Scheme for the construction of a single-furnace two-story furnace

Consider how to make a stove that extends over 2 floors. This is a very successful project - efficient and economical.

Foundation construction

Such a structure is much heavier than a conventional, single-tier one. Therefore, you need to take care of a strong foundation. It should be slightly larger than the stove base. Since the latter according to the project has dimensions of 900x900 mm, the dimensions of the “cushion” are 1000x1000 mm.

You will need:

- cement / sand / gravel;

- deck boards;

- fittings;

- waterproofing material (for example, roofing material).

The base can be either flush with the floor, or rise above it by several centimeters. The foundation scheme is simple - first they make a sand cushion, then they make the formwork and mount the reinforcement, and then the structure is poured with concrete.

After pouring, the foundation should be allowed to stand - about a month. Then the base is waterproofed. To do this, lay a roofing sheet - 1 or 2-3. Only after that the heating furnace is laid out on two floors. The surface of the "pillow" must be strictly horizontal.

The construction of the furnace

For construction, you will need high-quality materials and additional furnace elements. The required amount of both is presented in the tables.

Table 1. Masonry elements

Table 2. Additional elements

The masonry mortar is made from clay and sand. The ratio of components is from 1:1 to 1:2. It all depends on the type and quality of clay. To determine the exact ratio, several mortar balls or cakes are made with different proportions of the components. After that, they are left to dry. Those balls that have not cracked demonstrate optimal parameters.

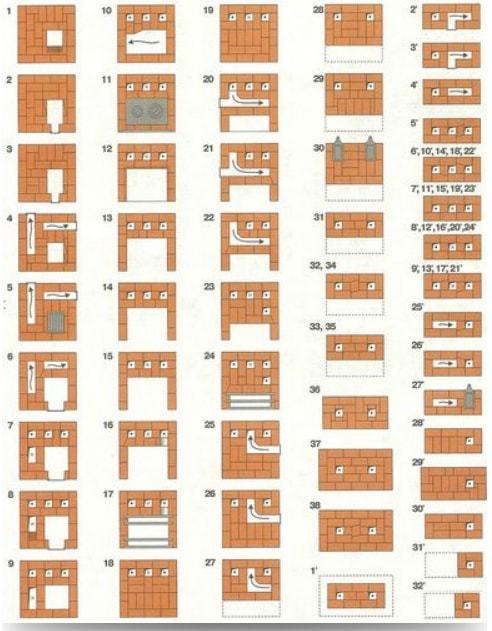

Laying scheme in rows (the numbers correspond to the row number):

- Attaches to the waterproofing layer. First laid out dry.

- On the second and third row, a blower door is mounted.

- Installation of the fire chamber. Fireclay bricks are in progress. The doors of the cleaning chambers are also mounted here.

- An asbestos cord is installed on the sides of the bottom of the firebox. After that, a grate will be installed on it.

- Mount the firebox door.

- From the 7th to the 10th rows - masonry according to the scheme.

- A corner is attached to the front. Here, the firebox is covered with a hob.

- From this to the 16th row, a cooking chamber is built.

- Mount corners that serve as a support for solid brickwork.

- This and the next row are solid masonry. Integrity is violated by three chimney openings indicated in the diagram.

- Mount the door of the next cleaning chamber. On the 23rd row lay out the drying chamber.

- A series of corners on which the chamber ceiling will rest.

- Installation of the cleaning chamber door. On the 29th row - masonry according to the drawing.

- Brick up a couple of valves.

The diagram shows that after the 38th row there is a new numbering. These rows belong to the next tier. 1-26 rows - masonry according to the drawing. On the 27th, the final valve is installed. 27-30 - all according to the drawing. 31-32 - the start of the chimney resting on the ceiling. If the latter is higher, the rows are added. The "attic-roof" part of the chimney is laid in a similar way. If there is an attic, the scheme is the same. At the exit - a two-story mansard oven.

