Schemes and examples

room

The simplest scheme for calculating the need for heat, depending on the area of \u200b\u200bthe room, was laid down in SNiPs half a century ago. It was supposed to allocate a thermal power of one hundred watts per square area. Let's say that 4 * 5 * 0.1 = 2 kilowatts of heat is required for a room measuring 4x5 meters.

Alas, simple calculations do not always give an accurate result.

The calculation by area neglects a number of additional parameters:

The height of the ceiling is far from always equal to the standard 2.5 meters in the 60s. In Stalinkas, three-meter ceilings are typical, and in new buildings - 2.7-2.8 meters high. Obviously, with an increase in the volume of the room, the power required to heat it will also increase;

- Insulation requirements for new buildings have changed dramatically over the past decades. According to SNiP 23-02-2003, the outer walls of residential buildings must be insulated with mineral wool or foam. Better insulation means less heat loss;

- Glazing also contributes to the thermal balance of the building. Clearly less heat will be lost through a triple-glazed window with energy-saving glass than through single-strand glazing;

Finally, in different climatic zones, heat loss will again differ. Physics, comrades: with a constant thermal conductivity of the building envelope, the heat flux through it will be directly proportional to the temperature difference on both sides of it.

That is why a somewhat complicated formula is used to obtain an accurate result: Q=V*Dt*k/860.

Variables in it (from left to right):

- Power, kWt);

- Heated volume (m3);

- Temperature difference outside and inside the house;

- warming factor.

The temperature difference is calculated as the difference between sanitary standards for residential premises (18 - 22 degrees, depending on winter temperatures and the location of the room in the center or at the end of the house) and the temperature of the coldest five days of the year.

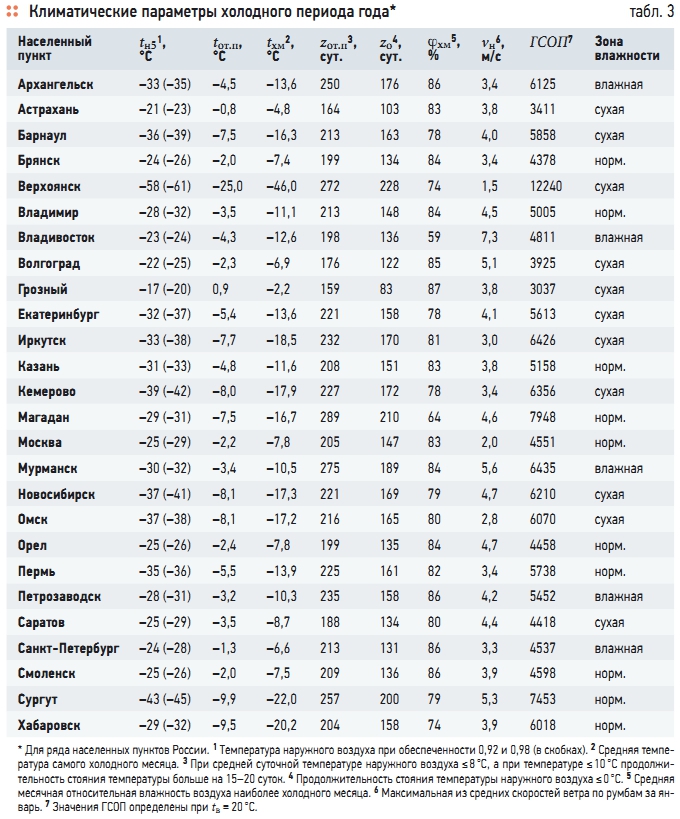

In the first column - the temperature of the coldest five-day days for some Russian cities.

The table will help you choose the coefficient of insulation:

Let's use this formula to select the heat output of a private house heating system with the following parameters:

- Foundation size - 8x8 meters;

- One floor;

- The walls have external insulation;

- Windows - triple glazing;

- Ceiling height - 2.6 meters;

- The temperature in the house is +22C;

- The temperature of the coldest winter five-day period is -15C.

