Types of noise

Different building materials react to sounds differently. Before considering the materials used for soundproofing, it is necessary to determine what noise is. Noise is unwanted sounds that vary in strength and frequency.

aerated concrete block

There are air and shock varieties of noise. Airborne noise - sound waves passing through the environment and, when interacting with building envelopes, create oscillatory movements that propagate further into neighboring rooms.

Impact noise is caused by impact or vibration loads on structures and propagates directly through them. To stop the propagation of noise, acoustic materials are used that absorb and reduce the strength of sound vibrations.

According to SNiP, the required sound insulation coefficient in an apartment (average sound absorption coefficient) is determined by the formula: acr = A / Sogr, where A is the sound absorption area, expressed in sq.m.; Sgr - total area of enclosing structures, sq.m. Most often, the sound absorption coefficient of insulation is 0.5 - this means that the wall of insulation absorbs up to half of the noise energy that falls on it.

Aerated concrete plaster

Another option for improving the sound insulation of aerated concrete is plastering on both sides. It is used for thin walls, together with reinforcement gives additional strength. Plastering will prevent moisture from entering the blocks, the finishing material should protect the material from destruction on both sides.

One of the disadvantages of aerated concrete is its low moisture resistance. In the case when it is the only building material, plastering is carried out outside and inside the building. Plaster for aerated concrete is selected especially carefully, because it serves not only to preserve its properties, but also to improve them.

How to choose the best soundproofing

After completing the preliminary work, you can proceed to the soundproofing of the premises. Soundproofing systems can be frame and frameless. The frame consists of an anti-noise material sheathed with gypsum fiber (GVL) and gypsum boards (GKL). The system without a frame consists of already prepared GVL sheets with glued boards, on which GKL sheathing is placed.

Frame systems have a number of advantages, including:

• they mechanically level the surface, the walls are smooth without plaster;

• the number of mounting points is three to four times less than for frameless ones, and this reduces possible vibration loads on the plates;

• the frame can withstand increased loads - you can hang on it, for example, a TV or air conditioner;

• the installation does not require specialists, the work is carried out according to the standard KNAUF technology.

Aerated concrete primer

The primer can be applied with a roller or brush. Aerated concrete has a high absorbency, and this complicates its primer. You will have to repeat this operation 2-3 times.

The choice of primers in stores is impressive, so you can choose the right one for yourself. Often the plaster is reinforced with a reinforced mesh, and the plaster is applied over it.

This is necessary when plastering the facade of the house. Finishing starts from the inside, because. for external and internal walls there is a different humidity. And while you are plastering from the inside, all the moisture will go through the outer wall.

Soundproofing index of aerated concrete airborne noise

A little theory about noise. The sound itself can be divided into three types, each of which has its own frequency, and passes through different materials in different ways.

Impact (vibration) - the impact passes through the wall, and vibrations begin in it, which create an audible sound on both sides of the wall.Vibration noise propagates very far, passing along walls, floors and ceilings, as the structures are rigidly connected to each other. Such noise includes: the sound of a hammer, objects falling to the floor, stomping.

Airborne noise (wave) is the most common and frequent type of noise that is emitted by a human voice, TV, barking dogs, etc. The sound wave propagates in all directions, part of the sound wave is reflected from the walls, part is damped, and part of the sound can pass through the wall.

Structural noise is an intermediate type of noise between shock and wave, sources are: garbage chute, pipes, elevator, ventilation system.

INTERIOR WALLS AND PARTITIONS

4.14 double walls or

partitions are usually designed with a rigid connection between the elements along the contour or

at individual points. The size of the gap between structural elements should

be at least 40 mm.

To increase sound insulation

double walls and partitions, the following design measures are recommended:

- increase in thickness

the gap between the elements of the double structure;

- elimination of hard connection

between elements of a double structure, as well as with structures adjacent to

walls and partitions.

