frequencies, the main problem is the so-called standing waves - the distribution of sound pressure that does not depend on time (but only on the location of the listener). The frequency values at which bass standing waves occur depend mainly on the area of the room, as well as on its shape. The larger the cinema hall, the lower the frequency of all resonances. In particular, in a very large hall, all standing waves are shifted to the inaudible region (below 20 Hz) and do not affect the sound quality. There is also a dependence on the shape of the room. The worst option is when it has multiple or identical dimensions in height, width and length: in this case, the resonance at the same frequency is amplified many times over. The most uniform distribution of low-frequency resonances has a room whose size ratio obeys the golden section rule (length/width = width/height and length = width + height).

To eliminate the negative effect of standing waves on basses, in most cases, special resonant sound-absorbing structures are used - membrane resonators or Helmholtz resonators. The principle of their operation is the absorption of sound energy at a certain frequency or in a narrow frequency range.

Based on the fact that the reverberation time should fit into a certain corridor of values (say 0.6-0.8 seconds), the calculated amount of both materials is used, placing them in the room in a strictly defined way. Most often, sound-absorbing and reflective panels cover walls and ceilings. But sound-absorbing materials are ineffective if you want to reduce the reverberation time of the room at low frequencies (20-160 Hz). For this purpose, special resonant sound absorbers are needed - special designs that effectively absorb sound energy at certain frequencies (the values \u200b\u200bdepend on the design parameters).

After installing wall acoustic panels, the sound in any of your rooms can be made almost perfect, and besides, by doing so, soundproofing the room from the inside, i.e. You won't hear much from outside. With the existing variety of acoustic sound-absorbing panels, it is not at all difficult to choose the right design that will harmoniously fit into the existing interior of the room.

You can recommend acoustic panels from such well-known companies as: Leto, ARMSTRONG, Ecophon, ROCKFON. Resonant sound-absorbing structures must be made to order, taking into account the size and shape of the room.

Soundproofing walls, ceilings and floors

Soundproofing technologies for floors, walls and ceilings are different from each other, therefore, we will consider each process separately.

Floor soundproofing

Floor soundproofing is done to block noise coming from the apartment located on the floor below, or vice versa, so that the noise produced in your apartment does not annoy the neighbors downstairs. To isolate the floor, you can use the "floating" floor method, or make a frame from a log.

In the first option, you need to spread soundproofing material over the entire surface of the floor, then make a concrete screed. After that, a laminate, or other type of flooring, is laid on the screed. In the frame method, it is necessary to make a crate of wooden bars (lag). Insulating material is laid between the lags, the field of this crate is closed with chipboard or boards. To reduce vibration noise, it is recommended to place special vibration-damping pads under the logs. Detailed article on floor soundproofing.

Wall soundproofing

You can block the sounds coming from the apartments of your neighbors on the floor by soundproofing the walls adjacent to them.Please note that it makes no sense to isolate all the walls in the apartment, including internal partitions. For wall insulation, you can use self-adhesive soundproofing membranes, combined panels or boards installed in a special frame. Keep in mind that the thicker the sound insulation layer is, the less usable area of your apartment will remain. Another important factor in the soundproofing of walls are through sockets, in order to block sounds coming through them, it is necessary to fill the empty space between your and the neighboring socket with soundproofing material, such as mounting foam. Detailed instructions for soundproofing walls.

Ceiling soundproofing

For soundproofing the ceiling, it is better to choose lightweight materials that will not peel off due to their own weight or heavily load the ceiling frame. If you already have a false ceiling installed, then you simply need to remove the panels and install the insulation on the main ceiling, then put the panels back in place.

Detailed instructions for soundproofing the ceiling.

Remember the "golden" rule - soundproofing is much easier and cheaper to do before finishing work than after the repair is completed!

Soundproofing apartments with acoustic panels

So in any apartment, especially where a family with small children lives, one cannot do without installing acoustic foam rubber panels.

In addition, transport and industrial equipment are powerful sources of sound vibrations.

