Laying tiles on a wooden floor is in most cases a difficult and troublesome task. This is due to the fact that very careful preparation of the base is required. Often this procedure is impractical: the tree is very mobile, it constantly expands or narrows. This creates an increased load on ceramics and tile adhesive. The first begins to crack, the second - to crumble. As a result, the floor covering may simply fall off. To avoid the troubles listed above, it is necessary to strictly observe the technology of laying ceramic tiles on wooden floors.

Floor preparation

Typically, a wooden floor is a plank flooring laid on lags. Before laying tiles, you need to make sure that the base is strong and reliable. If necessary, carry out repair and restoration work. In this case, they act as follows:

- First, the quality of the log and the subfloor is checked. This is especially true for old floors. To do this, you will have to completely remove the boards or wood boards. If there is any doubt about the quality or reliability of an individual lag or board, then it must be replaced.

Important! The step between the lags should not exceed 50 cm: the tile will give an additional load on the boards, if the distance is too large, they will bend. If this rule is not observed, additional lags will have to be installed.

- Logs should form a perfectly flat horizontal surface.

- The subfloor and logs must be treated with an antiseptic, which is necessary to protect the tree from the damaging effects of fungus, dampness, mold, etc.

- Then they move on to wooden flooring: they also check the quality of boards or plates, replace them if necessary, remove the old coating (varnish or paint).

- The plank base is laid on the logs and the quality of the resulting coating is checked, protruding nails or screws are removed, and polished.

But even now it is too early to start laying tiles on a wooden floor in a bathroom or any other room. The ceramics fastening technology itself is not much different from the traditional one, but the base requires additional preparation in one of the following ways.

Laying directly on boards

Is it possible to lay tiles on a wooden floor without an additional layer? This option is the least reliable, and therefore the least used.

The order of work will be as follows:

- First you need to provide waterproofing. To do this, the boards are covered with a thick layer of protective agent. You can use hot drying oil in the old fashioned way or prefer a more modern latex composition.

- Without waiting for the waterproofing agent to dry, a fiberglass masking net is laid.

- When the reinforcing coating is laid and the protective layer is dry, the mesh is fixed with self-tapping screws.

- The surface is covered with a primer solution, which will enhance the adhesion of the floor.

- And finally, the surface is covered with the following mixture: sand, liquid glass (or silicate glue) and water in a ratio of 2: 2: 1.

After drying, you can start laying floor tiles.

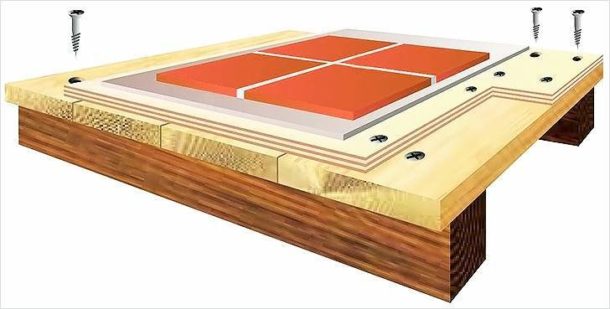

On wood boards (OSB, chipboard, plywood)

This is the so-called "dry" method. When preparing the floor in this way, you do not have to mess with solutions. However, this option is suitable for dry rooms, where the humidity level is not higher than average, and water rarely gets on the floor. Preparation for laying tiles on a wooden floor is carried out as follows:

- The boards are treated with an antiseptic.

If wood boards are laid on top, then the boards themselves can be laid loosely. The gap can be up to 15 cm.

- After the impregnation has dried, a waterproofing agent is applied on top.In this case, you will need plastic wrap or special construction paper (bituminous, waxed, etc.).

- Lay out the sheets. Plates should lie apart and loosely. The gap between them should be 5-10 mm. This is necessary to compensate for the expansion of the sheets. Compensation gaps are also left around the perimeter of the entire room.

- The plates are fixed along the perimeter of the room and along the length with the help of self-tapping screws. Hats should completely go into the sheet. As a result, the surface should remain flat.

- Compensation gaps are covered with sealant or foam. After drying, the excess sealant is cut off so that the material does not rise above the base. Then even laying of ceramics will be possible.

- A reinforced layer of waterproofing is also applied to the slabs, as described above.

- Then the surface is also treated with a primer and gluing tiles to plywood or OSB.

Thin screed

There are more reliable ways to lay tiles. One of them is the filling of a thin screed. This technique will protect the tile from the constant fluctuations of expanding and contracting wood.

- They also begin with the processing of the boards: first with an antiseptic, and then with a waterproofing compound.

- A special tape is glued along the perimeter of the room, which will not allow the screed to collapse at the points of contact with the wall.

- Install beacons. Usually the thickness of a light screed does not exceed 3 cm. Beacons are installed at an appropriate height.

It is desirable to reinforce the base. To do this, a mesh of metal or fiberglass is laid between the beacons.

- Prepare a screed solution. This can be a standard mixture of cement, sand and water, prepared according to the instructions. But it is better to use more modern products containing plasticizers, reinforcing elements, etc., such as self-leveling floor.

- While the solution is infused and matures, the floor is treated with a primer.

- The floor is poured with a screed and wait for complete drying. Then the tiles are laid on the wooden floor.

On GVL

The result will be outwardly similar to the processing of wood boards. However, the technology is slightly different: the boards must lie tightly, there is no talk of gaps.

Take for the floor moisture resistant gypsum boards, which are joined so as to completely cover the entire floor.

If necessary, spread the second layer of GVL. In this case, the sheets lie perpendicular to the first layer. The joints do not have to match. It is also desirable to treat the seams with a sealant or some kind of reinforcing compound. There is no need to process the gypsum fiber with anything else: it is completely ready for laying tiles on a wooden floor.

Laying tiles

When the base is ready, you can start laying ceramic tiles on the wooden floor. The technology of laying tiles is no different from finishing walls or floors from other materials:

- First, the markup is performed, the required amount of material is calculated.

- Then proceed to the tiling. An adhesive composition is applied to the base (it is better to take a product for complex surfaces or containing plasticizers), then tiles must be laid on the floor in a certain order.

- After the glue dries, all seams are covered with a special grout.

The video will help you figure out how to lay tiles on a wooden base correctly.