Solving problems with the attenuation of the boiler

If the shutdown of the flame is not caused by malfunctions of the boiler itself, but by other external reasons, you can try to fix the problems yourself. Some models of simple boilers can even be cleaned from soot and soot on their own, but this is a topic for a separate article.

Traction recovery

You can deal with what is clogged - a boiler or a chimney - by disconnecting the corrugated pipe of the exhaust system from the boiler itself. If there is a draft in the pipe, then we solve the problem with the boiler by calling the master. Otherwise, you will have to climb onto the roof and look into the pipe. If a blockage is found, it is necessary to remove those foreign fragments that interfere with the passage of smoke.

Chimney cleaning is a mandatory procedure to prevent its pollution.

If ice is found on the head, it must be carefully chipped off so as not to damage the chimney itself. Be sure to check the cleaning hatches. A sign that cleaning is needed is a large amount of soot and soot being removed from the inside of the canal.

It is still possible to reconcile with the blowing of the channel due to strong wind if this happens once or twice during the entire heating season. But if winds are a frequent occurrence in your area, you should take measures:

- First, you can try to build a pipe. High altitude will prevent the wind from pushing the air back with force.

- Secondly, a competent head configuration can help out, which will close the hole from the side where the winds predominantly blow.

If there is no electricity

A non-volatile boiler in conjunction with a circulation pump consumes not so much. It can be adapted for DC power and switched to battery operation. But for powerful boilers this is not suitable. The only way out is to connect the boiler to an alternative source of electricity, such as a gasoline or diesel generator.

If the gas pressure drops

The first step is to check the gas pipeline in the place where it departs from the main line. The joints, where there are traces of welding, as well as valves and taps, are carefully checked. The specific smell that is given to natural gas at distribution stations will help detect a leak.

The only option is to write an appeal to the appropriate authorities. Contact your neighbors - they most likely have the same problem. Drafting a collective petition will help expedite the decision-making process within the natural gas supplier organization in your area.

Why does a gas boiler often go out

If your parapet, floor or wall convector goes out quite often, you need to find out why this is happening and what needs to be done to fix the problem. One of the main reasons for this phenomenon may be the lack of oxygen. This is especially true for models of boilers that do not have an exhaust hood that enhances draft.

What else can contribute to the lack of air for the boiler:

- Clogged chimney - in this case, it must be cleaned;

- Installation of sealed plastic windows, significantly reducing the flow of fresh air into the room;

- Replacement of interior doors, as a result of which the gaps between the floor and the doors have become much smaller;

- The acquisition of a powerful hood, which takes part of the air flow to itself.

In addition to lack of air, the reason that the flame does not ignite may be a drop in gas pressure. The problem can be either on a common backbone (in this case, you just need to wait for specialists to fix it) or specifically on your network.

To find out if this is the case, you should treat all suspicious places with a sponge with soapy foam. Where there is a leak, bubbles will appear. It is better to entrust the work to eliminate such a problem to professionals.

A few more reasons why the boiler may turn off:

- Sensor malfunction - as a rule, these devices monitor the concentration of gases in the boiler and the temperature of the device. If a failure occurs, then naturally, the operation of the unit will be disrupted and it will have to be turned off for repair.

- Poor ventilation of the room - the boiler does not have enough fresh air. The easiest way to solve this problem is to open the door to the room or window. If a flame appears, then you need to think about an additional ventilation device so that the boiler does not go out all the time.

- Breakage of the meter, which does not pass gas in the right amount. This is usually expressed in the fact that the boiler is very loud, bangs and thumps. The numbers on the display do not change smoothly, but jerkily. Here you need to call only specialists. It is forbidden to do anything with the counter on your own.

The reason for the attenuation of the boiler may be related to the pipe. If it is burned out, then you will have to change it. There is no other option.

What devices use bimetal

The scope of the bimetallic plate is unusually wide. Almost all devices where temperature control is required are equipped with bimetal thermostats. This is due to the constructive simplicity and reliability of such relay systems. In our usual technique, thermostats are:

- In household heating appliances: stoves, ironing systems, boilers, electric kettles, etc.

