The choice of material for sound insulation

According to the builders, such a sound effect may be due to the lightness of the material, as well as errors made during installation work. But this drawback is quite capable of neutralizing modern building materials, a whole arsenal of which is offered by specialized stores. Laid on the roof in a special way in the so-called "roofing cake", they will provide reliable insulation from noise, help in maintaining warmth and comfort in the house.

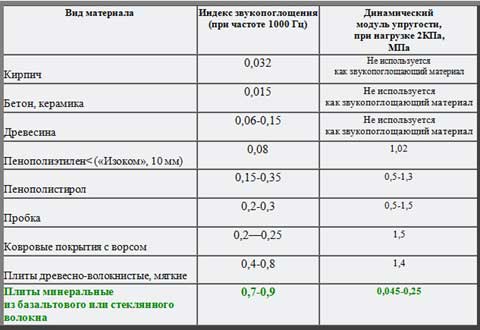

Roof soundproofing is not such a complicated process, but here it is important to choose the right material correctly. The main guidelines for its selection are the dynamic modulus of elasticity and the noise absorption index

The latter indicates how much of the total amount of sound energy has already been absorbed by the material, that is, it indicates how effectively the material worked as a sound insulator. This value is established by laboratory tests. As a rule, the noise spectrum in residential buildings varies within audio frequencies from 125 to 4000 Hz. Positive sound insulation of the roof will be ensured when using materials with indicators not lower than 0.6. For example, wood has a sound absorption index of 0.07-0.14, mineral wool - 0.6-0.9. Styrofoam, although it has established itself as an excellent heat-insulating agent, but its performance does not exceed 0.13-0.2, so roof soundproofing with its participation does not guarantee a good result.

The dynamic modulus of elasticity is measured in MPa and characterizes the elastic properties of the material. The higher this value, the worse the sound absorption. This effect is due to the fact that dense material is able to reflect sounds much better than loose material. Comparing blocks of basalt (with an elastic modulus of 0.05-0.25) or fiberglass slabs with foam plastic (whose index is from 0.5 to 1.4), the conclusion is that the use of fibrous materials is more appropriate.

Sound insulation of the roof is also carried out with the help of fiberglass. It is a little more expensive than other materials and when laying it, additional vapor barrier will be required, but in this way the insulation of the roof and the entire building as a whole will be ensured.

Roof soundproofing can also be provided with cork, which is usually sold in rolls. Having a loose structure, the cork will also become an additional heat-insulating agent for the roof. In stores you can also find a liquid cork analogue. Of course, its cost is different from the usual solid material, but the roof will look great.

Penofol is considered a wonderful steam, sound and heat insulating agent for the roof. By attaching it down with foil, the reflected heat will return to the house.

Another inexpensive way to reduce noise for a corrugated roof is to cover profile sheets with bitumen or polymer mastic. Such a solution will make the covering material heavier, due to which the sound insulation will also increase.

If the material has already been purchased, then the next step will be to select the most optimal design for installation work.

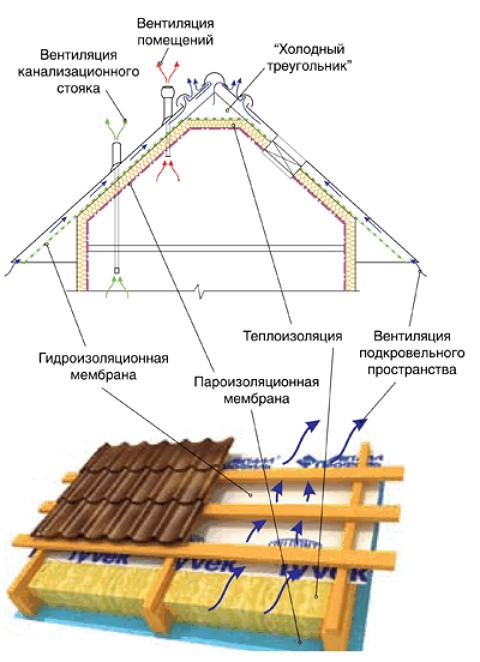

At the first stage of installation of roof sound insulation, rolled waterproofing is laid along the supports (rafters), which will significantly prevent the processes of decay of wood floors in the future.