So:

- We take the coefficient k equal to 0.8;

- Dt \u003d 22 - -15 \u003d 37;

- The volume of the house is 8*8*2.6=166.4 m3;

- We substitute the values in the formula: Q \u003d 166.4 * 37 * 0.8 / 860 \u003d 5.7 kilowatts.

Radiator

For all factory-made devices, the manufacturer specifies two parameters:

- thermal power;

- The thermal head at which the radiator is able to deliver this power.

In practice, a head of 70 degrees is the exception rather than the rule:

- In the central heating system, the coolant is heated to 90C only at the supply and only in the upper zone of the temperature graph (that is, at the peak of cold weather). The warmer it is outside, the colder the batteries;

- On autonomous heating, generally safe for plastic and metal-plastic pipes are 70C on the supply and 50 on the return pipeline.

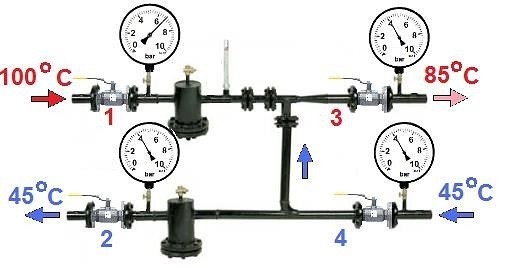

Heating system. On serving - 65 degrees.

That is why the calculation of the power of factory-made heating radiators (not only steel, but also any others) is performed according to the formula Q \u003d A * Dt * k. In it:

The beauty of the proposed calculation scheme lies precisely in the fact that these parameters do not need to be searched for. Their product (A * k) is equal to the result of dividing the power declared by the manufacturer by the thermal head at which the device will give this power.

Let's calculate heating radiators for the following conditions:

The plate radiator has a declared power of 700 watts at a thermal head of 70 degrees (90C / 20C);

- The actual air temperature in the room should be 25 degrees;

- The coolant will be heated up to 60C.

Let's get started:

- The product of the area and the heat transfer coefficient is 700/70=10;

- The real heat head under given conditions will be equal to 60-25=35 degrees;

- 10*35=350. This will be the power of the steel plates under the described conditions.

In the photo - a sectional steel radiator.

Very accurate calculation of heating radiators

Above, we gave as an example a very simple calculation of the number of heating radiators per area. It does not take into account many factors, such as the quality of the thermal insulation of the walls, the type of glazing, the minimum outside temperature, and many others. Using simplified calculations, we can make mistakes, as a result of which some rooms turn out to be cold, and some too hot. The temperature can be corrected using stopcocks, but it is best to foresee everything in advance - if only for the sake of saving materials.

If during the construction of your house you paid due attention to its insulation, then in the future you will save a lot on heating. How is the exact calculation of the number of heating radiators in a private house made? We will take into account the decreasing and increasing coefficients

Let's start with glazing. If single windows are installed in the house, we use a coefficient of 1.27. For double glazing, the coefficient does not apply (in fact, it is 1.0). If the house has triple glazing, we apply a reduction factor of 0.85

How is the exact calculation of the number of heating radiators in a private house made? We will take into account the decreasing and increasing coefficients. Let's start with glazing. If single windows are installed in the house, we use a coefficient of 1.27. For double glazing, the coefficient does not apply (in fact, it is 1.0). If the house has triple glazing, we apply a reduction factor of 0.85.

Are the walls in the house lined with two bricks or is insulation provided in their design? Then we apply the coefficient 1.0. If you provide additional thermal insulation, you can safely use a reduction factor of 0.85 - heating costs will decrease. If there is no thermal insulation, we apply a multiplying factor of 1.27.

