Features of metal gutters

Metal gutters have been used to divert water both in the past and in the modern world. At the same time, if a metal gutter system made of zinc or cast iron was previously common, today these alloys are not popular, since products made from them became unusable very quickly, because without a special coating such metals quickly rusted. Now users can purchase the following types of metal gutters:

- steel;

- aluminum;

- titanium-zinc;

- copper.

Each variety has its own special characteristics, therefore, depending on the specific material, the service life of the product and the price of the product may differ.

steel gutter

The most affordable option for a metal drain is a galvanized cold rolled steel system. The thickness of the metal is 0.5-0.7 mm, but this is quite enough to ensure high strength and durability of the drain. To extend the service life, as well as to give the structure a more decorative look, steel elements are coated on the outside and inside with one of the polymers, in particular, it can be:

- plastisol;

- pural;

- polyester.

Depending on the specific coating option, characteristics such as frost resistance, UV resistance, color fastness, and so on may vary. However, in general, this option has good performance, great color variety, affordable cost and long service life.

Copper drain

Copper is an environmentally friendly material that is easy to work with, as it is quite flexible and ductile, but at the same time strong. Products are not deformed under the influence of cold or heat, and there are no scratches or other mechanical damage on their surface. Thanks to these qualities, drainage systems can be given various forms, including non-standard ones. For the production of drainage elements, a copper sheet with a thickness of 0.55-0.9 mm is used. The copper system has the highest durability. These are reliable and durable products resistant to aggressive environmental conditions. However, their main drawback is that they are quite expensive and massive. Of course, if the financial issue is not a problem, then such a drain will really be able to maintain the integrity of the structure for many decades and at the same time become an exterior decoration.

Gutter made of titanium-zinc

This alloy is characterized by high corrosion resistance, durability and strength. However, its cost is comparable to the price of copper products. The composition of the alloy includes copper and aluminum, that is, materials characterized by ductility, and titanium is responsible for increasing corrosion resistance. The thickness of the metal used is 0.65-0.8 mm.

Aluminum drainage

Aluminum systems are considered the lightest of all types of metal gutters. Due to the low weight of the material, it becomes possible to increase the thickness of the elements. That is, the walls of the drains have a thickness of 1-1.6 mm, which makes the product as durable and reliable as possible.

In general, a metal drain is distinguished by high durability, strength, resistance to corrosion and mechanical damage, a wide variety of designs, is not afraid of exposure to the sun and cold, and caring for it is not particularly problematic. However, high cost, high weight and noise can be considered a disadvantage, especially if the system does not have an internal polymer coating.

Related video:

Choosing a drainage system for your home

A drain is an obligatory part of any house, the main task of which is to collect precipitation and divert it from the building. Gutter systems today also have a decorative value. They visually harmoniously connect the holistic view of the facade and roof.

Gutters can be internal and external, it all depends on the type of building. So, internal ones are more often installed in multi-storey buildings with a flat roof. It is not customary to mount them in private houses or cottages, but if they are used, then only as an addition (for example, to drain water from a terrace).

Outdoor structures are more common. They perfectly cope with the flow of rainwater and better protect the foundation and facade of the building.

Choosing a drainage system is not easy. This issue should be addressed at the initial stage of designing the structure of the house or before starting the installation of the roof. Before you go shopping, you should remember the basic rules:

- To determine the diameter of the downpipes, the size of the gutter, as well as the throughput of the drainage system, you should know in advance the area of \u200b\u200beach slope and the entire roof as a whole.

- A plan should be developed for the future placement of all drainage elements. This will allow you to better calculate the accuracy of the location of the entire structure, calculate the amount of materials needed, and also develop the correct sequence of construction work.

- Decide on the color of the future design and the type of materials. The construction market offers a wide range of various products from global and domestic manufacturers. Usually, the material is selected taking into account the type of roof and the financial capabilities of the owner.

- Depending on the precipitation in a particular area, the area of \u200b\u200bthe roof and the slope of the roof slope, pipes and gutter sections should be selected.

When choosing materials for a drain, you should pay attention to the frequency of rains. For example, for areas with a high percentage of precipitation, it is better to choose combined or steel systems.

Of the economical options - plastic.