Furnaces on two floors

The main task of the stove-maker in the construction of a two-story stove is to, taking into account the characteristics of the room, distribute the heat in such a way that it will not be too hot on the first floor and not too cold on the second. When calculating the stove, you need to remember that warm air rises, which means that less heat is needed to heat the second floor than for the first. Based on this, on the first floor you should not get carried away with a large length of channels, but it is better to save them for the second floor. If the room on the second floor is not large, then a hood will be quite enough for heating, accumulating heat after passing through the channels of the first floor.

Two-story furnaces should not be equipped with horizontal channels, as this significantly slows down the rate of movement of gases, and therefore contributes to increased soot formation. If the smoke channels are too long, the temperature of the gases at the outlet of the pipe may drop below 100ᴼ C, which will inevitably lead to the formation of condensate.

The stove of the second floor must fully rest on the stove of the first floor, it is strictly forbidden to place the stove of the second floor on the beams of wooden floors, since the wooden house will shrink over time and will tear the masonry at the junction of the stoves. Two-story brick ovens must be equipped with a direct-stroke valve to facilitate ignition after a long break between furnaces. In the event that the design does not allow for a direct stroke valve, you can pre-ignite the furnace through the last cleaning door.

Is stove heating possible in an apartment building? Yes, the designs of furnaces allow heating even fairly large buildings, if they are no more than two floors high.

There are several options for arranging the heating of two-story buildings, and, despite the new types of equipment that have appeared, stove heating does not give up its positions. The stove can be used both as a hob, and as a fireplace, and as an ordinary solid fuel boiler, if it is equipped with an additional water circuit.

Devices

The list of instruments and materials necessary for the construction of this furnace is given in Table. 2. Its design does not differ in any particular complexity, but it requires a sufficiently high qualification and accuracy from the performer.

Particular attention should be paid to the quality of the masonry not only of the firebox and the outer walls of the furnace, but also of the internal channels of the chimneys, since communication between the furnace smoke circuits that is not provided for by the design can lead to its inoperability.

TABLE 1

CHARACTERISTICS OF A DOUBLE-STOREY HEATING FURNACE WITH A SINGLE FUEL

Furnace dimensions in plan:

fuel section……………………………………..890×1150 mm

shield of the 1st floor……………………………………… 770 × 1020 mm

shield of the H-th floor………………………………………. 770×950 mm

Furnace height*………………………………………………………………………………………………7150 mm

Heat-releasing surface…………………………………………………………………………..20.0 m2

Average heat transfer with a single furnace fire per day………………………. 5500 kcal/hour

Total daily heat transfer…………………………………………………………..~ 132000 kcal

The amount of fuel burned per day (dry firewood)……………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………….

Heat transfer time after one firebox………………………………………………………………24 hours

* The total height of the furnace is indicated for a ceiling height of 3.4 m. It can be changed by reducing or increasing the number of rows in the masonry from 26 to 46 and from 60 to 82 rows.

TABLE 2

LIST OF DEVICES AND MATERIALS

Solid red brick (selected)………………………………………………………….1900 pcs.

Refractory brick……………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………170 pcs.

Red clay………………………………………………………………………………………………….2.1 m3

Refractory clay………………………………………………………………………………………………0.2 m3

Sand……………………………………………………………………………………………………………2.3 m3

Furnace door 350×350 mm………………………………………………………………………………… 1 pc.

Blower door 135×120 mm……………………………………………………………………….1 pc.

Cleaning doors 135×120 mm…………………………………………………………………………….5 pcs.

Stove valves 130×260 mm…………………………………………………………………………….2 pcs.

Pre-furnace sheet 500×700 mm………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………

Grate 400×400 mm……………………………………………………………………..1 pc.

1.

2.

3.

4.

5.

6.

7.

Heating a two-story cottage with a stove is quite simple, and such a system will not require any special attitude towards itself. The only condition that must be observed when using any stove: regular heating. Stove heating of a two-story house is very convenient to use, but the price for this ease will be the complexity of the installation, therefore, before erecting a stove heating system, it is necessary to draw up an accurate and specific work plan.