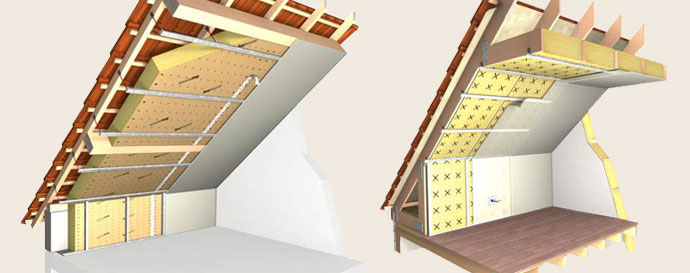

The next step is the most important. This is the correct installation of insulation, the main purpose of which is to protect the space under the roof from the action of adverse external environmental factors. Also, this layer is designed to increase the level of noise insulation of the roof.

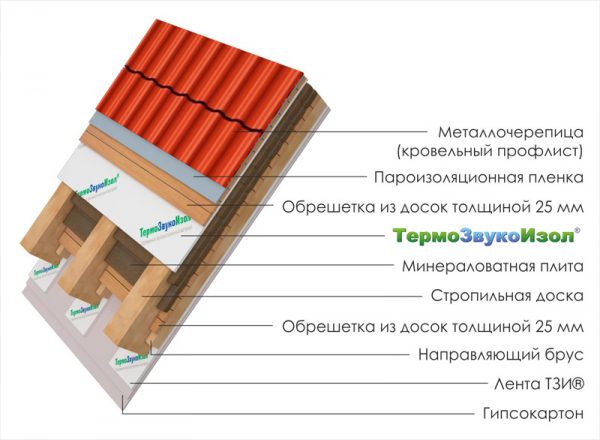

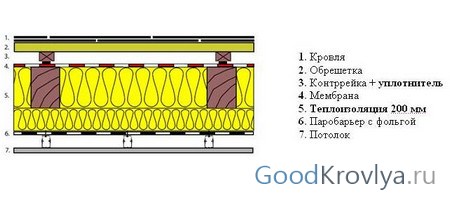

The sequence of laying soundproofing material when installing corrugated roofing

To perform roof soundproofing, you will need:

- wooden beam;

- vapor barrier film;

- polymer sand wool;

- staple gun;

- polyethylene foam or felt;

- insulation;

- sound absorbing boards;

- waterproofing material.

The process of laying hydro- and noise-insulating materials begins with the roof overhang on the rafters in a horizontal position. Noise and waterproofing materials are fixed between the rafters. In order to improve sound insulation, a layer of mineral polymer-sand wool up to 20 cm thick is added on top. Then, with an overlap of up to 15 cm, a vapor barrier film is placed

It is important not to overtighten the material, but to leave a slight sag. Materials are stapled with a staple gun

At the final stage of laying hydro- and noise-insulating materials, they are fixed with a counter-rail, and a small gap is left between the layers.

Next, a crate is made in increments of 90-120 cm. For its construction, it is better to use a wooden beam. Do not forget that the corrugated board should be fixed only after the complete sealing of all joints! An insulating material is installed between the rafters, which is connected to the crate from above, as a result of which the requirement to provide a gap between the soundproofing elements and the corrugated board is automatically fulfilled.

If the influence of the rafters, which act as acoustic bridges, through which the vibrations of the coating are transmitted to the sheathing of the walls of the building, is not eliminated, there is a possibility of reducing the sound insulation of the corrugated board, since a large resonating surface is formed and the insulation does not reduce its vibration.

