Factors affecting the operation of the boiler

They are:

- Design. A technique can have 1 or 2 circuits. It can be wall or floor mounted.

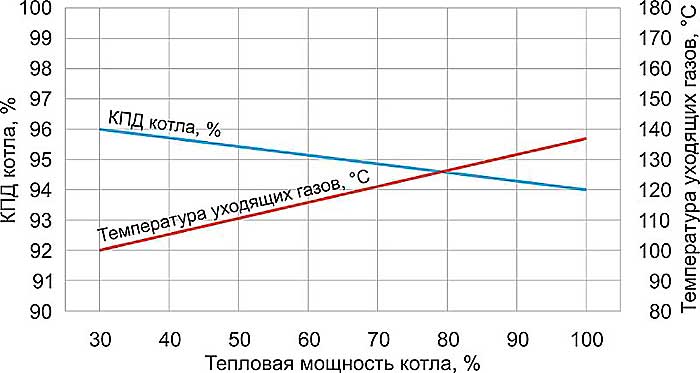

- Normative and actual efficiency.

- Competent arrangement of heating. The power of technology is comparable to the area that needs to be heated.

- Technical conditions of the boiler.

- Gas quality.

Design question.

The device can have 1 or 2 circuits. The first option is complemented by an indirect heating boiler. The second already has everything you need. And the key mode in it is the provision of hot water. When water is supplied, heating is completed.

Wall-mounted models have less power than those placed on the floor. And they can heat a maximum of 300 sq.m. If your living area is larger, you will need a floor standing unit.

P.2 efficiency factors.

The document for each boiler reflects the standard parameter: 92-95%. For condensation modifications - approximately 108%. But the actual parameter is usually lower by 9-10%. It decreases even more due to heat losses. Their list:

- Physical malaise. The reason is excess air in the apparatus when the gas is burned, and the temperature of the outgoing gases. The larger they are, the more modest the efficiency of the boiler.

- Chemical burn. What is important here is the amount of CO2 oxide that occurs when carbon is burned. Heat is lost through the walls of the apparatus.

Methods for increasing the actual efficiency of the boiler:

- Elimination of soot from the pipeline.

- Elimination of scale from the water circuit.

- Limit chimney draft.

- Adjust the position of the blower door so that the heat carrier acquires the maximum temperature.

- Elimination of soot in the combustion chamber.

- Installation of a coaxial chimney.

P.3 Questions on heating. As already noted, the power of the device necessarily correlates with the heating area. A smart calculation is needed. The specifics of the structure and potential heat losses are taken into account. It is better to entrust the calculation to a professional.

If the house is built according to building codes, the formula is 100 W per 1 sq.m. It turns out this table:

| Area (sq.m.) | Power. | ||

| Minimum | Maximum | Minimum | Maximum |

| 60 | 200 | 25 | |

| 200 | 300 | 25 | 35 |

| 300 | 600 | 35 | 60 |

| 600 | 1200 | 60 | 100 |

It is better to purchase foreign-made boilers. Also in the advanced versions there are many useful options to help you achieve the optimal mode. One way or another, the optimal power of the device is in the range of 70-75% of the highest value.

The optimal mode of operation of the gas boiler to save gas is achieved by eliminating clocking. That is, you need to set the gas supply to the smallest value. The attached instructions will help you with this.

Adjustment

Automatic control is provided by the heating controller.

It includes the following details:

- Computing and matching panel.

- Actuating device on the water supply section.

- An actuator that performs the function of mixing liquid from the returned liquid (return).

- Boost pump and sensor on the water supply line.

- Three sensors (on the return line, on the street, inside the building). There may be several in a room.

The regulator covers the liquid supply, thereby increasing the value between the return and supply to the value provided by the sensors.

To increase the flow, there is a booster pump, and the corresponding command from the regulator. The incoming flow is regulated by a "cold bypass". That is, the temperature drops. Some of the liquid that circulates along the circuit is sent to the supply.

