Download sample document

Annex 5 to Guidelines for the technical examination of pipelines of heat networks of public heat supply systems

ACT

TO HYDRAULIC TESTING THE HEAT NETWORK PIPELINE

AT TECHNICAL SURVEY

(recommended shape)

________________ "__" ____________

An object ___________________________________________________________

We, the undersigned ____________________________________________

(name of organization (enterprise)

__________________________________________________________________

position, full name)

drew up this act in that in the area from cell N ________

to chamber N ______________ of the route ________________________________

(pipeline name)

a hydraulic test of the pipeline was carried out

pressure _____________ MPa (kgf / sq. cm) for _______ min. With

subsequent inspection at a pressure of __________ MPa (kgf / sq. cm).

At the same time, ________________________________________________ was found

__________________________________________________________________

The pipeline was made according to the project __________________________________

Drawings N ________________________________________________________

Conclusion _______________________________________________________

__________________________________________________________________

__________________________________________________________________

The person who performed the technical

testimonial (person)

responsible for correct

condition and safe

pipeline operation);

body representative

State supervision;

third party representative

___________________________________

(full name, position)

organization representative,

operating heating networks

___________________________________

(full name, position)

You found what you were looking for?

* By clicking on one of these buttons, you help to form a document usefulness rating. Thank you!

Related Documents

- Act: samples (Full list of documents)

- Search for the phrase "Act" throughout the site

- "Act for hydraulic testing of the pipeline of the heating network during technical examination (recommended form)".doc

Documents you may also be interested in:

- Act on documents, valuables and money found at the scene of an aviation accident. Form No. 5

- Aircraft delay act

- An act for cleaning up a collar (trenches, vegetable stores). Specialized form N 14-OT

- Act to change the quality of products. Specialized intradepartmental form N LP-7

- An act for the withdrawal of units and parts containing precious metals from medical and other equipment. Form N 42-MT

- Act for the exclusion of the universal container from the inventory owned by the railway administration

- Act on geodetic, topographic and cartographic objects and works executed, accepted by the technical control department and handed over to the Fund by the enterprise

- An act on personal belongings, valuables, documents and awards of a deceased (deceased) soldier of the civil defense troops

- Act on personal belongings, valuables, documents and awards of the deceased (deceased) soldier

- Act on personal belongings, valuables, documents and state (departmental) awards of the deceased (deceased) serviceman, citizen called up for military training

Important nuances of testing

In this case, the checks themselves can be carried out in one of two ways:

- manometric;

- hydrostatic.

The first method of testing involves the use of pressure gauges that record and demonstrate the pressure in the system.

Note:

with the help of pressure gauges, the magnitude of the excess pressure is determined, which allows us to conclude that the test is reliable. The second method checks the actual readiness of the system for operation by checking the performance at a pressure 50% higher than the standard

Any test lasts at least 10 minutes, the allowable pressure drop during pressure testing is not more than 0.02 MPa

The second method checks the actual readiness of the system for operation by checking the performance at a pressure 50% higher than the standard. Any test lasts at least 10 minutes, the permissible pressure drop during pressure testing is not more than 0.02 MPa.

Good to know:

the main document evidencing the conduct of tests is the relevant act.

Act of hydraulic testing of heat consumption systems

Hydraulic testing is a type of non-destructive testing of the strength/density of equipment. It is carried out by creating excess pressure with water.

Download a blank form of the act of "Hydraulic check" (ITP, CO, pipe coil)

The frequency of hydraulic checks for heating installations and heat mains is 1 year.

