Heat Saving Secrets

Now it has become known that with the use of an elevator it is possible to save heat. To do this, it is necessary to reduce the temperature in the apartment at night, or during the day, when most of the residents are absent. The disadvantage of such savings is the need to subsequently increase the heat consumption to heat an already cooled room. But in a cool room, sleep is much better, scientists say.

To make the savings effective, they began to develop an elevator with an adjustable nozzle. It is also water jet like its predecessor. It differs not so much in design changes as in the depth of possible adjustment, without losing the high quality of its work.

But the technology continues to develop and analogues of conventional elevator units will soon appear, which are capable of producing fully automatically.

Types of heating elevators

Oddly enough, not even all plumbers serving multi-storey buildings know about heating elevators. At best, they have an idea that this device is installed in the system. But how it works and what function it performs is not known to everyone, not to mention ordinary people.

Therefore, let's eliminate such a gap in knowledge about heating systems and analyze this device in more detail.

What is a mixing unit

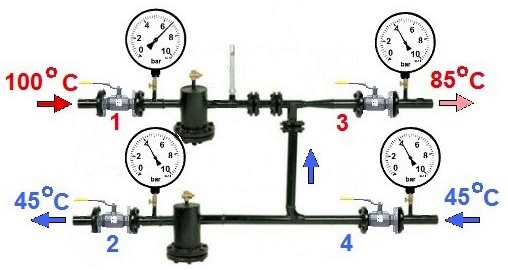

The boiler heats water usually up to 80-95°C, which is the optimum temperature for use in radiators. However, according to sanitary standards, the floor temperature should not exceed 30°C.

Considering the thickness of the floor screed and floor covering, the temperature of the heat carrier in the circuits is not higher than 55°C. That is why water for a warm floor is supplied through a mixing unit, it mixes hot liquid with a cooler one (which has already passed through the system and has had time to cool down). The scheme of the system is shown in the video:

System elements

When the hot coolant reaches the collector, it rests against the safety valve. The thermal head determines the temperature of the liquid and if it exceeds the set values, the valve opens slightly and the cold and hot coolant are mixed.

In addition, if the contours are long, they often make a pump-mixing unit with their own hands. It is equipped with a circulation pump, which drives water through itself and increases the pressure in the system. In addition to the main elements (two- or three-way valve and pump), there are additional parts in the assembly: a bypass (jumper), drain and shut-off valves, an air outlet, and an expansion tank.

In addition to the main elements (two- or three-way valve and pump), there are additional parts in the assembly: a bypass (jumper), drain and shut-off valves, an air outlet, and an expansion tank.

How to tighten the fittings for the metal-plastic pipe on the underfloor heating collector

How much and how can you tighten the fittings for metal-plastic pipes on the underfloor heating manifold?

I work with metal-plastic with such a key,

"Sponges" are thinner, you can spread out easily and quickly for any number.

In general, the nut on the fitting depends on the diameter of the pipes.

More often for a warm floor, a metal-plastic pipe is used, 16 mm, less often 20 mm.

The keys, if we talk about carobs, are on the 24th, 27th.

Is the collector also for metal-plastic pipes?

If the pipes are connected, for example, to a polypropylene manifold,

Again, there are subtleties, do we go through the “dad”, or through the “mom”?

You need to know this in order to advise which key is more convenient to work with.

In general, buy a universal one that I mentioned above (preferably two), suitable for any pipes, with any fittings.

