Types of noise

To choose the right soundproofing material, you need to take into account the effectiveness of noise, which depends on the very nature of the formation of extra decibels. Currently, there are two types of noise generation: air and shock.

The classification itself does not cause difficulties in understanding, however, we will give a brief description of these types:

Airborne noise refers to excessive vibration of the air, which occurs as a result of any mechanical action.

For example, loud music, talking in raised tones, breaking dishes during quarrels - all these sounds penetrate to you through socket openings, ceiling ceilings, an open balcony, etc.

Impact noises come from the falling of heavy objects on the floor of neighbors, the stomping of feet, the rearrangement of furniture, and so on.

Purpose and scope

Acoustic felt (aka Struttofiber) is a rolled material with high density and small thickness for sealing thin sheathing and frame soundproof structures:

- It allows you to create an excellent sound-absorbing layer for sound insulation, while the whole structure does not thicken.

- Acoustic felt, in some cases suitable for finishing to improve room acoustics

- It is made of polyester (synthetic) fiber without the addition of any adhesives, photo above, does not contain harmful substances, unlike other building sound insulation

Areas of application, as a heater and sound absorber:

- Frame cladding of walls and ceilings, made of thin timber or a metal profile, with a thickness of 20 millimeters or more

- In suspended ceiling system

- In stretch ceilings

- Walls (framework)

- pitched roofs

- In the floors along the lags

- humming equipment

- Wrapping large diameter pipes

- In air conditioning and ventilation systems

To improve acoustics and reduce stray resonance and echo:

- In recording studios and music studios

- Inside the cinemas

- In chambers with supply and exhaust units

- In server rooms

- In sololifts and pumping units

Acoustic insulation of car interiors

In soundproofing cars, felt is excellent as a sound-absorbing material; in terms of its performance, it is in no way inferior to Biplast, while its price is much more advantageous:

- Noise-absorbing material obtained from acoustic felt in sound insulation, in addition to the main function - the absorption of extraneous sounds, also automatically serves as an additional electrical safety and fire safety of your car

- The use of acoustic felt in the door skin will only absorb the sound that has seeped through the previous layers of noise insulation on the door, it also allows the skin to be pressed more tightly against the surface, which eliminates squeaks.

- Technical characteristics of felt - thickness 10-20 millimeters, sheet dimensions 75x100 centimeters, there may even be an adhesive layer and moisture impregnation

Treatment zones for soundproofing in a car:

- For plastic door trim

- Insulation of wheel arches inside the cabin

- To the ceiling

- Engine compartment bulkhead insulation

Sponge rubber options

Porous foam rubber is produced in several versions.

Sheet

The size of the foamed sheet rubber is on average 650 by 650 mm.

The thickness of the sheets is very different - from 5 to 45 mm.

They are used as gaskets and insulation.

The price of such material is from 250 rubles per kg.

Tape and roll

Porous rubber in the form of rolls and tapes is usually made into self-adhesive insulation for doors and windows, which are easy to connect to the surface without assistance.

To do this, simply remove the protective film from the side of the material on which the adhesive is applied. Serve such a tape in a state of several years.

The price of ordinary rolled rubber is from 120 rubles per kg.

corded

Foamed cords are used as heat insulators and sealants in a variety of fields. They are often made from silicone.

The price of such a product starts on average from 70 rubles per meter.

The benefits of felt

Felt is perhaps one of the most common insulating materials. It has a lot of advantages, which is why it is used in various industries and in particular in construction. The main advantage of this insulator is its efficiency. Soundproofing felt has the following advantages:

- The material does not emit dust;

- Can be used in rooms with any humidity;

- Sufficiently light specific gravity allows you to carry out installation work yourself;

- Easy to install, you can lay felt insulation yourself;

- It has heat and sound insulation qualities.

Using felt slabs for soundproofing a house, you can create effective protection for your living space from sounds and cold.

Types of felt and advantages

Due to the porous-layered structure, felt has almost unique sound absorption properties:

- Unlike other noise-insulating materials, felt not only reflects, but also absorbs any sound as much as possible.

- It does an excellent job of both suppressing external noise and suppressing internal noise in the car interior.

- When soundproofing doors, roofs, floors in the cabin and trunk, technical felt is used.

- Which has an excellent wrinkle rate, therefore it is convenient to install

- To reduce noise and vibrations coming from the bottom of the machine, it will be enough to lay felt plates under the rubber mats

Felt types

When soundproofing cars, felt imported and domestic is used:

- Technical felt, coarse wool

- Synthetic acoustic felt having a thickness of up to 20 millimeters

- Special multi-layer felt with a soundproof membrane

- This noise-canceling felt material does an order of magnitude better than many advertised noise isolators.