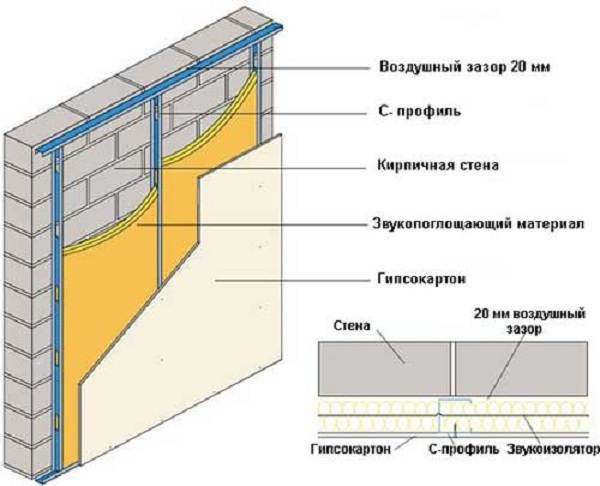

4.15 To increase insulation

airborne noise by a wall or partition made of reinforced concrete, concrete,

bricks, etc., in some cases it is advisable to use additional

sheathing at a distance.

As a lining material

can be used: plasterboard and gypsum-fiber sheets, solid

fibreboard and similar sheet materials attached to a wall

along wooden slats, along linear or point beacons made of plaster or

cement-sand mortar, on a metal frame. air gap

between the wall and the sheathing, it is advisable to make a thickness of 40 - 60 mm and fill

soft sound-absorbing material (mineral wool or fiberglass

plates, etc.). The optimal thickness of the sound absorber is the thickness of the air

interval.

4.16 interior walls,

separating residential and built-in noisy rooms, to which

increased requirements for airborne sound insulation (required index Rw = 54 - 59 dB), should be designed double with full separation of their

elements between themselves and from adjacent structures, excluding indirect

sound transmission to the isolated room along adjacent walls and ceilings. V

the case of using acoustically homogeneous structures as such walls

measures should also be taken to reduce the intensity of indirect

sound transmission to adjacent structures.

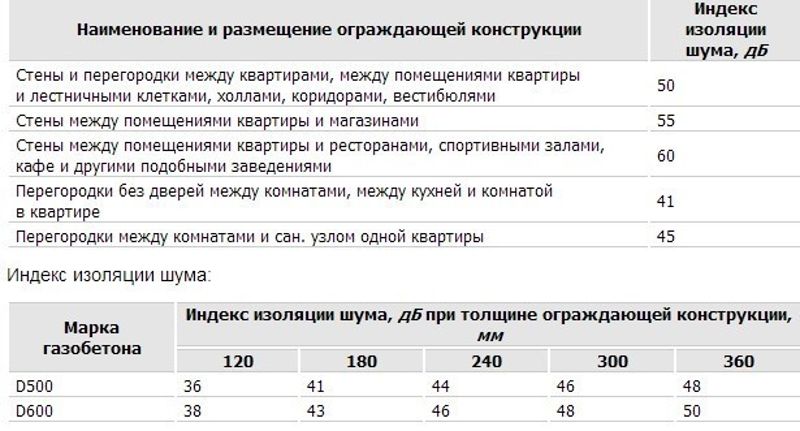

Normative values of airborne sound insulation indices Rw for rooms in residential and public buildings

Table 1.

| № | Name and location of the building envelope | R, dB |

| 1 | Walls and partitions between apartments, between apartment premises and stairwells, halls, corridors, lobbies: in category A houses in category B houses in category C houses | ≥54 ≥52 ≥50 |

| 2 | Walls between apartments and shops: in houses of category A in houses of categories B and C | ≥59 ≥57 |

| 3 | Partitions between rooms, between a kitchen and a room in one apartment: in houses of category A in houses of categories B and C | ≥43 ≥41 |

| 4 | Partitions between the bathroom and the room of one apartment | ≥47 |

| 5 | Walls and partitions between dorm rooms | ≥50 |

| Note - category A - highly comfortable conditions; category B - comfortable conditions; category B - the minimum allowable conditions. |

Displaying beacons

Beacons are required to level the plaster. These are special guides of the required height. After use, the beacons can be carefully removed and reused if necessary. There are steel and plastic beacons for plaster. The disadvantage of plastic products is their excessive flexibility. Much more practical than metal ones.

