Preliminary preparation.

A process such as soldering pvc pipes with your own hands involves certain preparatory steps. The most significant of them are:

- Cleaning of assembly parts.

- Installing nozzles on the device.

- Careful check of the tightness of the entry of the part into the nozzle. Those parts that do not fit well enough should be replaced immediately, since they still will not provide a decent quality for installing plastic pipes.

- After checking the quality of the interaction of nozzles and spare parts, you can turn on the tool for warming up. All components by this point should be cut and cleaned.

What units and materials will be required

For soldering PVC pipes, you must have:

Device for heating parts. As a rule, it is called "iron" or "soldering iron". Be sure to have a set of nozzles, they will definitely be required.

Pipe cutter, “cutter”

Before starting installation, it is extremely important to make sure that the knife is perfectly sharpened. If the actual state of affairs differs from that described, then the cutter must be sharpened or replaced, otherwise many errors will be made during the assembly process.

Rags (not fibrous) and alcohol or any other degreasing agent

Parts and nozzles must be perfectly clean at the start of heating.

It is interesting to know that all of the above methods are also relevant for the installation of pipes that carry gas.

Measuring and marking devices. As the first, the simplest tape measure of any convenient size is perfect, as the second - a pencil or marker.

In cases where it is a question of connecting components whose diameter exceeds 50 mm, it is necessary to acquire a centering device.

Sharp knife for chamfering. The best solution would be to purchase a beveler.

Consistent Soldering Technology

Soldering plastic pipes is best done in a room with good ventilation. This is due to the fact that when heated, polymers release toxins that are hazardous to health. At sufficient concentrations, they cause poisoning.

It is better to solder pipes with protective gloves

It is better to solder pipes with protective gloves

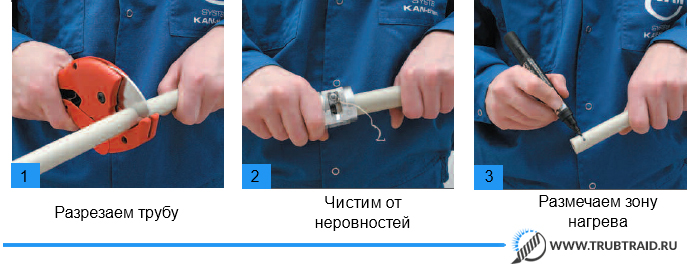

Preparatory stage:

- A blank of the required size is installed on the working body of the soldering iron;

- The temperature setting must be within 260 degrees;

- All additional parts are prepared, cleaned and properly placed;

- The soldering iron is turned on;

- Wait until the device reaches the required temperature, as evidenced by the green sensor.

Next, the pipe and coupling must be simultaneously placed on the soldering iron and blank. The pipeline is mounted in the inner part of the blank. The clutch is installed on the outside. The pipe must be pushed to the pre-marked part. The clutch is put on until it stops. For proper welding, you need to remember about the time.

At a low temperature, the level of diffusion will be low, which will affect the quality of the alloy. When overheated, the parts are deformed. The time is chosen depending on the diameter of the material.

When the parts are heated, it is necessary to quickly join them. In this case, alignment must be observed. For a few seconds, you can make a correction, but you can not rotate the products

It is important not to pull when working, but also not to rush

Differences between soldering plastic and metal-plastic

Many are interested in how to properly weld metal-plastic products. It is interesting that such a concept does not exist in the work of professionals. Weld aluminum pipes. In this case, the butt or overlap technique is used. Fittings are used for connection.

Types of fittings:

- Compression;

- Press fittings.

Press fittings are more durable. Pipes are connected by pressing, using a special tool.A simple wrench is used to tighten the compression joints. But such fittings do not include welding.

Aluminum reinforced polypropylene pipes are on the market. They are used in heating and hot water systems. It is these devices that need welding.

To avoid mistakes, it is better to watch the instructional video before soldering.

To avoid mistakes, it is better to watch the instructional video before soldering.

For metal-plastic products, welding is not used. But reinforced products are connected in this way. Among plastic pipes, PVC options are popular. Their expansion coefficient is small. The characteristic of the products allows them to be used only for arranging sewers. But pipes of large diameter can be taken for the central water supply. Installation can be carried out by welding or gluing.

PVC soldering secrets and safety measures

Soldering work should be carried out in a room with positive temperature. It must be taken into account that the colder it is, the longer the elements will warm up. However, there are a number of other rules that must be followed.

Features of soldering PVC pipes:

- The power of the iron should be 1200 watts.

- The manual device is used for pipes with a diameter of up to 32 mm. For large sizes, professional equipment is used.

- Before starting work, the device must be warmed up for 5-10 minutes. This is necessary for the device with nozzles to reach the desired parameters.

- After soldering, it is forbidden to scroll the connection. Otherwise, it may violate the integrity of the seam. You can only straighten the distortions so that the connection does not leak.

- No need to apply a lot of force to compress the parts. Otherwise, the gap will be filled with hot plastic and disrupt the patency.

