Installation of pumping equipment

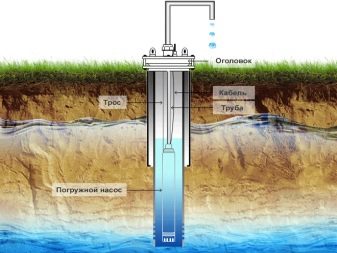

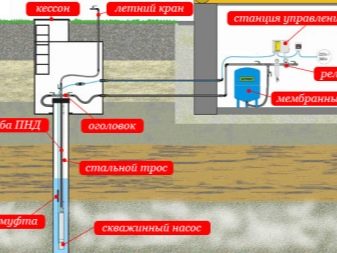

For a deep well, a deep water pump is needed. The power of the pump is calculated based on the daily water consumption of the residents and the depth of the water shaft. Installing such a pump is simple - a cable or cord is tied to the lugs on the body, the equipment is lowered into the water, but not to the very bottom, and not bringing one meter to the bottom so that silt is not captured.

The installation of a submersible pump is accompanied by the observance of some mandatory conditions, namely:

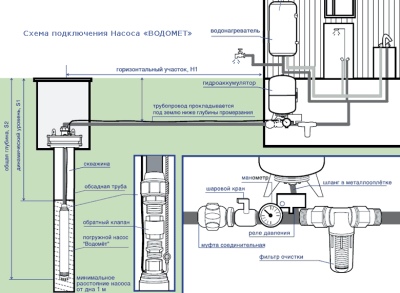

- The pump is connected with a three-core cable with a cross section of at least 2.5 mm 2, which is placed in the HDPE pipe to protect it from water. If there are connections along the length of the cable, it is better to make them not by twisting or soldering, but collapsible, and placed in a separate sealed enclosure;

- After turning on the pump, the first water intake must be drained into the ground, as it will be dirty. That is, the first time you need to pump out the well completely, but you need to direct the flow of water not to the main, but simply to the site, for example, to water the garden or vegetable garden;

- In addition, it is recommended that the first pumping be done not with the pump that will constantly work in the well, but with another, cheaper one, since dirt can quickly disable all seals and gaskets in the unit. The permanent unit is lowered into the well only when the water goes clean, without impurities;

- The pump must be equipped with a coarse filter, which is mounted on the suction. The fine filter is installed already at the outlet of the highway, before the entrance of the route to the house;

- If the pump is held on a cable, then the cable is selected from stainless steel or with a protective synthetic coating. If a cord is used, it must also be synthetic and reinforced.

After lowering the pump into the shaft, the hole of the well is covered with a head, the end of the cable or cord is attached to the head.

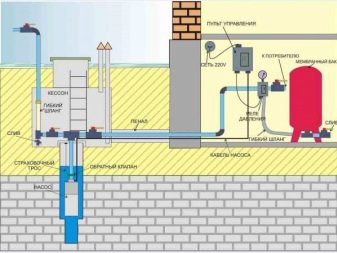

Hydraulic accumulator operation and control system

A hydraulic accumulator is a storage tank that creates pressure in the water supply system:

- The pump supplies water to the tank until it is full;

- From the battery, water goes to the house or through branches to the site;

- After a critical water withdrawal, the pump automatically turns on to fill the tank.

The maximum volume of the storage tank is from 10 liters to one ton. It all depends on the amount of water consumed by the consumer. In addition, the arrangement of the battery is also the equipment of the protection system, which is mounted last.

APCS (automatic instrument control system) turns the pump on and off depending on the mode of its operation and the water level in the accumulator, it is equipped with protection against pressure and voltage drops, from surges in the water level in the casing. All commissioning work related to the installation and testing of equipment should be carried out on an experimental pump in order to subsequently ensure the operation of the well correctly.

Finishing work:

- Staircase to enter the caisson;

- The installation of automated control systems is not in the well, but in the house. Then you will not have to go down into the pit often;

- Insertion of pressure gauges between the accumulator and the pump. Devices are recommended to be connected to the automated control system, and then their readings can be read in the house;

- Collector equipment for additional water distribution on the site and outbuildings. The collector is assembled and installed on the highway to the hydraulic accumulator;

- Instead of a caisson, you can lay out the walls of the pit with bricks, you get a warm underground room for a pumping station with support equipment. This is the most expensive, but also the most convenient solution in terms of well operation, saving space in the house, and in terms of equipment maintenance.

