Air heating boilers

Boilers for air heating - a type of heating equipment

A rather significant niche in the Russian market is occupied by air heating boilers. This is not a new, but quite effective way to heat any room (private house, garage, greenhouse, cafe, construction site, etc.).

Air boilers for heating systems

Unlike standard systems (where hot water or steam acts as a heat carrier), these devices use ordinary air. This greatly simplifies the design of the system, and also reduces the required number of additional components (batteries, radiators, pipes, etc.).

These devices work according to the following principle:

In the air heating boiler, the heat exchanger is heated;

Further, the air enters this heat exchanger through special filters;

After heating, the purified air, with the help of forced draft fans, is transported through air channels;

This is a cyclic process in which fresh air is also supplied with previously heated air.

Consider the advantages and disadvantages of these systems:

Advantages:-

Due to the presence of ventilation air ducts, in the summer season they can be used as cooling systems (when an air conditioning system is connected to them);

Lack of a water circuit (at low temperatures, the system does not freeze);

Saving gas (since the whole beneficial effect goes to warming up the air, and not radiators and batteries);

Possibility to install outdoors (Roof-top);

Ventilation and air humidification functions.

Flaws:-

Poor efficiency at very low temperatures (because the air cools very quickly and the system does not cope with the task);

Rapid cooling of the system (due to the properties of air);

Now think about whether to install an air heating boiler. although everyone decides for himself what is best for him.

- Aesthetic potential (by choosing air heating, you can design your house in almost any style, without having to think about where to hide the batteries or the convector). You can make the most of the overall look of the room.

- Relatively low cost (for a middle-income family, this is the best option for a heating system that will pay off in the shortest possible time).

- Sufficiently high efficiency (up to 90%) with the complete absence of intermediate carriers and low energy consumption.

- Easy to operate (the system is fully automated.

- High heating rate (no more than 20-40 minutes after starting the house is completely heated, which is especially in demand in winter)

- Durability (with proper installation and proper design, the air heating of a private house can last about 20 years, but if it is repaired in a timely manner, regularly inspected and used carefully, it can be much more).

- User safety (working equipment is blocked by the system at the slightest sign of danger).

But along with the obvious advantages, these systems also have their drawbacks, which must certainly be taken into account, especially for those who plan to install air heating at home with their own hands.

- It is possible to mount such a system only at the stage of building a house, in addition, it is necessary to work out this issue even in the design process.

- This type of heating system will require periodic maintenance.

- The system cannot be upgraded.

- Constant need for electricity (it is desirable to put a backup power supply).

The principle of operation of air boilers

Heating of residential, industrial or public premises is carried out with warm air heated by an air heater. The heater is connected to a system of air ducts that are routed to each room of the building. Low-temperature (160 degrees and less) gaseous products of combustion are brought out.

The use of an air heater allows not only to quickly warm up the room, but also to do it throughout the entire volume of the room, that is, evenly. After cooling down, the air returns to the heat generator via the return air ducts. Thus, the principle of operation of the system is based on the recirculation of air masses, to which fresh outdoor air is mixed.

To maintain the desired temperature in the premises, a thermostat (thermostat) is used. A special additional electronic unit allows you to very finely tune any climatic parameters of the air. The main electronic unit (processor) is used to control the air heater. It monitors the following parameters:

- The presence and pressure of gas in the system;

- Status of security elements;

- Power options.

In addition, the processor is busy controlling the humidifier, air conditioner, electronic filter and other equipment. All of the listed functions, if desired by the user, can be modularly added to the basic heating system.

Design features

Gas-generating stoves can be installed in residential premises.

Gas-generating furnaces of long burning - this will heat a solid fuel boiler with the same principle of operation. However, the former are distinguished by a simple design, which vaguely resembles potbelly stoves. At the same time, unlike a potbelly stove, the operation of the furnace is easy to control. The pyrolysis process is the basis of any gas-generating heating equipment.

In this case, we are talking about the release of gas from the fuel with a large percentage of heat capacity. When it is burned, several times more thermal energy is released, compared to conventional combustion of firewood. As a result, with one laying of wood, relying on the effect of pyrolysis, it is possible to heat a much larger area of the room. The release of gas from the energy carrier occurs in a special chamber at high temperature and under conditions of insufficient oxygen. The resulting fuel was previously discharged together with the combustion products to the outside. Now it enters the upper chamber of the equipment, where its oxidation ends with the subsequent release of a large amount of heat.