- And the solid bottom layer also reflects acoustic waves, thus extraneous sounds are additionally damped.

- It is worth adding that the cost of felt is quite affordable, so today it is the best and most economical solution for soundproofing cars.

Benefits

Felt acoustic insulation has many advantages:

- It is absolutely safe for the environment and humans.

- It does not contain harmful substances, it does not emit an unpleasant odor or caustic dust

- High density and thickness (up to 20 millimeters), allows it to be used in frame structures

- It has good sound absorbing properties

- Regarding moisture, it is impossible to say unequivocally, felt without impregnation or sizing absorbs moisture from the air

- Has high thermal insulation properties

- It does not support combustion

- Has high strength, elasticity and wear resistance

- The instruction informs that during its installation it is not required to heat the material and use personal protective equipment (mask, respirator, gloves), it does not fall into pieces that are unsuitable for further use

- Unlike mastic and bituminous materials, it is easily dismantled and can be reused.

- It has an aesthetic appearance and can be used as a top layer

- Retains properties throughout the service life

Noise isolation with felt

The main question is why almost all car manufacturers, including well-known German companies, use felt in standard soundproofing solutions:

- The answer is obvious because it's cheap!

- In addition, all the pieces of felt that they put at the factory inside the pillars, fenders, and other cavities of the car are usually tightly sealed in sealed polyethylene bags to prevent them from getting wet.

- At the service station, it is unlikely that repairmen will mess with polyethylene, installing felt sound insulation on your car

- Saving on everything is the motto of all manufacturers, so blindly trust the choice of repairmen, it is better to purchase material and do the work yourself

- Again, when using even synthetic felt, moisture condensation cannot be avoided.

- When you need the cheapest car soundproofing, then you can use the cheapest option - domestic felt

- Musical felt is called synthetic, it is preferable to other analogues, which is produced in large quantities.

You can watch a video about the implementation of felt sound insulation.

Felt types

To date, felt manufacturers offer various types of material that are used in a particular area. The most common is technical coarse wool felt. Insulation made from natural material is used for soundproofing apartments, houses and public buildings.

Synthetic felt is produced using synthetic fibers and a special adhesive base. Such a product has high rates of absorption of air and vibration sounds. Due to the environmental friendliness of the material, it can be used in residential areas.

Acoustic felt is produced in sheets of a certain size. Its parameters are 2.5 by 1.2 meters. with density. At 1500 gr. per square metre. Due to the lightness of the sheet, it can be installed by yourself.

Felt with built-in membrane. The main property of this material is that, despite the small thickness of the layer, a high level of protection against airborne sound is provided. Depending on the type of room and its characteristics, you can choose the most effective sound insulation from the appropriate type of felt.

Technical Coarse

This type of material is used as thermal insulation. Due to its low weight and good density, this insulator is very popular with modern construction companies. Plus, it has a low cost, so you can protect your home from sounds with maximum benefit.

Technical felt is produced with a thickness of 10 - 12 millimeters, so it is supplied in the form of a roll or plate. The roll is formed from a thirty-meter linen rolled into a roll. The width of such a canvas is 1.6 meters, which allows you to form segments of the required size. The density of sound insulation per square meter is 1.5 kg/m2. The characteristics of felt soundproofing allow you to use the material with maximum productivity.

Acoustic felt

An acoustic felt sound insulator is used when working with frame partitions, floors and ceilings. Due to good sound absorption, the material can be used in recording studios. Often this insulation is used for pitched roofs and ventilated facades. Also, acoustic felt can be used in the manufacture of a floating floor, which is a soundproof substrate. Such felt is made on the basis of 100% polyester fibers, so it is an environmentally friendly material that can be used for residential premises.

The dimensions of the canvas are 2.5 meters long and 1.2 wide, with a thickness of 10-12 millimeters. This type of canvas is used in particular for soundproofing the car interior.

Needle punched felt

This type of material is considered non-woven, and the fibers are interconnected by piercing with special needles. Various types of fibers are used in the manufacture, due to which the material has certain characteristics and can be used not only in construction, but also in other industries.

Due to the softness of needle-punched felt, it is often used as a heater for sewing shoes and clothes. In addition, such felt can be used for the manufacture of furniture products and car insulation. Felt is produced in rolls 30 meters long, and the web width is 1.5 meters. Due to the soft structure of the fibers, the fiber absorbs moisture well, leaving the shoes dry.

Special felt

The main difference between the material lies in its composition. In the manufacture of special felt, natural and synthetic fibers are used, which makes it possible to obtain a product that absorbs well any kind of sounds and noises. There are many options for the color of the canvas, which allows you to choose a shade in the manufacture of tension structures.