Information is taken by sensors and transmitted to control units, as a result of which flows are redistributed, which provide a rigid temperature scheme for the heating system.

Sometimes, a computing device is used, where the DHW and heating regulators are combined.

The hot water regulator has a simpler control scheme.The hot water sensor regulates the flow of water with a stable value of 50°C.

Regulator benefits:

- The temperature regime is strictly maintained.

- Exclusion of liquid overheating.

- Economy of fuel and energy.

- The consumer, regardless of distance, receives heat equally.

Table with temperature chart

The operating mode of the boilers depends on the weather of the environment.

If you take different objects, for example, a factory room, a multi-storey building and a private house, all will have an individual thermal diagram.

In the table, we show the temperature diagram of the dependence of residential buildings on the outside air:

| Outside temperature | Temperature of network water in the supply pipeline | Temperature of network water in the return pipeline |

| +10 | 70 | 55 |

| +9 | 70 | 54 |

| +8 | 70 | 53 |

| +7 | 70 | 52 |

| +6 | 70 | 51 |

| +5 | 70 | 50 |

| +4 | 70 | 49 |

| +3 | 70 | 48 |

| +2 | 70 | 47 |

| +1 | 70 | 46 |

| 70 | 45 | |

| -1 | 72 | 46 |

| -2 | 74 | 47 |

| -3 | 76 | 48 |

| -4 | 79 | 49 |

| -5 | 81 | 50 |

| -6 | 84 | 51 |

| -7 | 86 | 52 |

| -8 | 89 | 53 |

| -9 | 91 | 54 |

| -10 | 93 | 55 |

| -11 | 96 | 56 |

| -12 | 98 | 57 |

| -13 | 100 | 58 |

| -14 | 103 | 59 |

| -15 | 105 | 60 |

| -16 | 107 | 61 |

| -17 | 110 | 62 |

| -18 | 112 | 63 |

| -19 | 114 | 64 |

| -20 | 116 | 65 |

| -21 | 119 | 66 |

| -22 | 121 | 66 |

| -23 | 123 | 67 |

| -24 | 126 | 68 |

| -25 | 128 | 69 |

| -26 | 130 | 70 |

There are certain norms that must be observed in the creation of projects for heating networks and the transportation of hot water to the consumer, where the supply of water vapor must be carried out at 400 ° C, at a pressure of 6.3 bar. The heat supply from the source is recommended to be released to the consumer with values of 90/70 °C or 115/70 °C.

Regulatory requirements should be followed for compliance with the approved documentation with the obligatory coordination with the Ministry of Construction of the country.

Link to download the chart

- 110 - for industrial premises of categories C, D and D with emissions of combustible dust and aerosols;

- 130 - for industrial premises without the release of combustible dust and aerosols.

The limiting temperature, °C, of the heating surface should be taken:

- c) for low-temperature panels for radiant heating of workplaces - 60.

- d) for high-temperature radiant heating devices - 250.

- e) for building structures with built-in heating elements:

- - 26 - for floors of premises with a permanent stay of people;

- - 30 - for bypass paths, benches of swimming pools;

- - 31 - for floors of rooms with temporary stay of people;

- - 28, 30, 33, 36, 38 for ceilings with a room height not exceeding 2.8, 3.0, 3.5, 4 and 6 m, respectively.

What happens when hot water is turned on at the same time at two points of intake

The scheme becomes more complicated if, during the use of hot water at one point of intake, it becomes necessary to turn it on at another point, for example: when the shower is turned on in the bathroom, it becomes necessary to wash your hands in the washbasin of the toilet. In this case:

- the rate of use of hot water increases sharply, its consumption increases,

- there is a weak pressure of hot water;

- the flow of cold water into the boiler increases,

- a drop in the temperature of the boiler heat exchanger leads to the fact that the water temperature at the first point of intake ceases to be comfortable,

- a few seconds are needed to turn on the automatic boiler for heating,

- a few more seconds - so that both users at two points of the fence can use water at a comfortable temperature.