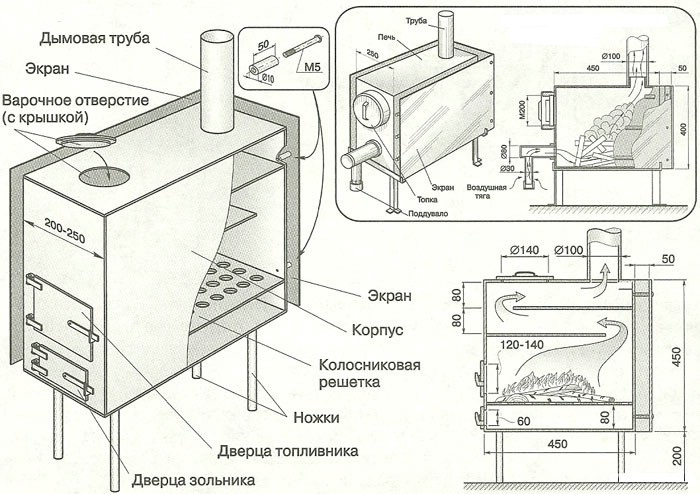

Air heating furnaces of long burning have the following schematic structure:

- housing made of thick steel or cast iron;

- convection shirt;

- combustion or primary chamber;

- secondary chamber or gas afterburner;

- ash pan;

- chimney;

- draft regulator;

- branch pipe for supplying secondary air.

Long-burning air-heating stoves can change their appearance and structure depending on the configuration and model. However, they all have a similar principle of operation. So, in the beginning there is a bookmark of the energy carrier. It can be ordinary firewood, pellets, seed husk, straw and other solid organic products. They also read about fuels for long-burning stoves.

Coal and coke are not suitable for long-burning steel furnaces. As a result of their combustion, the temperature of the heating equipment rises to a critical limit. This could lead to an accident.

Further, in the primary chamber, the usual combustion reaction occurs with a sufficient amount of oxygen. Then the equipment goes into long burning mode, that is, the temperature in the chamber drops. There is no full supply of oxygen. As a result, the firewood stops burning, but simply smolders. Of them

The gas-generating furnace can be installed anywhere, the main thing is that there is a chimney.

gas is released. It enters the secondary chamber. Secondary, heated air is also supplied there. The gas ignites, releasing a large amount of heat.

Economical long-burning stoves heat the room as follows:

- infrared radiation from a hot body;

- warm air currents that pass through the convection shirt;

- distribution of thermal air to adjacent rooms through air ducts connected to the stove.

Today on sale you can find equipment that can serve the DHW circuit and allows you to cook food. In the first case, the device is additionally equipped with a heat exchanger, in the second - with a frying surface.

Advantages and disadvantages of equipment

Economical long-burning stoves are marked by special attention of consumers due to a number of positive characteristics:

- The efficiency of the device can reach 80-85%;

- one bookmark of firewood burns for 8-10 hours;

- it is possible to purchase completely non-volatile models;

- modern appliances are equipped with a combustion control function;

- multifunctionality;

- durability;

- ease of use;

- affordable cost;

- depending on the power, it is possible to heat a room with an area of 40 square meters - 500 square meters.

There are also disadvantages:

- you can use fuel only with a low percentage of moisture content, up to 20%;

- formation of condensate;

- non-compliance with the rules for operating the equipment leads to the formation of soot accumulations on the chimney, which makes it difficult to clean;

- regular cleaning of the chimney;

- condensation on the floor.

If you strictly follow the rules for operating the equipment prescribed in the instructions, the use of furnaces will not create much trouble.

How much time and money do you need to spend to make solid fuel heating boilers with your own hands at home?

What accessories are needed to install a solid fuel boiler for water heating? The answers are here.

Oven-heater Miracle

Such a heating device for a long time qualitatively heats rooms for any purpose, while little fuel material is spent.

Device

This device is an all-welded steel construction. The transshipment sheet divides the combustion chamber into two compartments. At the top are the injectors and the injector. At the bottom - smoldering fuel.

The heater is covered with a special casing made of steel: it reduces the heating temperature of the walls of the device and allows the heat to escape evenly. Thanks to this element, it is impossible to burn yourself on the stove.

Principle of operation

The process of gas generation is the smoldering of fuel with minimal access to oxygen. Re-burning of gas occurs with the help of special nozzles.

Such a device can be heated with firewood, garbage, dry manure, peat. One bookmark of fuel material provides the structure with continuous operation for 6-8 hours.

Application area

Furnace-heater "Miracle" can be used for heating cottages, large cottages, industrial buildings, outbuildings, garages, greenhouses.