There are also L-shaped and T-shaped beacons; the choice of the section is caused by the tasks assigned to the profile. Beacons can be fastened with a mortar (on a cement-gypsum mixture) or with the help of special fasteners (dowels, self-tapping screws, etc.).

You can set up beacons using the artisanal method or the "spider" method. Each method has its own advantages and disadvantages. The cost of beacons starts from 4-5 rubles per meter. If necessary, you can order these products via the Internet at a lower price.

Soundproofing with foam block

The wide development of industrial and civil construction with new installation technologies requires the use of effective soundproofing materials. Economically important is the use of building materials obtained from non-deficient cheap raw materials, but at the same time providing sufficiently high sound insulation performance when used in building envelopes. Such materials include cellular concrete materials.

A common property that determines the specificity and choice of applicability of structures made of cellular concrete is the content

a significant number of pores. If the cement stone is not specially porous, then the pores are contained only in the aggregate. The introduction of an air-entraining or gas-forming additive into the cement paste makes it possible to reduce the bulk density of lightweight concretes with porous aggregates.

Due to porosity, the acoustic properties of cellular concretes are significantly improved compared to denser materials. The use of cellular concrete materials in wall structures with open or closed porosity makes it possible to increase their insulation index in comparison with walls made of homogeneous dense materials by 2...5 dB.

According to the terminology of SNiP 23-03-2003 “Protection from noise”, the main characteristic that determines the acoustic properties is the efficiency coefficient K. Here K is the coefficient that takes into account the relative increase in the flexural rigidity of the fence made of concrete on lightweight aggregates, porous concrete, etc. in relation to structures made of heavy concrete with the same surface density.

For solid enclosing structures with a density of y = 1,800 kg/m and more, K = 1.

For solid enclosing structures made of concrete on light aggregates, porous concrete; masonry of bricks and hollow ceramic blocks > coefficient K, average for grades of material, is determined according to SNiP and has values \u200b\u200bfrom 1.1 to 1.7, and for cellular concrete from 1.5 to 2. The coefficient K is closely related to the dynamic (initial) modulus of elasticity of the material U according to the dependence for solid section structures made of lightweight concrete.

K \u003d 0.72 (U / p3) 1/2,

where Ed is the dynamic modulus of elasticity of lightweight concrete Pa;

p is the density of cellular concrete, kg/m3.

To illustrate the foregoing, Table 1 shows data on the sound insulation of structures made of aerated concrete materials of D600 and D800 density grades.

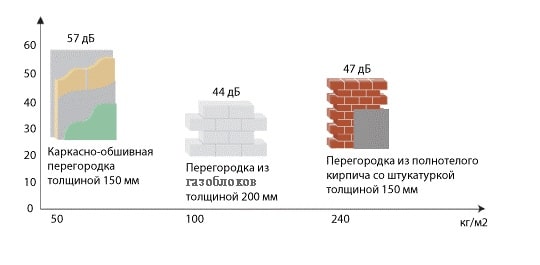

From table 1 it can be seen that for the most commonly used in mass construction partition thicknesses from 100 to 125 mm air insulation index noise Rw is between 29 and 43 dB. In accordance with the requirements of building codes for residential buildings, the required insulation index should be 41 ... 50 dB

(internal partitions). Therefore, to ensure the norms, it is necessary to use fences with a thickness of at least 125 ... 250 mm, and not 80 ... 100 mm, as is currently practiced. The only alternative option for enhancing the sound-proofing qualities of small-thickness cellular concrete fences is the combined use of additional double-sided plasterboard linings over a layer of mineral wool at least 40 mm thick.

For external walls, sound insulation should be at least 35 dB, and for inter-apartment walls 50-54 dB, the thickness of which can be obtained from Table 1.

The developed modern methods for assessing the soundproofing qualities of enclosing structures made of cellular concrete materials, based on the experimental data of specialized Testing Centers, make it possible to use them with sufficient confidence to ensure a favorable acoustic regime in housing.