Which materials to choose

When you have to choose materials for creating a drainage system, you should study all the proposed types. More recently, the drainage system could be created from bamboo, wood, or other improvised materials. But today's quality requirements no longer allow the use of such drainage systems that do not meet established standards and optimal technical characteristics. So, drainage systems made of steel or polyvinyl chloride are considered the most popular and best. No less popular are copper gutters.

Material Features:

1. Polyvinyl chloride gutters. This is a special type of plastic that is better known as PVC. It has properties such as resistance to any negative effects of external factors, including temporary weather changes. Such systems are not covered with a protective material, because they do not deform and do not deteriorate under the condition of constant moisture.

The lightness of the material also plays an important role. A PVC gutter is quick and easy to install, while still exerting additional pressure on the edge of the roof.

All PVC systems are dyed at the time of production, so the necessary protective impurities are added directly only to the raw materials. Such a drain does not fade for a long time, retains its shape better and is not subject to scratches and chips. The color of PVC products remains bright and beautiful for a long time.

PVC gutters also have some disadvantages. For example, with a strong scorching sun, products can be deformed and lose their original appearance. But first of all, it depends on the chosen manufacturer. In winter, the brackets may be damaged if they are not treated in advance by the anti-icing system.But even despite this, PVC materials have a lower cost, which is why they are so popular among consumers.

2. Steel gutters. Many consumers prefer steel drainage systems. They are made from galvanized steel, which has a web thickness of about 6 mm. The use of such a material is better because it is the least likely to form corrosion. Such properties are achieved due to the fact that the steel has a thin coating of zinc.

Such structures withstand any temperature fluctuations, and completely protect the gutters from a large accumulation of ice and snow. The disadvantage of this design is that it has a high noise level. For example, during a hailstorm, an unpleasant sound will be heard throughout the house.

The appearance of a steel gutter directly depends on the paint. Today, such a design can be painted in almost any shade. The gutter system can be depicted in any color, but then it also has some disadvantages. For example, painted steel will not be as resistant to damage as untreated material. Under constant exposure to UV rays, the paint will quickly begin to dry out and cracks may form on it. To restore the properties of the steel drainage system, it will have to be repainted from time to time. In order for such drainage systems to last longer, you should choose materials only from trusted manufacturers.

3. Drains made of copper. This material is similar in properties to a steel counterpart. Copper is less susceptible to corrosion and is resistant to natural changes. The only difference between similar structures and similar ones is their cost. Copper gutters are many times more expensive than steel structures, so they are classified as an elite category of goods.

All copper drainage systems have a beautiful presentable appearance, so they can be combined with natural materials such as stone and brick. It is worth noting that such structures differ not only in their appearance, but also in longevity. Copper drains can serve for 100 years and not deform from external negative impacts.

4. Gutters made of mixed materials. Today, many are ready to choose mixed types of materials for their homes or cottages. So, for example, it is better to give preference to plastic and metal. This combination is not only durable, but also beautiful appearance. Such structures consist of a frame, which is made of steel, and the outer part is made of plastic.

Every year, manufacturers are increasingly developing different storm water inlets, strainers, barriers, pipes, etc., to make it easier and faster to remove excess precipitation from the roof, through special tanks or sewers. Only a well-chosen gutter system will help you enjoy heavy rains and not worry about the condition of the foundation and facade of the house.

Varieties of drainage systems

The main function of the gutter is to divert rain and melt water from the roof surface. Such structures consist of a system of gutters, funnels and pipes. It is necessary to mount gutters on roofs of any configuration, but in different situations, drainage systems can differ significantly. For example, for flat roof systems, it is recommended to install internal drainage systems that look more like plumbing. For pitched roofs, external gutters are more common, which are mounted under the eaves and on the facade of buildings. It should be noted that external drainage systems do not spoil the appearance of the house, as they are made from high-quality materials, and can also be painted to match the color of walls and roofs.

In addition to dividing by installation option, systems can also be classified according to such criteria as:

- shape or section - there are round gutters and rectangular ones;

- size - it is selected depending on the area of \u200b\u200bthe roof and the annual amount of precipitation, the larger the diameter of the risers and trays, the more water will be collected and diverted;

- production material - according to this criterion, drains can be divided into metal and plastic, as well as concrete or wood, which are rarely used in the modern world.