Stove heating can work autonomously, and in this case, fuel shortages will not threaten. True, you must always take into account the fact that the stove occupies a rather large area, and you need to think about this in advance.In addition, being an excellent decorative element of the house, the operating temperature of the stove is practically impossible to adjust, which is why there is an uneven distribution of heat energy.

The choice of heat carrier and method of transporting thermal energy

The most rational solution in two-story houses, in which there are a large number of rooms and there is an overlap between floors, is the implementation of water heating. With a complex configuration of the building, in the vast majority of cases, there is no alternative to such heating. The system is a looped structure of pipes through which the coolant flows, and heat is transferred through radiators or heaters.

Also, heating with a warm floor can be arranged as an additional or only source of heat. Its principle of operation is similar to heating with radiators.

The choice of coolant is extremely important

The choice of coolant is extremely important

The use of underfloor heating, powered by electricity in the premises of the whole house, is a theoretically feasible option. However, this raises a number of problems in its implementation. Firstly, from an economic point of view, heating organized in this way is not always profitable. Secondly, there is a possibility that technically it is not possible to carry out the task of air heating.

Warm floor

Warm floor

Air can be used as a heat carrier in multi-level houses. In this case, it is necessary to solve the problem of its transportation. To implement such a project, it becomes necessary to create a system of channels in the space of the building, as well as equipping them with fans to pump air flow. Only in this way organized heating can ensure the delivery of heat to remote rooms and rooms located on the second floor.

Heating and cooking two-story oven

This two-story stove can heat two rooms on the ground floor and a room in the attic in small country houses. And the presence of a two-burner stove allows not only to cook food if necessary, but also to quickly heat one of the rooms on the ground floor. The photo shows the process of laying the stove and the stove in finished form.

Rice. 1. Drawing of horizontal sections (orders) indicating the layout of bricks in each row.

From rows 1 to 4, an ash pan is formed, a blower door is installed.

On the 4-5th row they put cleaning doors, on the 5th they put a grate, on the 6-8th they install a furnace door.

All doors are fastened in the masonry with a wire dia. 2 mm, and the frames of the furnace door are also wrapped with asbestos.

Please note that inside the firebox, the threshold and walls can be lined with refractory bricks placed on spoons, which are not tied with the rest. They are obtained "independent" from the main masonry

During the repair of the furnace, they can be easily replaced by first removing the stove.

A two-burner stove is installed on the 11th row. And since its length is slightly more than two and a half bricks, then on the 12th row, on the left and right, the bricks are cut off or cut off so that the slab can be freely removed during the current repair of the firebox.

Vertical smoke channels have a size of 13.5 × 13.5 mm

When laying, special attention should be paid to the thorough grouting of their internal surfaces.

On the 16-17th rows, a piece of pipe with a plug is embedded in the masonry, or a standard 140 × 140 mm door is installed to ventilate the cooking chamber, which is blocked on the 18th row with bricks resting on steel corners or metal strips.

Rice. 2. General view of the furnace and its sections

In the space from the 20th to the 24th row, you can, if desired, make a niche shelf for various household needs.

On the 20-21st and 25-26th rows, to clean the horizontal sections of the smoke path, two more cleaning doors should be installed or two halves of the brick should be laid instead.

On the 30th row, two valves are installed.

The version of the furnace proposed here is designed for a house where the height of the ceilings on the first floor is 2 m 60 cm, and on the second - at least 2 m 40 cm.

The design of the stove can be changed so that it can easily fit into a room with other dimensions, if you add (or reduce) the number of rows in the masonry.

After completing the laying of the fire-fighting fluff in the ceiling, proceed to laying the second floor of the furnace with the installation of a cleaning door on the 2nd-3rd row, and valves on the 27th row.

In order to melt the furnace, it is necessary to open all the valves. Hot gases, having passed the cooking stove, begin to move in two directions: along the furnace massif of the first floor and along the massif of the second floor. And if you close the valve No. 1, only the massif of the first floor will heat up. To heat the array of the second floor, it is necessary to close the valve No. 2, but the valve No. 1 must be open.

