Why do you need a water seal

In moonshine business, mash plays a very important role, on the success of which the final result will depend. The fermentation process is characterized by the conversion of sugar by yeast into ethyl alcohol and carbon dioxide. Carbon dioxide accumulates during fermentation, which can lead to an explosion of the container.

To prevent an accident, it is necessary to allow carbon dioxide to escape from the apparatus. But simply opening the fermentation tank will not work, because with the entry of air into the container with mash, the activity of bacteria that eat alcohol and produce vinegar is activated.

In order to avoid turning wine or moonshine into it, the fermentation tank is equipped with a water seal, which is designed to release carbon dioxide and not let air into the container.

The indispensability of a water seal in winemaking

Why do you need a water seal? In the process of fermentation, a large amount of carbon dioxide is released (about 4 m3 / 1 liter of alcohol obtained). If carbon dioxide accumulates in the tank, very high pressure will be created. And sooner or later there will be an explosion

Therefore, it is important to remove the gas from the inside, but in no case should oxygen be put into the tank. After all, in this case, bacteria will multiply, which convert alcohol into acetic acid.

In the meantime, oxygen does not penetrate into the fermentation chamber, the bacteria are in a dormant state.

.

In fact, this shutter is a special valve that brings carbon dioxide out and prevents oxygen from entering inside. Without it, it is impossible to make wine, because the result will be vinegar. Experienced winemakers and moonshiners vehemently discuss the need for its use. But if you are new to this business, then you can not do without it.

If we talk about Braga, then there is no unambiguous answer to the need for a water seal. But with this design, the mash can be kept longer without distillation, and it will not oxidize. And absolutely all alcohol will be safe.

Water lock on the braga

Types of finished hydraulic seals

These devices can have a different design, as a rule, they are of two types:

- Collapsible. The device consists of two flasks inserted one into the other. The advantage of this design lies in its small size and ease of use.

- Two-chamber. In essence, such water seals are bent tubes with compartments connected in series, into which water should be poured. An elastic band is attached to one end of the tube, it acts as a seal. At the same time, it is necessary to monitor its condition, since drying occurs over time, and to replace it in time.

A water seal can be purchased from a specialized store.

A water seal can be purchased from a specialized store.

Do-it-yourself installation of a drain in the shower under the tiles

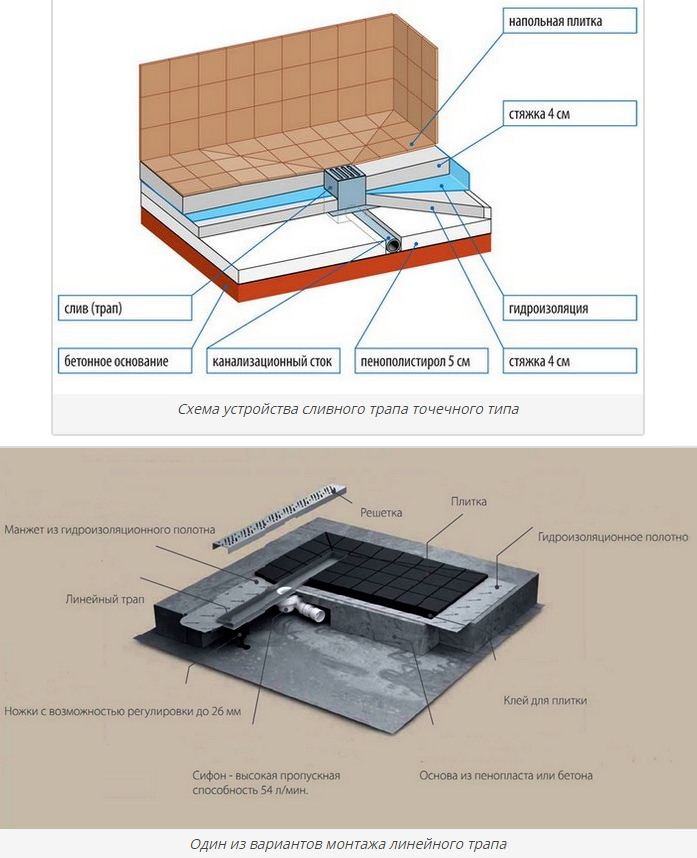

When installing a shower drain during the construction of a private house, usually there are no questions about how to make a drain in the floor of the shower cabin. In this case, the ladder is installed in the floor screed, which is then tiled, and a vertical outlet of the wastewater pipe is made into the sewer channel.