Acoustic foam rubber is an effective remedy not only against noise, but also against sound impulses that are below the limit of hearing. We are talking about infrasound, which is very harmful to the body: it negatively affects the heart, kidneys and lungs, and ultrasound, which inhibits biochemical processes in tissues.

Home theater acoustics how it all happens

When a sound wave traveling through the air collides with the building envelope, it is partially reflected, partially passes through, and partially absorbed. In addition, the sound shakes the barrier, makes it vibrate and radiate low-frequency waves into the room and beyond.

Things to keep in mind when setting up a home theater

If the walls mostly reflect sound, that's good for soundproofing and bad for acoustics.

If a significant part of the waves passes through the fence, this will reduce the sound insulation.

The greater the sound absorption capacity of the fence, the better for both acoustics and sound insulation.

The higher the modulus of elasticity of the wall material, the worse it is for both acoustics and sound insulation. Experts consider rooms with reinforced concrete walls the least suitable for musical purposes.

The acoustically worst room is a cubic one, as the reflected waves converge in the center and overlap each other.

We use acoustic foam rubber for efficient work in the office

Offices are known to generate and spread indoor noise pollution—footsteps, banging of drawers, doors, furniture, office equipment, phone calls and conversations—even if workers try to be as quiet as possible. All this reduces productivity and makes it difficult to focus on work.

However, if you equip the room with acoustic foam rubber, you can minimize sound vibrations.

Thanks to the soundproofing of the room, people hear and understand each other better. This relieves the nervous system of stress that causes various disorders, including chronic fatigue syndrome.

Video on how acoustic foam works:

How to make walls soundproof Let's start with sockets

As a rule, these include gaps and cracks in the wall, insufficiently fixed outlet sockets.

Through socket sockets must be terminated as follows:

- Remove the socket and mounting box.

- Cover the hole with a washer made of any soundproofing material - basalt cardboard, asbestos fabric or dense mineral wool.

- Putty the hole for better sealing.

- Return the mounting box and socket to their place.

Soundproof materials

Acoustic experts point out that there are no perfect insulators. Systems with a thick soft coating to stop the wave and a hard one to reflect it will help get rid of noise.

For proper sound insulation, the material must reflect the sound, preventing it from penetrating further. The fibrous, granular or honeycomb structure absorbs noise, which does not allow it to be reflected.

The methods of struggle are determined by the material used:

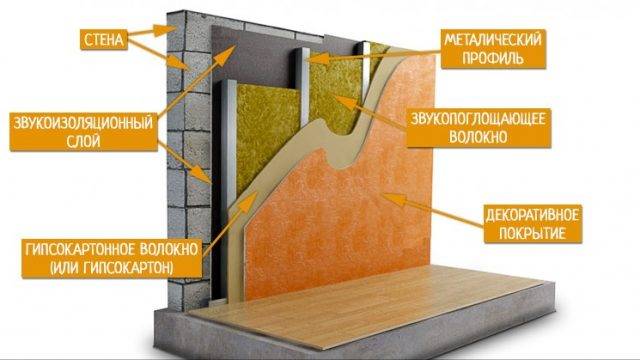

Drywall. Before installing the plates, it is required to seal the cracks in the wall, and then plaster the surface. Installation of drywall has features. For example, if the noise comes from the wall, then the frame attached to it will become its conductor. In this case, it is attached to the ceiling and floor near the "noisy" wall. It is also better to use rubber gaskets during installation, which create an additional barrier. The gaps between the plates are treated with mounting foam. To increase the effect, mineral wool or gypsum fiber is laid between the wall and drywall.

Ecowool, ZIPS panels. The panels are fixed to the wall surface. They consist of mineral wool glued on both sides with drywall. Additional holes are drilled for mounting. The combination of the ZIPS panel and ecowool will protect not only from extraneous noise, but also provide thermal insulation.

- Foam materials obtained by extrusion. They help to dampen not only the sound wave, but also the vibration. However, their sound insulation is an order of magnitude lower than mineral wool.

- Polyurethane boards are used in recording studios. Their dimensions are 600x1200x15. The material is lightweight, effective at delaying sounds and easy to install. The downside is the high cost.