- Heating systems: electric convectors, gas and solid fuel boilers with electronics.

- In electropackets of automatic shutdown.

- In electronics in measuring instruments, as well as in pulse generators and time relays.

- in thermal engines.

In industrial technology, bimetallic plates are installed in thermal relays designed to protect powerful electrical devices from thermal overloads: transformers, electric motors, pumps, etc.

Heating boilers Conord

Rostov plant "Conord" has a rich history and rich experience. Initially, the company was engaged in the repair of road equipment, but in the early 70s it was reoriented to the production of heating equipment.

At the same time, the name "Conord" appeared, which is an abbreviation for the words "Heating Boilers, Non-Standard Equipment, Rostov-on-Don". The newly born plant began its activity with the production of the DON-16 boiler, well-known throughout the USSR.

Heating equipment "Conord"

Today, the Conord plant is a modern enterprise, the technical equipment of which does not remind of its advanced age. Production lines are equipped with the latest high-precision laser machines, imported presses and robots, which allow you to quickly and efficiently produce reliable and affordable devices. The main part of the range is gas water heaters, as well as heating boilers - gas, solid fuel and combined.

The range of boilers is quite diverse. First of all, the products differ in the gas burner device used (for brevity, they are called automation). Three varieties are available.

Automation AGU-T-M (Russia)

- is cheap;

- does not need power supply (a bimetallic plate is used as a temperature sensor);

- does not impose special requirements on operating conditions and is inexpensive to repair (replacing a bimetallic plate - the only "weak link" - costs only 50 rubles).

This type of automation is quite common in our country and its use is not limited to the Conord trademark. You can also see it in such Russian boilers as Mimax and some others.

There is no ignition system in AGU-T-M, so the boiler has to be started with a lighter or a match.

Automation Euro SIT (Italy)

- igniter with safety device (thermocouple);

- sectional burner with Polidoro tubes;

- gas valve SIT;

- temperature sensor;

- thrust sensor.

Unlike AGU-T-M, this automation reacts not only to a gas shutdown, but also to a deterioration in draft in the chimney.

The temperature of the heat carrier is set using a thermostat and maintained automatically by a gas valve.

A piezoelectric spark gap is used to ignite the boiler.

Honeywell (USA)

An economy mode function has been added, to enter which the ignition knob must be turned all the way.

Also, the boilers "Conord" are divided into single-circuit and 2-circuit.

The former are intended for connection only to the heating system, the latter can additionally function as a flowing gas water heater.

Unlike many other boilers with two circuits, Conord does not turn off the heating while using hot water. The heat exchanger of the 2nd circuit is heated by the fire tubes. But still, the amount of heat supplied to the heating circuit decreases at this time.

Navien boilers from the largest Korean manufacturer, as a rule, work properly. But still it is a technique, and sometimes it can fail. Consider the types of malfunctions of the Navien boiler, as well as troubleshooting methods.

We will talk about the functions of an inverter for a heating boiler in this topic.

Do you know why double-circuit gas boilers are purchased more often than single-circuit ones? At this link https://microklimat.pro/otopitelnoe-oborudovanie/kotly/dvuxkonturnye-gazovye-kotly-dlya-otopleniya-chastnogo-doma.html we will consider the advantages of this type of equipment, as well as installation and selection features.

What are the models

The main types of Lemax gas boilers are:

- Floor models with steel or cast iron heat exchanger.

- Wall-mounted on solid fuel.

Solid fuel type of equipment is represented by two models:

- Wood stoves.

- Coal boilers.

Wall-mounted boilers are available only double-circuit: they are capable of operating at pressures up to 3 bar. In all cases, Italian automation and circulation pumps are used. Wall-mounted models come with a 6 liter expansion tank. This equipment is guaranteed for 2 years. Floor modifications equipped with steel heat exchangers are also in high demand. For their manufacture, high-strength metal 2 mm thick is used.

There are 5 models of steel boilers with different capacities:

- Lemax Premium.