Manufacturing technology involves the use of modern equipment and complex professional systems. With the use of such felt, substrates for a floating floor are made, and in the manufacture of stretch ceilings. Also, such a canvas is used in the equipment of ventilation systems and communication elements.

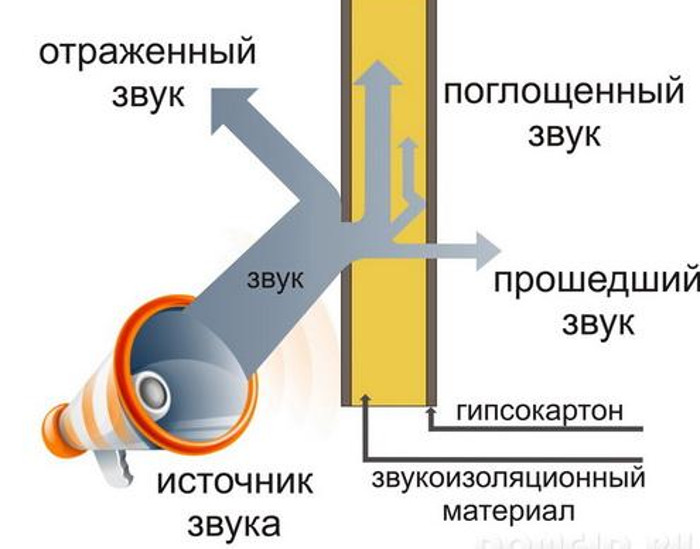

Separation of materials

In turn, soundproof materials are also divided into two types: sound-absorbing and sound-proof, which differ from each other in their structure. The sound-absorbing material has a porous or fibrous structure, passing through which the sound is first slowed down and then absorbed. For example, felt boards, cork sheets and mineral wool.

Due to the density of the structure, soundproofing material does not absorb excessive noise, it completely repels it: brick, concrete and other analogues. In practice, a good effect can be achieved by combining the materials of two structures, the so-called sandwich panels.

DIY installation

If it is necessary to install soundproofing of an apartment, then first of all it is necessary to draw up a plan for the work. It is not always necessary to cover all the walls with a protective layer, sometimes it is enough to process only one or two of them. In other situations, it may be necessary to think about soundproofing the floor, ceiling.

When carrying out work, it is necessary to take into account how effective insulation is required. Sometimes it may be sufficient to use a thin layer of acoustic felt, and in other cases a material of significantly greater thickness will be required.

It should be borne in mind that there is no point in using a single layer of felt when working in an apartment. As a rule, several layers of materials are needed, each of which performs certain functions, including the final finish.

Needle felt

Needle felt

Therefore, two installation options can be considered:

- Using a thin layer This is necessary if very powerful soundproofing is not needed or if work is carried out in a small apartment.

- The use of powerful protection. This is required where residents are constantly suffering from loud sounds coming from outside.

First, the order of work will be considered in the case when the owner needs a relatively thin protective layer for the apartment.

The procedure for installing the material on the wall will be described. Installation of sound insulation is carried out as follows:

It is necessary to clean the wall of dirt, remnants of old wallpaper and other debris.

If there are bumps, cracks, potholes, then they must be carefully repaired with putty.

It is necessary to pay attention to the places where the pipes exit. There may be gaps between them and the wall, which must be sealed with acoustic sealant.

Additionally, it is required to treat the wall with a deep penetration primer

It will repair cracks not seen before and make the surface have better adhesion to the coating. In addition, such treatment will serve as an obstacle to the formation of pathogenic flora.

Then a special sound-absorbing membrane is used, gluing it to the wall surface.

After that, hot-fiber sheets (GVL) are installed, attaching them to the wall with special dowels and self-tapping screws.

Then put a layer of self-adhesive acoustic felt. In most cases, it is not necessary that it exceed 1 centimeter.

After that, another layer of hot-fiber sheets is placed.

The total thickness of the layers with this method of laying does not exceed 3.7 centimeters. It is necessary to lay sheets of felt and GVL so that there are no gaps between them. On the outer layer of hot fiber sheets, it is necessary to seal the gaps with putty.

On such a protective layer, you can glue wallpaper or make other final wall decoration.

Technical felt

Technical felt

If a thick layer of sound insulation is required, installation will be more laborious. In this case, the recommended course of action would be:

- It is necessary to prepare the surface of the wall. To do this, it is cleaned, potholes are repaired and treated with putty.

- The membrane is then glued on.

- A frame is installed on the wall. It can be made from a metal corner or wooden bars. In the latter case, the strength will be significantly lower. Acoustic felt is laid in it. You can use mineral wool instead, and install a layer of felt on top of the frame.