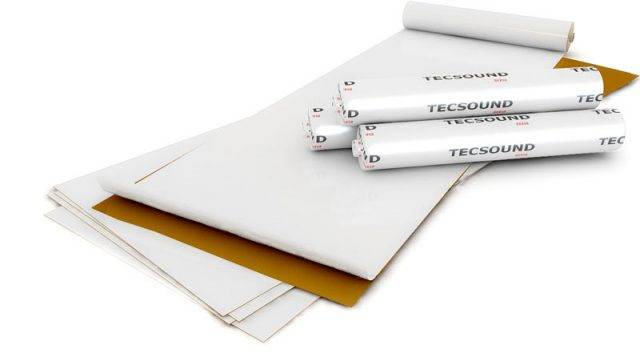

- Soundproof membrane. Modern material 35 mm thick. Independent use is rarely used. As a rule, it supplements the previous types of insulators. Installation is quite simple, as the membrane is very flexible. High density well protects against noise. The main disadvantage is the high cost.

- Cork flooring has a beautiful decorative look. Installation takes place with glue. The fabric is thin but insulates well.

As you can see, there are enough insulating materials. The main task is to choose the right option at an affordable price.

It is better to purchase materials from trusted manufacturers, since construction work is quite laborious and lengthy. Popular are:

- URSA;

- rockwool;

- Shumanet;

- ISOVER;

- Fonstar;

- Softboard;

- Texound 70;

- Maxforte.

The cheapest, but high quality is ISOVER Zvukozashchita. Its cost is 100-200 rubles per 1 sq.m. Rockwool ACOUSTIC BATTS has proven itself well for 110 rubles. per 1 sq.m.

Maxforte Standard has a high degree of protection. Environmentally friendly material eliminates noise up to 65 dB.

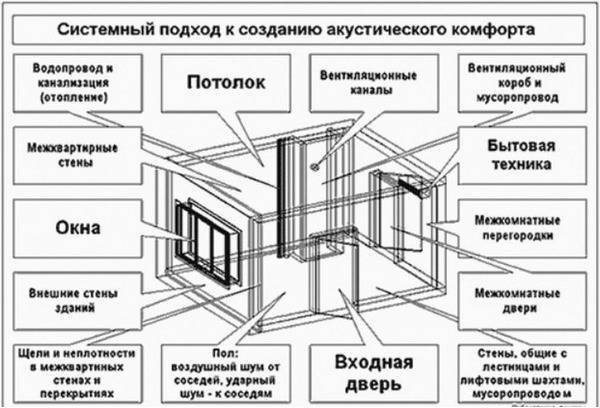

Types and sources of noise

Before proceeding with the soundproofing of an apartment, let's look at the types and sources of annoying noise. After all, to get rid of noise, sometimes it is enough to isolate a certain element of the apartment’s design and not spend money on complete soundproofing.

Noise is of two types:

- Wave noise - transmitted through the air, from the source to the eardrums, using sound waves.Wave noise includes loud music, raised voices, barking dogs, and so on.

- Vibration noise - transmitted by vibrations along the walls emanating from the source. Vibration noise includes - hitting a wall with a sledgehammer, the operation of a puncher or a washing machine.

Now let's deal with the sources of noise:

- Noise from the street - comes mainly through the windows. The sound of squealing brakes, the voices of screaming children and grandmothers, the hum of a flying plane - all this is noise coming from the street. You can get rid of street noise by installing high-quality triple-glazed windows. An additional soundproofing element can be curtains made of dense material.

- Noise from the entrance - enters through the front door. In order not to hear the sounds of a working elevator or neighbors cursing on the landing, it is enough to soundproof the front door. In addition to upholstery of the door with sound-absorbing materials, it is necessary to install seals between the leaf and the frame, otherwise the noise isolation will be ineffective.

- Noise from adjacent apartments - comes through walls, through sockets and gaps between floor slabs. Noise from neighbors is the most common reason for wanting to soundproof an apartment. If there is only one source of constant annoying noise, then it is enough to soundproof the walls adjacent to the source. If you are unlucky, and noisy neighbors surround you from all sides, then in this case, you will have to do a complete soundproofing of the apartment.