If it is not difficult to decide on the shapes and sizes of the drainage system, since there are clear recommendations from experts on this issue, then choosing a specific material can be extremely difficult. Of course, you can proceed from the option of finishing the roof, for example, if the roof has a metal tile cladding, then it is reasonable to make a metal drain. However, this approach is not always justified and in some cases it is quite possible to choose a plastic roofing system from corrugated board. So, plastic or metal drain - which material is better? We will analyze this issue in more detail, considering the advantages and disadvantages of each of the options.

Features of the plastic drain

Manufacturers paint components for plastic gutters according to the RAL scale, which allows you to match them to the roofing. The most popular systems are brown, silver or copper. Plastic sills look better in combination with a roof made of ceramic and bituminous tiles.

Advantages of plastic systems:

- Weight is lighter than metal, does not load the roof truss system. Thanks to this property, plastic drainage systems can be installed during roof repairs on old buildings, where the roof frame has already dilapidated.

- Plastic does not corrode.

- The ability to maintain characteristics at temperatures from -50 to +70 degrees.

- Resistance to aggressive environments. Recommended for use on the coast or near factories.

- Ease of installation. The design can be assembled independently, all the necessary components are sold in specialized stores.

- The walls are smooth, which does not allow dirt and small debris to linger on their surface. Even without constant care, the plastic construction retains a well-groomed appearance for a long time.

- Low noise during rain.

Design flaws:

- Low load resistance. Snow and ice coming off the roof surface will permanently damage the plastic. To strengthen the structure, you need to correctly calculate the required number of brackets and install them in increments of 50-60 centimeters.

- Temperature fluctuations are reflected in the linear dimensions. To prevent cracks from forming in the structure in winter, it is assembled using special compensators and rubber seals.

- When the air temperature drops in winter, the plastic becomes brittle. If the winter is snowy, the gutters will burst under the pressure of precipitation.

- In the sun, the color gradually fades.

Plastic drains expand in the summer. A 10-meter-long structure increases to 2.5 centimeters.

Criterias of choice

The drainage system is selected according to two indicators:

- The material from which the structural elements are made.

- Element sizes. This is mainly the width of the trays and the diameter of the pipes.

Plastic or metal?

Today, manufacturers offer gutter systems made either from steel sheet (galvanized and painted), or from copper, or from plastic.

Note that steel drainage systems have been used in the construction of drainage systems for a long time. And today it is one of the sought-after species. It can be said that it is:

- increased strength of the elements,

- their long term use

- the ability to arrange in different colors due to painting,

- low price,

- ease of installation.

Copper drains belong to the premium class category. In terms of all technical and operational characteristics, they are superior to both steel and plastic ones. They have an excellent appearance, but a very high price. That is why copper gutter systems are not as popular as the other two.

As for plastic products, the first thing that consumers pay attention to is the low price. But the main advantage of this material is 100% corrosion resistance.

According to their operational characteristics, these drains are not much inferior to steel and copper. For example, they have a smooth inner surface, which ensures a quiet flow of water. They are lightweight for easy installation. But they also have one rather serious disadvantage. This is a rupture of plastic pipes in winter if an ice jam has created in them. Today, many manufacturers of plastic drainage systems offer models that can withstand any load. Therefore, it is necessary to choose those.

How to calculate the size of gutters

The calculation of the dimensions of the elements of the drainage system is carried out relative to the area of the roof slopes. Here is a table with some ratios regarding plastic and metal systems.

| Roof slope area, m² | Gutter width (plastic-metal), m | Pipe diameter (plastic-metal), m | Number of drainpipes for one slope, pcs. |

| Up to 70 | 0,9/1 | 0,75/0,75 | 1 at the edge of the wall |

| 70-140 | 1,3/1,5 | 1/1 | 1 at the edge of the wall |

| Up to 110 | 0,9 | 0,75 | 1 in the center of the eaves |

| 110-200 | 1,3 | 1 | 1 in the center of the eaves |

| Up to 140 | 0,9/1,25 | 0,75/0,9 | 2 risers |

| 140-220 | 1,3/1,5 | 1/1 | 2 risers |

Even from this ratio, it is clearly seen that plastic structures are smaller in size, but they pass through the volume of water exactly the same as large metal systems. It turns out that even in this case, plastic gutters are preferable. But we must pay tribute to the manufacturers of metal drainage systems, which today offer products made of galvanized steel, coated on both sides with a polymer layer. First of all, this increases their service life, and secondly, it brings technical characteristics closer to plastic counterparts. But in terms of strength, metal is still better.