I would like to warn you: it is possible to smoke through the gaps of the frames of valves No. 1 and No. 2. To avoid this, it is recommended to replace these valves with rotary dampers (gate).

Rice. 3. Plan of placement of the furnace.

For the construction of such a furnace (excluding pipes and foundations), the following materials and devices are required:

Brick red M-150 - 1080 pcs. Clay - 185 kg. Sand - 77 buckets Corner No. (70 × 70 mm) 80 cm - 2 pcs.; No. 94 (40 × 40 mm) 80 cm - 6 pcs.; No. 4 (40 × 40 mm) 40 cm - 2 pcs. Furnace casting: furnace door - 1 pc. blower door - 1 pc. door for cleaning - 5 pcs. valve - 3 pcs. grate - 1 pc. two-burner stove - 1 pc. Wire steel to dia. 2 mm - 20 m Asbestos cord diam. 5 mm - 10 m Roofing iron - 1.5 m2

Important points related to the installation of solid fuel heating systems

The place for the furnace should be chosen with great care. It is desirable that it be erected against a load-bearing wall. This optimizes the performance of this equipment.

When you have to create stove heating for a building consisting of several floors, you should pay close attention to the design of the dwelling. Installation of equipment for space heating can only be carried out taking into account the characteristics of the cottage

If the house is built of brick, then the role of the foundation for the furnace can be played by metal beams, which are embedded in the masonry. This is done with concrete mortar.

Perhaps you decide to do everything yourself. I would like to warn you against such a step. The fact is that the construction of the furnace should be carried out by professionals. An unskilled approach can seriously affect its properties. In order not to have to overpay, it is better to immediately use the services of a specialist in this field.

Features of furnace heating systems

It must be understood that stove heating is a rather complex system that requires taking into account many nuances. If the masters make this or that mistake, the owner of the house will have to pay. Below we will dwell on the frequent problems that arise due to improper construction of the furnace structure.

What are the advantages of heating a private house with wood, peat or coal? It should immediately be noted that they differ in autonomy. The furnace can be built anywhere. She does not need access to communications. In some areas, this is the only option available.

If there is no gas main at the location of the house, the stove, which can be completely autonomous, can become an alternative heating option. Such heating is a classic option for organizing heating in a wooden house.

Undoubtedly, stove heating of a private house also has disadvantages. Firewood can be bought everywhere, but it needs to be stored somewhere. A small closet is clearly not suitable. You will have to build a separate building. What to say about the place for combustible materials, if the furnace itself takes up a lot of space? In addition, to warm up a room with this device, you will have to spend a lot of time.

The stove takes up a lot of space in a wooden house.The larger it is, the warmer it is. In other words, it will be really cozy in a large cottage. For example, heating a wooden house with a stove would be appropriate if there is enough space in the building to accommodate it.

The low efficiency of this equipment often causes the search for another way to maintain a comfortable temperature in the home. As a rule, gas boilers, which we have already mentioned above, are an alternative.

Despite this, many are still building such heating systems. Perhaps this is due not only to good consumer properties, but also to the fact that the stove creates a special comfort that is difficult to convey in words. It can only be felt. In addition, the food cooked in it acquires a unique taste.

List of materials

Brickwork is a classic version of the furnace device, as the material warms up evenly and slowly.

- single red brick M-200 - 1600 pcs;

- fireclay brick Sh-8 - 250 pcs;

- wedge-shaped fireclay brick Sh-44 - 100 pcs;

- smoke damper 26x26 centimeters - 2 pcs;

- smoke damper 13x26 centimeters - 3 pcs;

- damper (dimensions are determined locally) - 1 pc;

- two-burner hob (dimensions are determined along the way) - 1 pc;

- grate 20x28 centimeters - 5 pcs;

- furnace door 21x25 centimeters - 1 pc;

- blower door 14x25 centimeters - 1 pc;

- cleaning door 7x13 centimeters - 2 pcs;

- steel corner 60x60x5 millimeters - 1.5 m;

- steel strip 50x5 millimeters - 20 m;

- chamotte clay - 100 kg;

- sand, ordinary clay - the amount is determined by the need for the material.

