The nuances of thermal insulation of a flat roof

Insulation of flat roofs is carried out according to special rules that differ from the principles of thermal insulation of pitched counterparts. The analogy can be traced only in the sequence of laying the layers of the roofing cake. Flat structures do not have truss systems, among the elements of which it is convenient to place a heat-insulating layer.

There is nothing to nail the crate, which forms a ventilation gap for ventilation of the components. Instead of channels for ventilation, if necessary, peculiar vents are created by partially gluing the coating to the underlying base.

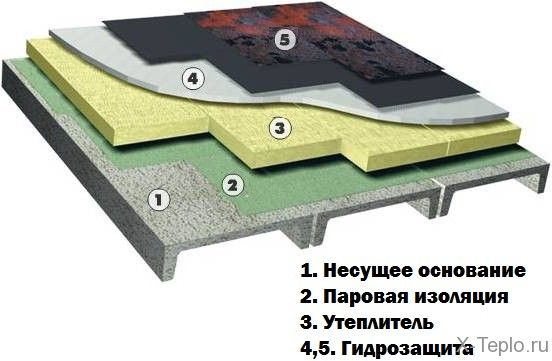

According to building traditions, a flat roofing pie is arranged by successively hoisting its components on top of each other. Traditional ingredients include:

- Vapor barrier. It plays the role of a barrier to household fumes. It is located on the side of residential, economic, etc. premises.

- Thermal insulation. Prevents the passage of heat waves from the inside to the outside of the building and in the opposite direction. At the same time it copes with the duties of a barrier to sound vibrations.

- Waterproofing. Covers the thermal insulation from the outside, protecting it from atmospheric water. It is laid in 4-6 rows, depending on the size of the roof slopes that direct water to water inlets, and on the technical characteristics of the roofing material. The outer layer of waterproofing of a conventional roof serves as a top coat. When constructing ballast roofs, gravel, topsoil, paving slabs, etc. are laid on top of the waterproofing.

Violation of the sequence of layers and laying rules ends in failure for the owners, who are forced to pay considerable sums for repairs or even for a total reconstruction of the roof.

It should be noted that the indicated layers, together with their laying sequence, are used only if it is necessary to preserve the heat obtained during space heating.

There is no reason to insulate the roof of a summer kitchen or a barn for storing summer equipment. In such situations, the roofing pie includes only waterproofing if it is arranged on a concrete base, or consists of a prefabricated screed and waterproofing if corrugated board is used as the base.

This is interesting: Equipment for the production of metal tiles and manufacturing technology: we paint the essence

Ways of laying thermal insulation

Insulation of a flat roof from the outside can be carried out in one or two layers.

The first option has found its application in industrial buildings, temporary structures. One layer is suitable for both operated and non-operated roofs. It should be understood that with increased loads that arise as a result of using a roofing plane, the reliability of a thin layer will not be enough, therefore, to give additional rigidity, a reinforced mesh is placed in the base. Make sure that the insulation plates are located in the same plane, this will prevent temperature drops and condensation.

Two layers of thermal insulation will give the roof the required thickness, which will lead to more comfortable living in such a building. The material of the lower layer of thermal insulation should be slightly different from the upper one. It must have great thermal stability, despite its small size. As a rule, the thickness of such a product is from 70 to 170 millimeters. As for the top layer, it will distribute the mechanical loads arising from the upstream elements. The thickness of the upper plates is significantly less than the heat-resistant layer and is about 30-50 millimeters. Despite such small parameters, they perceive high loads well.

Plate materials for thermal insulation of flat roofs

The three materials that have been described above, if you have a desire to use them for insulating a flat roof, will require special equipment.

Moreover, in the case of foam concrete and polystyrene concrete, which is very bulky, we add to this mountains of sand and cement or many flights of concrete trucks, so noise, din, dirt, and other attributes are guaranteed. Only PPU is an exception: a small installation + a compressor and 4 barrels (tons) of liquid turn into 15-20 cubic meters of insulation already on the roof.

And, nevertheless, often those who carry out flat roof insulation have neither the equipment for spraying polyurethane foam, nor the desire to use these technologies. 95% of contractors prefer to use "slab" materials. Firstly, it is often cheaper, and secondly, the only thing you need to lay them is “human hands”

For many, this is also important when “Get Smart” is not needed (the movie was so funny - did you watch it?).

So, all that is needed is to lay the slab insulation, and along them, to perform a leveling with a cement-sand mortar, and then waterproofing with liquid rubber.