Advantages

Such a heating device starts heating immediately after kindling. Warmth will come to the house in about 20-30 minutes. In addition, its advantages include independence from gas, oil, electricity, uniform heating of the entire room, work with any type of fuel (with the exception of coal), high efficiency.

The Chudo oven is an economical and easy-to-use device that does not require special maintenance and care. The combustion process can be controlled. Installation of such equipment will be inexpensive. It can cook food and heat water.

Principle of operation

Gas air boilers work according to the following principle:

- First of all, the boiler heat exchanger is heated;

- Then the cold air from the room enters the heat exchanger, passing through special filters;

- The purified heated air is blown into the air ducts by means of forced-action fans.

The heating process is cyclical. It involves not only cold, but also previously heated air masses.

Evacuation of fuel combustion products is carried out through the chimney. Exhaust gases do not come into contact with the room air. The chimney, as a rule, is led out through the roof of the building. But for a number of high-performance modern models, the chimney is placed horizontally, for which a hole is punched in the wall of the house.

With the air heating method, inexpensive plastic chimney pipes can be used. This is due to the fact that in modern high-efficiency models of units with an efficiency of 95%, the temperature of the fuel combustion products at the outlet of the boiler is approximately 40°C.

These models include Goodman gas boilers manufactured in the USA of the GMS / GDS and GMP series.

Other materials of the section:

Description of the operation of gas boilers that do not depend on the supply of electrical energy.

Air type heating is one of the types of heating systems in buildings. Their main element is air heating boilers. and the coolant is air. Such systems can be used both in public institutions and for heating private housing, the area of \u200b\u200bwhich is 100 square meters or more. The most remarkable thing is that the air heating system can be installed both at the construction stage and in an already erected facility.

Disadvantages of long burning stoves

The disadvantages of such furnaces include:

The need for a metal, necessarily carefully insulated chimney

This requirement is usually kept silent by hardware vendors. Meanwhile, it is very important, since operation without observing this condition is simply impossible. Previously, it was said about the incomplete burnout of flue gases in the gas generation mode. Getting into a cold pipe, they instantly form soot and condensate, similar to tar, smelling bad and flowing down the pipe walls.

- This publication is devoted to the use of fireplace stoves with a water circuit.

- An overview of the Bavaria fireplace stoves is waiting for you at this link.

If a collecting pipe is used, then the upper assembly part must be inserted into the lower one, and not vice versa. The pipe must be at least 1.5 meters above the roof ridge, since this combustion mode produces a large amount of soot that pollutes the roof.

The need for such a pipe, taking into account ceiling grooves, passage through the roof, an umbrella, etc., often more than doubles the cost of the furnace itself.

This will have to be done at least once every 3 months with the constant operation of the furnace. Signs of the need for cleaning are smoke coming out when the firebox is opened, the absence of a rumble when the stove is ignited, and increased consumption of firewood. That is why it is better to make the chimney collapsible - this will greatly facilitate its cleaning of tar and soot.

Use only in rooms with temporary stay of people

In Soviet times, regulatory documents regulated the surface area of stoves with a temperature of 120 degrees (it was forbidden to operate stoves with 5% or more of such an area in residential premises). Since then, no one has canceled this norm, but it is not customary to mention it among manufacturers of furnace equipment. Such stoves should not be installed in bedrooms and areas where children stay for a long time.

Incomplete combustion of fuel has a harmful effect on the environment

Chimney smoke in damp windless weather descends, enveloping nearby houses. And to heat a gas-generating furnace, unlike a brick one, you have to constantly.

The choice of a stove for a summer residence or a country house should be approached individually, taking into account the characteristics of housing, the time spent in it, the availability of a sufficient amount of fuel and other factors. If possible, the classic brick oven, time-tested, remains the preferred option. The long-burning furnace can be considered as an auxiliary one. As the main one, it should be used only when there is a recurring need for heating a home.

Design of gas generating furnaces

The gas-generating furnace is a separate direction in the heating equipment industry. The principle of its operation is as follows: solid fuel burns with a small amount of oxygen, under the influence of low temperature values, pyrolysis gas is produced. This substance mainly consists of methane and carbon monoxide, has a high heat transfer coefficient, which contributes to a multiple increase in the efficiency of such equipment. Fuel in such a design burns out almost completely. Heat is transferred through heat exchangers to the fluid in the system.

Gas-generating furnaces of various types are offered by many manufacturers of heating equipment. You can also make them yourself.