And one more table comparing the advantages of plastic and metal gutters.

| Plastic gutters | metal |

| Cheaper than metal | High strength characteristics, because it is made of galvanized sheet with a thickness of 0.6 mm |

| Less waste during installation | Diverse decorative design |

| The degree of deformation is lower | Does not respond to temperature changes |

| Doesn't scratch during installation | Perfectly harmonizes with metal roofing materials |

| The same is true during operation. | Copes well with temperature changes |

| Don't worry about minor imperfections | Does not deform under the influence of sunlight |

| When deformed after the snow melts, it can be restored in shape and size | Has a large bearing capacity |

| Installation is easier than metal | Not as brittle as plastic |

| Less weight | This is a non-combustible material |

| Neutral to biological and chemical stresses | Service life 15-30 years |

| Better soundproofing properties | |

| Does not corrode | |

| Service life 10 years |

These comparative characteristics can be offered in order to make the right choice of a drainage system. The main thing, as practice shows, is long-term operation and appearance, which should fit into the design of the house. We can speak about efficiency only from the standpoint of an accurate calculation of dimensions.

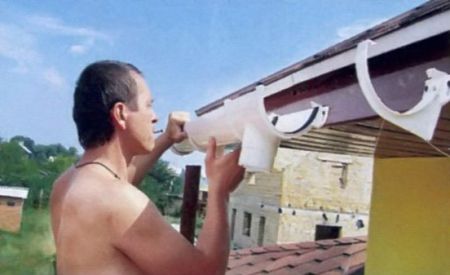

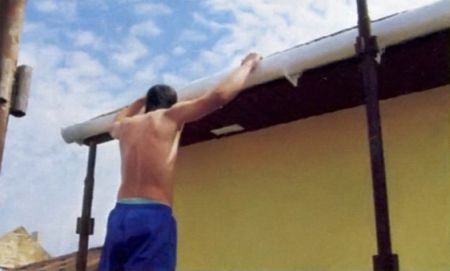

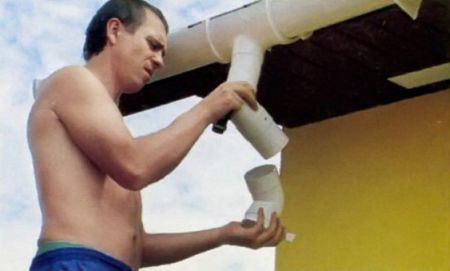

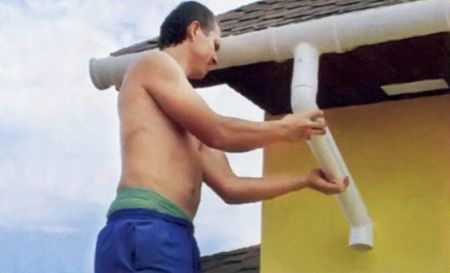

PVC gutter installation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Roof gutter - a system for the organized collection, transportation of melt or rainwater flowing down from the slopes into a storm sewer or a special container.

It consists of gutters, water intake funnels, pipes through which the movement of fluid occurs.The elements of the drain are hermetically connected to each other, and then fixed on the rafter legs or cornice board. Plastic and metal systems perform the same functions:

- Prevent spontaneous descent of melt or rain water from the slope. Thanks to the liquid, it is organized in an organized way through the gutters and pipes to specially equipped places.

- Protects wall decoration from getting wet. If the water from the slope flows in an unorganized way, it gets on the facade cladding, which spoils the appearance, and then leads to accelerated destruction of the material. If the house is wooden, then with constant contact with water, the walls become moldy and rot.

- Maintains the integrity of the foundation. Water falling from the height of the roof onto the blind area gradually destroys the foundation. Because of this, the foundation of the house can be damaged, which will be difficult and expensive to repair.

- Stops ground blur. If the house has an unorganized drain, the water flowing from the slopes erodes the soil, which causes puddles and dirt to appear.

- Increases the life of the roofing material. When melted and rainwater stagnates, the roof coating is gradually destroyed, small cracks form on the surface of the material, and metal roofs become covered with rust.

