How can you create pressure in the heating system

- 1 Pressurization, which is performed by filling the circuit with coolant through a jumper connected to the water supply. This process is accompanied by pressurization of the heating system to values that are 2-3 times higher than the operating parameters. Pressure testing is performed to avoid pressure drops and displacement of air trapped in the line. During the operation, continuous monitoring of the parameters on the manometer should be carried out.

- 2 Check the heating main for tightness and leaks. The verification is carried out in two stages. First, there is a cold stage - the pressure in the line gradually increases (the time interval between increases is 15 minutes) until the minimum operating value of the indicators in the circuit is reached. After 30 minutes, the initial pressure should be maintained with an error of no more than 0.06 MPa downwards. After two hours, the changes should not exceed 0.02 MPa. The hot stage is carried out after connecting the working boiler to the line. The test pressure must be set to the maximum working level. The fixed values should remain the same as those made according to the original calculation.

- 3 Creation of working pressure, for which it is enough, after pressure testing, to discharge the excess volume of the coolant through any valve or air valve (air vent).

Important! The tightness test should be carried out after three days of operation of the heating system. Once all tests have been successfully carried out, and leaks (if any) have been eliminated, you can continue to operate the system.

Once all tests have been successfully carried out, and leaks (if any) have been eliminated, the system can continue to operate.

What to do if the pressure drops in the system

If you find a decrease in pressure, the first step is to turn off the pump. And then act on the basis of the readings of the pressure gauge:

- If the static pressure also drops, there is a leak somewhere. You need to inspect all the elements and eliminate it. Please note that even a very small hole (less than a millimeter) can be the cause, so finding damage can be difficult. With a large length of the pipeline, it is possible to localize the leak area: turn off the branches one by one. As soon as the fall stopped, the site was determined - depressurization on the one that had just been turned off.

- If the pressure is stable when the pump is turned off, the pump is out of order, it must be carried in for repair or replaced.

An increase in pressure is less common, but it also happens. It is usually caused by an increase in temperature in the system, and it rises due to insufficient circulation of the coolant. But why the coolant circulates poorly needs to be dealt with.

- First, we check the performance of the pump. Turn off and watch. If the pressure continues to rise, it's not the pump. If it stabilizes, it's his fault.

- We clean the filters and mudguards.

- If the pressure continues to rise, an air lock may have formed - we bleed the air in the system.

- If this does not help, we check the condition of the shut-off valves - maybe someone accidentally or intentionally closed it, blocking the coolant flow.

- Another reason - due to a breakdown or failure of automation, the system is under constant replenishment.

Using this algorithm, you can independently determine the cause of the abnormal state of the heating system and eliminate it.

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until the moment when water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the filling valve of the system open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system.Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

Water or coolant choose the optimal system filling

Antifreeze for heating system

The optimal composition of the liquid should be determined by the parameters of the heating system. Often the heating system is filled with water, as it has a number of significant advantages. The determinant is the affordable cost - they often take plain tap water. However, this is fundamentally wrong. A large number of metal elements and alkali will contribute to the formation of build-up on the inner walls of pipes and radiators. This leads to a decrease in the passage diameter, an increase in hydraulic losses in certain sections of the pipeline.

But how to properly fill a closed heating system with water in order to avoid such troubles? Experts recommend using distilled water. It is maximally purified from impurities, which affects for the better its physical and operational properties.

Energy intensity. Water accumulates heat well in order to subsequently transfer it to the room;

Minimum viscosity index

This is important for closed heating systems with forced circulation and affects the power of the centrifugal pump;

When the pressure in the pipes increases, the boiling point shifts upwards. Those

in fact, the process of transition from liquid to gaseous state occurs at a temperature of 110°C. This makes it possible to use high-temperature heating modes.

But if there is a possibility of exposure to negative temperatures, then water, as a liquid for filling heating systems, is unacceptable. In this case, antifreezes should be used, in which the crystallization threshold is much lower than 0 ° C. The best option is solutions of propylene glycol or glycerin with special additives. They belong to the class of harmless substances and are used in the food industry. Solutions based on ethylene glycol have the best technical qualities. Until recently, they filled closed heating systems. However, they are extremely harmful to humans. Therefore, despite all their positive qualities, the use of ethylene glycol-based antifreezes is not recommended.