With this key, it is even convenient to hold the polypropylene manifold on which the metal-plastic fitting will be mounted.

www.remotvet.ru

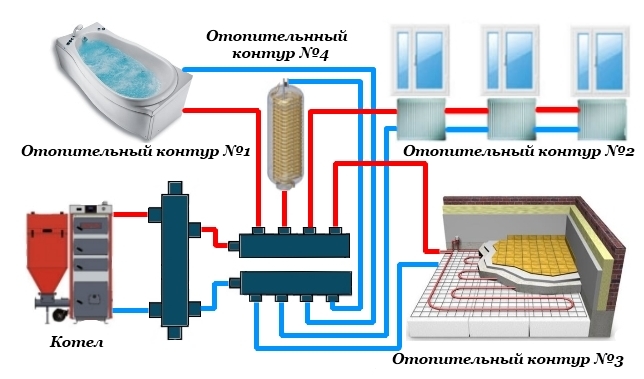

The composition of the collector heating system

A simple collector heating circuit

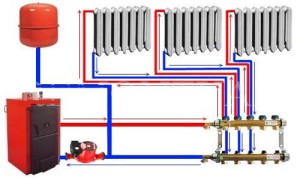

At the first stage, it is necessary to familiarize yourself with the principle of designing autonomous heat supply. The simplest collector heating scheme consists of a single distribution unit, to which the individual pipelines of the system are connected.

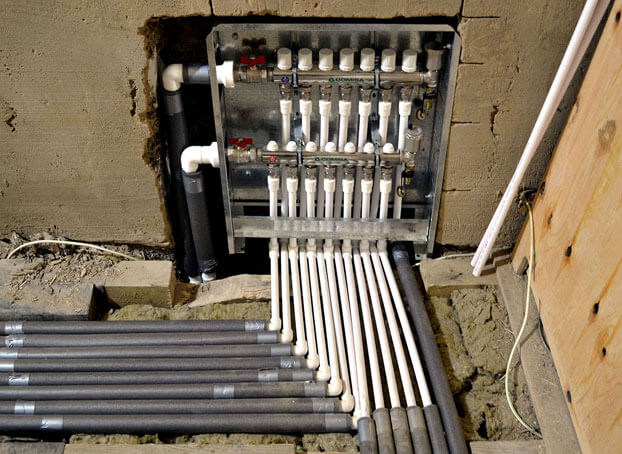

The composition includes standard components - a boiler, a circulation pump, an expansion tank and a safety group. The collector unit is installed directly next to the boiler and consists of two elements:

- Input. It is connected to the supply pipe from the heating device and distributes the hot coolant along the circuits;

- Day off. Return pipes from separate highways lead to it. It is necessary to collect the cooled water and send it to the boiler for further heating.

Complex collector groups for heating are equipped with devices for regulating the volume of coolant supply - thermal heads (inlet) and mechanical stops at the outlet.

It is best to purchase factory-made collectors. Since they are designed for certain heating parameters.

Multilevel collector heating

This principle is used to organize heat supply to a one-story private house, where the power of the circulation pump will be sufficient to ensure normal pressure in the pipes. For a two-story building, two collector groups for heating can be installed. One of them will be intended for distribution to separate circuits, and the second serves as the main component of a warm water floor.

For such a scheme, it is necessary to calculate the parameters of each circuit. Most often, it becomes necessary to install the following additional components:

- Circulation pumps for each circuit;

- Mixing node. Required to control the temperature of the coolant in the collector. The channel connects the direct and return pipes and with the help of a control device (two or three-way valve) flows are mixed with different degrees of heating.

Collector scheme of a two-story house

The traditional collector heating scheme of a two-story house includes distribution nodes on the first and second levels. But it all depends on the total area of the premises and, as a result, on the length of individual highways.

You also need to take into account heat transfer and optimal thermal conditions in each room.

All collectors located in residential premises must be installed in special closed boxes.

What is it needed for

When installing water pressure systems, there is a rule: the total diameter of all branches should not exceed the diameter of the supply pipe. With regard to heating equipment, this rule looks like this: if the diameter of the boiler outlet fitting is 1 inch, then two circuits with a pipe diameter of ½ inch are allowed in the system. For a small house, heated only with radiators, such a system will work efficiently.

In fact, there are more heating circuits in a private house or cottage: warm floors. heating of several floors, utility rooms, garage. When they are connected through a tapping system, the pressure in each circuit will be insufficient to effectively heat the radiators, and the temperature in the house will not be comfortable.