Where to stop

The final choice should be made taking into account the whole range of evaluation criteria.

First of all, they proceed from the fact that the drainage system has its direct functions, and first of all it must cope with them. The rest is, to a certain extent, secondary. In addition, it does not determine the facade appearance of the building, but, on the contrary, it matches the existing (planned) roof and wall decoration.

You should immediately carry out all the necessary calculations in order to determine the list and number of necessary components. This will allow, having learned the prices in local stores, to assess their financial capabilities in terms of purchasing a particular system.

- In regions with difficult operating conditions (high probability of ice, heavy snow, severe frosts, etc.), preference should still be given to high-quality metal systems. But on the coast, plastic will still be better.

- For a roof made of corrugated board or metal tiles, a metal drain with an appropriate harmonizing color will be most appropriate. For soft roofing, on the contrary, plastic versions of systems suggest themselves.

- A copper gutter system on some “poor” roof will look absolutely ridiculous. And vice versa - a copper roof in combination with galvanized gutters. That is, one must intuitively understand the difference between harmony and obvious kitsch, "dust in the eye."

Well, for the rest - rely on your taste and, of course, financial capabilities

In this case, it is best to pay attention to the products of proven, reputable manufacturers who accompany their products with a good quality guarantee. These include the German company "Docke", the French "Nicoll", the British "Hunter", and, of course, the domestic "Alta-Profile", "Aquasystem", "Grand Line", "Metal Profile", "Marley"

At the end of the publication - a video, which also gives advice on choosing drainage systems:

How to take care of your drainage system

Not enough competent installation for the full functioning of the drain. Roofs, especially those with a slight slope, are prone to the accumulation of debris and dirt. In order for drainage to work properly, gutters and pipes must be cleaned periodically.

Do an audit of gutters at least twice a year: in late autumn and early spring.In the first case, leaves, branches and other autumn debris brought to the roof by the wind are removed from the gutters. The gutters can be cleaned with a non-metal brush using a degreaser (dishwasher, for example). Then you can stretch the watering hose and flush the pipes and gutters under pressure.

In spring, the roof may contain packed snow, icicles and various litter. They are cleaned with a plastic shovel, trying not to damage the drain and roof. It is also possible to clean the gutters with a soft brush.

With proper installation and timely maintenance, the drainage system will function for many years. This approach will allow the owner of the house not to worry about the integrity of the foundation and walls, and the rainwater collected by the drain can be useful in the household.

Articles about drainage systems

How to avoid mistakes in choosing

Here are a few criteria that you need to pay attention to first of all:

- Weir diameter. This indicator ranges from 5–15 cm. The diameter should correspond to the angle of inclination of the roof slope, and the larger the slope, the larger the diameter.

- Price. The most affordable option is plastic spillways, as well as galvanized structures. Drains made of copper, zinc and titanium are the most expensive.

- Type of roofing. For bitumen and ceramic - a plastic version is suitable, for metal or corrugated board - only metal products are needed.

- Weight. Before choosing and then installing roof gutters, do not forget that a reliable truss frame is needed to fix metal products;

- Climate. The gutter is selected taking into account the climatic features of the construction region, the temperature regime in the area.

Which drain to choose in the end decides the owner of the house. To buy a reliable product, study the reviews of the products offered on the market, and choose only products from trusted manufacturers.

Features of plastic drainage systems

Plastic drains are made of PVC, connecting it with stabilizers. Systems have earned the reputation of inexpensive and lightweight. Plastic is inferior in durability to copper, but can last up to 20-25 years. In addition, you can choose the color to your liking, preserving the style in the design of the building.

Fasteners, pipes and gutters are available in a wide range. Installation of the kit is the assembly of finished elements using a minimum of sealants and adhesives. Tightness is ensured by rubber seals, which makes the system flexible.

Adapters and elbows, couplings and plugs are present in sufficient quantities for a reliable connection of pipes. Whatever the angle of inclination of the roof and the complexity of the roofing, it is easy to choose the right size spillway system. With bituminous and ceramic tiles on the roof, plastic devices are successfully combined in material and color. Ebbs made of golden and copper, brown and silver plastic are popular.

We list the advantages of plastic devices:

- Ease. For those older roofs with partially dilapidated roof rafters, the low weight of the plastic system becomes the most important quality.