Note that heating a home with single windows and poor thermal insulation results in large heat (and money) losses. When calculating the number of heating batteries per area, it is necessary to take into account the ratio of the area of \u200b\u200bfloors and windows

Ideally, this ratio is 30% - in this case, we use a coefficient of 1.0. If you like large windows, and the ratio is 40%, you should apply a factor of 1.1, and at a ratio of 50% you need to multiply the power by a factor of 1.2. If the ratio is 10% or 20%, we apply reduction factors of 0.8 or 0.9

When calculating the number of heating batteries per area, it is necessary to take into account the ratio of the area of \u200b\u200bfloors and windows. Ideally, this ratio is 30% - in this case, we use a coefficient of 1.0. If you like large windows, and the ratio is 40%, you should apply a factor of 1.1, and at a ratio of 50% you need to multiply the power by a factor of 1.2. If the ratio is 10% or 20%, we apply reduction factors of 0.8 or 0.9.

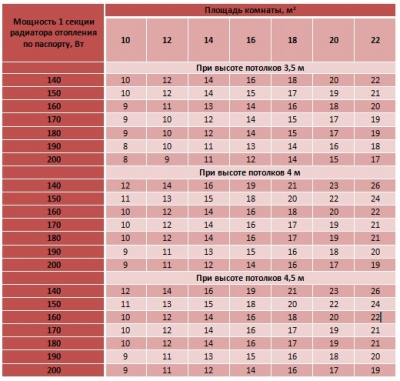

Ceiling height is an equally important parameter. Here we use the following coefficients:

Table for calculating the number of heating radiator sections depending on the area of \u200b\u200bthe room and the height of the ceilings.

Is there an attic behind the ceiling or another living room? And here we apply additional coefficients. If there is a heated attic upstairs (or with insulation), we multiply the power by 0.9, and if the dwelling is by 0.8. Is there an ordinary unheated attic behind the ceiling? We apply a coefficient of 1.0 (or simply do not take it into account).

After the ceilings, let's take up the walls - here are the coefficients:

- one outer wall - 1.1;

- two outer walls (corner room) - 1.2;

- three outer walls (the last room in an elongated house, hut) - 1.3;

- four outer walls (one-room house, outbuilding) - 1.4.

Also, the average air temperature in the coldest winter period is taken into account (the same regional coefficient):

- cold to -35 ° C - 1.5 (a very large margin that allows you not to freeze);

- frosts down to -25 ° C - 1.3 (suitable for Siberia);

- temperature up to -20 ° C - 1.1 (central Russia);

- temperature up to -15 ° C - 0.9;

- temperature down to -10 °C - 0.7.

The last two coefficients are used in hot southern regions. But even here it is customary to leave a solid supply in case of cold weather or especially for heat-loving people.

Having received the final thermal power necessary for heating the selected room, it should be divided by the heat transfer of one section. As a result, we will get the required number of sections and will be able to go to the store

Please note that these calculations assume a base heating power of 100 W per 1 sq. m

If you are afraid of making mistakes in the calculations, seek help from specialized specialists. They will perform the most accurate calculations and calculate the heat output required for heating.

Air heat exchangers

One of the most common heat exchangers today is tubular finned heat exchangers. They are also called snakes. Where they are not only installed, starting from fan coil units (from the English fan + coil, i.e. "fan" + "coil") in the indoor units of split systems and ending with giant flue gas recuperators (heat extraction from hot flue gas and transmission for heating needs) in boiler plants at CHP. That is why the calculation of a coil heat exchanger depends on the application where this heat exchanger will go into operation. Industrial air coolers (HOPs) installed in meat blast freezing chambers, low-temperature freezers and other food refrigeration facilities require certain design features in their design. The spacing between the lamellas (fins) should be as large as possible in order to increase the time of continuous operation between defrost cycles. Evaporators for data centers (data processing centers), on the contrary, are made as compact as possible, clamping the interlamellar distances to a minimum. Such heat exchangers operate in “clean zones”, surrounded by fine filters (up to HEPA class), therefore, such a calculation of a tubular heat exchanger is carried out with an emphasis on minimizing dimensions.