This group includes: polystyrenes, mineral wool, stone wool, foam glass

Styrofoam for roof insulation

Now, when we say expanded polystyrene, we understand extruded polystyrene foam. I believe that few people already use ordinary PSBS for thermal insulation of construction projects. Looks like it's not for sale anymore. Although - Russia is big, maybe where it is still being produced and continues to be laid.

Now in Russia there are many dozens (and maybe more than a hundred) manufacturers of extruded polystyrene foam. Describing what it is and how it is done is off topic here. I note that today, this is the most massive method and material for insulating a flat roof. The process is to lay the sheets tightly over the entire surface, possibly gluing between the resin. It looks like the photo below.

Orange slabs of extruded polystyrene foam indicate that it is used, possibly foam. Previously, only this material was of this color. But today there are many manufacturers. Therefore, the color differentiation of extruded polystyrene foam no longer allows you to determine belonging to a particular brand, in contrast to the color differentiation of pants on the planet Plyuk, in relation to the social status of chatlans and boys.

Roof insulation with stone wool

The method of warming a flat roof with rockwool stone wool is identical to the previous one: we spread the pack and lay the sheets, fitting them to each other. Plates are usually two-density: on the one hand, the density is greater than on the other. The high-density side is usually marked with a black stripe. This side of the rockwool slab is laid up.

The photo shows a classic flat roof insulation. It can be seen that the vapor barrier is spread. Stone wool slabs are laid on top.

Thermal insulation of a flat roof with foam glass

Foam glass is, on the one hand, a relatively new material, but on the other hand, it has been known for a long time. It just wasn't used. I suppose they didn’t do this in the Union, so as not to “waste” raw materials - broken glass, bottles.

In general, in my subjective opinion, this is better than the 2 previous slab materials.

On this, a brief overview of the methods of insulating a flat roof with various materials is completed.

After the insulation or repair of the insulation has been completed, the next step is ventilation and ramping, after which it will be possible to proceed with waterproofing with liquid rubber.

If you have questions that were not raised in this article about flat roof insulation methods or in other materials of the b2bb2c.ru site regarding bitumen-polymer emulsion or polyurethane foam, make a request through the form in the Contacts section.

Pitched roof than and how to insulate

This type of roofing is most common in private construction and is the most in demand. Consider which insulation is best for a sloped roof.

According to the degree of insulation, there are two types of sloping roofs:

- A warm roof is a roof in which the insulation is mounted directly on the roof slopes between the rafters. This method of roof insulation is used when it is planned to arrange an attic in the attic.

- Cold ventilated roof. In this case, only the lower part of the roof is insulated, and the slopes are left alone to the delight of the winds. It will not be possible to live in such an attic - it is only suitable for household needs.

The main types of heaters used

In the beginning, consider the so-called warm roofs. This roof has a slightly more complex structure than a flat one. For its thermal insulation, a so-called "roofing pie" is created, which includes a heater for a pitched roof, a vapor barrier layer and a moisture protection layer. Otherwise, condensation will inevitably appear. The main thing in the insulation of slopes is a good fit of the heat insulator to the rafters and the crate.

The following materials are suitable for warm roofs:

#one. Basalt wool is the most fireproof of all heaters. It has low thermal conductivity, high environmental friendliness. Mice and rats do not like this cotton wool, it does not get wet in the rain, it is easily cut with a knife and weighs little. She is also very flexible.

#2. Polyurethane foam - this insulation is made directly at the construction site and applied with a special gun into the space between the rafters. PPU has excellent adhesion to any surfaces, low weight, monolithic layer, long service life (50 years). And he is not afraid of fire. But for its spraying, you will need special equipment and the involvement of a specialized team in the process of warming, which performs these works.

#3. Ecowool - 80 percent consists of cellulose fibers. The rest is antiseptic and refractory additives. This "breathable" insulation does not take any fungus or mold. The coating is seamless - which means that there will be no cold bridges. Ecowool is assigned to serve for 50 years, at least. It absorbs noise well, and saves heat no worse than polystyrene foam.

#4. Penoizol is a modified polystyrene, for sloping roofs it is often used in the form of plates. This elastic continuous coating does not burn (and does not melt), does not get wet and has a low thermal conductivity.