An insulating gasket made of any elastic material, for example, ordinary felt or polyethylene foam, will help to solve this problem of soundproofing corrugated roofing. Insulating strips installed along the rafters will prevent the transmission of noise from the corrugated roof to the house.

For a comfortable stay in a private house, it is important to take care not only of heat, but also of the soundproofing of the roof. There is a wide variety of materials to help achieve the task.

Insulation work can be carried out both during the construction of a new house and in a time-tested dwelling. About why it is important to make soundproofing, what material to choose and how to install, read our article.

More than 80% of modern houses are covered with metal tiles or corrugated board. These roofing materials have important advantages. The service life of the coating can reach 60 years, stamped metal sheets stand out for their aesthetic appeal. They are reliable and easily endure any vagaries of the weather, and the cost is affordable for most people.

Nevertheless, such a roofing material has a significant drawback - low sound insulation and high thermal conductivity. Unlike outdated slate or roofing felt, the sound of a drumming downpour is perfectly transmitted. Insufficient sound insulation of the roof of a house made of metal tiles can be explained by several options:

Poor-quality crate contributes to the appearance of noise due to strong gusts of wind. This may be due to the fact that the laths of the crate have different thicknesses, nailed with different pitches. As a result, the corrugated board will sag and resonate strongly.

Saving on self-tapping screws also leads to a decrease in sound insulation. In addition, the recommended 8-10 pcs. per square meter. But the noise will increase due to the fact that they did not use roofing fasteners, but what was found in the garage

Therefore, it is important to follow the manufacturer's recommendations exactly.

If the corrugated roof was mounted "in a stretch", then the noise will appear during temperature changes.In the cold, the material will begin to shrink and the grooves will move out of the design position.

A small slope angle leads to a lot of noise during rain

Therefore, they try to make either steeper slopes, or increase the thickness of the soundproofing material.

And although it is difficult to influence the last point, all the reasons described before it are in the hands of the residents themselves. All that is required for soundproofing a roof made of metal is to perform installation in accordance with the requirements of regulatory documentation. This will not only increase the comfort of living in the house, but also make it more reliable, which means there will be savings on major repairs.

Noise isolation technology

Soundproofing measures for roofing with metal tiles will be more effective if planned at the design stage and carried out during the main roofing work.

If necessary, you can soundproof the already finished roof by laying insulating material from the side of the attic. Work is performed in the following order:

- After assembling the rafter frame, a waterproofing material (film, membrane or ordinary roofing material) is laid on the rafters.

- A rack frame is nailed over the waterproofing. At the same time, each rail must be treated with mounting foam or silicone glue on the underside before installation in order to prevent damage to the waterproofing film and the appearance of “sound bridges”.

- Soundproofing material is laid on the frame, in no case crushing or ramming it. A layer of insulation (foam plastic, foam plastic) is laid on top of the sound insulator, fixing it on the rafters.

- Then, along the rafter legs, a counter-lattice and a crate are attached, on which the finishing roofing is laid.

How to deal with unwanted metal roof sounds

To reduce roof noise, you can take the following measures:

- You can increase the strength of the coating by properly fixing the metal tile to the crate. At the same time, for fastening, you must use the recommended number of fasteners - according to the standard, there should be eight of them.

- When constructing a truss structure, the elements are laid in increments of 0.8–1.1 m.

- All flaws, irregularities in the design of the rafters must be eliminated so that the resulting crate has a completely flat surface, without any depressions and elevations.

- But even in the case of ideal laying of metal tiles, it is not possible to achieve complete sound insulation - additional measures are required. This concerns the need to use soundproofing materials.

Features of soundproofing materials

The category of soundproofing materials includes materials with a sound absorption coefficient (IS), starting from 0.4 units. It shows the amount of sound energy absorbed by the insulating material in relation to all received. It is clear that the larger it is, the more effective this insulator is.

Considering the importance of this parameter, manufacturers must indicate the value of IZ on the packaging or in the accompanying instructions, or label the material itself.