Therefore, branched heating systems are performed by collectors, this technique allows you to adjust each circuit separately and set the desired temperature in each room. So, for a garage, plus 10-15ºС is enough, and for a nursery, a temperature of about plus 23-25ºС is required. In addition, warm floors should not heat up more than 35-37 degrees, otherwise it will be unpleasant to walk on them, and the floor covering may be deformed. With the help of a collector and a shut-off temperature, this problem can also be solved.

Video: using a collector system for heating a house.

Collector groups for heating systems are sold ready-made, while they may have different configurations and the number of taps. You can choose a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are universal and do not always fit the needs of a particular home. Their alteration or refinement can significantly increase costs. Therefore, in most cases it is easier to assemble it from separate blocks with your own hands, taking into account the features of a particular heating system.

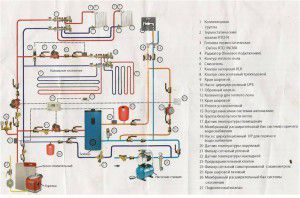

Collector group for heating system assy

The design of the universal manifold group is shown in the figure. It consists of two blocks for direct and reverse flow of the coolant, equipped with the required number of taps. Flowmeters are installed on the supply (direct) manifold, and thermal heads are located on the return manifold to control the temperature of the return water in each circuit. With their help, you can set the required flow rate of the coolant, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves. The supply and return manifolds are combined into one unit with brackets, which also serve to fix the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles. and if some of the taps are not involved, installing it will be clearly inappropriate.

The rules for mounting the finished block are shown in the video.

Comb - manifold assembly

The most expensive elements in the manifold distribution block are flow meters and thermal heads. To avoid overpaying for extra elements, you can buy a collector assembly, the so-called "comb", and install the necessary control devices with your own hands only where necessary.

The comb is a brass tube with a diameter of 1 or ¾ inches with a certain number of branches with a diameter for heating pipes ½ inch. They are also connected to each other by a bracket. The outlets on the return manifold are equipped with plugs that allow you to install thermal heads on all or part of the circuits.

In order to save money, the collector for heating systems can be assembled from individual elements on your own or completely done by yourself.

How the elevator works

In simple words, the elevator in the heating system is a water pump that does not require external energy supply. Thanks to this, and even a simple design and low cost, the element found its place in almost all heating points that were built in the Soviet era. But for its reliable operation, certain conditions are needed, which will be discussed below.

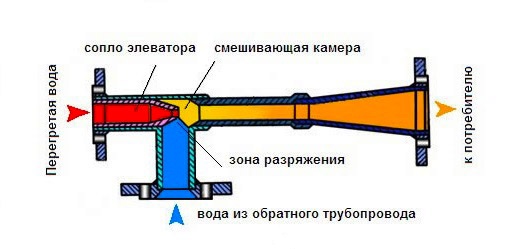

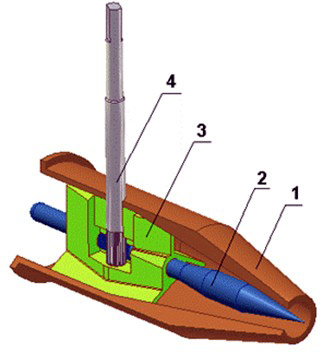

To understand the design of the heating system elevator, you should study the diagram shown above in the figure. The unit is somewhat reminiscent of an ordinary tee and is installed on the supply pipeline, with its side outlet it joins the return line. Only through a simple tee would water from the network pass immediately to the return pipeline and directly to the heating system without lowering the temperature, which is unacceptable.