Well improvement options

After installation of the equipment, it is possible to effectively ennoble the well.There are a lot of answers to the question “how to ennoble the system”, it all depends on the desire and possibilities. The most accessible and frequently used means by which well improvement can be carried out include the following options:

- The caisson is equipped with a ladder for ease of use.

- The system is equipped with a control and monitoring device. It is located in the house and allows you to control processes without having to open and go down into the caisson. The control system allows you to protect the system from voltage fluctuations in the mains, from work in "idle" and overheating.

- Pressure gauges are installed between the pump and the accumulator. They can work autonomously or be connected to a control system.

- Before the accumulator, which is necessary for a comfortable stay in the house, a branch assembly with shut-off valves (tee) is mounted. They can be used to flush the system, to connect additional points for watering the garden or vegetable garden, to provide baths with water, etc.

- Instead of a caisson, a special insulated room is being built. Where all equipment and devices are located. This approach, although more expensive, allows you to provide comfortable and high-quality access to the water supply system. It is possible to order a caisson with an already fitted fastening and fixing system for all equipment, including the casing.

A source on a suburban area is primarily necessary for the uninterrupted supply of water for household needs. But the aesthetic side is also very important - in a neat, well-groomed dacha, you don’t want to see a protruding pipe entangled in hoses. Decorative design of a water well will help ennoble the structure and close it with the help of a variety of materials and elements - it all depends on your imagination.

There are a huge number of design options, we will consider some of them - both simple options and original solutions. The choice of a particular type depends on the characteristics of your site, the nature of the surrounding landscape and, of course, your personal preferences and capabilities.

Options for arranging a well for water

Before thinking about the question of how to equip a well for water, it is worth finding and preparing a convenient place, performing work on drilling and “forming” the well. Only when the well is ready, you can start planning the arrangement.

Before starting work, it is worth “sketching” the layout of all nodes, deciding on the exact models of equipment, calculating the required number of components

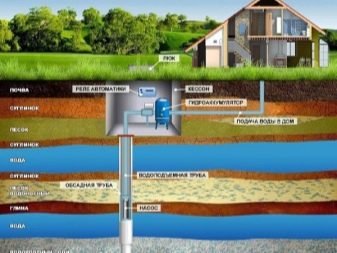

It is also important to understand how the system works effectively. The principle of operation of the well construction system:

- The pump pumps water through pipes into a pressure tank.

- The pipe system passes through the caisson, where filters and other necessary devices are installed.

- Water enters the accumulator and fills it. The pump will automatically stop pumping.

- As water is used, the tank empties. The pump constantly or in the set mode pumps water to replenish the used water.

- Water is not consumed directly, but "settles" in the tank.

Wells for water in the country can be equipped in the form of a column, that is, a kind of well with the withdrawal of water to the surface level. In this case, the caisson is not used. The head is installed on a specially prepared area around the well (concreted area). A pump is attached to it with a cable, from which a hose is pulled to the surface, a crane is equipped above the head.

With the help of additional hoses, water is "delivered" to the country house or for irrigation in barrels. It is problematic to use such a system in winter, since it is necessary to insulate the surface elements of the system.

Tips & Tricks

- If people live in the house seasonally, the equipment can also be placed inside, but in this case an underground caisson is placed.Since during the period when the house is empty, the water in the well may freeze, and the caisson will maintain a positive temperature. At the same time, inside the country house itself, it is imperative to drain the water from the system pipes.

- If the soil in the area is problematic, then it is advisable to protect the water pipe with a special casing. The electrical cable is also placed in a protective HDPE pipe. It is better to connect hydraulic equipment to the system through special valves. Collapsible connections are more convenient to maintain and replace in case of breakage.

Regardless of the type of equipment chosen, it is imperative to include a check valve in the connection diagram, which is mounted after the pump

Please note that a coarse filter is installed in front of the hydraulic accumulator tank. During the operation of the well, it is important to carefully monitor the pressure level of the pneumatic device of the membrane tank.