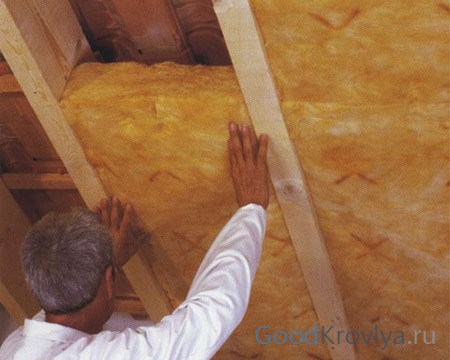

One of the best sound insulators are fiber, say, mineral wool. The fibers randomly located in it make the mineral wool sufficiently elastic, so it perfectly resists the vibration that occurs when rain drops hit the surface of a metal roof.

Soundproofing installation

Soundproofing of metal tiles is arranged in the following order:

- Work begins with the laying of rolled waterproofing along the rafter legs.

- Next, proceed to the stuffing of thermal insulation on the crate.

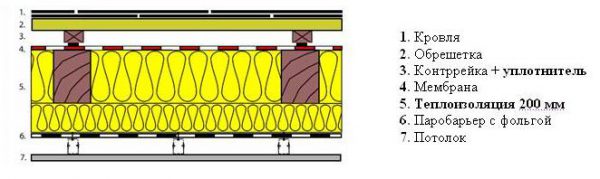

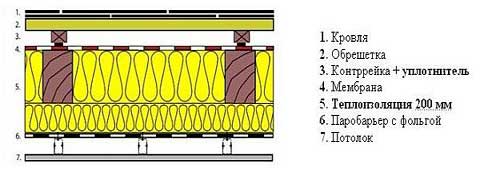

- To increase the level of heat and noise insulation, mineral wool is laid directly on the heat-insulating layer. The soundproofing layer must have a sufficient thickness - about 200 mm.

Sometimes you need to soundproof the finished roof of a house made of metal. In such cases, soundproof mineral wool is placed between the rafters.This procedure has its own subtleties: mineral wool should not be damaged or wrinkled during installation. Therefore, the material is cut with an allowance so that the layer is fixed between the rafters with some effort. The cut-out layer of sound insulation is inserted into the inter-rafter space with the middle part, after which, starting from the center, the edges are pressed.

Noise-absorbing material can be laid in two layers:

Scheme of a multilayer roofing pie

Compliance with the scheme of the device of a multi-layer roofing "pie" below will allow to achieve the maximum reduction in the noise of the attic roof. Insulation of this kind effectively performs the task of absorbing shock sound waves.

To reliably protect the roof from the effects of impact noise, the coating is separated by means of a sealant from the supporting system of the rafters. A gasket made of soundproofing material is placed between the rafter leg and the counter-batten.

If it is required to perform sound insulation of a roof that has been erected for a long time, then heat-insulating and sound-absorbing mineral slabs are laid between the rafter legs at a distance from the inside of the attic. In this case, crushing or any other deformation of the material must not be allowed. When cutting the noise-insulating insulation to the dimensions of the space between the rafters, a small allowance in width of 7-10 mm is provided. This will allow you to tightly insert the cut-out layer of insulation between adjacent rafters.

Causes of noise

Even competently, without additional sound insulation, it has a high resonant capacity, which amplifies the noise during rain, due to the small thickness of the sheets and the properties of the metal.

Loud sound causes discomfort, especially if the roof space is used as a residential attic. This flaw is reinforced by the following flaws in the design:

- Curve crate. If the crate is made of material of different thicknesses or the step between the bars is “floating”, the metal tile sheets located above wide areas sag, which gives a resonating effect, creating a lot of noise with every gust of wind.

- Lack of fasteners. To fix the sheets of metal tiles to the crate, special roofing screws with a neoprene seal are used, and at least 7-10 fasteners are used for each square meter of the coating. If there are fewer attachment points, the resonating effect that occurs when drops fall on the slope is enhanced.