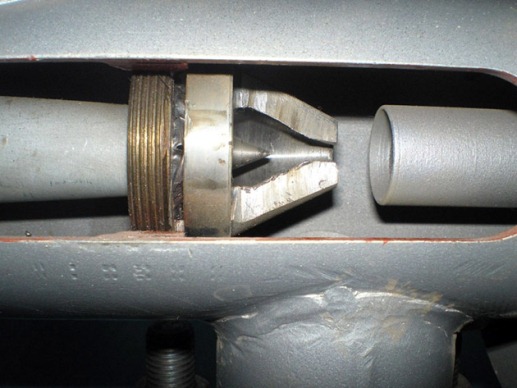

A standard elevator consists of a supply pipe (pre-chamber) with a built-in nozzle of the calculated diameter and a mixing chamber, where the cooled coolant is supplied from the return. At the outlet of the node, the branch pipe expands, forming a diffuser. The unit operates as follows:

- the coolant from the network with a high temperature is sent to the nozzle;

- when passing through a hole of small diameter, the flow velocity increases, due to which a rarefaction zone appears behind the nozzle;

- rarefaction causes suction of water from the return pipeline;

- the flows are mixed in the chamber and exit into the heating system through a diffuser.

How the described process takes place is clearly shown by the diagram of the elevator node, where all flows are indicated in different colors:

An indispensable condition for the stable operation of the unit is that the pressure drop between the supply and return lines of the heat supply network is greater than the hydraulic resistance of the heating system.

Along with the obvious advantages, this mixing unit has one significant drawback. The fact is that the principle of operation of the heating elevator does not allow you to control the temperature of the mixture at the outlet. After all, what is needed for this? If necessary, change the amount of superheated coolant from the network and sucked water from the return. For example, in order to lower the temperature, it is necessary to reduce the flow rate at the supply and increase the flow of coolant through the jumper. This can only be achieved by reducing the nozzle diameter, which is impossible.

Electric elevators help to solve the problem of quality regulation. In them, by means of a mechanical drive rotated by an electric motor, the diameter of the nozzle increases or decreases. This is realized by means of a cone-shaped throttling needle that enters the nozzle from the inside for a certain distance. Below is a diagram of a heating elevator with the ability to control the temperature of the mixture:

1 - nozzle; 2 - throttle needle; 3 - housing of the actuator with guides; 4 - shaft with gear drive.

A relatively recently appeared adjustable heating elevator allows the modernization of heating points without a radical replacement of equipment. Considering how many more such nodes operate in the CIS, such units are becoming increasingly important.

Elements of the heating circuit

Modern heating, in which collectors for heating are used, involves the creation of a large structure, it includes the following main elements:

- Thermal energy source. It is the first starting point from which the heated coolant is directed to pipelines and heating radiators. The power of heating units must be calculated as accurately as possible so that the equipment functions in accordance with its purpose.

The process of choosing a boiler and calculating its parameters is a very important moment when creating a heating structure. An underestimated power indicator will not allow the circuit to work to the fullest, as a result of which the rooms will not be warm enough. An overestimated value of the required heat transfer will lead to excessive fuel consumption, which will require the installation of control elements, and, accordingly, additional financial costs;

Circulation pump. A closed heating circuit with a comb requires forced circulation of the coolant. To do this, install circulation pumps in the heating system. due to which the necessary pressure is created to move the heated liquid, the optimum temperature is ensured, which guarantees high-quality work.

When choosing a circulation pump, according to the instructions, a number of parameters are taken into account. The power of the engine of the circulation device does not apply to the main indicators, it only determines the amount of energy consumed by the engine

Attention should be paid to the speed and volume of the pumped liquid per unit of time.

Pumps must be selected very carefully. The fact is that in order to ensure high-quality heating, it is necessary to select it with a power margin that exceeds the calculated parameters by about 10 percent, since property owners often add a heating area without replacing the circulation device.

Cabinets. This type of heating structure needs to hide its components, such as a do-it-yourself heating manifold, pipelines, ball valves in boxes or cabinets specially equipped for this. They are either fixed outside or built into the walls.

Beam scheme and warm floor

The beam scheme allows you to combine a home-made collector for heating and a "warm floor" system. But this design has a number of features.