But what can fill the heating system - water or antifreeze? If there is no possibility of exposure to low temperatures, water is the best choice. Otherwise, it is recommended to use solutions of a special coolant.

Automotive antifreeze must not be poured into the heating system. This will not only lead to a breakdown of the boiler and failure of the radiators, but it will also be dangerous to health.

Pressure in a closed heating system

The circulation pump creates an increased pressure on the pipeline section located behind it, thereby providing a number of advantages:

- The maximum length of the circuit becomes virtually unlimited (for a circuit with natural circulation - no more than 30 m). It is only necessary to select a pump with sufficient power and devices with sufficient strength (in the area with the highest pressure).

- Smaller pipes can be used.

- Radiators can be connected in series (single-pipe circuit).

- If the radiators are connected in parallel (two-pipe circuit), then with a circulation pump, the heat distribution in the circuit will be more uniform.

- Since the coolant moves faster, it does not have time to cool down much, which means that the boiler operates in a sparing mode.

- A system equipped with a circulation pump can be operated in low temperature mode, which may be required during the off-season. In a thermosiphon system, under such conditions, the convective flow will not be powerful enough to push the coolant through all pipes and radiators.

The pressure developed by the circulation pump is called dynamic.

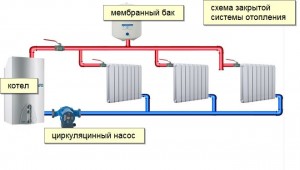

Closed heating system

Obviously, it must meet two requirements:

- Be no more than the value specified in the instructions for the boiler and other appliances.

- Have enough power to overcome the hydraulic resistance of the heating circuit, which depends on its duration, configuration (single-pipe with serial connection of radiators or two-pipe with parallel), pipe diameters and speed of the coolant. The user does not need to make complex calculations linking all these parameters. He just needs to adjust the pump power so that the temperature difference between the supply and return is not too large - usually 20 degrees.

In private homes, circulation pumps usually develop such pressure that, in total with static pressure (which does not go anywhere), it is 1.5 - 2.5 atm. As you move away from the pump, the dynamic pressure, “eaten up” by the hydraulic resistance of the circuit, gradually drops, while remaining quite high.

Under such conditions, an open-type expansion tank would have to be raised too high - about 10 m for each atmosphere - otherwise the coolant would splash out of it. Therefore, instead of an open one, a sealed membrane expansion tank with an air cushion is used, and the system is called closed because of this.

While a mixing unit is used in private houses, the elevator unit of the heating system performs a similar function in a centralized system. We will analyze the principle of operation and the connection scheme in the article.

The list of necessary tools and the procedure for performing work on the installation of the heating system, see here.

What pressure value is considered normal

A stable amount of atmospheres in the line helps to reduce the level of heat loss and the fact that the circulating coolant has almost the same temperature to which it was heated by the boiler.

It is necessary to talk about what pressure should be, taking into account what kind of heating system we are talking about. Options:

Pressure in the heating system of a private house. With the open heating method, the expansion tank is the communication link between the system and the atmosphere. Even with the participation of the circulation pump, the number of atmospheres in the tank will be equal to atmospheric pressure, and the pressure gauge will show 0 bar.

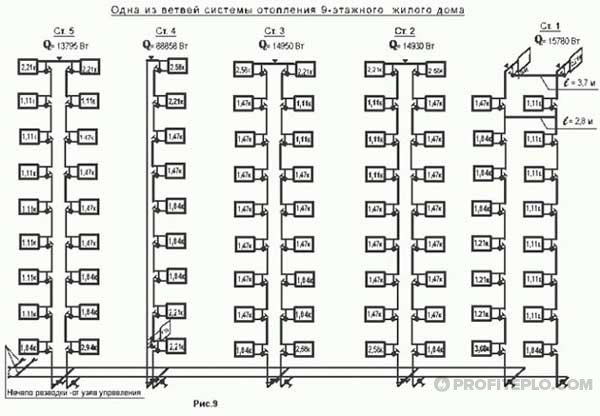

Pressure in the system of a multi-storey building. A characteristic feature of the heating device in multi-storey buildings is a high static head. The higher the height of the house, the greater the number of atmospheres: in a 9-story building - 5-7 Atm, in 12-story buildings and higher - 7-10 Atm, while the pressure in the supply line is 12 Atm. Therefore, it is necessary to have powerful pumps with a dry rotor.