Advantages and disadvantages of furnace heating

But the furnace heating system also has a number of disadvantages. Firstly, the dimensions and weight: the stove installed in the house will look good, but a significant reduction in usable space will still be noticeable. The large weight of furnace structures necessitates laying the foundation. Secondly, the system has a long warm-up time. Of course, this quality works in both directions, because prolonged heating in the future leads to an equally long cooling. The efficiency of stoves is also their disadvantage, since most of the heat will go either into the pipe or to heat the walls.

The cap of the first tier must be covered, but the openings for cleaning it and cleaning the lower passages are on the second floor. The furnace and lining are usually made of fireclay bricks, and basalt cardboard must be laid between them. This solution helps to prevent the possible occurrence of cracks in the masonry.

Video about furnace heating:

The main types of brick ovens

So, depending on the functions performed, brick ovens in country houses are divided into the following main types:

- Heating stoves. As you know, such a device is intended exclusively for heating the air in the room. It can heat one room or the whole house if it is built into the wall.

- Cooking ovens - are created with exclusively utilitarian purposes for cooking. In addition, mushrooms, berries and fruits can be dried on a brick cooking oven. Often such stoves are installed in summer kitchens.

- Cooking and heating furnaces. A classic building that can not only heat a room or the whole house, but also be used for cooking food. A multifunctional multicooker with a solid history.

The technology of building brick ovens, proven over the centuries, allows you to create a highly efficient device that will quickly heat up the room, be safe to use and become the center of gravity of the whole house.

heating and cooking stove

Russian stove with a firebox, ordering and finishing

Creation of drawings

A Russian stove with a fireplace is quite a rarity. The scheme that will be considered combines a Russian stove with a firebox and a fireplace.In the event that the laying of the stove is carried out according to the drawings that are attached, the stove can easily heat approximately 40-50 square meters of living space.

The stove is built according to the “double-deck hood” system and is heated evenly from all sides.

A modern Russian heating tepushka (stove) with a firebox meets some household requirements. On a cast-iron stove, it is possible to cook a wide variety of food, and in the crucible - dishes of traditional Russian cuisine. It is quite convenient to dry various fruits, mushrooms and berries in the oven.

This design provides for a very comfortable couch, on which, if wooden beds are attached, there may be enough space for two adults.

A variant of the Russian stove, in which there are arched ceilings of openings.

The drawing contains the facade of a Russian stove (an option in which there are arched ceilings of openings).

From the side of the stove at the base of the furnace, a very large niche is arranged, which is heated from above and from the sides. First of all, it is done so that the furnace has a large heat transfer - an additional amount of heat will flow into the room from it. In winter, our ancestors warmed young domestic animals in a similar under-heating.

The firewood racks that are built on the sides of the fireplace will store wood chips so that the stove can be fired. In different places of the array, seven stoves of various sizes are provided, in which it is possible to conveniently store or dry small items. In addition, stoves decorate the stove: together with a cascade of shelves and arches, they will give the fireplace an elegant look.

If there is a desire, it is possible to replace some of the arches with straight lintels. The stove can also be decorated with shelves and arches made of bricks of a different color, or of a more intense color.

Furnace operating modes

Outwardly, "Teplushka" almost does not differ from an ordinary Russian stove. except that in one of the corners there is a firebox.

Russian tepushka can be heated in two modes. With a traditional (in Russian) firebox, you will need to remove the damper and open the valve. In order to switch to the second mode, in which the crucible will warm up somewhat more intensively, it will be necessary to open the valves, after which the furnace door of the hob. In this case, one of the valves will have to be closed, and the crucible is closed with a damper. In such a case, the furnace door will act as a blower.

From the crucible, flue gases through the valves that are open will be directed to the chimney.