Before you start working on its creation, you need to familiarize yourself with them:

- installation of a heating collector must be carried out on the condition that it is equipped with control valves and thermostatic valves on absolutely all circuits;

- when laying pipes for a “warm floor” heat supply system, electrothermal drives and thermostatic heads are certainly used. Thanks to these devices, "warm floors" will be able to quickly respond to changes in temperature and maintain the necessary microclimate in each of the rooms;

- the option for arranging the distribution system is different - typical (performed according to the standard scheme) and individual. The last method deserves special attention. In this case, the boiler operates in normal mode without significant temperature fluctuations, and fuel is consumed sparingly.

Features and purpose

The collector is an important part of the water supply system in an apartment or a private house. It performs an important function - it stabilizes the pressure in the equipment that consumes water and, in fact, delivers it from the source to the consumer.

It can be, for example, a faucet or a toilet in an apartment. We can give a simple example known to many. When someone takes a shower, the water in the kitchen should not be turned on, as this will lead to a temperature drop.

That is, a person in the bathroom can get burned with hot water or cool down with cold water, depending on which kitchen faucet was open. If the apartment has a collector, such problems will not arise.

If a collector is installed in the heating system, then the liquid is first supplied to the batteries through this device. The plumbing works in a similar way: the central branch enters one collector, and is not divided into a large number of branches.

Each branch has a shut-off valve

Next, we will consider in more detail the options for how the solution can be implemented, what are the installation rules and the very purpose of the collector in the apartment.

Classic wiring diagram

Any water supply system (house or apartment) is designed to supply water from the source to the consumer. And if there is only one consumer, the scheme is clear, but what if there are several of them?

Then earlier they acted simply by inserting a T-shaped splitter into the pipe. The next consumer was connected to one outlet, and the water-consuming device was connected to the other.

This solution is quite widely used today in the device of water supply for houses and apartments. After all, it has important advantages over the others: simplicity of design, accessibility and short length of pipes.

But this approach also has disadvantages:

- difficult repair - to carry out the procedure for one consumer, it is necessary to turn off the entire system;

- if several consumers are turned off, the pressure in the system is significantly reduced: the farther “through the pipe” from the source, the worse the indicator. In such a situation, the nearest consumer will actually be in a privileged position. An example with the simultaneous consumption of water in the bathroom and in the kitchen was given above.

Features of the beam scheme of collectors for heating

The scheme of the polypropylene heating manifold, which is shown in the photo, can be considered optimal if the house has several floors or the building has a large number of rooms and utility rooms.

So, the heating collector connection scheme implies that it will be installed on each floor (sometimes there may be several), and pipes are already laid out from it. As a rule, the instruction provides that the installation of elements of the heating system is carried out in walls or a cement screed.

The design of the heating structure and its branching should be drawn up before the start of repair work, so as not to spoil the base for laying the flooring later.

The principle of operation of the elevator

The principle of operation of the elevator

The elevator assembly is a fairly voluminous container, somewhat similar to a pot. But this is not the elevator itself, although it is called that. This is a whole node, which also includes:

- Dirt traps - because the water from the pipe comes not quite clean.

- Magnetic mesh filters - the unit must ensure a certain purity of the coolant so that batteries and pipes do not clog.

After cleaning, hot water flows through the nozzle into the mixing chamber. Here it moves at high speed, as a result of which water is sucked in from the return circuit, which is connected to the side of the mixing chamber. The process of suction, or injection, occurs spontaneously. Now it is clear that by changing the diameter of the nozzle, it is possible to regulate both the volume of the supplied coolant and its temperature at the outlet of the elevator.

As you understand, for a heating system, an elevator is a pump and a mixer at the same time

And what is important - no electricity

There is one more point that experts pay attention to - this is the ratio of pressure inside the supply pipeline and the resistance of the elevator.

This ratio should be equal to 7:1. Only such a ratio ensures the efficiency of the entire system.