All this time, both users cannot fully use hot water. She comes intermittently. Unproductive consumption of water, uselessly going down the drain, increases dramatically.

What if one of the users turned off the water? In this case, the consumption of hot water drops sharply. A temperature jump occurs on the heater of a double-circuit gas boiler. As a result, the temperature of hot water rises sharply at the point of intake, which continues to work. The user cannot fully use the water, it goes into the sewer until the automatics work on the boiler, and the water of the desired temperature begins to flow to the user in a stable mode.

Since such situations are repeated several times every day, the unproductive consumption of hot water is increasing every day. At the same time, one should not forget about the discomfort that users experience during moments of unstable hot water supply.

Water temperature in the heating system

- In a corner room +20°C;

- In the kitchen +18°C;

- In the bathroom +25°C;

- In corridors and flights of stairs +16°C;

- In the elevator +5°C;

- In the basement +4°C;

- In the attic +4°C.

It should be noted that these temperature standards refer to the period of the heating season and do not apply to the rest of the time. Also, information will be useful that hot water should be from + 50 ° C to + 70 ° C, according to SNiP-u 2.08.01.89 "Residential buildings". There are several types of heating systems: Contents

- 1 With natural circulation

- 2 With forced circulation

- 3 Calculation of the optimal temperature of the heater

- 3.1 Cast iron radiators

- 3.2 Aluminum radiators

- 3.3 Steel radiators

- 3.4 Underfloor heating

With natural circulation, the coolant circulates without interruption.

Matching the temperature of the heat carrier and the boiler

Regulators help to coordinate the temperature of the coolant and the boiler. These are devices that create automatic control and correction of the return and supply temperatures.

Regulators help to coordinate the temperature of the coolant and the boiler. These are devices that create automatic control and correction of the return and supply temperatures.

The return temperature depends on the amount of liquid passing through it. The regulators cover the liquid supply and increase the difference between the return and supply to the level that is needed, and the necessary pointers are installed on the sensor.

If you need to increase the flow, then a boost pump can be added to the network, which is controlled by a regulator. To reduce the heating of the supply, a “cold start” is used: that part of the liquid that has passed through the network is again transferred from the return to the inlet.

The regulator redistributes the supply and return flows according to the data taken by the sensor, and ensures strict temperature standards for the heating network.

What is the difference between supply and return heating

And so, to sum up, what is the difference between supply and return in heating:

- Feed - the coolant that goes through the water conduits from the heat source. This can be an individual boiler or central heating of the house.

- The return is water that, having passed through all the radiators, goes back to the heat source. Therefore, at the input of the system - supply, at the output - return.

- It also differs in temperature. The supply is hotter than the return.

- Installation method. The conduit that is attached to the top of the battery is the supply; the one that connects to the bottom is the return line.

After installing the heating system, it is necessary to adjust the temperature regime. This procedure must be carried out in accordance with existing standards.

The requirements for the temperature of the coolant are set out in the regulatory documents that establish the design, installation and use of engineering systems of residential and public buildings. They are described in the State building codes and regulations:

- DBN (V. 2.5-39 Heat networks);

- SNiP 2.04.05 "Heating, ventilation and air conditioning".

For the calculated temperature of the water in the supply, the figure is taken that is equal to the temperature of the water at the outlet of the boiler, according to its passport data.

For individual heating, it is necessary to decide what the temperature of the coolant should be, taking into account such factors:

- The beginning and end of the heating season according to the average daily temperature outside +8 ° C for 3 days;

- The average temperature inside heated premises of housing and communal and public importance should be 20 ° C, and for industrial buildings 16 ° C;

- The average design temperature must comply with the requirements of DBN V.2.2-10, DBN V.2.2.-4, DSanPiN 5.5.2.008, SP No. 3231-85.

According to SNiP 2.04.05 "Heating, ventilation and air conditioning" (clause 3.20), the limiting indicators of the coolant are as follows:

Depending on external factors, the water temperature in the heating system can be from 30 to 90 °C. When heated above 90 ° C, dust and paintwork begin to decompose. For these reasons, sanitary standards prohibit more heating.