- Ease of installation. Assembly can be done by hand, without contacting a specialist. Any detail is available in the construction market.

- Resistant to corrosion and chemical irritants. This material does not need a protective coating, does not react to active substances. Passing large amounts of moisture, weirs do not rust, and their inner surface remains smooth.

- Silent operation and absence of sounds from falling drops.

- A large selection of beautiful colors and shades that are compatible with any color of the roof of the house.

- Convenient cleaning with a water jet from a hose, gutters and pipes do not accumulate dirt and debris.

Among the shortcomings, the first place is occupied by the ability to break under the influence of ice and snow, especially in conditions of low - up to -40 degrees Celsius - temperature. Fragility is enhanced by the property of plastic to change shape under the influence of temperature changes. This should be taken into account when installing the system, inserting seals and rubber parts to compensate for expansion.

Dislikes plastic and bright sun. The pipes are not kept in the package for a long time under high temperature conditions. The coating can fade and fade under the influence of ultraviolet rays. The metal covered with an oxide film remains unchanged, acquiring a beautiful greenish or black patina.

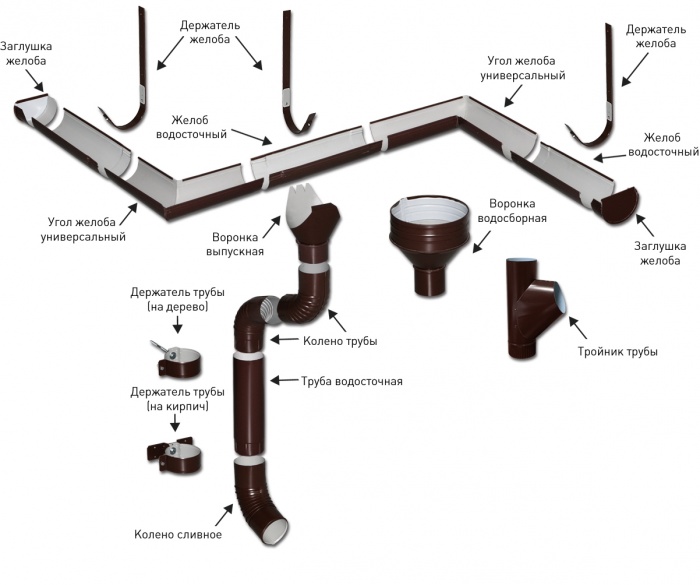

Elements of the drainage system and their installation

In the drainage system, all elements are interconnected and perform a role specially assigned only to it. However, the main role of accepting water flowing from the roof is assigned to inclined gutters. It is they who take the first loads, and it is in them that all the liquid flowing down from the roof accumulates.

Then the water rushes along inclined gutters to the funnel, and through it into vertical drainpipes, which are assembled from several sections. These pipes carry water to the ground. Usually, other elements are used in the drainage system, such as elbows, plugs, clamps, trays, additional spillways, drains, etc. All of them are attached to the roof and facade structure using special brackets.

Select items based on:

- architectural features of the building;

- roofing (its shape and area);

- maximum amount of precipitation;

- drainage and anti-icing systems.

So, if you take downpipes with a diameter of 80-90 mm, then they are quite suitable for a roof with a total area of up to 100 m2. With a larger roof area, pipes with a diameter of 100-125 mm will be needed. When calculating the cross section of pipes, it is worth starting from the fact that 1 cm2 of the section drains water from 1 m2 of the roof area.

Having decided on the choice of the drainage system (the material of its manufacture), as well as having dealt with the elements necessary for your structure, you can proceed to their installation. At this stage, it is worth knowing that there are general principles for installing the system and the rules for carrying out work, which are indicated in the instructions by the manufacturers of the elements.

So. The installation of the drainage system begins with the marking for fastening the water intake funnels (first of all) with their subsequent installation (and fastenings and funnels). Then there is a marking under the holders of the gutters and their installation. At the same time, for each individual type of gutters, a certain distance between the fasteners is provided. For example, for most plastic gutters this distance is 60 cm from each other, for metal gutters it is 90 cm. When marking and installing, do not forget about the slope towards the water intake funnels.