- No gaps between the pipe joint and the inside of the fitting are allowed. Otherwise, leaks will occur under pressure.

- The soldered area must be completely cool before use.

- After completion of work, the iron is cleaned of plastic. So on the device there will be no carbon deposits, and the elements for soldering will not be damaged.

Use a flat wooden stick for cleaning. So the teflon will not be damaged. Metal objects can scratch the surface and make the nozzle unusable, because the plastic will begin to stick to the coating.

The soldering machine should be placed in such a way that it is stable.

The soldering machine should be placed in such a way that it is stable.

When working with power tools, it is important to observe safety precautions. Otherwise, you may get burned or injured.

You need to work with protective gloves. The room must be clean and dust-free. Otherwise, the particles will settle on the plastic and disrupt the quality of the soldering.

The soldering iron is placed horizontally on the surface. During operation, it is forbidden to turn off the equipment. Work begins when the iron is fully heated. In modern models, this is indicated by an indicator. For old-style options, wait 20 minutes.

The soldering of polyethylene pipes does not have a complex technology. Welding may have features if you solder reinforced products

However, it is important to take precautions. Soldering pipes correctly will help the basic secrets and rules. Also, follow the instructions exactly.

Also, follow the instructions exactly.

Varieties and choice of equipment

Soldering equipment is a device that, using high temperatures, creates a reliable hermetic connection. For welding plastic and cast iron products, different equipment can be used.

For welding polypropylene, 2 main groups of equipment are distinguished:

- Mechanical devices. They are used when the amount of work is large and a lot of manpower is required.

- Manual apparatus. Can be used for small diameter pipes for independent work.

The mechanical device includes a support frame, a block, a hydraulic unit. There are grips on both sides of the equipment. Inserts are observed in their middle. Their task is to properly distribute pressure and centering.

For soldering pipes, it is better to use 2 people

For soldering pipes, it is better to use 2 people

The ends are leveled with an electric trimmer. It is a rotating disc with double-sided knives. The main element of the unit is an electric heater. It is installed inside and is a disk with a heating element.

To perform soldering manually, you need to purchase a special iron. The principle of operation resembles a household appliance, although the appearance of the devices is different. The design of the iron includes a heating plate, a thermostat and a handle. The plate has two holes for soldering parts. Due to the Teflon coating, heated plastic does not stick to the device.

Varieties and cost of soldering irons.

Such a unit as a soldering iron for plumbing can be quite different, depending on the current needs and financial capabilities of the master.

Forte WP6308

The main parameter of such a device, which is worth paying attention to, is power. This characteristic determines the heating rate and, in many respects, its efficiency.

The number and specificity of nozzles is also important, because the range of products that can be processed depends on this factor. When planning to acquire such a device as a soldering device, it is necessary to pay attention to the manufacturer.

| Power | 800 W |

| Maximum operating t °C | 300°C |

| heating type | Periodic |

| Nozzles: | Ø20 / 25 / 32 mm |

| Powered by voltage | 220 V |

| Heating to working condition | up to 15 min |

| Price (approx.) | from 10 to 15 c.u. |

Many potential consumers are also concerned about such a factor as the cost of the tools in question. It should be understood that the price of the device can be quite different, from 500 rubles (inherently primitive and often unreliable “irons”) to tens of thousands of rubles.

Important! If there is a lot of work and you need to do 100 - 120 rations. Do not breathe burnt plastic, take care of yourself .. It is quite possible to purchase a high-quality tool for 2500 - 4000 rubles

The price of soldering largely depends on the individual working conditions and usually amounts to at least 200 rubles for the installation of one joint.

It is quite possible to purchase a high-quality tool for 2500 - 4000 rubles. The price of soldering largely depends on the individual working conditions and usually amounts to at least 200 rubles for the installation of one joint.

This state of affairs unmistakably indicates that the purchase of an “iron” can justify itself from a financial point of view after completing one order, if we are talking about reusable use.

Well, if the master has the opportunity to ask for the necessary tools for the time of work, then such a solution can rightly be called the most optimal. In other situations, the question arises either about renting a “soldering iron” or about acquiring your own device.

SPT-2200; Power - 2200 W; working t – 300 °C

One way or another, a high-quality, reliable tool for the installation of water pipes from plastic pipes, with the decoding of the abbreviations of which can be found on our website,

will never be superfluous in the hands of an experienced specialist or a person who plans to become one in the foreseeable future, performing such work for himself or on a commercial basis.

Watch the video instruction - 4min 31sec:

How the assembly is carried out

The further work process is carried out as follows:

- Regardless of how welding is carried out - without a soldering iron or with it, marking must be done.

- Following the instructions for the device, it is necessary to warm up the connected parts, and after starting the connection, do not allow the pipe to rest against the wall of the fitting. Correct markup can help with this.

- Leave the mounted area to cool completely and ensure its immobility.

- After that, you need to make sure that there are no defects (sagging, deviations from the common axis, leaks).If any of the described defects is detected, the unsuccessful section must be disassembled and reassembled, using new components and taking into account the mistakes made.