How to improve the sound insulation of aerated concrete

Different tasks require different soundproofing. For example, you are recording sound and you need a room without extraneous sounds and without echo. Or you are dancing, constantly jumping on the floor.

There are three types of soundproofing:

- Soundproof

- sound-absorbing

- damping

Soundproofing materials dampen wave noise at medium and high frequencies, damping materials dampen low-frequency structural sound. Sound-absorbing materials absorb sound, preventing it from bouncing off the walls, such material is needed against the echo effect.

Ways to improve the sound insulation of aerated concrete:

- Thick plaster wall.

- Using special soundproof boards.

- Using mineral wool and drywall.

Plastering aerated concrete walls will increase the sound insulation index by 2-4 dB.

Conclusion. Dense aerated concrete (D500-D600) from 150 mm thick can be used as partitions, but still a brick wall isolates sound better. But there are times when a brick wall is too heavy for the house, and then you have to use aerated concrete or structures made of profiles, drywall and mineral wool.

Also, from the advantages of aerated concrete partitions, we will name the speed and cost of masonry. Aerated concrete is cheaper, and the laying speed is higher. But the option with the use of drywall and soundproofing wool is also very good, because the weight of the partition is even less, and the sound will be better retained than that of aerated concrete.

https://youtube.com/watch?v=MqgHJ4tFVWA

cork

Improved sound insulation of aerated concrete blocks can be obtained by installing a cork cover. Soundproofing with cork is becoming more and more popular every day, and its advertising in hardware stores is increasingly common. Cork flooring is made of natural material and environmentally friendly, does not emit extraneous odors into the air of the room.

The material absorbs high-frequency sounds well. It may happen that you have noisy neighbors, then when you cover the oak with a 1 cm layer of cork, you will not experience much difference before and after. Noise reduction will be about 18-20 dB (conversation is kept at 45 dB, noise in offices - up to 60 dB).

Cork is supplied in sheets or rolls. At present, Portugal is the best producer of cork. A novelty in this field is a cork spray applied with a spray gun and reaching a thickness of 3 cm.

For fastening, it is better to use quick-setting rubber glue, then you do not have to keep the plates suspended for a long time

It is important to keep in mind that it is better to create several thin cork surfaces than one thick one.

About the disadvantages of aerated concrete blocks

Despite the many advantages of aerated concrete, it also has its drawbacks.

When choosing a building material, it is very important to take into account all the parameters and criteria, since not only the reliability of the proposed structure depends on this, but also its service life.

- Aerated concrete has a low compressive density, so it is considered brittle. The reliability of a partition or wall made of this material directly depends on the evenness and reliability of the foundation. If you plan to build using aerated concrete blocks, you should make a foundation that will give minimal shrinkage, otherwise the wall may crack and collapse.

- The material has a high degree of water absorption, as a result of which it is quite difficult to carry out finishing work. It is not uncommon for the plaster to completely crumble.To work with aerated concrete walls, you should use a special soil mixture that can penetrate deep into the middle of the block.

- Aerated concrete is not the best option for fixing massive decorative elements and furniture. In order to fix something on the wall surface, plastic dowels are not suitable; it is much more efficient to use ordinary self-tapping screws. They fit well into the surface due to the air structure of the blocks. The only thing that should not be forgotten is that the material absorbs moisture, which means that metal parts are subject to oxidation and rusting. If you use self-tapping screws, then only covered with a protective layer or galvanized. The problem can be prevented by using non-oxidizing metals.

To build your own home, you can use any type of building material, the main thing to consider when choosing all the advantages and disadvantages of products. There is no ideal building material that would have all the qualities and characteristics, all have pros and cons. When selecting the appropriate material, you should approach it with full responsibility and calculation, only in this case you can get what you need.