- Installation without taking into account the thermal expansion of the material. If, during installation, the self-tapping screws are screwed all the way, sinking the hat, the sheets can be deformed due to thermal expansion, creating a loud rumble and crackle.

Requirements for soundproofing materials

You can make a soundproofing finish for an iron roof with various materials. There is no universal remedy, each case requires an individual approach. Main selection criteria:

- Strength. The product must maintain integrity under mechanical stress.

- Lack of response to changes in humidity levels and temperature changes.

- Resistance to UV radiation. The material must not decompose or release toxic substances when heated.

- A product of sufficient thickness will help to make the balcony noiseless.

- A simple and reliable fastening is capable of facilitating the process of soundproofing the roof.

The fulfillment of all conditions will ensure the reduction or complete disappearance of sounds from rain and wind.

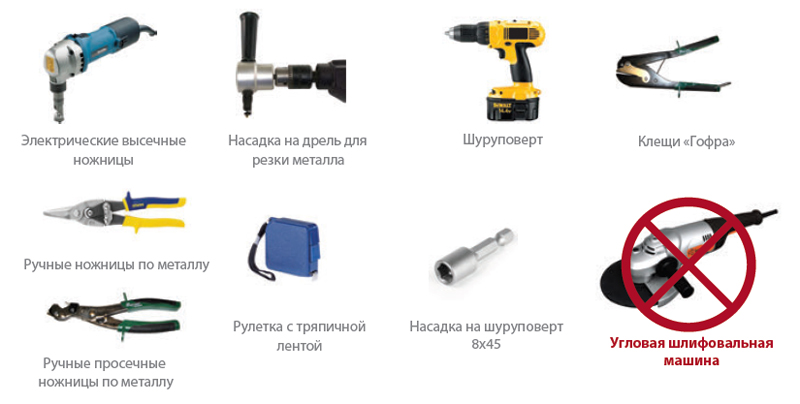

A set of tools for laying a roof from a profiled sheet

Tools for working with corrugated board.

- A tape measure will help you install the crate with the same distance, as well as make all the necessary measurements.

- You will need a clerical knife in order to cut noise and heat insulating materials.

- Screwdriver with various types of nozzles.

- Staple gun. It is needed for fixing noise and waterproofing.

- A gun that is used to work with sealing compounds. This device will be needed to seal the joints at the last stage of work.

- Pliers of the "corrugation" type will be needed when bending the folds on the sheets necessary to fix the drainage systems.

- A strip bender is needed to bend the sheet in the gutters of the drain.

- Lever hand scissors, punched electric shears for metal cutting.

What materials to choose for soundproofing the roof

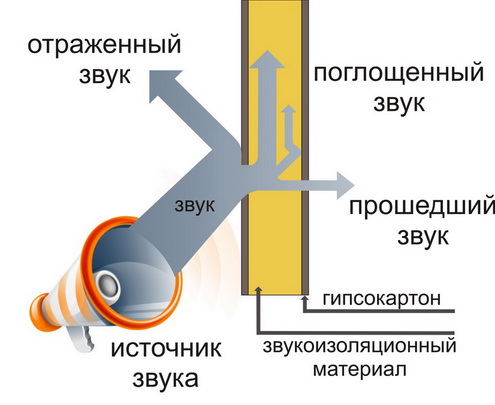

In order to correctly select the soundproofing material, it is necessary to have some knowledge of acoustics in the construction field. If you listen only to other people's advice and do not understand the essence of the process of absorbing sound waves, then there will be no guarantee that you will effectively solve the problem of sound insulation. To choose the right material for sound insulation, you need to know the following two indicators: the sound absorption index and the dynamic modulus of elasticity.

The first tells about what part of the total amount of radiated sound energy the material has already absorbed, that is, how effectively it worked as a sound insulator. This value is evaluated in laboratory tests (the sound frequency range from 125 to 4000 Hz is the noise spectrum in residential buildings).

The principle of soundproofing.