Pressure in a closed heating system. The situation with a closed highway is somewhat more complicated. In this case, the static component is artificially increased to increase the efficiency of the equipment, as well as to exclude air penetration. The required pressure in the heating system of a private house is calculated by multiplying by 0.1 the difference between the highest and lowest points in meters. This is an indicator of static pressure. Adding 1.5 bar to it, we get the required value.

Thus, the pressure in the heating system in a private house with a closed circuit should be in the range of 1.5-2 atmospheres. An indicator outside the range is considered critical, and when it reaches mark 3, there is a high probability of an accident (depressurization of the line, failure of units).

Yes, a large pressure improves the operation of the equipment, but the technical characteristics of the installed boiler should be taken into account. Some models withstand 3 bar, but most are designed for 2, and in some cases 1.6 bar

It is important, when setting up the equipment, to achieve an indicator in a cold system that is 0.5 bar lower than the value stated in the passport. This will prevent the pressure relief valve from constantly tripping.

It is important to remember that it is pointless to measure the water pressure in the heating system or try to regulate it in a single apartment. The only thing that depends on the owners of the living space is the choice of batteries and the diameter of the pipes in the pipeline

For example, cast iron is not recommended, as they can only withstand 6 bar. And the use of pipes of a larger diameter will lead to a decrease in pressure in the entire heating system of the house. When moving to an apartment with old heating, it is better to immediately replace all possible elements.

Another parameter that affects the amount of pressure in any heating main is the temperature of the coolant. A certain amount of cold water is pumped into the mounted and closed circuit, which ensures a minimum pressure. After heating, the substance will expand and the number of atmospheres will increase. Therefore, by adjusting the temperature of heating water, you can control the pressure in the circuit. Today, heating equipment companies offer the use of equipment with hydraulic accumulators (expansion tank). They do not allow pressure to increase, accumulating energy within themselves. As a rule, they are included in the work when they reach the mark of 2 atmospheres.

It is important to regularly check the accumulator in order to empty it in time. It would also be useful to install a safety valve, which can be activated at a pressure of 3 atm and a filled tank in order to avoid an accident.

Open and closed heating systems filling principle

An open system is equipped with an expansion tank at its highest point. The surface of the heat-transfer fluid in it is in direct contact with atmospheric air. The closed system is equipped with a diaphragm expansion tank hermetically isolated from the atmosphere.

Heating systems of any type can be filled as follows:

- tap water supplied to the lowest point of the system - through the make-up valve;

- water (distilled) or antifreeze, supplying liquid from a container (well, reservoir):

- by pouring manually and / or by means of a pump to the upper point (a fitting for an air vent or through an open expansion tank);

- by pumping through the lowest point - make-up inlet.

Many homeowners know the simplest (and worst!) way to fill open systems is via an expansion tank. Water / antifreeze is poured in intermittently to release air. It is not recommended to repeat this method in closed systems, using the nozzles of the upper air vents. The air that initially fills the system passes upward through the layer of water being poured, dissolving in it. Air locks that prevent the flow of water through pipes and radiators will be guaranteed to you.

Then how to fill a closed heating system? The recommended way to fill any heating system is to supply liquid under pressure (from a water pipe or tank using a pump) through the bottom make-up valve.

Location of the heating system feed unit.

Closed systems

Before filling a closed heating system with water, the valve should be opened and a basin placed under it.

When starting a gas boiler, another important procedure is performed. Remove the front cover from the boiler, find a cylindrical booster circulation pump, which has a removable cover in the middle. Turn on the boiler, set the operating temperature on it. The pump starts gurgling due to the presence of air. It needs to be eliminated. To do this, slightly (not completely) unscrew the lid with a screwdriver until water starts to drip from the inside. As soon as this happens, twist it back. Wait 2-3 minutes and repeat the procedure a couple more times. When the device becomes quiet, the electric ignition will turn on. The boiler will start to supply heat in operating mode. Once again they look at the pressure in the system, and if necessary, briefly open the make-up tap.