This is interesting: Do-it-yourself foam block barbecue

Soundproof characteristics

Table of soundproofing properties

Even at the design stage of a building, when choosing building materials, one should take into account such a property as sound insulation. Considering aerated concrete as a building material, one can note with satisfaction that its properties fully meet these requirements. During the production of blocks, a chemical reaction takes place between lime and aluminum powder. As a result of this process, the concrete composite foams. Aerated concrete is filled with air bubbles of different sizes. The cellular mass perfectly delays sound waves, and the blocks become light. It is known that the lower the density and the greater the volume, the higher the soundproofing qualities. These properties are fully possessed by blocks.

The magnitude of the sound intensity is measured in decibels. Zero value is the lower threshold of human hearing. When studying the properties of building materials, the noise absorption index was derived. The permissible norm for residential premises is 41 dB. Walls built from aerated concrete blocks have a coefficient of 43-44 dB. Also, sound insulation is measured by the sound absorption coefficient at a frequency of 1000 Hz. Autoclave coefficient - 0.2 Hz, wooden surface - 0.1 Hz, brick - 0.05 Hz, concrete - 0.02 Hz.

Competitors of aerated concrete blocks

Due to the low cost of aerated concrete blocks, it is rather problematic to choose a material that is more suitable for construction. Among the closest competitors are ceramic bricks and foam concrete. All competing materials are similar in color, shape and other parameters. The main difference parameter is the density and structure of the product. Aerated concrete has a porous structure and low weight of the structure. Depending on the proposed construction and the characteristics of the materials, the optimal ratio of price and quality is selected.

Summarizing

Aerated concrete is a recently appeared building material with many advantages and advantages.

When choosing a material, it is important to look at the brand of the product, its dimensions and adhere to the manufacturer's requirements. If you adhere to all the norms, then you can choose the most suitable type of material for building and soundproofing a house.

The variety of building materials today is quite large. Depending on the requirements and the construction project, the most suitable material is selected. Despite the recent emergence of aerated concrete blocks, this building material has gained popularity for indoor and outdoor work.Using aerated concrete blocks, you can build a reliable and durable house, which will have all the conditions for a comfortable life.

JOINTS AND KNOTS

4.17 Joints between internal

enclosing structures, as well as between them and other adjacent

structures should be designed in such a way that after

construction was absent during operation

buildings did not have through cracks, crevices and leaks, which drastically reduce

soundproofing fences.

Joints in which in the process

operation, despite the design measures taken, mutual

movement of joined elements under the influence of load, temperature and

shrinkage deformations, should be designed using durable

sealing elastic materials and products glued to joined

surfaces.

4.18 Bearing elements of floors

should be supported on internal and external walls or wound into them. free

adjoining load-bearing elements of floors to walls is not recommended.

At junctions without

winding the joined element, a figured joint is recommended,

preventing mutual displacement of elements and supplemented by the use

sealing material. The same junction design should be taken in

places of passage through holes in the ceilings of vertical self-supporting

elements, such as ventilation units.

Joints between carriers

wall elements and ceilings based on them are designed with filling

mortar or concrete. If as a result of loads or other influences

opening of seams is possible, measures must be taken in the design to avoid

allowing the formation of through cracks at the joints.

4.19 Joints between carriers

elements of internal walls are designed, as a rule, with filling with mortar

or concrete. The mating surfaces of the joined elements must form

cavity (well), the transverse dimensions of which provide the possibility

densely filling it with mounting concrete or mortar to the entire height of the element.

It is necessary to provide measures to limit the mutual movement of docked

elements (device of keys, welding of embedded parts, etc.). Connecting

details, releases of fittings, etc. should not interfere with the filling of the joint cavity

concrete or mortar. Filling of joints is recommended to be done with non-shrinking

(expanding) concrete or mortar.

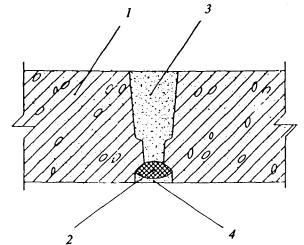

4.20 acoustically homogeneous and

double partitions, based on the load-bearing structures of the floor, should

be installed on sealing and leveling materials (cement-sand

mortar, cement pastes, etc.). At their junctions with the ceiling there should be

the use of sealing material is provided for the entire depth of the joint

(drawing ).