- Premium nova.

- Gasman.

- Clever.

- Patriot.

The Premium nova model is considered the most advanced today. Thanks to automatic settings, the device can independently start the Lemax gas boiler and set the optimal operating parameters in the system. For devices of the Patriot series, the presence of a closed combustion chamber is characteristic. They are produced exclusively single-circuit, without the need for electrical power and a chimney. The presence of a cast-iron heat exchanger with a thickness of 4 mm for the Leader and Wise units extends the service life by about 2 years. They are not afraid of various pollution and corrosion effects.

Types of gas boilers

According to the type of installation, boilers are divided into wall-mounted and floor-mounted units.

Floor gas boilers are characterized by greater power, which means the ability to heat large areas of premises, long service life due to the fact that heat exchangers for such heat generators are made of steel or cast iron. For floor boilers, a separate room is required - a furnace.

Wall-mounted boilers are more compact and have less weight, which allows them to be installed on the walls of rooms.This type of heat generators is characterized by limited power, shorter service life, increased requirements for the quality of cleaning of the coolant and heated water. Gas boiler malfunctions can vary depending on the type of installation.

By design, boilers are divided into single-circuit, used only for space heating, and double-circuit, intended, in addition to heating, for heating hot water.

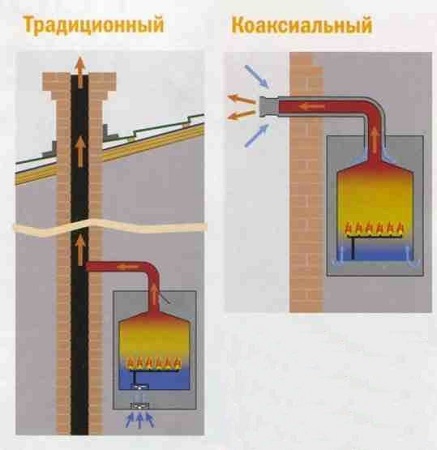

According to the type of removal of combustion products, heat generators are equipped with systems with natural or forced draft. In the first case, the units are connected to a traditional chimney, which is led to the roof of the building, and the exhaust gases are emitted due to natural draft. To ensure it, ventilation ducts are arranged according to certain rules. One of them is that the upper level of the chimney must be located at least 500 mm above the roof ridge, or at the same level with it at certain distances from the ridge. The reason why the gas boiler blows out may be that these conditions are not met. Boiler units with natural draft are equipped with open combustion chambers or atmospheric burners, while the air for the burner is taken from inside the room.

In the second case, the boilers are equipped with a coaxial chimney, which is a “pipe in pipe” design, which is led out through the wall of the room. The air necessary to support combustion enters from the outside through the outer pipe, and combustion products are removed through the inner pipe. In forced draft boilers, closed combustion chambers are installed.

And, finally, according to the method of ensuring the circulation of the coolant, boiler units are divided into volatile and non-volatile. In volatile boilers, there are circulation pumps powered by the mains and creating pressure in the heating system. In addition, volatile boilers are equipped with sophisticated automation that controls and maintains the established operating modes, including an electronic ignition system. Non-volatile heat generators do not require connection to electrical networks, and the movement of the coolant occurs due to natural pressure drops as a result of its heating. Ignition of non-volatile boilers can be done using a piezoelectric element, by pressing a button.

The gas boiler goes out what to do and how to fix

If you have a turbine boiler and the flame does not ignite in it, you should listen to how it works. If the sounds are heard stronger than usual, or vice versa, silence is the problem, most likely in the built-in fan, which will have to be repaired or bought a new one.

Usually there are 3 options when the boiler is not working:

- The device is turned off completely;

- The appliance is turned on, the display is on and the indicator is on, but the flame does not ignite;

- The flame ignites, but quickly goes out.

First you need to check whether power is supplied to the convector. The reason for its absence may lie not only in a power outage, but also in the operation of the machine on the switchboard.