This completes the filling of the closed heating system with water, and it remains to make its additional debugging. It lies in the fact that with the help of control valves on the radiator pipes, you can slightly tighten the heat supply to the batteries, which are located near the boiler, and increase its supply to distant radiators. Now there will be no hitch with how to properly fill the closed heating system with water, and you can do this work yourself quickly and efficiently.

Method of control and diagnostics

Manometers are used for control. These can be sensors with a digital or analog output for connecting to a microcontroller, or classic models with a dial and an arrow.

Due to the presence of dynamic pressure, the pressure generated by the pump, as well as various resistances of the wiring elements, the pressure in the circuit is not constant at various points

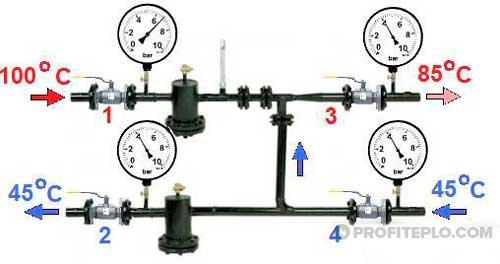

It is important to know the meanings:

- Before and after the boiler

- At the inlet and outlet of the circulation pump (each, if there are several).

- Similarly, on both sides of the coarse filter.

- in the expansion tank.

Given the serial connection of all these elements, it will take only two or three pressure gauges to get a complete picture of the state of the system.

1 - boiler; 2 - safety group with expansion tank; 3 - heating radiators; 4 - coarse filter; 5 - circulation pump; 6 - pressure gauges

The measuring range and scale of the pressure gauge must correspond to possible changes in pressure in the system, but without excessive margin, so as not to lose accuracy. Seeing, for example, the pressure drop after the coarse filter is only 0.2–0.3 bar, one can judge that it is time to clean it.

Changes in pressure in the circuit as a whole or in a separate section give a clear, unambiguous signal of a breakdown or other problem that requires an immediate solution. An accurate diagnosis can be performed by a specialist, however, based on the information specified in the instructions for the boiler or circulation pump, and the values of pressure gauges, you can independently find out the reason why the heating system is losing efficiency and the batteries have become worse to heat the room.

We fill the system from below

So, back to pumping fluid into the system. We use a container of a suitable volume (a plastic barrel with a volume of 200 liters is well suited). We lower a pump into it, which creates the pressure required for pumping liquid no higher than 1.5 atm (typical value in the range of 1-1.2 atm). Such pressure requires the creation of a pressure head of 15 m by the pump (for the submersible "Baby" it reaches 40 m).

After filling the barrel with water, we start the pump, watching the liquid level, which should be located above its inlet to prevent "airing". The level drops - add water. Antifreeze should be pumped from a container of a smaller volume (bucket) so as not to immerse the body of the submersible pump in the liquid (and then not wash it) - it is enough to immerse the inlet pipe. You will have to add antifreeze often, periodically turning off the pump.

The filling of the system is carried out with open Mayevsky taps on installed heating radiators with substituted containers for collecting water. When the liquid comes out of all the air vents, close the valves, continuing the pumping process.

We control the pressure on the pressure gauge (the boiler device is suitable). When its value exceeds the hydrostatic one, equal to the pressure in the liquid column with a height from the lower to the upper point of the system (a height of 5 m gives a static pressure of 0.5 atm), we continue to fill the system, monitoring the pressure gauge when the pressure reaches the required value.

Pumping antifreeze pump "Kid".

After filling the system, turn off the pump, open the air valves (the pressure will inevitably drop), and then pump up the water. We repeat the process several times, displacing air bubbles.

We complete the filling by inspecting the system for leaks. After the pump is turned off, the hose connected to the outlet is under pressure. If antifreeze was pumped in, first disconnect the hose from the pump inlet and drain the liquid into a container, trying not to pour over the mechanism body.