Plate heat exchangers

Currently, plate heat exchangers are in stable demand. According to their design, they are completely collapsible and semi-welded, copper-soldered and nickel-soldered, welded and soldered by diffusion (without solder). The thermal calculation of a plate heat exchanger is quite flexible and does not present any particular difficulty for an engineer. In the selection process, you can play with the type of plates, the depth of forging channels, the type of fins, the thickness of steel, different materials, and most importantly, numerous standard-size models of devices of different sizes. Such heat exchangers are low and wide (for steam heating of water) or high and narrow (separating heat exchangers for air conditioning systems). They are also often used for phase change media, i.e. as condensers, evaporators, desuperheaters, precondensers, etc. The thermal calculation of a two-phase heat exchanger is slightly more difficult than a liquid-liquid heat exchanger, however, for experienced engineer, this task is solvable and not particularly difficult. To facilitate such calculations, modern designers use engineering computer databases, where you can find a lot of necessary information, including state diagrams of any refrigerant in any deployment, for example, the CoolPack program.

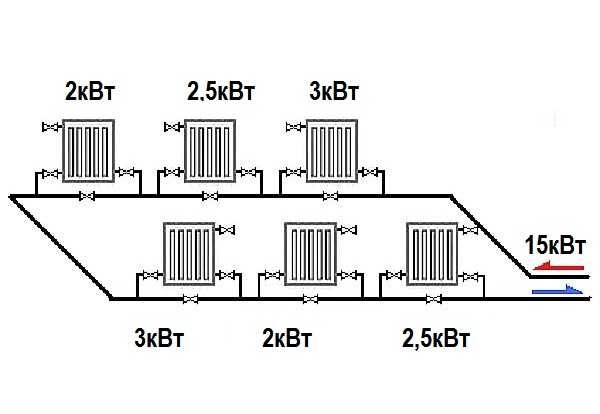

Determination of the number of radiators for one-pipe systems

There is one more very important point: all of the above is true for a two-pipe heating system. when a coolant with the same temperature enters the inlet of each of the radiators.A single-pipe system is considered much more complicated: there, colder water enters each subsequent heater. And if you want to calculate the number of radiators for a one-pipe system, you need to recalculate the temperature every time, and this is difficult and time consuming. Which exit? One of the possibilities is to determine the power of the radiators as for a two-pipe system, and then add sections in proportion to the drop in thermal power to increase the heat transfer of the battery as a whole.

In a single-pipe system, the water for each radiator is getting colder and colder.

Let's explain with an example. The diagram shows a single-pipe heating system with six radiators. The number of batteries was determined for two-pipe wiring. Now you need to make an adjustment. For the first heater, everything remains the same. The second one receives a coolant with a lower temperature. We determine the % power drop and increase the number of sections by the corresponding value. In the picture it turns out like this: 15kW-3kW = 12kW. We find the percentage: the temperature drop is 20%. Accordingly, to compensate, we increase the number of radiators: if you needed 8 pieces, it will be 20% more - 9 or 10 pieces. This is where knowledge of the room comes in handy: if it is a bedroom or a nursery, round it up, if it is a living room or other similar room, round it down

You also take into account the location relative to the cardinal points: in the north you round up, in the south - down

In single-pipe systems, you need to add sections to the radiators located further along the branch

This method is clearly not ideal: after all, it turns out that the last battery in the branch will have to be simply huge: judging by the scheme, a coolant with a specific heat capacity equal to its power is supplied to its input, and it is unrealistic to remove all 100% in practice. Therefore, when determining the power of a boiler for single-pipe systems, they usually take some margin, put shutoff valves and connect radiators through a bypass so that heat transfer can be adjusted, and thus compensate for the drop in coolant temperature. One thing follows from all this: the number and / or dimensions of radiators in a single-pipe system must be increased, and as you move away from the beginning of the branch, more and more sections should be installed.