But it's not all about efficiency

Pay attention to the fact that the pressure inside the system - and this is the supply and return circuit - must be the same. It is acceptable if in the return it will be a little less

But if the difference is significant, for example, in the supply pipeline 5.0 kgf / cm2, and in the return pipe below 4.3 kgf / cm2, this means that the pipeline system and heating devices are clogged with dirt.

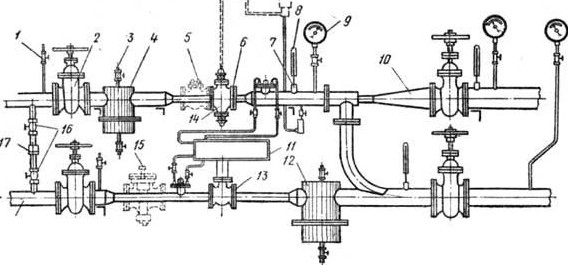

Scheme of switching on an adjustable water jet elevator

Another reason is also possible - during the overhaul, the diameters of the pipes were changed to a smaller side. That is, the contractor thus saved.

Is it possible to regulate the temperature of the coolant? It is possible, and for this it is better to use an adjustable water jet elevator.

In the design of such a device, a nozzle is installed, the diameter of which can be changed. Sometimes the adjustment range, and this applies more to foreign analogues, is large enough, which is not so necessary. Domestic elevators have a smaller range shift, but, as practice has shown, this is enough for all occasions.

True, adjustable elevators are rarely installed in residential buildings. Their installation in public or industrial premises is much more efficient. With their help, you can save up to 25% on heating costs only due to the fact that they allow you to reduce the temperature at night, as well as on weekends and holidays.

Pipe selection

Before starting work directly related to the creation of a heat supply system, it is required to coordinate the main parameters of pipelines. First of all, the source of thermal energy, the inlets and outlets to the collector, as well as the pipeline must be of the same diameter. Otherwise, when using pipes of different diameters, adapters are used. Their installation requires additional material costs and time for installation.

The supply and return pipes, through which the coolant moves, are made of different materials, but experts recommend using polypropylene pipes (for more details: “Do-it-yourself installation of a heating system from polypropylene pipes“).

Their advantage lies in the availability, practicality and ease of use during installation work. The selection of polypropylene pipes should be based on hydraulic calculations.

Failure to comply with the required diameters for pipes leads to such negative consequences as:

- violation of the circulation of the coolant;

- airing the heating circuit;

- uneven heating.

Polypropylene pipes manifold Far

Hello dear forum users! Sorry if I'm bringing up a question that has already been discussed.

Multi-apartment new building, polypropylene risers, they decided to make the wiring also with polypropylene (diameter 20). I would like to put Far collectors. After a long study of the topics of the forum and the range of products - porridge in my head. Interested collectors are adjustable 3/4″ outputs 1/2″ (3 - hot water and 2 + 3 - cold water taps). Elbows, as it turned out, come with metric threads and pipe threads, the pipe thread is divided into Eurocone and Flat-Faced. Flat-Faced, as I understand it, is ideal for me, but it’s not realistic to find them in Rostov (it’s probably too late to order).

Explain what is better to take with TR or MP. As far as I understand, the conclusions of the MP are attached through the adapter MP-TP, and on the TR there is already a fitting adapter for soldering polypropylene. With TR it is possible to immediately fit, but there are sharp edges that can cut through the gasket.

Here is such a mess. Do not throw stones at me in plumbing I do not understand.

Those who make repairs have never done wiring with a collector, so they took the choice. Today it was proposed to make a prefabricated manifold from polypropylene tees (in one place, the distance between the terminals is minimal as in a conventional manifold (little space), that is, it looks like a regular manifold), hang taps on the bends. In this regard, more questions have been added:

- How much such a collector will be less (or more?) More reliable.