In hydraulics, the following tests are subject to heat energy consumers:

- heating networks

- heat points

- heating systems

- heating networks of heaters and heaters themselves

- DHW/heat supply heat exchangers

Hydraulic checks of heat mains

According to paragraph 14.4 of the TCP 458-2012 “Hydraulic checks of heat mains are carried out with a pressure of 1.25 working pressure, but not less than 0.2 MPa. Lines of pipes are kept under test pressure for at least 10 minutes. After reducing the pressure to the working one, a careful inspection of the pipelines along their entire length is carried out. The results of the tests are considered satisfactory if during their performance there was no pressure drop and no signs of leakage or sweating in the welds and most of the metal, noticeable permanent deformations, cracks or signs of rupture. For hydraulic testing, water with a temperature not lower than +5C and not higher than +40C should be used. Hydraulic checks of pipelines must be carried out at positive air temperature outside"

In cases where the facility is heated from the heat mains of RUE "Minskenergo" or UE "Minskkommunteploseti", the acts are provided by the organizations listed above.

Look carefully at filling out the act, the characteristics of the heat mains (length, diameter, connection point) specified in the act of hydraulic tests must correspond to the networks on the balance of the consumer in accordance with the act of separation of the balance belonging of heat networks

An example of a completed act of a hydraulic check of a heating network:

Hydraulic checks of internal heat consumption systems

Clause 20.10 of TKP 458-2012 says that every year at the beginning of the heating period in hydraulics, elevator units, heaters, heat exchangers are tested for a pressure of 1.25 working pressure, but not lower than 1 MPa (10 ata). Under the elevator unit, the authors most quickly know the entire thermal unit, due to this, in connection with the established practice, 1 MPa (10 atm) is taken as the pressure for which the thermal unit is tested.

Heat exchangers, whether these are hot water or heat supply systems, must be pressure tested with the pressure indicated in the passport, but not lower than 1 MPa. Very often they are tested for 12.5 ata or 16 ata.

The heating system is tested for a pressure of 1.25 working pressure, however, not lower than 0.6 MPa (6 atm) for heating systems with cast-iron design radiators. heating systems from panel and convector heat supply are tested at 1 MPa (10 ata).

Successful checks are recognized during which within 10 minutes there was no pressure drop (more precisely, in clause 20.13 of the TCP 458-2012) in the systems under test.

The need for pre-flushing of the pipeline

Before carrying out all events, the heating networks of the house are disconnected from the heating main and the coolant is drained. If the heating circuit has been in operation for some time, it must be flushed before pressure testing.

Flushing can be done in several ways. Its purpose is to clean pipes from scale, salt deposits and rust.The appearance of various deposits on the inner diameter of the pipeline prevents the normal circulation of the coolant, increases the hydraulic resistance in the system and reduces the heat transfer of heating radiators.

Due to various deposits and deposits, the diameter of the pipeline decreases, which contributes to an increase in the load on pumping equipment and heating boilers. All this contributes to the excessive consumption of energy and adversely affects the efficiency of the heating system at home.

That is why pipes are regularly flushed. Otherwise, this will affect the comfort of staying in the premises of the house and the cost of heating, for which residents pay. Even in a single room, the batteries can warm up unevenly, so the room will be noticeably colder.

Another reason why pipe flushing is so necessary is that deposits containing sulfur, magnesium, zinc, potassium and copper destroy and thin the metal walls of pipelines over time. As a result, they become vulnerable to increased coolant pressure in the circuit.

To flush the line, use a manual or electric compressor. If flushing is performed for preventive purposes, then the frequency of such a procedure is once every 4-6 years.

Washing methods

There are several ways to flush. Each of them uses different equipment:

-

Air impact method

is to use the so-called "shock wave". It causes delamination of plaque from the inner surface of the pipes. After the air hammer, a normal flush with water is performed to remove loose deposits. -

Hydrochemical washing

performed using special chemical compounds that dissolve salt deposits. However, it is not used as an independent method, because it does not allow to remove silt deposits in the lower sections of the contour. As a rule, hydrochemical washing is used in combination with other measures. -

Pneumohydraulic flushing technique

also called bubbling. During the procedure, a complex effect on deposits is carried out. To do this, compressed air and water are simultaneously supplied to the system under pressure. The technique is very effective, because it allows you to clean the pipes from any deposits. -

Complex flushing is considered the most effective,

during which several of the methods listed above are used at once. It is usually used in pipelines of small diameter and with severe pollution.