- Noise from your apartment - comes to the neighbors in the ways listed above and annoys them. If you often have noisy companies, if you are a musician rehearsing at home, if you have children who love to jump and have fun loudly, then in order to maintain good relations with your neighbors, it is better for you to soundproof the walls, ceiling and floor without waiting for the visit of the district police officer.

Beware the noise

Noise is a set of sound waves that are able to transfer their energy to physical bodies and be reflected from them. And noise pollution is acoustic vibrations of various origin and spectrum, whose intensity and energy violate acoustic comfort. These vibrations can be heard from the outside and formed inside the room. Moreover, internal ones are more dangerous than external ones. After all, the noise coming from the street is kept by the walls of the building and double-glazed windows. And there is almost no protection from internal noise in the room.

In other words, acoustic foam prevents the release of vibrational energy that can cause vibrations in solids.

For the sound to be good

Even in a very small room, it is not difficult to achieve an acceptable sounding home audio system. To do this, you must follow the following recommendations of experts.

The distance from the speakers to the wall behind them must be either Oz or Oz from the distance to the opposite wall. If this is not possible, then a layer of sound-absorbing material with a thickness of at least 40 mm should be placed on the wall behind the speakers.

The columns are installed at an equal distance from the side walls.

The optimal height of the speakers is 1.2-1.5 mot of the floor.

The distance between the columns is chosen experimentally by shifting and pushing them apart. Vocal music is best for testing the sound of the system.

Rear speakers will help create the effect of surround sound in a home theater.

If you want to hide the speakers, install an £M in-ceiling recessed system. Preference should be given to models with swivel speakers that allow you to optimize the sound in the listening area.

Acoustic design

Some companies provide acoustic design services. They take measurements on site, find the optimal location for the loudspeakers, and calculate the required sound attenuation for each surface and zone in the room.Then acoustic modules are made for walls and ceilings, and panels of different designs and thicknesses are used in the same room. This allows you to achieve very good acoustics, but, unfortunately, such work is not cheap (from 12 thousand rubles per 1 mg of the finished surface).

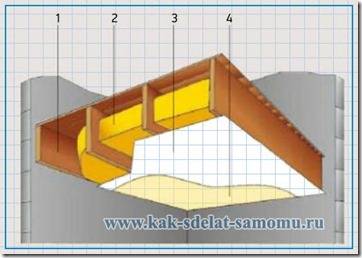

Ceiling: Acoustic preparation

Acoustic ceiling structure: a crate is attached to the ceiling (1), sound-absorbing plates (2) are installed, they are covered with a film (3), and then with an acoustically transparent fabric (4)

Types of noise

Building acousticians traditionally divide noise into air noise and impact noise (the latter is sometimes referred to as structural noise). Airborne noise is generated by fluctuations of a source in the air, shock is the result of mechanical action on a solid barrier and the propagation of vibration along it.

Airborne noise hardly overcomes walls and partitions made of heavy materials (brick, concrete), since its intensity is usually not enough to shake such an obstacle. But it easily penetrates through cracks and holes. Therefore, the fight against airborne noise involves the maximum sealing of the room.

Structural noise is able to "travel" throughout the house, being transmitted by structures connected to each other. It can be generated not only by steps or the work of a construction tool, but also by loudspeakers placed on the floor or close to the wall, vibrating at a low frequency. Comparatively thin (3-10 mm) damping pads do a good job with this kind of noise.

materials

With the construction of new houses, there is an increasing tendency to reduce the weight of the structure. This reduces the cost of the foundation, which negatively affects the soundproofing of the room. Not everyone is interested in hearing what his neighbors are doing. That is why soundproofing an apartment is a concern not only for those who live in old panel houses, but also in new buildings.

Due to the large assortment of soundproofing materials on the market, you can get confused. The choice should be approached responsibly, because each material has its own purpose. Increasingly, people are interested not only in how well the material will fight sound, but also whether it is safe to use it in a residential area. Not everyone wants to breathe phenol vapors and install glass wool.