Positive sound insulation of the roof will be possible if materials with an indicator of at least 0.6 are used. So, for example, for wood, this sound absorption index is 0.07-0.14, for mineral technical wool it is 0.6-0.9, for polystyrene, although it is in good standing in terms of heat-insulating quality, it looks very modest - 0 .13 - 0.2. Therefore, foam is not recommended for soundproofing roofs.

The dynamic modulus of elasticity has measurements in MPa, it characterizes the elastic properties of materials. The higher it is, the worse the sound is absorbed by the material. This is because dense material reflects sound better than loose material. By comparing fiberglass or basalt slabs (their modulus of elasticity is 0.05-0.25) with foam plastic (its index is from 0.5 to 1.4), we can conclude that fiber materials are more suitable.

In addition, fiberglass can also be used for soundproofing. It is a little more expensive, and besides, you will need additional vapor barrier of your roof, but at the same time you will also insulate your building.

Cork can also be a good sound insulator (usually it is sold in rolls up to 10 m, with a thickness of 2 to 8 mm). It will also serve as a heater. There is a liquid cork material, it is not cheap, but the roof will look great.

An excellent sound, steam and heat insulator is penofol (its thickness is 8 m). If you attach it with the foil down, the reflected heat will return back into the house.

Another inexpensive way to reduce noise on yours is to cover it with a polymer or bituminous mastic. It will make the covering material heavier and reduce the sound of rain, which reinforces the corrugated board.

If you choose an excellent soundproofing material, then you will simultaneously solve the problem of thermal insulation, since any fibrous and loose material retains heat perfectly. After you have purchased quality material, the next step is to select the optimal design for installation.

Video instruction

First of all, I note that sound insulation is performed in exactly the same way as thermal insulation, since the same fibrous materials are able to protect the room both from the cold and effectively dampen noise. Therefore, the work is performed in the following sequence:

Preparation of materials

So, for soundproofing the roof, as well as any other surfaces, mineral wool, namely basalt wool, is an excellent solution. The only thing to keep in mind is that low-density cotton wool does the job better, as it is softer.

The fact is that the dynamic modulus of elasticity of the material is directly related to the density. The higher it is, the lower the soundproofing qualities. By the way, the same applies to the thermal insulation qualities of mineral wool - with an increase in density, thermal conductivity also increases.

I must say that even special mineral plates designed for soundproofing can be found on sale.Manufacturers claim that due to the special arrangement of the fibers, they have a higher sound absorption index. However, it only makes sense to use it for dampening percussive sounds.

Since our task is only to dampen acoustic noise, it makes no sense to use a special mineral wool, since it is more expensive. At the same time, the usual thermal insulation material also copes well with the task.

In addition to basalt wool, some other materials will be needed:

Penofol, which will serve as a vapor barrier, and also provide additional sound insulation;

- Rails for mounting the crate;

- Antiseptic for wood;

- Scotch.

That's all we need to insulate the roof.

Roof preparation

Before starting the soundproofing of the roof of the house, it is necessary to prepare the truss system, i.e. treat the truss system with an antiseptic. You can apply the composition with a brush or even a spray.

Along the way, carefully inspect all the details of the structure. If you find cracks on certain parts, be sure to strengthen them by laying bars or boards. If this is not done, then after soundproofing the truss system can quickly become unusable.

Noise protection

Acoustic protection is performed as follows:

| Illustrations | Actions |

|

Mineral wool laying:

|

|

Vapor barrier. As I said, we will use penofol as a vapor barrier, i.e. polyethylene foam coated on one side with foil. It attaches like this:

|

|

Lathing installation. Fill the slats on top of the rafters, to which you will later attach the finishing material. The batten can be fixed either vertically or horizontally, depending on the type and location of the finishing material you are going to use. |

This completes the work. We examined how the roof is soundproofed from the inside after laying the roofing. However, the work can also be done from the outside during the installation of the roof, which is even easier.