In what cases is

The act is required for:

- Commissioning of new equipment. The act will confirm that each element is in its place, the installation was carried out responsibly, the system is working.

- The onset of the heating season. After a summer break in operation, the pipes could fail. After checking their throughput, an act is drawn up.

- Repairs already carried out.

- The occurrence of stopped emergency situations on the pipeline. Specialists thus reveal the amount of necessary work, the weaknesses of the existing heating network.

For the uninterrupted operation of the heating system, control preventive checks are necessary, reliable information about the quality functioning of the system at startup.

The essence and types of crimping

Now heating is most often carried out by a "water circuit" system. At the same time, heated water circulates through the works, imparting its thermal energy to the premises. Leaks are unacceptable, the pipeline must be completely sealed for normal operation. Crimping, on the other hand, specifically creates a volume in the pipe that is larger than normal.

When this is done with the help of air, it is called pneumatic pressing.

When using water, then hydropressing. The latter method is considered safer and therefore more popular.For this reason, an example of hydropressure is given as a blank.

When testing, it is recommended not to exceed the pressure inside the pipe by more than 15 MPa. When it comes to raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the usual working pressure by more than 30%.

In multi-storey buildings, they resort to pneumatic pressure testing if the pipes are very old and there is a possibility of flooding. But then there is a level of risk and all residents should be notified of the tests being carried out.

The work process is simple, but multi-stage. The algorithm looks like this:

- The necessary materials and equipment are being prepared.

- Draining the liquid that was in the heating system earlier.

- Uploading a new one.

- Creating the highest possible test pressure.

- Removal of control measurements in 10 minutes.

- Flushing, adjustment of the heating system to normal pressure inside.

- Documentation of the work performed, the formation of reports and acts.

But the list of procedures looks like this only if there are no “thin places” in the heating system and, accordingly, the tightness in it is not broken. If the pressure drops quickly, does not hold, then the system needs to be repaired. In such a situation, the specialist performs the necessary actions (replacing the pipe, sealing the joints, cleaning, etc.), and then starts the pressure test from the very beginning. Only a heating system that has passed the test is admitted to the heating season.

An important nuance! Pressure testing should be carried out after cleaning and flushing the pipes. Otherwise, salt and other deposits inside them can mask possible external damage and breakthroughs.

If there are deposits of the order of 1 cm on the inner surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the general indicators. To document the cleaning, a special act is also drawn up.

Crimping act

Crimping can only be carried out by authorized licensed organizations that service the heating systems of a residential building. In apartment buildings, these activities are carried out by a service office. Upon completion of the tests, an appropriate document is issued. The form of the act on pressure testing of the heating system is given below.

The document must contain the following mandatory items:

- The name of the system or section, as well as its extent.

- Control and testing devices and tools with which the tests were carried out.

- Duration of crimping and pressure generated.

- The values on the devices that were obtained during the events.

- The act is signed by the customer, the foreman who carried out the pressure testing, the work inspector. Be sure to indicate the certificate of the specialist who is responsible for conducting the tests.

The public service is responsible for carrying out work in an apartment building. When conducting hydrotesting in a private house, the owner of the house is considered the responsible person.

Crimping price

The total cost of the work is calculated in the final estimate, which indicates all the activities and tests carried out. It is impossible to specify the exact amount, since a lot depends on the type of wiring, the state of the system and other parameters.

When calculating the final cost of work, the following is taken into account:

- The volume of work carried out, which depends on the dimensions of the house, the branching of the network.

- Condition of the heating system. It is cheaper to test on a new system or networks that have been serviced not so long ago. If you have to deal with old networks that have not undergone preventive maintenance for a long time, then the price will be higher.

- Take into account the number of flaws and damage, as well as the complexity of repair and restoration work.