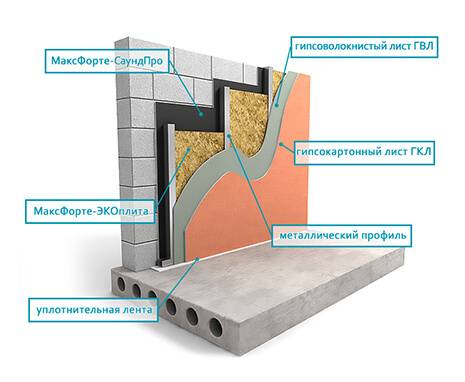

In this article, we will consider materials for soundproofing the walls of the Russian manufacturer MaxForte.

Which can be used for frame and frameless circuits.

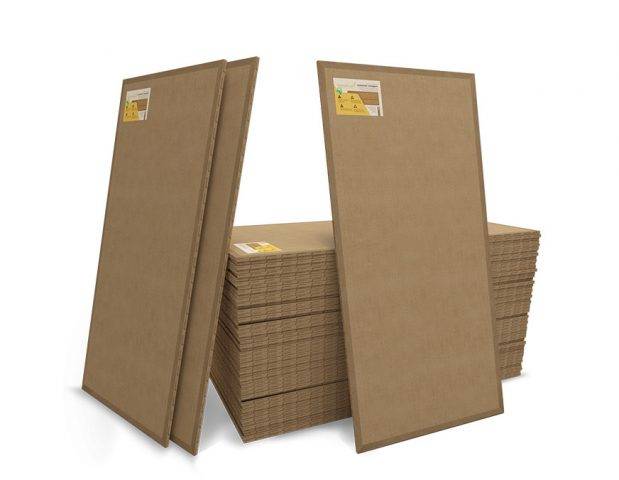

MaxForte EcoSlab

Sound-absorbing basalt slabs of volcanic rock.

They have excellent acoustic properties. Plates are used for soundproofing the most complex objects: cinemas, recording studios.

Environmentally friendly material. Can be used as fire protection. High sound absorption coefficient αW at all frequencies (including low ones).

Without phenol and slags.

- Nonflammable material.

- Without smell.

- Moisture resistant.

- Maximum class "A" for sound absorption.

MaxForte EcoAcoustic

Plates made of polyester fibers (acoustic synthetic winterizer), without glue in the composition. For shaping, thermal bonding technology is used. The material does not emit or contain harmful substances. Only primary raw materials are used in production. For maximum sound absorption, aerodynamic fiber laying is used. When working with the material does not require overalls, gloves and a respirator.

Plates made of polyester fibers (acoustic synthetic winterizer), without glue in the composition. For shaping, thermal bonding technology is used. The material does not emit or contain harmful substances. Only primary raw materials are used in production. For maximum sound absorption, aerodynamic fiber laying is used. When working with the material does not require overalls, gloves and a respirator.

- They are made from homogeneous raw materials.

- Without fiberglass.

- Hypoallergenic product.

- Not afraid of water.

- Maximum class "A" for sound absorption.

MaxForte SoundPro

Rolled composite material, a new generation. Created taking into account theoretical developments in the field of building acoustics. With a thickness of 12 mm, it provides maximum protection against airborne and impact sound. An indispensable material in small apartments. Without glue in the composition and chemistry.It also acts as fire protection and thermal insulation.

- Completely nonflammable.

- Not afraid of water.

- Phenol and odor free.

- Easy installation.

- Maximum class "A" for sound absorption.

For enhanced sound insulation, a combination of materials is recommended, for example, MaxForte SoundPro and MaxForte EcoPlyta. Using such a scheme will allow you to get the highest sound absorption, including low frequencies (stereo systems, home theaters)

For enhanced sound insulation, a combination of materials is recommended, for example, MaxForte SoundPro and MaxForte EcoPlyta. Using such a scheme will allow you to get the highest sound absorption, including low frequencies (stereo systems, home theaters)

But it is not always possible to "eat" precious centimeters from the wall and you need to do it as subtly and efficiently as possible. In this case, frameless soundproofing will be a proven option.