An approximate calculation of the number of sections of heating radiators is a simple and quick matter. But clarification, depending on all the features of the premises, size, type of connection and location, requires attention and time. But you can definitely decide on the number of heaters to create a comfortable atmosphere in winter.

Pressure and other characteristics of aluminum batteries

If for some reason the boiler is turned off, be sure to drain the hot water from the radiator, otherwise the pipes may burst.

In multi-storey buildings with central heating and in individual heating systems for cottages and apartments, aluminum batteries are often used. They are designed for a pressure of 16-18 atmospheres. Aluminum radiators have a modern design, excellent thermal and strength parameters and are currently the most common.

They are made from die-cast aluminium. This manufacturing technology ensures high strength of finished products. Aluminum radiators are structures from separate sections, from which batteries of the required length are assembled. They come in 80mm and 100mm deep sizes with a standard section width of 80mm.

Aluminum has a thermal conductivity 3 times greater than that of steel or cast iron, so these batteries have a very high heat transfer rate. The high thermal power of radiators of this type is also achieved due to additional fins, which provide a large area of contact between the air and the heated surface.

Aluminum radiators are designed for pressure from 6 to 20 atmospheres.Reinforced models of aluminum batteries are also produced, designed for the CIS countries - for apartment buildings with a central heating system with more stringent operating conditions. Such batteries are made of durable high quality aluminum and have thicker walls.

Aluminum heating batteries are small and light, while they are characterized by high heat transfer. They have an attractive appearance. It is generally accepted that such batteries are optimal in conditions of autonomous heating (cottages, private houses, summer cottages, estates). However, the working pressure of aluminum radiators of 16 atmospheres allows them to be installed in apartments in multi-storey buildings.

Calculation of different types of radiators

If you are going to install sectional radiators of a standard size (with an axial distance of 50 cm in height) and have already chosen the material, model and the desired size, there should be no difficulty in calculating their number. Most of the reputable companies that supply good heating equipment have the technical data of all modifications on their website, among which there is also thermal power. If not power is indicated, but the flow rate of the coolant, then it is easy to convert to power: the coolant flow rate of 1 l / min is approximately equal to the power of 1 kW (1000 W).

The axial distance of the radiator is determined by the height between the centers of the holes for supplying/removing the coolant

To make life easier for buyers, many sites install a specially designed calculator program. Then the calculation of sections of heating radiators comes down to entering data on your room in the appropriate fields. And at the output you have the finished result: the number of sections of this model in pieces.

The axial distance is determined between the centers of the holes for the coolant

But if you are just considering possible options for now, then it is worth considering that radiators of the same size made of different materials have different thermal output. The method for calculating the number of sections of bimetallic radiators is no different from the calculation of aluminum, steel or cast iron. Only the thermal power of one section can be different.

To make it easier to calculate, there are average data that you can navigate. For one section of the radiator with an axial distance of 50 cm, the following power values are accepted:

- aluminum - 190W

- bimetallic - 185W

- cast iron - 145W.

If you are still only figuring out which material to choose, you can use these data. For clarity, we present the simplest calculation of sections of bimetallic heating radiators, which takes into account only the area of \u200b\u200bthe room.

When determining the number of bimetal heaters of a standard size (center distance 50 cm), it is assumed that one section can heat 1.8 m 2 of area. Then for a room of 16m 2 you need: 16m 2 / 1.8m 2 \u003d 8.88 pieces. Rounding up - 9 sections are needed.

Similarly, we consider for cast-iron or steel bars. All you need is the rules:

- bimetallic radiator - 1.8m 2

- aluminum - 1.9-2.0m 2

- cast iron - 1.4-1.5m 2.