You need to check it every month, and if necessary, pump it up with a compressor. In conclusion, it should be noted that when arranging water wells on your own, you should understand the mining process, which is regulated by law.

- In many cases, registration of a newly created well is impossible without obtaining a license. Violation is punishable by a fine. Individuals will have to pay up to 5,000 rubles for violating this rule, and up to 100,000 rubles for legal entities.

- Without registration and obtaining a license for drilling, it is possible to extract resources from reservoirs that are not used for centralized water supply systems. If no more than 100 cubic meters are taken from the well. If water is taken for own needs and does not involve entrepreneurial activity.

In the next video, you are waiting for the arrangement of the well and the introduction of water supply into the house.

How to drill a well under water unsuitable places

In order to successfully locate a well in a summer cottage, it is necessary to exclude unsuitable places. The main thing is the presence of an aquifer. But when it is available, in some cases it is still forbidden to dig the source.

Unsuitable places:

- Nearby are places of groundwater pollution;

- It is impossible to drill a well near sewerage and sewage;

- Polluted water bodies nearby;

- Unsuitable places with underground communications;

- Areas with a large root system of trees are not suitable.

Water must meet sanitary standards. If they are violated, then it is impossible to make a well. It is also not advised to locate the source next to the neighbor's fence. Who knows what he's going to build. If there is no evidence against the work, then you can safely mount the well.

Best time to drill a well for water

It is necessary to consider in advance the optimal time for drilling a well for water. Each season has its own characteristics of carrying out these works, its advantages and disadvantages. But absolutely everyone agrees that this event cannot be held in the spring.

The reason for the impossibility of making a well in the spring:

- The level of groundwater is rising due to floods;

- It is impossible to objectively choose a place of work and determine the depth of the aquifer;

- Difficulties arise with the delivery of certain equipment.

In most climatic regions, drilling cannot be carried out from March to May. In colder climates, this time starts from April and lasts until mid-June. Even in regions with a dry climate, it is quite dangerous to carry out these works, all the same, the water level is unstable.

The time from July to September is considered the best option for drilling. At this time, it is best to determine the water level. But there are other pluses in these seasons: dry and stable soil, free access to machinery, warm and comfortable weather.

Start drilling after harvest.This is quite practical, since the technique will not damage the plants and the vegetables will not be contaminated when flushing the well. But it is worth considering that all agreements on the account of time must be made in advance.

Options for wells without a caisson

As you know, for the best protection and convenience of the location of all nodes of the system, a protective structure is arranged, which experts call the caisson. Most often, it is deepened into the ground, and only part of it is visible on the surface. If you do not have it, it is better to make a structure that will take on protective functions.

Wooden structures

Undoubtedly, the most common and popular option for a number of reasons:

- The tree is very convenient to work with - making a well with your own hands will not cause difficulties for almost anyone.

- To work, you will need a simple set of tools: a hacksaw, a hammer and nails or a screwdriver and self-tapping screws and measuring devices (tape measure, square and construction pencil). With their help, you can make almost any design.

- The price of the material is quite democratic, and for the structure you can use various trimmings and short boards left over from other works and not applicable for something else.

- Wooden structures look very attractive and fit perfectly into the natural landscape.

The work is carried out quite simply:

- First, you should prepare the base, from the point of view of practicality, the concrete option is most preferable - this way you will reliably protect and create a solid and even base for your decorative structure.

- Next, it is worth considering the design and dimensions of the future structure. Remember that it should provide normal access in case of repair of system components. If the building is large enough - one half of the roof can be a door, if the element is in the form of a well log house - there should be an opening hatch on top.

- After that, the material is marked and cut into pieces of the desired size. It is best to fasten the elements with self-tapping screws - they are more resistant to weathering and hold much better than nails.

- The finished structure must be treated several times with a protective compound for wood, this will extend its service life by at least twice. Subsequently, it is desirable to repeat the treatment once a year.

Structures made of stone and brick

Most often, such structures are an impromptu well, closed with a lid on top ().