To calculate the optimal indicators, special graphs and tables can be used, in which the norms are determined depending on the season:

- With an average value outside the window of 0 °С, the supply for radiators with different wiring is set at a level of 40 to 45 °С, and the return temperature is from 35 to 38 °С;

- At -20 °С, the supply is heated from 67 to 77 °С, while the return rate should be from 53 to 55 °С;

- At -40 ° C outside the window for all heating devices set the maximum allowable values. At the supply it is from 95 to 105 ° C, and at the return - 70 ° C.

The dependence of the coolant temperature on the outside air temperature

A specific table of the ratio of outdoor temperature and coolant depends on factors such as climate, boiler equipment, technical and economic indicators. Reasons for using the temperature chart The basis for the operation of each boiler house serving residential, administrative and other buildings during the heating period is the temperature chart, which indicates the standards for the coolant indicators, depending on what the actual outside temperature is.

- Drawing up a schedule makes it possible to prepare the heating for a decrease in the temperature outside.

- It is also energy saving.

ATTENTION! In order to control the temperature of the heat carrier and have the right to recalculate due to non-compliance with the thermal regime, the heat sensor must be installed in the central heating system

Optimum water temperature in a gas boiler

Usually they put a lattice fence that does not interfere with air circulation. Cast iron, aluminum and bimetallic devices are common. Consumer choice: cast iron or aluminum The aesthetics of cast iron radiators is a byword.

They require periodic painting, as the rules require that the working surface of the heater has a smooth surface and allows easy removal of dust and dirt. A dirty coating forms on the rough inner surface of the sections, which reduces the heat transfer of the device. But the technical parameters of cast iron products are on top:

- little susceptible to water corrosion, can be used for more than 45 years;

- they have a high thermal power per 1 section, therefore they are compact;

- they are inert in heat transfer, therefore they smooth out temperature fluctuations in the room well.

Another type of radiators is made of aluminum.

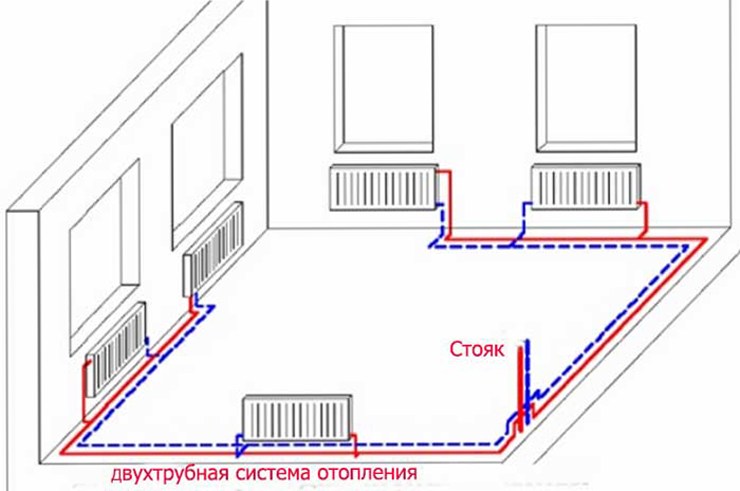

A single-pipe heating system can be vertical and horizontal. In both cases, air pockets appear in the system. A high temperature is maintained at the inlet to the system to warm up all the rooms, so the piping system must withstand high water pressure. Two-pipe heating system The principle of operation is to connect each heating device to the supply and return pipelines. The cooled coolant is sent to the boiler through the return pipeline. During installation, additional investments will be required, but there will be no air jams in the system. Temperature standards for rooms In a residential building, the temperature in the corner rooms should not be lower than 20 degrees, for interior rooms the standard is 18 degrees, for shower rooms - 25 degrees.