If, after hydrotesting, leaks and parts that need repair or replacement were detected, then repair operations are carried out by a qualified specialist.The cost of these works is also included in the overall estimate. After repair and restoration measures, a repeated pressure test is carried out. All work done is included in the total cost of testing activities.

Purpose of testing

Tests must be carried out after the creation of a new network or after a major overhaul, maintenance work and reconstruction of an existing one, and also before the start of the heating season.

After that, a new test is performed, and this happens until the results corresponding to the norm are obtained. Actually, there are two stages of testing: preliminary and final.

Note:

pressure testing is carried out to check the tightness and integrity, as well as to detect possible defects in any section of the water supply system, including boilers.

Such checks are the most popular process for pressure testing heating systems. This happens by simulating a water hammer, when a pressure is pumped in the system that exceeds the norm by several times.

Specialist's note:

all marriage and defects found at the time of the pressure test must be eliminated immediately and without delay.

Important nuances of testing

In this case, the checks themselves can be carried out in one of two ways:

- manometric;

- hydrostatic.

The first method of testing involves the use of pressure gauges that record and demonstrate the pressure in the system.

Note:

with the help of pressure gauges, the magnitude of the excess pressure is determined, which allows us to conclude that the test is reliable. The second method checks the actual readiness of the system for operation by checking the performance at a pressure 50% higher than the standard

Any test lasts at least 10 minutes, the allowable pressure drop during pressure testing is not more than 0.02 MPa

The second method checks the actual readiness of the system for operation by checking the performance at a pressure 50% higher than the standard. Any test lasts at least 10 minutes, the permissible pressure drop during pressure testing is not more than 0.02 MPa.

Good to know:

the main document evidencing the conduct of tests is the relevant act.

Components of the act of pressure testing of the heating system

At the top left, information about the organization that conducted the check is indicated. Ideally, there should be a signature for approval by the chief power engineer of the heat supply organization.

At the top right should contain information about the subscriber. That is, who is the client and consumer of heating services. This may be a partnership of residents of a particular house, some organization that occupies the building, the owner of a private house, etc.

It is important that names and other information be accurate and detailed. In this case, the address is required

The main part of the act states:

- Town.

- The number of signing the act (and the crimping itself).

- Heat supply organization: its form of ownership, name, full name of the representative.

- Which of the representatives of the subscriber carried out the acceptance of the heating system after the test: full name, position.

- To what indicators the pressure in the system was raised, kgf / cm2 are indicated.

- To what indicators did it fall after 10 minutes following the shutdown (the units of measurement here are also kgf / cm2, it is also permissible to measure it in MPa if there are accurate data on this).

- The system passed or did not pass the test (the filler needs to underline the correct option).

The final part consists of signatures and seals (if any) of representatives of:

- Subscriber.

- Heat supply organization.

- Service organization.

In general, the act of pressure testing of the heating system is a convenient primary document, the completion of which is the responsibility of the heat supply organization.

The heating system is an important element of any home.

Therefore, it is extremely important that it works flawlessly. The most common heating today is a water circuit.

To avoid various unpleasant moments, you should carefully monitor the health of the pipeline.

To do this, before putting the house into operation, after repairing the heating and every time after the heating season in the warm season, the entire heating system must be checked for its correct and reliable functioning: are there any hidden defects, are all connecting fittings and butt joints in good condition and other. This test is commonly referred to as pressure testing of the heating system.

What is an act of crimping, why is it needed

The act of pressing - legal document

. It is official proof that:

In the form of the act there are several items

which should be filled in as accurately and completely as possible. Namely:

- the name of the object (house, site) where the check was carried out;

- time and date of pressing;

- test area (for example, a heating main or a node)

- instruments with which the system was tested;

- results of visual inspection of seams, joints, taps;

- the value of the working pressure and the load on the heating system, the duration of the load;

- the values shown by the pressure gauge at the end of the test;

- indicators of the magnitude of the pressure drop;

- data on the elimination of defects and leaks;

- conclusion about the readiness of the system for operation;

- signatures of responsible parties.