If everything is in order with the voltage, you can proceed with the repair. To do this, unscrew the front panel of the boiler with a screwdriver and remove it or fold it back. Then find the fuse box and check each one. If there is a blown one, it must be replaced with the same value. If after these steps the unit works - excellent, but not - you will have to call a specialist.

When displaying any error on the convector display, you can read what it means in the technical data sheet of the device.

Some problems that cause the device to turn off can be fixed by yourself:

- A clogged sump can be cleaned by first shutting off the taps of the device;

- Fix the circulation pump by unscrewing the screw in the center of the pump and releasing air;

- Add air if the pressure in the tank is too low;

- Repair any leaks and add water to the system.

This is how you can try with your own hands to resume the operation of a gas heating boiler of various brands, for example, AOGV, Dani, Weber, Aton, AGV.

What is a bimetallic plate

An element that has the property of deforming (bending) in one direction under the influence of elevated temperature is called a bimetallic plate. By the name, you can guess that the plate contains two metals. Each of them has its own value of the coefficient of thermal expansion. As a result, when such a plate is heated, one component of it expands by a certain amount, and the second by another.

This leads to a bend, the shape of which depends on the difference in temperature coefficients. The rate of deformation is directly proportional to the change in temperature. When the plate is cooled, it acquires its original position. The plate is a monolithic connection and can work indefinitely.

Manufacturers overview

The main difference from other analogues is the affordable price and the absence of the need for electricity to work.

Keber boilers are also popular, they are equipped with an automatic security and regulation system, under which accurate gas supply and temperature stabilization are performed.

The company "Termotechnik" (Termotechnik) represents a large selection of boilers and offers units of floor, parapet types, gas and solid fuel. Many years of experience ensures excellent quality and guarantees product reliability and long service life.

Eliminating problems associated with blowing out the boiler requires special care and responsibility. It is necessary to check all components of the boiler to determine and eliminate the cause of the malfunction. If the recommendations presented did not bring results, it is worth calling the masters of the gas service. Remember that getting rid of problems quickly will prevent additional breakdowns and protect not only the entire system, but also the residents of the house.

Watch the video in which the specialist considers one of the most common reasons: why the gas boiler goes out in the wind, what needs to be done, what work should be done to improve the draft in the boiler:

Gas boilers are the most economical, easy to install and subsequently operate type of heat generators used in autonomous heating systems. However, like any engineering equipment, gas boilers can sometimes fail, and the most common type of failure is self-extinguishing of the burner. To understand why the gas boiler goes out or find out the cause of other problems, you need to know about the types of boilers and the principles of their operation.

Gas boiler Conord specifications and features

The thickness of the steel sheets used to make the furnace of the Conord boiler is 3 mm. The material has a refractory powder coating, thanks to which the life of the boiler, as the manufacturer assures, is 15 years.

The efficiency of boilers of this brand is 90%.

Such a high rate was achieved due to the installation of turbulators in the fire tubes.

Branch pipes for connection to pipelines are located on the rear panel of the heat generator.

Their diameters are 50 mm or 2 inches (heating circuit connection) and 15 mm or ½ inch (DHW).

The smallest model provides heat generation in the amount of 8 kW. The oldest representative of the line has a capacity of 30 kW. Intermediate values: 10, 12, 16, 20 and 25 kW.

The diameter of the chimney depends on the power of the appliance. For boilers with a heat capacity of up to 12 kW inclusive, it is 115 mm, for more powerful ones - 150 mm.

Heat generators of this brand have built-in expansion tanks with a volume of 8.5 liters. The maximum allowable coolant pressure is 6 atm.

An important feature of the Conord boilers is the ability to operate at a gas pressure in the pipeline of only 0.6 kPa (usually the pressure in the distribution gas pipeline is maintained at 1.3 kPa)

The boiler blows out in strong winds what to do in this case

Mechanical heating boilers can go out due to the fact that they are blown out by strong winds. Any atmospheric phenomena - rain, high humidity, low atmospheric pressure, wind can affect traction, causing its excess or lack, and also cause reverse thrust. Outcome: the boiler went out. What to do in this case?