Having fixed the holders, we lay the gutters on them, which are preliminarily hermetically connected. At the same time, they are laid, starting from the funnels, and placed below the edge of the roof. Upon completion of the installation of gutters, we mount downpipes, if necessary, an elbow. Pipes are lowered without bringing them to the ground 15-30 cm, unless, of course, the design and architecture provide for water to be drained into a container specially designed for this purpose (barrel, "mountain" stream, etc.). The installation of vertical pipes is completed by attaching a drain to them.

It is also worth noting that vertical pipes, like gutters, must be attached to the wall of the house 1-2 m apart. For these purposes, special clamps or brackets are used.

Violation of the rules for installing drainage systems can lead to their damage, sagging and other undesirable consequences. Still consequences can be caused by improper care for them. For example, from spring to autumn, various natural debris (leaves, branches, dust, etc.) often collects in drains, which prevents the normal movement of water. For these purposes, it is sometimes worthwhile to audit the gutters, clearing them of unnecessary items.

In winter, the threat to gutters is icing, snow and ice. You can also fight this by installing snow retainers, and if finances allow, then an anti-icing system.

Useful little things

Its life expectancy depends on the section of the drain. If you choose the wrong section (less than necessary), then the drain will often overflow, and eventually collapse.

PVC gutters are suitable for almost any roof covering, and with professional installation and proper care, they can last for many years.

When designing a drain, do not forget about the drainage system. Or, as a cheaper option, mount a knee, thereby diverting water away from the foundation.

Views: 13895

Comments

RSS

Types of drainage systems

In the absence of a drainage system, walls and foundations are exposed to the negative effects of rain and melt water. The destruction of exterior finishes and load-bearing structures is accelerated. A properly selected drain will postpone the overhaul of the building for a significant period.

Any system for draining water from the roof of a building has the same components: adapters, funnels, corners, elbows, plugs, gutters and pipes of different diameters. A variety of parts and fastening materials allows you to assemble a system of any complexity, length and configuration.

Drains are divided into two groups:

- plastic: PVC, polypropylene and polyethylene;

- metal: steel, copper, zinc and aluminum.

The choice of material for mounting a roof drainage structure depends on the shape of the roof, the amount of precipitation, and the average air temperature in the region. Before buying a drain, you need to carefully study all the subtleties of the proposed options. Sometimes you need to give preference to metal, in other cases it is more practical to use inexpensive plastic.

Accessories for the drainage system

Whatever gutters and pipes the owner chooses for his house, they need to be attached to the walls and roof with something. It is better to immediately purchase all fasteners and transition elements, along with the main design of the gutters. Therefore, to begin with, it is necessary to develop a project, calculate the required number of parts, their size and shape.

Any drain consists of several mandatory elements:

- gutters - guides of round, trapezoidal or rectangular section. The gutter is attached under the roof and is designed to collect water flowing from it.

- Water inlet - a funnel in which water is collected from connected gutters.

- The pipe can have a different configuration, consist of several parts. It is designed to drain water from top to bottom, to the ground, a drainage well or sewer.

- Drain - the lower part of the pipe, should not be lower than 300 mm from the ground.

- Fittings: couplings, tees, elbows, plugs, corners, adapters - are necessary to assemble the drain of the desired shape.

- Accessories, such as storm water inlets, drippers, nets, are designed to direct the flow and clean it of debris.

- Brackets - fasteners with which the gutter is attached to the overhang, the clamp holds the gutters on the facades. These parts are universal, suitable for gutters of any manufacturer.

Any structure for draining water from the roof must be assembled after careful calculations.

How to choose gutters and their fragments

The determining values for choosing a drain are:

- The material from which it is made (the pros and cons of each drain were mentioned above).

- The area of the slopes - depends on the configuration of the roof, is calculated from the frontal projection of each individual slope.

- Funnel drainage area - a parameter set by the manufacturer shows how much roof area one pipe with a funnel can drain water from.

After choosing the material, proceed to the sketch of the future drainage system. Calculate the area of each slope separately. By dividing this value by the capacity of the funnel specified by the manufacturer, the required number of risers is obtained. All gutters, funnels, pipes, fasteners are indicated on the drain drawing.

Advice!

Do not neglect small details and accessories when calculating the system. As practice shows, fittings and fasteners take up to 60% of the amount allocated for the purchase of gutters.