The forms of the act of hydraulic testing may differ slightly from the forms of pneumatic pressure testing. When selected, you can focus on SNiP 3.05.04-85

.

The act must be signed on the same day when the heating system was tested. The act is endorsed by responsible persons from the organization that conducted the tests, from the organization that carries out technical supervision, and from the managing organization.

The heat supply system is an engineering structure that allows you to observe and maintain the temperature parameters of the building in the winter months. A big misconception is that the heating system can work smoothly without various planned preventive measures. Of the latter, hydraulic tests of the heating system are of great importance.

These activities are carried out to find weak areas of the system that can let users down at the most inopportune time. You can see the crimping process in the photo below or in the video in our article.

Pressure testing of the heating system

The process of pressure testing, first of all, includes checking the system with increased pressure. After that do the following types of work:

- hydropneumatic check;

- chemical flushing of heating pipes;

- hydrostatic tests (direct pressure testing);

- repair of pipes and radiators;

- preventive and preparatory work.

After carrying out all the above procedures, an official document is drawn up: an act of pressure testing of the heating system. The sample looks like this

.

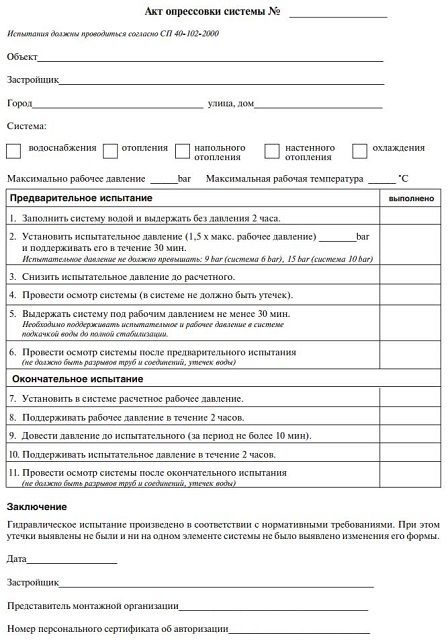

System pressure test certificate No. ___

Tests must be carried out in accordance with SP 40-102-2000

An object: _____________________

Developer: _________________

City: _________________, street, house: _____________________

System: (check as appropriate)

water supply, heating, underfloor heating, wall heating, cooling

Maximum operating pressure _____ bar, maximum operating temperature ______ C

Preliminary test completed

1. Fill the system with water and hold for 2 hours

2. Set test pressure (1.5 x operating pressure) _____bar and maintain it for 30 minutes

3. Reduce the test pressure to the design pressure

4.Inspect the system (the pipeline cannot have any leaks)

5. Maintain the pipeline under working pressure for about 30 minutes

6. Inspect the entire pipeline after the preliminary test

Ultimate test

7. Set the hydraulic design working pressure in the system

8. Maintain working pressure for 2 hours

9. Bring the pressure to the test level (no more than 10 minutes)

10. Maintain test pressure for 2 hours

11. Inspect the entire system after the final test

Conclusion

The hydraulic test was carried out in accordance with all regulatory requirements for this procedure. At the same time, no leaks were detected and no changes in the shape of the pipeline elements were noticed.

Date: ______________

Developer: __________________

Representative of the installation organization: ___________________

It should be noted that the acts of hydraulic tests may differ from the provided sample, but it also the following points should be noted:

- the length of the heating system;

- a detailed description of the area where the tests were carried out;

- a listing of all tools and equipment with which all work was carried out;

- all measurements and readings obtained during the test are included;

- at the end of such an act, the signatures of all members of the commission are put: the customer, the work acceptance officer (representative of the company that carried out the pressure testing) and the responsible specialist, the number of his certificate must be indicated.