All heat insulators listed above are suitable for a cold roof. But besides this, you can also use glass wool, which is distinguished by a budget price. It does not burn, environmentally friendly, does not contain organic matter. If it is tightly joined to the insulated surface, then the house will be warm. Various types of fiberglass-based roof insulation are not recommended for insulating roof slopes. This is because, due to their weak elasticity, they will eventually begin to lag behind inclined surfaces. As a result, the level of thermal insulation will significantly deteriorate.

Popular brands of insulation for pitched roofs

#one. Stone wool from basalt.

The manufacturer TechnoNIKOL produces this insulation in rolls (Teploroll) and in slabs (Rocklight).

Rolled basalt wool is more suitable for slopes. In addition, we can name the products of the Danish company Rockwool and Linerock Light plates.

Isover pitched roofing is a material produced using TEL technology by the French concern Saint-Gabin. These are slabs 5 and 10 centimeters thick and 61 centimeters wide.

Knauf insulation glass wool is produced by the largest German company in the form of rolls 1.2 meters wide. Innovative technology made it possible to obtain a practically non-caking material.

URSA GEO fiberglass insulation is distinguished by the large length of thin glass fibers, due to which there are many air gaps between them. This will save more heat.

#3. Polyurethane foam and penoizol.

As for PPU and penoizol, there are a lot of manufacturers of these heaters. If you decide to use any of these types of thermal insulation, then find in your region a specialized company that deals with room insulation using these heat insulators.

Thermal insulation technologies

The method of insulation and the sequence of work depends on the type of flat roof. They are traditional and inversion. Inverted roofs are usually exploitable. Traditional roofs do not perform additional functions.

Thermal insulation of a traditional roof

The “roofing cake” of a traditional type of roof is made from the following layers:

- concrete base or metal profile;

- vapor barrier;

- insulating material;

- waterproofing layer.

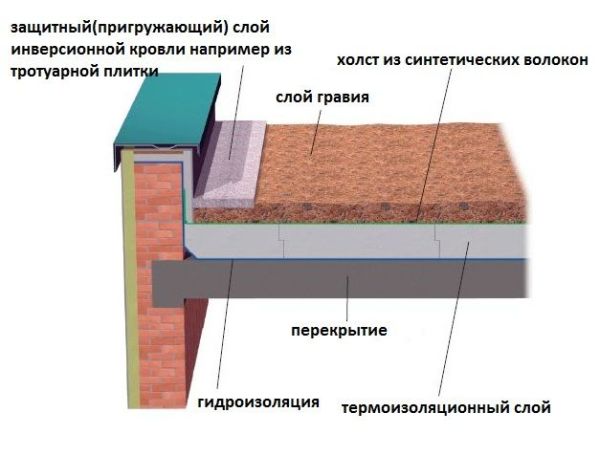

Inverted roof type

The sequence of layers for thermal protection of an inverted roof is somewhat different. In this case, the insulation system looks like this:

- bearing base;

- waterproofing;

- insulating material;

- geotextile;

- crushed stone backfill;

- finish coating.

Exploited and non-exploited roofs

Unexploited roofs have only the main protective function. The surfaces of exploited roofs can additionally serve as a garden, a terrace, a sports ground, a recreation area. Therefore, the insulating structure of the exploited roof must be especially durable and reliable. When installing a single-layer insulation system on such a roof, a concrete screed must be made on top of the insulation.

Single layer and double layer insulation

Depending on the number of layers of insulation, the insulation system can be two-layer and single-layer. With a single-layer system, the heat-insulating layer is made of an insulating material of the same density. In this case, the heat insulator must be sufficiently dense and durable.

This design is usually used in the reconstruction of an old roof or in the construction of warehouses, industrial buildings and garages.

When installing a two-layer insulation system, two layers of insulation are laid. The bottom layer has the main heat-shielding function. It has a greater thickness compared to the top layer, high thermal insulation characteristics. In this case, the strength of the material can be relatively small.

The top layer of insulation additionally carries the function of redistributing the load. Its thickness is less, while the density and compressive strength must be high.

The two-layer design allows to achieve high strength of the insulation system with relatively low weight. As a result, the load on the floors is reduced.