With the arrangement of the drain in the apartment, things are somewhat different. In the bathrooms of apartment buildings, most often, the thickness of the screed is not enough to arrange a vertical ladder in the shower. Therefore, to equip the booth with this product, they first raise the floor level in the room, at the same time ensuring its slope. As a rule, a height of 12-15 cm is enough to place a siphon and a drain pipe under the screed.

Install a ladder in the shower floor with your own hands, observing the following sequence:

- First, using a tape measure, measure the location of the ladder with the expectation that a multiple of the tiles should fit from the drain to the walls, not forgetting the tile joints (1.5-2 mm). So the floor will look more aesthetically pleasing than with cut tiles.

- Then the ladder is connected to the sewer drain through pipes. The slope of the drain pipe must be at least 3 cm per linear meter.

- If it is necessary to insulate the screed, use foam sheets 5 cm thick and with a density of at least 35 kg / cu. meter, but it is better to use extruded polystyrene foam, as it is harder and less exposed to a humid environment.

- Insulation sheets are laid on the rough surface of the floor and adjusted to the dimensions of the plumbing ladder, and a concrete screed is made on top with a layer of about 4 cm, which should fill the entire space up to the drain flange.

- It is necessary to allow the screed to dry until completely hardened.

- Then, from the waterproofing material, you need to make a gasket for the flange, which should overlap the flange with a margin. Inside the gasket, it is necessary to cut a hole along the inner diameter of the flange.

- The upper part of the flange must be placed on the gasket and screwed to the lower part of the structure.

- After that, the screed must also be covered with a rolled waterproofing agent. The laid material should overlap the flange gasket and go onto the walls by a few 3-5 cm.

- Next, you need to insert its inner part with a siphon into the body of the shower drain.

- Then you need to pour the finishing screed with a slope of about 10 mm per meter of pouring. To do this, guide plastic rails are placed on the surface of the floor with a waterproofing agent, beveling them towards the drain. You can buy ready-made systems for making a ladder in the shower.

- The pouring of the second layer of the screed should be lower than the height of the siphon so that it can be leveled with the tiles. The guide rails are not removed from the screed. At the same time, so that the solution does not get into the drain and onto the walls, it is recommended to seal the grate of the ladder with adhesive tape, and the corner between the floor and walls - with waterproofing tape.

- Next, the surface is tiled, starting from the drain hole to the walls. The tile should be flush with the grate of the drain or a few 3-5 mm. above.

- After the tile adhesive has dried, it is necessary to rub the seams with a waterproof material matched to the color of the ceramic tile.

- The areas where the tile comes into contact with the body of the drain must be carefully and carefully sealed with silicone sealant.

- At the end of all work, a protective grille is mounted and fixed on the body of the shower drain.

A properly installed shower ladder will make the adoption of water procedures more comfortable, give the bathroom an original look.

The design and function of the shower drain

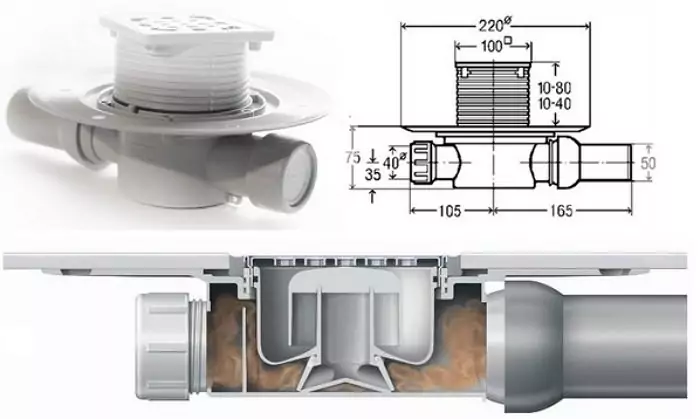

The simplest shower drain in the bathroom under the tiles is a device made, as a rule, of metal, plastic or metal-plastic. This device provides effective collection and removal of water from the floor of the shower cabin. The shower drain has a simple design and low cost, it is convenient to use and install, trouble-free during operation.

The design of the ladder for draining water in showers consists of the following elements:

- a funnel with a flange for receiving water from the shower, in the lower part of which there is an outlet pipe for draining liquid into the sewer. A waterproofing membrane is attached using a flange;

- decorative removable grill to hold objects, jewelry that accidentally fell on the floor, large debris;

- siphon for the implementation of a water seal inside the drain drain for the drain in order to prevent the penetration of unpleasant odors from the sewer into the bathroom.

Thus, in addition to collecting and draining water, shower drains perform a number of other useful functions:

- retention of debris that can enter the sewer pipes and cause clogging;

- preventing the penetration of stench into the bathroom, thanks to a dry seal or water seal;

- providing easy access to the drain for cleaning it in case of blockage.