How is it calculated

The control method is selected, then the calculation is made

The calculation-winter and reverse order of water inflow, the amount of outside air, the order at the breakpoint of the diagram are taken into account. There are two diagrams, where one of them considers only heating, the other one considers heating with hot water consumption.

For an example of calculation, we will use the methodological development of Roskommunenergo.

The initial data for the heat generating station will be:

- Tnv - the amount of outside air.

- Tvn - air in the room.

- T1 - coolant from the source.

- T2 - return flow of water.

- T3 - the entrance to the building.

We will consider several options for supplying heat with a value of 150, 130 and 115 degrees.

At the same time, at the exit they will have 70 ° C.

The results obtained are brought into a single table for the subsequent construction of the curve:

So, we got three different schemes that can be taken as a basis. It would be more correct to calculate the diagram individually for each system.Here we considered the recommended values, without taking into account the climatic features of the region and the characteristics of the building.

To reduce electricity consumption, it is enough to choose a low-temperature order of 70 degrees and uniform distribution of heat over the heating circuit will be ensured. The boiler should be taken with a power reserve so that the load of the system does not affect the quality operation of the unit.

Protection against low temperature of the coolant in the return of a solid fuel boiler.

What will happen to a solid fuel boiler if its "return" temperature is below 50 °C? The answer is simple - a resinous coating will appear on the entire surface of the heat exchanger. This phenomenon will reduce the performance of your boiler, make it much more difficult to clean and, most importantly, can lead to chemical damage to the walls of the boiler heat exchanger. To prevent such a problem, it is necessary to provide appropriate equipment when installing a heating system with a solid fuel boiler.

The task is to ensure the temperature of the coolant that returns to the boiler from the heating system at a level not lower than 50 °C. It is at this temperature that the water vapor contained in the flue gases of a solid fuel boiler begins to condense on the walls of the heat exchanger (transition from a gaseous state to a liquid one). The transition temperature is called the "dew point". The condensation temperature directly depends on the moisture content of the fuel and the amount of hydrogen and sulfur formations in the combustion products. As a result of a chemical reaction, ferrous sulfate is obtained - a substance useful in many industries, but not in a solid fuel boiler. Therefore, it is quite natural that manufacturers of many solid fuel boilers remove the boiler from the guarantee in the absence of a return water heating system. After all, here we are not dealing with the burning of metal at high temperatures, but with chemical reactions that no boiler steel can withstand.

The simplest solution to the low return temperature problem is to use a thermal three-way valve (anti-condensation thermostatic mixing valve) . The thermal anti-condensation valve is a thermomechanical three-way valve that ensures the admixture of the coolant between the primary (boiler) circuit and the coolant from the heating system in order to achieve a fixed temperature of the boiler water. In fact, the valve allows the still unheated coolant to pass through a small circle and the boiler heats itself. After reaching the set temperature, the valve automatically opens the access of the coolant to the heating system and works until the return temperature drops below the set values again.

Piping of a solid fuel boiler - Anti-condensation valve

Piping of a solid fuel boiler - Anti-condensation valve

Briefly about the return and supply in the heating system

The water heating system, using the supply from the boiler, supplies the heated coolant to the batteries, which are located inside the building. This makes it possible to distribute heat throughout the house. Then the coolant, that is, water or antifreeze, after passing through all available radiators, loses its temperature and is fed back for heating.

The simplest heating structure is a heater, two lines, an expansion tank and a set of radiators. The conduit through which the heated water from the heater moves to the batteries is called the supply. And the conduit, which is located at the bottom of the radiators, where the water loses its original temperature, returns back, and will be called the return. Since, when heated, the water expands, the system provides a special tank. It solves two problems: a supply of water to saturate the system; accepts excess water, which is obtained during expansion. Water, as a heat carrier, is directed from the boiler to the radiators and back. Its flow is provided by a pump, or natural circulation.

Supply and return is present in one and two tubular heating systems. But in the first there is no clear division into the supply and return pipes, and the entire pipe line is conditionally divided in half. The column that leaves the boiler is called the supply, and the column that leaves the last radiator is called the return.