- Drywall or GVL can be used as the top layer. After installation, the gap must be hermetically sealed.

Such a soundproof layer can reach a thickness of seven or more centimeters. It is able to make the wall much thicker, but at the same time provides high-quality sound protection.

When installing a protective layer in the vehicle interior, self-adhesive felt for cars can be used.

In order to create comfort, a lot is needed, but good sound insulation is one of the first places. The use of felt for noise insulation allows not only to solve such problems, but also to do it at a moderate cost.

Types of felt for sound insulation

This material has several varieties:

- The most common is coarse wool felt. It is used mainly in construction. Sometimes this type is produced as a self-adhesive felt, which allows it to be fixed on a wall or in another necessary place.

- Sometimes a multi-layered acoustic felt is produced that includes a built-in membrane that enhances its soundproofing properties.

- Needle-punched felt is a non-woven material. In it, the fibers are fastened by piercing with special needles. This variety has found wide application in tailoring and footwear, for the production of furniture and soundproofing the interior and trunk of a car.

- There are special types of felt. They are made using complex technologies for use in certain situations (for example, as an underlay for a floating floor, for use when installing a stretch ceiling or when installing communications elements).

Usually the thickness of coarse wool felt is 10-12 millimeters. One of the most famous brands is StP acoustic felt.

Why you need soundproofing

Why you need soundproofing

For use as a soundproofing layer in a car interior, it is convenient to use car felt, which is hermetically packed in cellophane. This is due to the ability of felt to actively absorb moisture, including from the air. Such insulation is placed under the car mat and, thanks to moisture insulation, serves for a long time without losing its quality.

Sheet 10 mm thick

Sheet 10 mm thick

Felt Features

Speaking about the features of felt fabric, the following characteristics should be noted:

- The material is made from environmentally friendly raw materials, which makes it possible to use the insulator for residential and industrial premises;

- The sound insulation coefficient is very high, so it is often used in modern construction of houses and industrial buildings;

- Due to the plasticity and flexibility of the material, it can be laid on any surface, while the felt will not slide over the surface;

- Felt fabric does not rot, so it can be used in conditions of high humidity.

- Light weight makes it easy to transport and install as sound insulation.

Felt technical or coarse wool is used for noise and heat insulation of residential premises, as well as industrial buildings. The manufacturing technology of coarse wool felt involves the use of exclusively natural raw materials without the addition of synthetics. The finished product has a high level of protection against sound and vibration waves, and also protects well from the cold.

Such material is often used as a heater for public buildings: hospitals, schools, canteens and other buildings. Felt fabric is easily cut and cut, which makes it possible to obtain absolutely any form of insulation. On the shelves of a hardware store, felt falls in rolls or slabs. The thin felt web is mainly rolled up, while the thicker felt is in the form of slabs.

Specifications

This material is made from the wool of certain breeds of sheep, as well as from polyester fiber, which has similar qualities. No adhesives are added to its composition. Felt material has good mechanical strength, elasticity and durability. Throughout the entire period of use, the material fully retains its useful properties.

Wall soundproofing

Wall soundproofing

Noise-insulating felt has a fibrous structure and is able to actively absorb moisture and keep it inside. After the sheet gets wet, its soundproofing properties deteriorate significantly.

The density of coarse wool felt is 1500 grams per square meter. It is produced most often in the form of sheets measuring 2.5 × 1.2 meters.

Soundproofing the ceiling

Soundproofing the ceiling

Additional Information! This material is non-flammable and does not rot. Felt is able not only to reflect sound, but also to absorb it. One of its important features is ecological purity and hypoallergenicity. If you use this material, then even people suffering from allergies will not experience any inconvenience from it. This material, when used, does not leave debris, separate fibers and does not emit dust.

The use of felt is also advantageous because it is cheaper compared to other soundproofing coatings.

Acoustic felt has high creasing rates. This allows it to be laid in hard-to-reach places and where there are sharp corners or a complex-shaped surface, it is easy to place in the car.

In addition to protecting against noise, the material has good thermal insulation properties.

The light weight of felt makes it easy to transport and install.

Sound absorbing felt

Sound absorbing felt

Production

Felt is made using sheep wool. The production technology includes the process of felting raw materials, due to which the fibers are twisted together, forming a dense web. Felt fabric is produced both in rolls and in slabs. In addition, felt can have different colors and specifications, which can be selected according to certain criteria.

Modern technologies for the manufacture of felt allow the use of synthetic fibers, which are similar in their characteristics to woolen material. Synthetic felt is distinguished by its strength and durability, while the insulating parameters remain the same.