This data is for sections with a center distance of 50 cm. Today, there are models on sale with very different heights: from 60cm to 20cm and even lower. Models 20cm and below are called curb. Naturally, their power differs from the specified standard, and if you plan to use "non-standard", you will have to make adjustments. Or look for passport data, or count yourself. We proceed from the fact that the heat transfer of a thermal device directly depends on its area. With a decrease in height, the area of \u200b\u200bthe device decreases, and, therefore, the power decreases proportionally. That is, you need to find the ratio of the heights of the selected radiator to the standard, and then use this coefficient to correct the result.

Calculation of cast iron radiators. It can be calculated by the area or volume of the room

For clarity, we will calculate aluminum radiators by area. The room is the same: 16m2.We consider the number of sections of a standard size: 16m 2 / 2m 2 \u003d 8pcs. But we want to use small sections with a height of 40 cm. We find the ratio of radiators of the selected size to the standard ones: 50cm/40cm=1.25. And now we adjust the quantity: 8pcs * 1.25 = 10pcs.

Pressure in the heating system of a multi-storey building

The following factors influence the actual pressure value:

- The condition and capacity of the equipment supplying the coolant.

- The diameter of the pipes through which the coolant circulates in the apartment. It happens that wanting to increase the temperature indicators, the owners themselves change their diameter upwards, reducing the overall pressure value.

- The location of a particular apartment. Ideally, this should not matter, but in reality there is a dependence on the floor, and on the distance from the riser.

- The degree of wear of the pipeline and heating devices. In the presence of old batteries and pipes, one should not expect that the pressure readings will remain normal. It is better to prevent the occurrence of emergency situations by replacing your old heating equipment.

How pressure changes with temperature

Check the working pressure in a high-rise building using tubular deformation pressure gauges. If, when designing the system, the designers laid down automatic pressure control and its control, then sensors of various types are additionally installed. In accordance with the requirements prescribed in the regulatory documents, control is carried out in the most critical areas:

- at the coolant supply from the source and at the outlet;

- before the pump, filters, pressure regulators, mud collectors and after these elements;

- at the outlet of the pipeline from the boiler room or CHP, as well as at its entry into the house.

Please note: 10% difference between standard working pressure on the 1st and 9th floor is normal

Features of the calculation of thermal loads

The calculated values of indoor air temperature and humidity and heat transfer coefficients can be found in special literature or in the technical documentation supplied by manufacturers to their products, including heat units.

The standard method for calculating the heat load of a building to ensure its efficient heating includes the consistent determination of the maximum heat flow from heating devices (heating radiators), the maximum heat energy consumption per hour (read: “Annual heat consumption for heating a country house“). It is also required to know the total consumption of thermal power over a certain period of time, for example, during the heating season.

The calculation of thermal loads, which takes into account the surface area of the devices involved in heat exchange, is used for various real estate objects. This calculation option allows you to most correctly calculate the parameters of the system, which will provide efficient heating, as well as to conduct an energy survey of houses and buildings. This is an ideal way to determine the parameters of the on-duty heat supply of an industrial facility, which implies a decrease in temperature during non-working hours.

Varieties

Consider steel panel-type radiators, which differ in size and degree of power. Devices can consist of one, two or three panels. Another important structural element is finning (corrugated metal plates). In order to obtain certain thermal output indicators, several combinations of panels and fins are used in the design of the devices. Before choosing the most suitable device for high-quality space heating, you need to familiarize yourself with each variety.

Steel panel batteries are represented by the following types:

Type 10. Here the device is equipped with only one panel. Such radiators are light in weight and have the lowest power.

Type 11. Consist of one panel and a finning plate.Batteries have slightly more weight and dimensions than the previous type, they are distinguished by increased thermal power parameters.

- Type 21. The design of the radiator has two panels, between which there is a corrugated metal plate.

- Type 22. The battery consists of two panels, as well as two fins. In size, the device is similar to type 21 radiators, however, in comparison with them, they have a greater thermal power.

Type 33. The structure consists of three panels. This class is the most powerful in terms of heat output and the largest in size. In its design, 3 finning plates are attached to three panels (hence the digital designation of the type - 33).