The cooking oven can be heated in three modes. Firewood must be burned on the grate of the firebox. In the first mode, hot smoke gases through open valves and hail will directly enter the chimney, while heating only the stove and bricks of the combustion chamber.

The mouth must be closed with a damper so that the flue gases go from the crucible to the lower heating chamber of the furnace.

In order for the heating pad to be able to switch to the second mode, in which the couch and crucible will warm up, you will need to open one of the valves and close the other. The crucible is then closed with a damper. Hot smoke gases will change their direction and enter the furnace through the window. After it warms up, gases will enter the chimney through the open valves.

In order to switch to the third mode, simply close the valve. The hot smoke gases in front of the window will change their direction and descend into the chimneys of the lower heating of the stove. Having passed along the entire perimeter of the lower mass of the stove and giving off heat in this place, the flue gases through the window will enter the chimney, after which they will go into the atmosphere through the open valve. In the third mode, the lower part of the outer perimeter and the niche under the oven will be intensively heated.

Furnace heating of a two-story house

Today, Yuri Mikhailovich Kishulko, a hereditary stove maker, gives us advice on stove heating.Yuri Mikhailovich's father, a self-taught stove-maker from the Vitebsk region, improved his skills all his life. From early childhood, the son helped his father, absorbing the wisdom of the furnace business. Today, Yuri Mikhailovich is a virtuoso and a real enthusiast in his field, easily laying out complex stoves that can heat a two-story house, and fireplaces in small living rooms.

When arranging stoves in a room, one should strive to ensure that they are located mainly near the internal main walls. It is not recommended to install furnaces near external walls, as this complicates and increases the cost of building chimneys. The stove, if possible, should be open and free to heat the room. For heating the kitchen, living rooms and utility rooms, stoves should be grouped into a so-called thermal unit. In this case, the chimneys are combined into one brick riser.

Compact ovens and hearths up to 700 kg can be installed directly on a solid floor. If this is not enough, the floors are reinforced with additional beams. Furnaces weighing more than 700 kg are placed on the foundation. The foundation is buried in the ground by at least 0.5 - 0.6 m for single-story furnaces without shell pipes and at least 1 m for two-story furnaces and root pipes. The foundation of the furnace must not be tied up with the masonry (foundation) of the building wall, since different shrinkage is possible.

If you have two floors...

The designs of the bases for the furnaces of the upper floors are chosen depending on the structures of the walls of the building, the relative position of the main walls and the orientation of the furnaces themselves. The simplest solution is to install the upper floor oven on the lower floor oven, however when repairing the first floor oven it is difficult to maintain the upper oven. For a more even distribution of the load on the lower furnace, a reinforced concrete slab is laid on it (at the level of the intermediate floor). Sometimes, when laying racks made of square, round or profiled steel, they are embedded in the array of the lower furnace (at the corners), and the lower ends of the racks are embedded in a solid foundation. From above, a solid platform is made of channels and corners, on which the upper furnace is installed.

In brick buildings, the installation of products on rails or steel beams of various profiles embedded in brickwork to a depth of at least 38 cm (one and a half bricks) is widely used. To prevent the brick from collapsing, the embedding is done with the help of gaskets. The space between the beams is filled with lightweight concrete or masonry. When laying out the stoves themselves, it is better to use clay mortar, when heated and cooled, it will work in unison with the brick, which means that your stove will remain intact and functional for many years. The brick is laid in the form of a vault. The beams are fastened with ties. If you have a dacha, for heating the second floor, it is most practical to install a small cap or shield that is heated from a stove located on the first floor. Sometimes the shield can be interlocked with a small fireplace (if the height of the chimney allows). If stove heating is the main one in your house, then you need an option with stoves on the first and second floors, which can be heated separately. Based on this, a house project is made, rooms are tied, etc.

Let us consider in detail a heating two-tier thick-walled stove with heat transfer on the first floor - 3.7 kW and on the second - 2.7 kW, its dimensions are 64x115 cm. larger oven with built-in oven.