The solution to the problem lies in the following:

- You can install a special umbrella fungus on the edge of the pipe, which will cover the chimney from unwanted effects;

- And you can increase the pipe itself, if its length is not enough.

By the way, this is not the only problem that can arise with the chimney. In addition to blowing smoke, frost may form on the pipe. The reason for this phenomenon is condensation.

The fact is that moisture tends to accumulate and freeze over time, and then become so thick that it simply blocks the access of oxygen and the flame dies out, and the boiler turns off.

However, it happens that it is very difficult to knock down ice growths and then you have to defrost them. You can purchase a disposable burner with a small canister. To melt the ice, you need to light the burner and stick it into the cleaning hatch. When the pipe warms up, the boiler can be put into operation.

Bimetal boiler plate

Heating systems on natural gas are devices of increased danger, therefore, they include various sensors for monitoring the condition. So, the main element of safety is a thrust sensor. It determines the correct direction of the exit of combustion products, that is, from the combustion chamber towards the chimney. This prevents carbon monoxide from entering the room and poisoning people.

The main component of the draft sensor is a bimetallic plate for a gas boiler. Its principle of operation is similar to that of any bimetal, and the dimensions and parameters of the material are calculated in such a way that exceeding the temperature of 75 degrees in the channel leads to deformation of the plate and actuation of the gas valve.

Conclusion

Considering the options for a heating boiler for your home, it is recommended to pay special attention to Lemax equipment. The products of this domestic manufacturer are presented in a fairly wide range of various modifications that can satisfy any customer needs.

Existing models are distinguished by good power and high performance. Many of them have automatic equipment that ensures the safety of the procedure, how to connect the Lemax boiler.

From this article you will learn what problems can arise in the automation of gas boilers, why it is not possible to ignite the igniter, because of which the boiler can turn off for no reason, and most importantly, we will figure out what actions need to be taken to diagnose and eliminate this malfunction.

The owners of non-volatile gas boilers are probably familiar with the situation when, for some reason, it is not possible to ignite the boiler, or a lot of time is spent on ignition. In this case, the problem lies in the automation of the boiler.

Today, in domestic and imported gas equipment, the EUROSIT 630 gas valve is most often used. It is he who performs the functions of maintaining the set temperature of the coolant and, in the event of an emergency, completely shuts off the gas supply to the burners. Further start-up of boilers with such automation is possible only manually. However, not always the reason for the emergency shutdown of the boiler is a real accident.

Let's try to understand this using the example of the Zhytomyr-3 boiler. Of the automation, it provides protection against the loss of the flame on the igniter and violation of traction.

Note:

All gas hazardous work must be carried out exclusively by representatives of specialized organizations that have the appropriate permits. Therefore, this article is provided for informational purposes only. Also, this article will help to control the work of the master and, possibly, save you from the need to purchase unnecessary spare parts.

Let's decide what we will call the ignition of the igniter. The EUROSIT 630 valve control knob allows you to switch the boiler to three main modes:

- disabled;

- ignition;

- temperature adjustment (1-7).

To ignite the pilot burner (igniter), it is necessary to turn the control knob to the “ignition” (spark) position, press it and use the piezo ignition button to ignite the pilot burner. Next, the handle is held for a few seconds (no more than 30) and released. The igniter should continue to burn. This is what we will call the ignition of the igniter. If the igniter goes out, you need to repeat the procedure a few more times. If this does not help, you need to look for a malfunction.

At the moment of ignition of the igniter, the flame heats up the thermocouple, which in turn generates EMF (approximately 25 mV for serviceable SIT thermocouples), which flows through the circuit of the automation sensor (sensors) to the solenoid valve.

By pressing the handle of the gas valve, we manually open the solenoid valve, supplying gas to the igniter, which, in the event of correct operation of the equipment, is held by the EMF generated by the thermocouple and remains in the open position after releasing the handle. The thermocouple itself performs the function of protection against loss of flame on the igniter. The sensors in the circuit are normally closed and, when triggered, open their contacts, ensuring a complete shutdown of the boiler.