Each of the presented types can differ in the length of the device and its height. Based on these indicators, the thermal power of the device is formed. It is impossible to calculate this parameter on your own. However, each panel radiator model undergoes appropriate tests by the manufacturer, so all results are entered in special tables. According to them it is very convenient to choose a suitable battery for heating various types of premises.

Conclusion

As you can see, in fact, there is nothing complicated in the correct calculation and increase in the efficiency of the system of discussed systems. The main thing is not to forget that in some cases, high heat transfer from heating pipes can lead to large annual costs, so you should not get carried away with this process either ().

In the presented video in this article you will find additional information on this topic.

In fact, you are a desperate person if you decide on such an event. The heat transfer of a pipe, of course, can be calculated, and there are a great many works on the theoretical calculation of the heat transfer of various pipes.

To begin with, if you started heating the house with your own hands, then you are a stubborn and purposeful person. Accordingly, a heating project has already been drawn up, pipes have been selected: either these are metal-plastic heating pipes or steel heating pipes. Heating radiators are also already looked after in the store.

But, before acquiring all this, that is, at the design stage, it is necessary to make a conditionally relative calculation. After all, the heat transfer of heating pipes, calculated in the project, is a guarantee of warm winters for your family. You can't go wrong here.

Methods for calculating the heat transfer of heating pipes

Why is the emphasis usually placed on the calculation of heat transfer of heating pipes. The fact is that for industrial heating radiators, all these calculations have been made, and are given in the instructions for the use of products. Based on them, you can easily calculate the required number of radiators depending on the parameters of your house: volume, coolant temperature, etc.

Tables.

This is the quintessence of all the necessary parameters, collected in one place. Today, a great many tables and reference books are posted on the Web for online calculation of heat transfer from pipes. In them you will find out what is the heat transfer of a steel pipe or cast-iron pipe, the heat transfer of a polymer pipe or copper.

All that is needed when using these tables is to know the initial parameters of your pipe: material, wall thickness, internal diameter, etc. And, accordingly, enter the query "Table of heat transfer coefficients of pipes" into the search.

In the same section on determining the heat transfer of pipes, one can also include the use of manual Handbooks on the heat transfer of materials. Although they are getting harder and harder to find, all the information has migrated to the Internet.

Formulas.

The heat transfer of a steel pipe is calculated by the formula

Qtp=1.163*Stp*k*(Twater - Tair)*(1-pipe insulation efficiency),W where Stp is the surface area of the pipe, and k is the heat transfer coefficient from water to air.

The heat transfer of a metal-plastic pipe is calculated using a different formula.

Where - temperature on the inner surface of the pipeline, ° С; t

c - temperature on the outer surface of the pipeline, ° С; Q-

heat flow, W; l

— pipe length, m; t

— coolant temperature, °C; t

vz is the air temperature, °С; a n - coefficient of external heat transfer, W / m 2 K; d

n is the outer diameter of the pipe, mm; l is the coefficient of thermal conductivity, W/m K; d

v —

pipe inner diameter, mm; a vn - coefficient of internal heat transfer, W / m 2 K;

You perfectly understand that the calculation of the thermal conductivity of heating pipes is a conditionally relative value. The average parameters of certain indicators are entered into the formulas, which may and do differ from the real ones.

For example, as a result of the experiments, it was found that the heat transfer of a polypropylene pipe located horizontally is slightly lower than that of steel pipes of the same inner diameter, by 7-8%. It is internal, since polymer pipes have a slightly larger wall thickness.

Many factors affect the final figures obtained in tables and formulas, which is why the footnote "approximate heat transfer" is always made. After all, the formulas do not take into account, for example, heat losses through building envelopes made of different materials. For this, there are corresponding Tables of amendments.

However, using one of the methods for determining the heat output of heating pipes, you will have a general idea of \u200b\u200bwhat kind of pipes and radiators you need for your home.

Good luck to you, builders of your warm present and future.