Refractory bricks (chamotte) are not produced in Belarus. Sold only imported brick from neighboring countries. The average price for it is 2000 rubles apiece. Tiles for lining furnaces in Belarus are produced by the only enterprise PUE "Volkovyskstroy-materials". Ceramic tiles are intended for cladding and laying the front surfaces of domestic heating stoves, cookers and fireplaces.

The design of the tiles is durable, durable, securely attached to the brickwork. Tiles are sold in ready-made sets, their cost starts from 800 thousand Belarusian rubles for the simplest option.

air heating

In this category we will include all methods of heating without the mediation of a coolant - water, oil, antifreeze and any others. The air in the room is heated by direct contact with the heating element.

Buleryan

The furnace is a firebox, which is surrounded by thick pipes with open ends up and down. The pipes heat up and provide convective mixing of the air in the room.

Their orientation in different directions speeds up the process. If it is necessary to heat several isolated rooms from Buleryan, air ducts are laid out with natural or forced circulation.

Advantages:

- Existing furnaces provide almost complete combustion of fuel due to the fact that they provide long-term smoldering with a limited supply of oxygen. Thus, an efficiency is ensured that is unattainable for traditional stoves.

- Buleryan does not take up much space and does not require its own premises. The stove for heating two floors may well be placed in the living room or dining room. There will be no soot and odors.

- The distribution of air ducts will be cheaper than the distribution of a water heating system. Although, taking into account the necessary thermal insulation, and not much.

Flaws:

- It is almost impossible to lay air ducts after finishing the final repair so as not to spoil the aesthetics of the room. The heating plan for a two-story house - both the heat source and the wiring - will have to be thought out in advance.

- Any stove heating of a two-story house is associated with the need to store supplies of firewood, coal, pellets or peat briquettes.

In the photo - a Buleryan oven in the living room.

brick oven

An ordinary Russian stove usually has very impressive dimensions.

It occupies up to a third of the area of the house and is quite capable of heating several rooms. It is clear, however, that two-story heating stoves are somewhat more complex structures.

In general, there are almost no standards in the field of designing brick ovens. The specific implementation depends on the size of the room, the location of the stove, the imagination of the stove-maker, or, alternatively, the order found on the Internet of a ready-made solution invented by someone else.

A typical heating stove on two floors is a firebox located below and a cap or ducted chimney that makes several turns on the second floor.

Execution options can be varied. For example, it is enough to put a cast-iron stove on the firebox, laying an asbestos cord under it to isolate the room from combustion products - and you get a heating and cooking stove on two floors.

The stove can stand in the middle of the room or in the corner; finally, if desired, you can even organize water heating of a two-story house with natural circulation, simply by placing a coil in the firebox.

Dignity:

In the absence of gas, stove heating is the cheapest way to heat. The brick oven pleases the owners with a large thermal inertia: it is usually heated once a day for 2-3 hours, while the rest of the time it gives off the accumulated heat.

Flaws:

- Again, you will need a supply of fuel, which will take up a fair amount of space in the yard.

- Folding the stove so that condensation does not appear through the masonry, so that the stove does not crack and smoke into the room is an art that is gradually being lost.

If you are not afraid of experiments, you can try to do this work yourself; but in the absence of any experience, it is better to be prepared for various surprises.

Gas convectors

Another way that air heating of a private two-story house can be done with a minimum of time and money is the installation of gas convectors.

Each device is a closed burner with air intake from the street and removal of combustion products to the same place through a coaxial pipe. The heat exchanger heats the air in the room. Devices can work both from the main gas, and from bottled.

Advantages:

- Complete autonomy of heating each of the premises of the house.

- Low project cost. The price of each convector is 4-8 thousand rubles. Given that you do not need a boiler and wiring from it, this will mean tangible savings.

Flaws:

- The main gas, alas, is not everywhere.

- Installation of convectors is possible only on the outer wall of the house.

- Drilling wide holes for a coaxial pipe in, for example, reinforced concrete is still a pleasure.

- see here.