How to install soundproofing without making a frame with MaxForte SoundPro:

Everyone chooses the best way for themselves based on the calculation of forces, personal preferences and financial capabilities.

If you make soundproofing according to our recommendations, you can safely count on good comfort and silence.

Sound insulation of walls is carried out using the following materials:

Cork panels.

For better sound insulation, combinations of materials are recommended, for example, membranes and plates.

In addition to the basic materials, depending on the method of soundproofing you choose, you will need:

- Metal profile or wooden bars for frame guides.

- Drywall, chipboard, or other decorative wall covering.

- Doubel screws.

- Mountings for plates.

- Screws.

Interior walls and partitions

How to soundproof the wall in this case?

A wooden frame is created, then hard and soft layers are formed. A lining is used to create a hard layer, a soft layer is formed from soundproof boards.

Concrete interior walls in prefabricated houses themselves have good soundproofing properties. The problem lies in the poor joining of the plates, the presence of cracks, holes for pipes and sockets.

In this case, careful sealing is necessary, otherwise the process of soundproofing the walls in the apartment will not bring the desired results.

Walls made of porous concrete should be carefully plastered, this will reduce their sound transmission.

Functional purpose of soundproofing

Noise isolation occurs in two directions:

- Soundproofing - any noise behind the wall will be reflected and not reach the person.

- Sound absorption - all emitted noise will be absorbed and will not go outside the room.

Before starting work, it is worth identifying the sources of noise. If the neighbors below cause concern, then there is no point in soundproofing the walls. It is worth finishing the floor.

If you are going to sing karaoke at night, then it is necessary to isolate not only the walls, but also the ceiling with the floor. However, no soundproofing material will protect against vibration noise.

Types of noise

Noise is usually classified into several types:

- Air - all sounds transmitted through the air (scream, laughter, speech). They enter the premises through doors, windows, cracks.

- Acoustic - appears in empty rooms, can be easily eliminated by arranging furniture.

- Percussion - most common in apartment buildings (the sound of a hammer drill and other construction tools). Penetrates walls and ceilings. Its intensity depends on the proximity to the source.

- Structural - noise from vibrations during the operation of construction equipment. It hits through walls and ceilings. As a rule, impact and structure noise accompany each other.

The first barrier to the sound wave is the wall. High-quality sound-absorbing partitions will save the nerves of neighbors.

In soundproofing, the quality of the material used is of great importance. Most domestic sound insulators do a poor job. Often the noise from the ninth floor is heard on the ground floor.

Noise norms

Loudness is measured in decibels. Permissible noise standards in apartment buildings are 40-45 dB, comparable to a quiet conversation between two people. The norm is valid in the daytime from 7 to 23 hours. At night, the rate drops to 25-30 dB. For comparison, a human whisper has a volume of 20 dB.

In noisy enterprises, the permissible noise level is 85 dB. In such conditions, a person can be up to 8 hours a day. During this time, no harm is done to the human body. For work at an increased noise level, special protective equipment is used. The critical value for a person is 110 dB, when hearing irritation begins. When the sound is raised to 130 dB, unpleasant sensations appear on the skin.

In apartments, increased noise causes unpleasant emotions, a sense of peace is lost. This causes the space to be protected by soundproofing the walls. Before starting installation work, it is recommended to determine the noise level in order to select the optimal sound insulator.

What material will give the best soundproofing of the walls

To protect against noise, materials with sound absorption and sound insulation properties are used.

The maximum effect can be achieved with the simultaneous use of modern soundproofing materials, which are stunned by both properties (sound absorption, sound insulation). For example, good insulation is obtained by combining coir and cork boards, or by using plasterboard and gypsum fiber together.

The modern soundproofing panel system (ZIPS) is made in the form of a “sandwich” with a thickness of 40 mm to 120 mm and consists of several layers of drywall and mineral filler.

A good design makes it easy to attach this material to the wall.