What insulation for a flat roof is better to choose

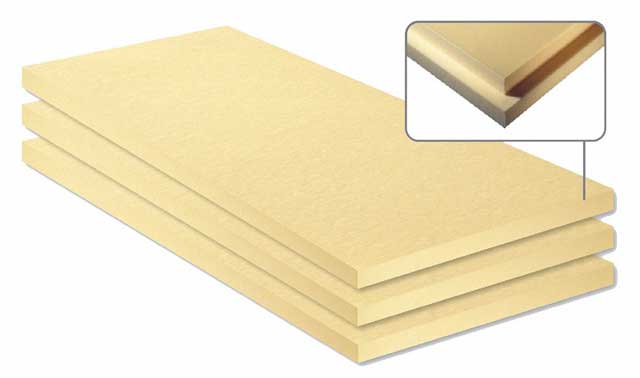

Styrofoam brand URSA XPS. The excellent quality of the heat-insulating material produced by the international holding URALITA attracts many developers. It contains flame retardants, which increase the fire resistance of the insulation. This material is excellent for thermal insulation of an inverted exploitable flat roof. The plates on the sides have cutouts that guarantee their perfect joining without the formation of cracks.

Penoplex Roof. Russian-made extruded polystyrene foam is produced in the form of plates, on each side of which there is an L-shaped edge. It provides perfectly even joining and continuity of the heat-insulating layer, which prevents the formation of cold bridges. Penoplex plates do not absorb water, that is, in this case, you can do without additional protection against precipitation.

- XPS CARBON ECO is a roof insulation for low-rise or country houses.

- XPS CARBON ECO DRAIN - drainage grooves on the boards help ventilate the flat roof.

- CARBON PROF is a particularly rigid and durable expanded polystyrene, which is able to withstand enormous loads. It is used in roofing pies of high-rise buildings, shops or warehouses.

- CARBON PROF SLOPE - no less durable than CARBON PROF, but this material has a special "trick". It is supplied as a set of five slabs with different slopes of the top plane. With their help, a slope is formed on a flat roof.

Basalt mineral wool TECHNORUF from TechnoNikol. TECHNOROOF 45, 50, 60 and 70 is designed for single-layer thermal insulation of flat roofs. The numbers in the marking indicate the density of the plates in compression. The thermal conductivity of the material is so low that with the help of these plates it is possible to insulate the roofs of parking lots.

TECHNOROOF boards are also used for two-layer thermal insulation: 50, 60, 70 for the top layer and 25, 30, 35, 40 for the bottom one.

https://youtube.com/watch?v=dpkpAXvQVqI

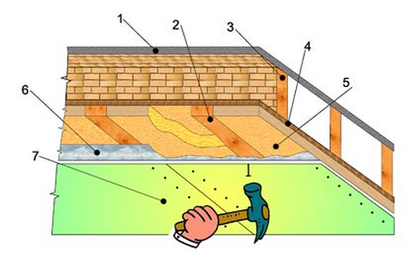

Flat roof internal insulation

Insulation of flat roofs from the inside of the premises, as a rule, is carried out with an already existing and operated structure, since this is a less effective method.

keeping warm. But the most significant

the disadvantage of this option is that the installation of the heat-insulating layer is carried out by reducing the height of the rooms, and this, as you understand, is not always aesthetically pleasing.

Installation from the inside of the building is quite simple and does not require special skills and knowledge, only the inconvenience of doing work can be called an unpleasant moment. Before starting work, it will be necessary to think over the lighting system of the room and provide outlet points for connecting lighting fixtures. Then, retaining strips are nailed to the already existing ceiling, so that cells with a size of 350 - 500 mm are formed. The height of the strips is selected depending on the thickness of the heat-insulating layer, which in turn is determined by the thermophysical properties of the material used and the calculated value of the required heat transfer resistance.

Fig.5

At the beginning, the bars are nailed around the perimeter of the room, then with the help of planks the rest of the space is divided into squares. A pre-cut heat-insulating material is inserted into the formed cells. Do not forget that when cutting soft insulation, it is necessary to provide mounting allowances of 10 - 15 mm, which will ensure the installation of the workpiece by surprise. When using rigid materials, you will have to use a temporary mount to keep the insulation in the cells. This can be done 1 - roofing; with short wooden slats or 2 - retaining slats; use the cord by pulling it “cross 3 - power structure; on the cross "on top of the insulation in the cell. Also 4 - operated ceiling; you can resort to the method of gluing, 5 - insulation; but undesirable. Temporary fastening 6 - vapor barrier layer; removed after the gaps are filled 7 - finishing coating; between the heat-insulating material and the frame of the cell with polyurethane foam. When expanded, it will fix the insulation in the desired position. After that, you will need to deal with the electrical wiring system, steel pipes, square or round, are used for its installation and brought to the right points. This work is carried out after the installation of the thermal insulation layer. Do not forget about the vapor barrier membrane, which will prevent moisture from entering the insulation. Otherwise, dampness will significantly reduce the life of the insulation system. At the end, finishing work is carried out, the installation of lighting fixtures and the design of a new ceiling.