- Tees are not reinforced, how bad is that? (reinforced pipes)

- Valves on taps (also made of polypropylene), as far as I understand, are ball valves, i.e. unable to regulate? only close - open? Are there adjustable faucets made of polypropylene?

I tend to Far collectors, but if the connections on the taps are a weak point, then maybe a prefabricated one is better?

www.mastergrad.com

Conclusion

Since the reconstruction of all heating points will not take place soon, the elevators will serve as mixers there for a long time. Therefore, knowledge of their structure and principle of operation will be useful to a certain circle of people.

In the heating points of old apartment buildings, you can see the elevator unit. The equipment, installed many decades ago, continues to work properly and ensure the transfer of heat energy to all points. Why you should not rush to change obsolete equipment. So, what is a node and how it works - this should be understood in more detail.

The elevator assembly of the heating system is a device of a certain type that performs the functions of an injection or water jet pump. The main tasks are to increase the pressure inside the heating system, increase the pumping of the coolant through the network, and increase the volume growth.

A durable thermal unit can transport a significantly superheated coolant, which is economically beneficial. For example, one ton of water heated to +150 C contains much more thermal energy than the same volume with indicators of +90 C. The use of a thermal unit ensures the rapid movement of the carrier through the system, while without turning the liquid substance into steam - the property is constantly explained maintained pressure, which keeps the carrier in the aggregate liquid state.

The principle of operation and the diagram of the node

Elevator cofferdam operation algorithm:

- The heated coolant passes through the pipe in the direction of the nozzle, then under pressure the flow accelerates and the effect of the water jet pump starts.Therefore, while the water passes through the nozzle, the carrier is circulated in the system.

- At the moment the liquid passes through the mixing chamber, the pressure level decreases to normal and the jet, entering the diffuser, provides a vacuum in the mixing chamber. According to the ejection effect, the coolant with an increased pressure index entrains water through the jumper, which returns from the heating network.

- The mixing of the cooled and heated flow takes place in the heating elevator chamber, therefore, when leaving the diffuser, the flow temperature drops to +95 C.

Having considered what a thermal unit is in an apartment building, the principle of operation of an elevator, you should know that for the normal functionality of the unit it is important to ensure the proper pressure drop in the main and return lines. The difference in indicators is needed to overcome the hydraulic resistance of the heating system in the house and the device itself

Externally, the elevator looks like a large tee made of metal pipes, equipped with connecting flanges at the ends. But if you look at the drawing, then the device of the elevator of the thermal unit from the inside is more complex:

- the left branch pipe looks like a nozzle, narrowing to the calculated diameter;

- immediately behind the nozzle is the cylinder of the mixing chamber;

- connection of the return line is achieved by the lower branch pipe;

- the branch pipe on the right is a diffuser with an extension that directs hot water into the heating system.

A detailed diagram of the elevator heating unit is required when connecting the system. The connection is carried out as follows: the left branch pipe - to the supply line of the central network, the lower one - to the pipeline with the return flow. Shut-off valves must be installed on both sides, supplementing them with a strainer, which is needed to screen out large particles and inclusions. Also, the design of the heat point is supplemented by pressure gauges, thermometers and heat meters.

Advantages and disadvantages of a thermal unit

Despite the moral obsolescence of the equipment, the simplicity of design and low cost explain the demand for a heating elevator. The device does not need to be connected to the mains, it works non-volatile. Many users argue that the scheme is irrational and with a low efficiency (up to 30%) of the device, the heating of the coolant should be reduced by abandoning the unit.

But if the heating elevator is removed, then the diameter of the main pipes will have to be significantly increased in order to ensure the normal flow of the coolant with a low temperature, and this will lead to additional costs. Therefore, it is premature to abandon the jet pump.

The disadvantages include the impossibility of controlling the water temperature, but when using devices with nozzle diameter adjustment, the minus is leveled. Adjusting the nozzle will help control the speed of the supplied coolant, change the vacuum parameters in the mixer chamber and, as a result, control the temperature of the water supply.