A shower drain with a dry seal or water seal saves space in a small bathroom, eliminating the need for a bathtub or a bulky shower enclosure with a high tray, which also saves the family budget. But before you buy a floor drain for a shower floor, it’s important to carefully understand its types, because we choose a device designed for a long service life.

Varieties of drain structures for the shower

There is a wide variety of shower drains in the floor for this type of tile. Shower ladders may differ in shape, design, size (in height), according to the materials of manufacture. With regards to the shape of the gratings, they can be rectangular, square or round.

And by design, wall, point and linear fixtures are distinguished. Linear structures are installed, most often, in the corner or along the edge of the shower. Point drains can be located anywhere on the floor under the tiles, while wall-mounted devices are mounted mainly at one of the walls. The drains also differ in the type of outlet: horizontal or vertical. It depends on its location in which direction the sewer pipe will be connected to the drain.

As a rule, the design of most ladders provides for an ordinary water seal located in the siphon. But such a device has one significant drawback - if you do not use the shower for a long time, the water inside evaporates, and unpleasant odors penetrate the bathroom. In this case, it is better to choose a floor drain with a dry shutter.

Structures with a dry seal completely isolate the premises from the penetration of odors from the sewer, since in this device, in addition to the water seal, there are several more dampers that block the channel under their own weight. When water enters the drain channel, these dampers open, allowing the liquid to pass freely, and then close again.

The drain in the tiled shower floor is installed in the most convenient place for this. The main thing is that the ladder is located at the lowest point of the bathroom, ensuring the effective collection of the flowing liquid. So, the drain hole can be mounted in the following places:

- In the center of the shower cubicle or with a slight offset to one side. Standard drain location option. In this case, it is necessary to provide an appropriate floor slope from the four walls.

- Near the wall. In this case, the floor slope is made from one of the walls towards the drain hole. As a rule, slotted drains with high throughput are arranged in this way, since such devices are less likely to become clogged.

- In the corner. This type of drain hole looks great on the floor without being conspicuous. In this case, the slope of the floor surface is made in two planes to the desired angle, ensuring the flow of water to a certain place.

It is worth noting that when choosing a shower drain, you must also pay attention to the height of the fixture. This parameter determines how much you need to raise the level of the floor covering at the drain hole.

Of course, everyone wants the floor height to be as low as possible, but keep in mind that the greater the height of the ladder, the higher the throughput. Therefore, there is a special type of drain with adjustable height, by choosing it, you can adapt the device to any height of the screed.

What material to prefer

A shower drain in a tile floor is made of plastic, stainless steel, cast iron and even glass.Plastic structures are lightweight, resistant to aggressive influences, easy to clean, have a long service life, so they have earned popularity among both residents of private houses and apartments. The water drains through the gap in the floor between the shower tray and the grate, and also goes through the through holes at the top of the grate.

Plastic ladders are equipped with a decorative grille of a removable or non-removable type of various shapes and patterns. The height of the plastic product ranges from 75-180 mm. It is possible to install such a shower drain in the floor under the tiles both in a dotted way in an open area, and in an angular or linear method near the wall. Since plastic is compatible with almost any floor covering, such products are often used for public showers (sports schools, gyms, baths, etc.).

All components of the shower drain, in addition to the grate and legs, are made of high-strength plastic. And the siphon in such products, as a rule, is made using the technology of floating balls with a dry valve. After the flow of water passes through the siphon, the balls sink to its bottom, blocking the penetration of unpleasant odors from the sewer channel. However, this design slightly reduces the throughput of the device.

To reduce the cost of the product, the legs of some devices are made of perforated steel tape. And in order to give the ladder the desired height, this very tape is bent in certain places. In addition to steel tape, adjustable screw feet can be used in the product design.

Well proven sewer ladders made of stainless steel. Moreover, not only the body of the product can be steel, but also a decorative removable grille. Usually they are installed in bathrooms and toilets with increased hygiene requirements - medical facilities, swimming pools, sanatoriums, children's camps, etc.

Linear ladders made of stainless steel look especially beautiful. They are almost invisible in the floor, lined with ceramic tiles, natural or artificial stone. The modern solution of stainless steel drains is one of their forms, made in the form of the Latin letter "U".

Cast iron sewer drains are installed in sanitary facilities with harsh operating conditions - laundries, public showers and baths, specialized laboratories. For the removal of household and rainwater, exclusively cast-iron vertical drains DN 100 mm are used.

Cast iron devices have the highest throughput, are most resistant to corrosion, so that their service life can reach 50 years. As a rule, these products are produced with a water seal.