In this case, penofol is attached from the inside and the crate is immediately mounted. Then, mineral wool is laid on the outside of penofol, after which a superdiffuse membrane is attached to the rafters. When installing sound insulation from the outside, there is no need to additionally fix it.

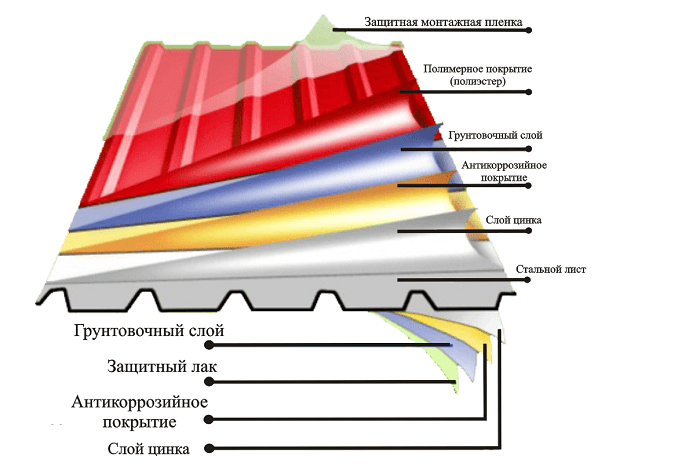

Properties of roofing corrugated board

The most significant advantages of corrugated board are:

- ideal impact strength and ability to withstand severe mechanical stress;

- unpretentiousness and durability;

- thermal and climatic inertia.

In addition to the positive characteristics, corrugated board has one drawback: minimal sound insulation (the coating increases the volume of ambient sounds several times). Residents of houses whose roofs are covered with corrugated board often complain about increased noise, any rain, hail makes such noise that it seems like machine-gun fire has begun.

Builders are convinced that this is due to errors that are made during installation, as well as the lightness of the material. But experts say that in fact, noise can be removed with the help of a roofing pie, which is truly complex and has the necessary thermal insulation composition.

A good assembly will also save you from unnecessary noise.

Selection and installation of soundproofing material for houses

The main criteria for the selection of soundproofing materials are the sound absorption index and the dynamic modulus of elasticity.

Each of these values significantly affects the effectiveness of sound insulation.

The index shows what part of the sound energy from its total amount the material can absorb. This figure is determined in the laboratory. For good sound insulation, materials are taken in which this value is not less than 0.6. For fiberglass and mineral wool, the index ranges from 0.7 to 0.95, for foam plastic - 0.15-0.25, for polyurethane boards - 0.5-0.75. If a metal tile is used, it is best to take TZI (thermosound insulation), it absorbs up to 87% of external noise.

The internal space between the rafters is filled with sound-absorbing material based on mineral wool or fiberglass, which simultaneously performs the function of thermal insulation along with sound insulation.

The dynamic modulus of elasticity characterizes the elastic properties of the material (elasticity, viscosity) and is measured in MPa. Naturally, the lower the indicator, the better the soundproofing properties. Therefore, fibrous and loose materials, such as mineral wool and fiberglass slabs (0.15-0.25 MPa), are best suited for soundproofing the roof.

In most cases, choosing a high-quality heat insulator will help solve the noise problem, but some nuances must be taken into account. First, take care of good acoustic isolation at the points of contact. Secondly, to provide a gap between the sound insulation and the metal tile.

Usually, the insulation is laid between the rafters, from above it borders on the crate, on which the metal tile is laid. Thus the second requirement is fulfilled automatically. But the first thing you need to take care of.

Wood and metal rafters are good conductors of sound and should be further insulated. Elastic materials are used for this: from ordinary felt to polyethylene foam. Gaskets cut out of them are installed along the roof rafters and at the junction points, so noise insulation is reduced and the first requirement is met.

The reason for the appearance of extraneous noise can be poor-quality installation of the roof, namely, poorly fixed sheets of metal tiles, so you must strictly follow the instructions for installation and flooring of the material and you should not save on self-tapping screws.