Due to the characteristics of the material, there is a certain specificity of construction:

- Due to the large weight of the elements, it is necessary to fill the strip foundation, otherwise after a year or two the entire surface will crack due to the subsidence of the structure into the ground.

- If the structure is made of stone, it should be about the same size, so it is much easier to stack. It is best to take red brick - ceramics are resistant to moisture and will last a very long time.

- After laying the stone and drying the solution, the surface can be washed, removing dirt and coated with a special compound - so your impromptu well will look even better.

- Looks good options that combine stone with wood. For example, a stone base and a wooden top, or stone walls and a wooden roof.

Caisson installation works

The caisson is made of metal, sometimes it is made by brickwork, but the most common way of its construction is achieved by assembling it from concrete rings. The whole structure is beautifully welded and only then installed in place - you also need to carefully monitor the sealing of the concrete ring. The metal caisson is treated with a composition that protects it from corrosion - such a process must be done every year before the winter period.

A concrete caisson is made with a diameter of at least one meter - a larger diameter of the ring requires significant difficulties in installing and maintaining the well. Installation begins with digging a hole to a depth of 2 m 30 cm and a diameter of 1 m 60 cm - it must exceed the height and diameter of the ring. The pipe is placed in the center of both the ring and the hatch - by doing so, they get rid of the difficulties in further operation, which is associated with installing and lifting the pump. But, in extreme cases, you can slightly shift the ring in relation to the pipe.

The installation of the ring begins with the laying of a concrete pad around the pipe made of sand and gravel, which are carefully compacted. Next, they make a solution of cement, sand and fine gravel 1: 3: 2, respectively, for the strength of the structure, it is pre-reinforced with metal rods. The prepared structure is poured with mixed concrete, after which, you should wait for it to harden.

The inner surface of the ring must be absolutely intact - this determines the service life of the structure. And for a better bond, the ring is installed in the prepared solution. After installing the ring, the bottom coating is leveled, after which another ring is mounted on it on a mortar layer, and the joint is additionally treated with a sealing mixture.

Final work

To close the well for the winter period, a cap is used, which closes the hatch and saves the pipe from freezing. A well is built around it from bricks - 3-4 rows are laid on cement mortar. The use of a well is designed to bring the dimensions of the caisson to the diameter of the hatch and ensure the free flow of moisture from it. The gap between the rings and the pit is covered with sand, and after the masonry has hardened, holes are made in it in a circle for attaching anchor bolts.

To make the structure durable, it is poured from above with a cement solution. And, hooks are welded to the hatch and hinges for the lock are installed. Upon completion of work, a lock is inserted into the loops. A concrete screed is made around the hatch, which protects it from moisture - it is made to a depth of 30-40 cm. The brick is placed downward to ensure normal rainwater runoff away from the pit. Upon completion of such work, it can be confidently stated that the well is mothballed for the winter.

