In most typical apartments, one standard option is provided for the location of sockets - on the wall. This is not always convenient, and meters of additional wires “spread” around the rooms: extension cords, power filters, which spoil the design and get underfoot. The issue of placing sockets in a studio apartment is especially relevant, where walls and partitions can be completely absent between functional areas? Solving the problem is simple: just install sockets in the floor, taking into account the future location of the equipment.

Varieties

Currently, there are several main types of electrical installation devices for the floor:

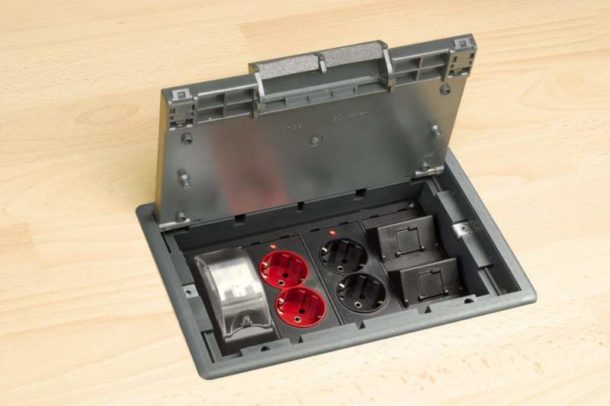

- simple sockets with a cover that protects the connector from moisture and dust ingress;

- hatches - embedded structures, more complex and complex, a type of recessed device;

- columns - racks made of a rigid profile with a cavity for placing wiring devices inside it;

- minicolumns.

Also, sockets are divided according to other parameters:

- By color - white, gray, graphite, black, brown, with a pattern for finishing material.

- According to the material of manufacture - plastic and metal.

- By the number of connected plugs - from 1 to 12.

- By type of design - retractable, rotary, stationary, built-in devices.

Device security level

A number of factors are taken into account here:

- fire safety;

- degree of protection from moisture and dust;

- ability to withstand mechanical stress;

- the maximum weight that the product can support.

So, metal sockets do not burn or melt, withstand weight from 200 kg to 4 tons, are well protected from mechanical damage, so they are installed in crowded places.

The plastic device is suitable for the home. It can withstand weight up to 300 kg, is resistant to mechanical stress, does not support combustion.

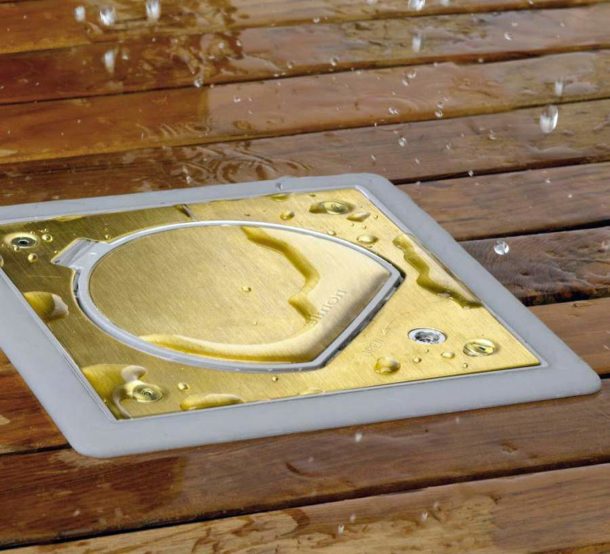

The degree of dust and moisture protection is shown by the IP Index (Ingress Protection Rating). The minimum value is 22, the maximum is 69. High-quality dust and moisture-proof floor sockets have an IP 67 index, that is, almost the maximum.

Floor rosette columns

The floor rosette column deserves special attention. It is a telescopic stand made of aluminum or plastic that rises from the floor and rests on the ceiling without the need for fixing with dowels. It can accommodate wiring devices of any European standards. Inside the column is divided into 2 channels for separate power and low-current lines. Electrical communications are brought to the device through floor channels or a stretch ceiling.