The act of crimping is an important legal document, so you should carefully fill it out, avoid blots and corrections. In the event of an emergency situation with heating, with its help it will be possible to prove the fault of the company that conducted the system check and receive compensation for the damage caused.

For owners of private houses will have to contact regional offices

heating companies. Alternatively, you can use the services of private companies. But since the responsibility for the correct work is very serious, then the work should be entrusted to competent, certified professionals, whose professional suitability is confirmed by the relevant documents on admission to such work.

You can also carry out all the work on checking the heating system yourself, if you are confident in your abilities, but all the same, you will have to carry out a control hydraulic check in the presence of an inspector who is authorized to draw up this act.

When work is done

All measures that relate to checking the heating for leaks are performed in such cases:

- During preparation for the heating season;

- When replacing circuit sections;

- After repair of heating devices;

- When putting the property into operation.

The test procedure itself is a confirmation of the tightness of the circuit

.

This procedure includes the following components:

- Supply of air or water with a given pressure to the heating pipelines using special equipment;

- Finding deformations in the heating circuit;

- Elimination of violations.

It is worth noting that modern heating schemes allow such events to be carried out with a minimum number of personnel.

Hydropneumatic testing

As a rule, control pressure testing and flushing are recommended to be carried out at the end of the heating season. If at this time it is possible to identify weaknesses and defects in the system, then there is a whole season without heating ahead, when repairs can be carried out.After capital or current repair work, the networks are again filled with water and repressurized. Usually this is done in the fall.

Hydropneumatic tests are carried out in the following sequence:

- At the end of the heating season, the condition of the shut-off valves, heating and elevator units, as well as heating risers is checked.

- Preventive flushing of pipelines is carried out to remove various blockages.

- During flushing, the entire line, equipment and components are inspected for leaks. If any are identified, urgent repairs are carried out.

- The condition of the thermal insulation of open sections of pipelines is checked.

- Then they carry out pressure testing and fill the networks with a regular coolant so that they are completely ready for the new heating season.

To carry out hydropneumatic tests, the circuit is filled with water, then an electric or manual pump is connected, and the pressure is raised to the required level. Pumping equipment must be equipped with a built-in pressure gauge.

To check the intra-house network, the pressure is increased by 1.5-2 times, starting from the working value. When testing old networks, it is enough to increase the pressure by 25-50% of the operating parameter. The test pressure indicator depends on the limit value that the devices installed in the network can withstand.

Sequence of the pressing process

The entire crimping process is planned in advance. This is documented in compiling a crimping program

which should include:

Before starting the pump, a preliminary visual check of the connections and the condition of the shut-off valves is carried out, and plugs are also installed to isolate the heating system from the water supply pipes. Further, according to the procedure, the boiler with the expansion tank is turned off, the pipes are flushed (once every 4-6 years

) from deposits of various kinds or debris. Flushing must be done regularly, since pipes that are “overgrown” from the inside have a drop in thermal conductivity. Washing can be done in a variety of ways. Here the technical parameters of the heating system are taken into account.

During hydropressure, the prepared system (that is, after washing) is filled with a coolant - water, then a compressor is connected to the drain valve. The pressure is increased to the set value and the pressure gauge is monitored. If the heating system does not have weak points that will immediately break, the pressure gauge will not show any significant pressure fluctuations. If it shows a strong drop in pressure, then you definitely need to look for a leak. It's good that it's easy.

When pneumocompressing use a pneumatic pump. To detect defects in connections, it is recommended to treat them with a soapy solution before checking. The pump is hooked up to the heating system and blows air into the pipes

. Further actions are the same as in the first case. And don't forget about safety.

If, during the test, leaks or ruptures were found in the heating system, they are eliminated and the test is carried out again. This procedure can be repeated more than once until the system is completely sealed. Usually this process is carried out by specialists of public or private organizations with access, knowledge and skills that can follow the entire sequence of the process and ensure safety. After that, you can proceed to the preparation of the act of crimping.