In a single-pipe line, heated water from the boiler flows sequentially from one battery to another, losing its temperature. Therefore, at the very end, the batteries themselves will be cold. This is the main and probably the only disadvantage of such a system.

But the single-pipe option will gain more pluses: lower costs for the purchase of materials are required compared to the 2-pipe; the diagram is more attractive. The pipe is easier to hide, and it is also possible to lay pipes under doorways. Two-pipe is more efficient - two fittings (supply and return) are installed in parallel in the system.

Such a system is considered by experts to be more optimal. After all, her work is unsteady on the supply of hot water through one pipe, and the chilled water is diverted in the opposite direction through another pipe. Radiators in this case are connected in parallel, which ensures uniformity of their heating. Which one establishes the approach should be individual, while taking into account many different parameters.

Just a few general tips to follow:

- The entire line must be completely filled with water, air is a hindrance, if the pipes are airy, the heating quality is poor.

- A sufficiently high fluid circulation rate must be maintained.

- The difference between the supply and return temperatures should be about 30 degrees.

Optimal values in an individual heating system

Autonomous heating helps to avoid many problems that arise with a centralized network, and the optimal temperature of the coolant can be adjusted according to the season. In the case of individual heating, the concept of norms includes the heat transfer of a heating device per unit area of the room where this device is located. The thermal regime in this situation is provided by the design features of the heating devices.

Autonomous heating helps to avoid many problems that arise with a centralized network, and the optimal temperature of the coolant can be adjusted according to the season. In the case of individual heating, the concept of norms includes the heat transfer of a heating device per unit area of the room where this device is located. The thermal regime in this situation is provided by the design features of the heating devices.

It is important to ensure that the heat carrier in the network does not cool below 70 ° C. 80 °C is considered optimal

It is easier to control heating with a gas boiler, because manufacturers limit the possibility of heating the coolant to 90 ° C. Using sensors to adjust the gas supply, the heating of the coolant can be controlled.

It is a little more difficult with solid fuel devices, they do not regulate the heating of the liquid, and can easily turn it into steam. And it is impossible to reduce the heat from coal or wood by turning the knob in such a situation. At the same time, the control of heating of the coolant is rather conditional with high errors and is performed by rotary thermostats and mechanical dampers.

Electric boilers allow you to smoothly adjust the heating of the coolant from 30 to 90 ° C. They are equipped with an excellent overheating protection system.

The influence of temperature on the properties of the coolant

In addition to the above factors, the temperature of the water in the heat supply pipes affects its properties. This is the principle of operation of gravitational heating systems. With an increase in the level of water heating, it expands and circulation occurs.

However, in the case of using antifreezes, the excess temperature in the radiators can lead to other results. Therefore, for heat supply with a coolant other than water, you must first find out the permissible indicators of its heating. This does not apply to the temperature of district heating radiators in the apartment, since antifreeze-based fluids are not used in such systems.

Antifreeze is used if there is a possibility of low temperature affecting the radiators.Unlike water, it does not begin to change from a liquid state to a crystalline state when it reaches 0°C. However, if the work of heat supply is outside the norms of the temperature table for heating upwards, the following phenomena may occur:

-

Foaming

. This entails an increase in the volume of the coolant and, as a consequence, an increase in pressure. The reverse process will not be observed when the antifreeze cools; -

Formation of limescale

. The composition of antifreeze includes a certain amount of mineral components. If the norm of the heating temperature in the apartment is violated in a big way, their precipitation begins. Over time, this will lead to clogging of pipes and radiators; -

Increasing the density index.

There may be malfunctions in the operation of the circulation pump if its rated power was not designed for the occurrence of such situations.

Therefore, it is much easier to monitor the temperature of the water in the heating system of a private house than to control the degree of heating of antifreeze. In addition, ethylene glycol-based formulations, when evaporated, emit a gas harmful to humans. Currently, they are practically not used as a heat carrier in autonomous heat supply systems.