see photo

Drilling wells with blowdown

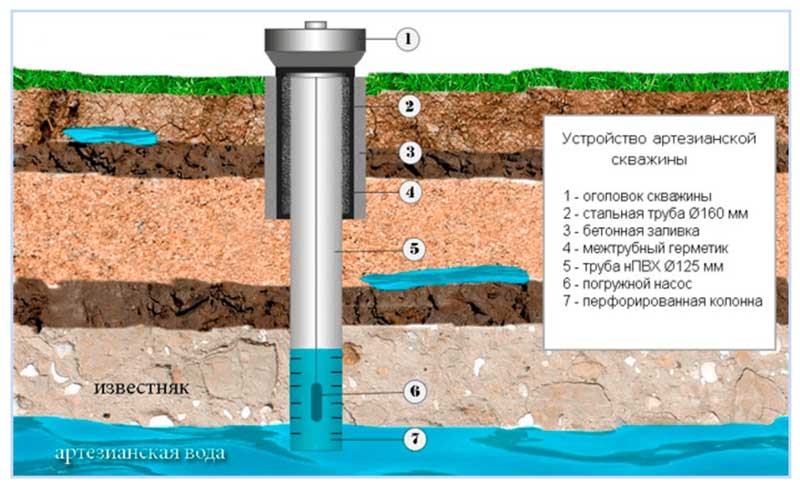

The concept of design and the main elements of the well

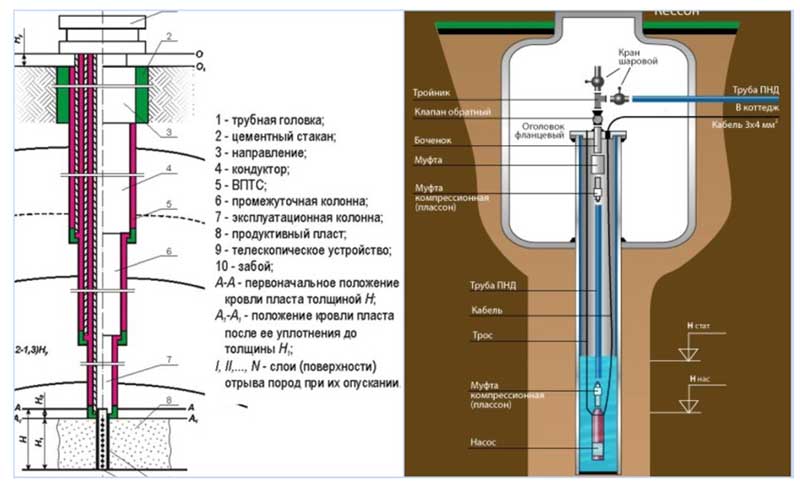

The design for a well is a set of elements of a soil excavation with a diameter in diameter much smaller than their length, which ensures a durable and reliable creation of a channel between the earth's surface and the exposed deep reservoir fluid. The main purpose of the borehole channel is geological exploration and evaluation of underground resources, study of the structure of the section, maintaining the pressure of the working layer, monitoring the exploitation of deposits, and the extraction of natural resources.

Wells are divided into the following components:

- The wellbore is a soil working in which casing and filter pipes are located.

- The mouth is the beginning of the wellbore from a pipe segment fixed on the surface of the earth.

- Bottomhole - the lower part of the borehole channel, the bottom.

- The cementing ring is a cement-sand mixture pumped into the space between the walls of the wellbore and the casing pipe, which performs the functions of sealing and strengthening the well channel.

Rice. 2 Well scheme

- Filter - the lower section of well casing pipes, immersed in the reservoir with the resource being extracted. As a filter, a part of the wellbore without casing pipes is used, on the bottom of which fine-grained gravel or a special filtering device is placed.

- Casing string - casing pipes connected together and immersed in the wellbore are needed to isolate the borehole from the earthen rock of the wellbore.Provides efficient and reliable operation of the well, preventing soil from entering the channel and protecting it from external pressure.

In the oil and gas industry, intermediate casing strings are used to separate incompatible geological zones that require different modes of drilling a well channel. In the drilling industry, the following intermediate well strings are used:

- Solid. Completely cover the entire trunk, regardless of the location of the main interval.

- Shanks. Columns intended for casing only the open hole interval with partial overlapping of the main one.

- Flyers. Special intermediate casing strings that serve only to close the defective gaps of the main string, excluding the following casing strings.

Rice. 3 Well section

Installation of equipment

The equipment must ensure the stability of the water supply. For uninterrupted supply, there are various types of pumps, and their operation requires electrical power. The simplest option for arranging a place for well equipment is a pit. The undeniable advantage of such a site is that it can be made from improvised materials.

Due to the fact that moisture can get into the pit, experts recommend this type of platform for equipment as an adapter. Methods for arranging sites with an adapter imply that the role of the caisson is played by the casing string. It is possible to apply the method if the arrangement of the casing string is made in one container and the tightness of the pipes is ensured. For such a case, pipes are usually selected from steel. Plastic is not recommended for the design of the adapter, as the pump is fixed to the water pipe, and not suspended from a cable.