The junction of partitions to the outer and inner walls should be decided

similar to the connection to the ceiling.

4.21 Carrier conjugation

elements of internal walls with external walls should be carried out with

by inserting the inner wall into a groove or into a joint between the elements of the outer wall and

the device of a monolithic joint, excluding the formation of through cracks.

4.22 When designing a joint

between the prefabricated elements of the interfloor ceiling within the premises should be

arrange the joint monolithic, excluding the formation of through cracks and

place sealing gaskets made of sealing materials at the joint

(drawing ).

1 - the bearing part of the floor; 2 — partition element;3 — sealant

(sealing gasket or cord);4 — solution

Figure 16 - Scheme of a constructive solution for the junction of a double partition to

overlap

1 - prefabricated floor element; 2 — sealant; 3 — mounting

concrete; 4 — solution

Figure 17 - Scheme of a constructive solution

located within the premises of the junction of the elements of the floor using

sealing material

4.23 Joint design in double

walls located within the premises should not create a rigid connection

between the layers of the wall. At the junction in the gap between the layers of a double wall

a sealing bar with soundproof gaskets should be placed.

4.24 When designing prefabricated

structural elements must take such a configuration and dimensions

abutting sections that provide placement, sticker, fixation and

required compression of sealing materials and products when their application

provided for in this Code of Practice.

When sizing

gaps and cavities (wells) in the joints, tolerances should be taken into account when

production and installation of prefabricated elements With so that, with possible

under adverse conditions, reliable sealing of the joint was ensured,

provided by the project.

We increase the indicator

The sound insulation of aerated concrete partitions is increased by performing the following manipulations:

- Carrying out additional plastering.

- Use of special finishing tiles.

- Innovative designs consisting of several layers also help to get rid of unpleasant sound from the outside.

The sound insulation of aerated concrete blocks will increase by 3 dB if the surface is additionally covered with a layer of plaster. This option is used most often. You do not need to spend a lot of money on it, and the work is done by hand. The method is also used in combination with other materials. For example, this increases the sound insulation of gas silicate blocks.

The sound insulation of aerated concrete walls will be from 39 to 43 dB if the putty material is applied to both sides of the wall. The process will give a result, which will also depend on the thickness of the deposition.

Partitions made of aerated concrete must be of high quality and correctly installed. Sound insulation is provided at the maximum level after the processing of the seams. The importance is played by the analysis of external factors that can adversely affect the process.

Styrofoam has many varieties. Among them, penoplex and polystyrene foam are popular. Materials are safe for humans. In work, their main characteristic is ease and convenience. Thanks to them, it is possible to achieve a reduction in the level of external noise up to 36 dB.

Experts with extensive experience in construction recommend combining aerated concrete with various finishing materials. Thanks to this, it will be possible to additionally obtain an attractive surface. Modern building materials are easy to install. The effect depends on the individual preferences of the owner.

For additional sound insulation, mineral wool is placed between the slab and the finishing layer. Its thickness should not exceed 30 mm. At a short distance from the block, wooden bars or blocks are fixed. Professional builders also insist on installing a waterproofing layer. Thanks to this design, it will be possible to absorb another 5 to 10 dB of external noise. If you leave the air gap, you will be able to achieve an additional indicator of 20 dB.

Gas block is a popular material today. With its help, it is possible to provide the necessary level of sound insulation. Think about the criteria in advance, especially if the building is located in a noisy place. Thanks to this, it will be possible to create optimal conditions for the rest of the whole family. You get used to the sound, but why do it if there is another possibility?

Sound insulation of aerated concrete and brick

Aerated concrete is a light and porous material with a high level of sound absorption. Due to these qualities, these products are often used in new buildings as partitions. Due to the small thickness, but effective sound insulation, the use of aerated concrete blocks in the construction of the wall does not have to be additionally soundproofed.

For maximum protection against sound waves, a wall made of dense material is suitable. The best solution would be to use a brick that is heavier than aerated concrete. However, if we consider low-frequency sound, then it is better to use a porous surface for it, so aerated concrete becomes a more suitable option.