Installing a noise barrier is an important step in arranging the roof of your home, and the main thing here is not to make a mistake and do everything right.

Share this helpful article:

The sound of spruce branches on the roof

Breathtaking stories about the benefits of living in a country house can be listened to for a long time: silence, birdsong and a peaceful atmosphere.

But the silence is rarely long, or rather, until a heavy hurricane begins in the area and rain with hail, or a lone tired woodpecker sits on the roof to rest and at the same time clean its beak. And then existence in a house with a metal roof turns into a pitch hell. The fractional knock of fir cones and tree branches falling from a hurricane, multiplied by an echo, will make you think: “How to soundproof the roof of a house?”

Naturally, the process of competent sound insulation will depend on the type of roof or roof of a private house. Recall that the existing soundproofing material, and this is about 95 percent, are lightweight sound absorbers. According to their physical characteristics, light noise absorbers do not reflect, much less cut off, acoustic noise of a wave nature.

Therefore, properly made soundproofing should solve the problem of eliminating three types of noise:

shock

structural

acoustic.

Installation and installation of soundproofing materials is carried out simultaneously with roofing work. Such activities allow you to make a "pie" of thermal, waterproofing and acoustic protection.

Troubleshooting options

As a rule, sound insulation is included in the set of measures for glazing a balcony, when the roof is insulated and sealed. A well-organized process provides protection from external sounds in adverse weather conditions. But if the work was carried out poorly and the roof on the loggia or balcony periodically starts to make noise, it becomes necessary to carry out additional sound insulation. The way to solve the problem directly depends on the cause of extraneous sounds.

The most commonly used measures are:

- The soundproofing of the canopy is carried out with soft polymers designed to reduce the sound of raindrops.

- In case of poor-quality fixation of the roof, additional strengthening of the structure is carried out.

- Change the angle of the visor on the balcony.

- Incorrectly selected visor parameters need to be trimmed.

Cardinal measures include the complete replacement of a metal visor with a plastic structure. It is easier to soundproof a loggia than a balcony. Usually only the front part needs insulation, and the sides are left unchanged.

You can provide the roof of the balcony with reliable sound insulation with your own hands. Dismantling the decorative lining of the ceiling is the most time-consuming moment. After the completion of the main stage of work, it will need to be returned to its original place.

When the decorative trim of the roof has been removed, a visual inspection of the quality of fixation of the metal roof is carried out. Existing gaps are eliminated with insulating material.

The surface of the visor or canopy is cleaned of all contaminants. After that, it is pasted over with the material chosen for sound insulation. The organization of work in the warm period does not require additional fixation measures. It is enough to remove the protective film and press the material with the adhesive side to the inner surface of the roof.

Comment!

Low temperature reduces the adhesive properties of the material, so it needs to be heated.

A blowtorch or a building hair dryer will come to the rescue. If work with open flames is carried out indoors, fire safety measures should be taken into account.

The source of the rumble may not necessarily be raindrops. The excessive width of the visor is one of the reasons for annoying noise on the balcony. To ensure sound insulation, it is enough to leave a visor 15 cm wide, and remove the excess area.

Poor-quality fixation of the material on the roof is another reason for the formation of vibration and vibrations. If you close up the gaps and strengthen the fasteners, then the sound insulation of the balcony will increase markedly.

The process of soundproofing itself is not difficult, but working at height is associated with a high danger to health and life. Therefore, it is better to entrust the arrangement of the balcony roof to industrial climbers who have the necessary skills and equipment for organizing high-altitude work.

Sergey Novozhilov is an expert in roofing materials with 9 years of practical experience in the field of engineering solutions in construction.

The relevance of the fight against noise for the roofs of private houses remains unchanged. The progress in the development of soundproofing materials, from the use of mineral wool to the use of acoustic systems, has reached the roof. How to carry out the correct soundproofing of the roof with your own hands?