outdoor installation

With this approach, all layers of insulation and waterproofing are located on the outside of the floor. Accordingly, it is required to create such a heat-saving "pie" that can withstand all temperature and climate changes. There are two main types of flat roofs, insulated in different ways:

- Classic

- Inversion

The classic roof is insulated according to the standard scheme and the layers are laid in the following order, counting from the bottom up:

- Floor slab

- Vapor barrier film

- insulation

- Waterproofing

This scheme has a significant drawback - external waterproofing requires periodic maintenance and repair. It is produced every two or three years and this entails additional costs, although such a roofing device is slightly cheaper than another option - inversion.

This type of roofing is considered more expensive to install, but it can withstand temperature extremes better and does not require such frequent repairs. Its fundamental difference from the classic version will be a different scheme for laying layers and arrangement:

- The first will be, as in the previous case, the floor slab

- Then - screed

- Next up is waterproofing.

- Next up is a heater.

- A special film is laid on top - a filter

- Expanded clay or gravel covers the cake, at least 50 millimeters thick

This solution allows you to protect the waterproofing gasket and significantly increase its service life.

Inverted exploited surface

A common problem of an exploited roof is the wear of the waterproofing layer. After the integrity of the insulation is broken, the roof begins to leak and often it is impossible to do without repairs. Manufacturers of roofing products have thought about this problem and have released a completely new material. Polymer membranes became their brainchild. They differed from all types of roofing and were very elastic. During several years of actual operation, it turned out that such a product easily withstands sudden temperature changes, does not lose its properties even in extreme cold, and is resistant to direct sunlight and mechanical damage.

The polymer membrane is laid by thermal welding. This is a completely safe method for humans, but it is unlikely that such work can be done by yourself. The fact is that a welding machine for this business costs quite a lot, however, if desired, it can be rented.

Now, let's go back to the inversion sequence of the roof layers. If you make a cross section, you can immediately notice the differences from traditional installation, namely: the heat-insulating material is above the waterproofing. It is laid on the base and acts as a vapor barrier layer. A reinforcing mortar is applied over the thermal insulation boards, but most developers simply pour another layer of cement-sand screed.

Such a surface has some advantages:

- Waterproofing material, which is closed by the thickness of the roofing cake, will last much longer than usual.

- Moisture will never penetrate into the thermal insulation product, therefore, the properties of this material will always be at a high level.

- Roof repair is very easy. To do this, the external screed is dismantled and the thermal insulation plates are pulled out.

If you plan to create an exploitable roof, then it is best to do this using the inversion method.

Expanded clay backfill - its disadvantages

Expanded clay backfill is fragile, by itself it is not capable of being the basis for a built-up waterproofing carpet. Therefore, on top of it, it is imperative to arrange a reinforcing cement-sand screed. Moreover, it should be borne in mind that such a screed, being a cold bridge, increases the heat loss of the roof. A screed over thermal insulation will also have to be done in the case of using liquid polyurethane foam, since its strength is not enough to withstand the roofing carpet.It is recommended to apply the screed only after the final hardening of the material, otherwise it is difficult to achieve evenness of the base. It is also not easy to create a solid base from expanded polystyrene concrete, since for this it is necessary to pour the material in thin layers and wait until they completely harden, only then the expanded polystyrene granules are distributed evenly and voids do not appear. However, in practice, builders speed up installation by pouring thick layers of expanded polystyrene concrete, which creates voids that cause shrinkage and even failure of the base for the roofing carpet, which ultimately leads to irregularities on the carpet itself. Water gets into these irregularities, which, when frozen, can break the waterproofing. It is worth noting: the cement-sand mortar, which is the binding component of expanded polystyrene concrete, needs at least 28 days to gain strength. Moreover, if the screed does not dry out completely, and a waterproofing coating is already deposited on it, then soon swellings and bubbles may form on it. Because of the bubbles, the roofing carpet will lose elasticity, and over time, cracks will appear in it, leaks will begin. Foam concrete, like expanded polystyrene concrete, contains a cement mortar, which means that if the material does not dry completely, then it is likely that the waterproofing deposited on it will swell in some places and begin to let moisture through.