Another option for a site for arranging equipment, the caisson mentioned above. This is a sealed container, which is considered reliable and durable. The container can be equipped ready-made or made by hand. Caissons are either plastic or steel. Plastic sealed, weigh a little, easy to install. Steel options are airtight, reliable, but need to be treated with anti-corrosion compounds, they have a higher price

The equipment is mounted after the site is mounted, while it is important to take into account some of the nuances

How to drill a well video

Preparatory work before drilling a well has a number of features. You will need to choose the right installation location. You can drill a source, both in the basement and outside the house

But in any case, it is important to comply with sanitary requirements

Also, special attention is paid to the working season. To find out how much the service costs in winter and summer, you can ask the company

For the improvement of any suburban economy requires water. It is needed for construction work, for landscaping the territory and just for personal needs.

But what if there is no centralized water supply system on the plot? The output will be an autonomously organized object - a well or a well. The difference between them lies in the depth of the aquifers, service life and cost. The preferred option is to install water wells.

Brief content of the article:

Peculiarities

What equipment for arranging a well for water may be required is well known to specialists of drilling companies. If it is decided to carry out these works independently, then it is worth studying the features of the arrangement of the well in more detail. The work usually includes the development of the mine and the installation of special equipment in it. For a well under water, you must:

- caisson;

- pump;

- autonomous power supply;

- cap.

The arrangement of a water well should provide:

- water purity;

- frost protection;

- conditions for connecting service equipment.

The constructed room near the well is considered more convenient, as it facilitates the installation of pumping equipment, as well as its installation. At the stage of arrangement, a water pipe is introduced into the well, and electrical power is supplied to the pump.

As additional equipment are considered:

- filters for water purification;

- manometers;

- relay for the pump;

- control automation.

Earthworks also have their own characteristics, since taking into account some of the nuances, you can significantly save on the purchase of pipes. For example, if the location for the well is chosen near the house, then not only the volume of pipes required will decrease, but also the volume of earthworks.

If we consider in more detail the features of drilling, then the methods and mechanical devices for this will be used differently. For example, it is more convenient to organize a well for personal needs with a hand drill. Farms often use special percussion devices or electric tools. You can't just pick one tool or another.

Specifically taken equipment is suitable for the characteristics of the soil. It is most laborious to carry out work with a hand drill, but under certain conditions, drilling a well up to 15 m deep can be available to the owner of a private house. Is there a need for a well of such depth, the diagram will help to figure it out.

Conclusion

In conclusion, about how to equip a well for water after drilling. Most often, ennoblement consists in planting flowers around the caisson. Also, a low-growing shrub is planted around the well or a gazebo is made directly above the caisson.

In fact, my wife and I were not going to acquire a well in the past 2009. At first they wanted to build a house and only then take up water. So everything turned out to be a matter of chance. During a January visit to the dacha, we heard a characteristic noise. It turned out that drilling work is going on at the site of the neighbors. For us, this was a surprise - we did not even imagine that this could be done in the cold. However, it turned out that winter is the best time to drill a well. There are several reasons for this.

Firstly, the drillers are not loaded and therefore provide winter discounts, and secondly, the ground freezes at this time, which means that the damage to the beds from the operation of the equipment is minimal.

After some gathering of information, we decided to use the services of the same company that worked for our neighbors. These specialists, although they were from Moscow, drilled a lot in our area and knew quite well the features of local soils.

Usually, a well of small depth (about 20 m) is mastered by drillers in one day. In our country, due to frost and some features of the soil, the work stretched for two days. Only by Sunday evening the masters left, leaving us a rusty "stump" and a head of the structure for further well construction.

Spring chores.

The first task as the soil thawed was the cleaning of the clay selected from the well. The fact is that the drillers did not warn us about the advisability of laying sheet material on the ground before starting work. We did not manage to remove the soil during the campaign, because it was thrown between the rear wheels of the car. So we removed the rest of the clay already in May.

We also failed to properly pump the well in frost: we also solved this problem in the spring. From the explanations of the drillers, I already knew that the well can only be operated with a centrifugal pump, but at the time of commissioning, it is acceptable (and even desirable) to use a vibration pump for a short time.

The fact is that the vibration pump is not so afraid of water polluted with sand and is able to effectively prepare the well for the operation of a more “gentle” centrifugal pump. After several hours of pumping, the thick milk at the outlet turned into a slightly cloudy liquid. It was possible to move on.