The standard height of the rosette column is 1.5 m and 2.7 m, with the possibility of increasing to 3.25 and 4.5 m.

A double-sided column is an ideal solution for offices and other premises where it is necessary to connect a large number of equipment at the same time. Each column can have up to 32 45 x 22.5 mm modules. In this case, sockets can be mounted on 1 or 2 sides.

A mini-column differs from a column in height. Such a rack rises above the floor to a height of 25 cm or 68.5 cm and is also equipped with a large number of sockets.

Why can't standard sockets be used?

Often people are confused by the rather high price of floor sockets. There are also difficulties with their acquisition: they can not be found in every store. Then there may be a temptation to save energy and money and install ordinary sockets, overheads, in the floor. However, this is absolutely impossible for a number of reasons:

- Wall devices are not designed for the loads that models installed in the floor are subjected to: they are not walked on, furniture is not placed on them, etc. Ordinary sockets will break very often.

- Wall models do not have moisture and dust protection, so the risk of a short circuit increases many times over.

- Devices do not close with lids when not in use, which can also lead to accidents.

- They protrude from the surface, are not suitable for hidden placement, when placed on the wall it is imperceptible and does not cause discomfort. On the floor, even a slight protrusion will be noticeable, you can stumble and fall on it.

- The IP index does not exceed 44, which may be insufficient for more severe floor conditions.

Thus, ordinary wall outlets, even built-in ones, are not suitable for use on the floor, so you need to purchase only special devices designed for high loads.

To avoid a short circuit and fire, you need to connect the wires to the device in a plastic box, this will provide maximum insulation.

Rules for choosing sockets for the floor

Currently, a fairly large number of electrical installation products for the floor are used. They are used to connect various devices: telephones, computers, television equipment, etc. They are made from a variety of materials. To purchase the most suitable model, you need to check it according to several criteria:

- The degree of moisture protection - the higher it is, the better the device is protected from water penetration. For dry rooms, devices with a low index are suitable; for wet rooms, you should choose the maximum protection.

- The required depth of the cover - it can vary from 6 to 26 mm. This parameter depends on the height of the fill or raised floor and the finish used.

- Required number of sockets. There can be single and pair modules, there are also combinations of 4, 6, 8 and 12 devices.

- Accounting for the type of outlet.

- Color - usually matched to the finish of the floor or the interior of the entire room.

- Modification - a simple socket in the floor, a hatch, a column, a mini-column.

- The material from which the socket is made. The most common steel, plastic, brass, aluminum. In order not to overpay for unnecessary functions, you need to know a few features of the device. So, plastic models are not much inferior to their metal "brothers" in terms of strength and wear resistance: they are able to withstand a load of up to 300 kg. At the household level, this is an almost imperceptible difference. But when arranging offices and passageways, preference should be given to metal devices: they are more durable and durable.

- Ease of opening the cover of the device, tight fit.

- The required quantity is 1, 2, a small socket block or column.

- Operating conditions.

Important! When buying, be sure to check the completeness of the device in the package. If any part is missing, it will no longer be possible to install the outlet.

Device installation instructions

Installing a socket in the floor is quite simple, all activities can be performed independently. Installation does not require special skills or devices.

- First, choose the place where the outlet will be located.

- Conduct a cable channel with wires to the installation site of the outlet.

- Further actions depend on the material of the floor. In a wooden one, a groove of a suitable size is simply cut. The hatch is fixed in this hole. With a concrete floor, the process becomes more complicated. Filling will be done first. A special box for the device is installed on the floor, which is usually included. Pour the mixture over the floor and let it dry. After hardening, carefully remove the box.

- The socket housing is installed in the finished niche and fixed with the help of the accessories included in the kit.

- The socket is connected to the mains.

- The installation of the protective cover completes the installation of the outlet.

When the device is fixed, it is necessary to check its performance, as well as the quality of installation. Then they find out how tightly the covers close and protect the outlet from water penetration.

Floor standing units are great for large open spaces as they get rid of ugly wires, as well as for cluttered rooms as they help to unload the space and organize the workplace.