Features of installation work

When backfilling the trench, fine-grained material should be used, such that the size of the particles can easily enter between the corrugation ribs. The size of the particles of earth, stones or gravel should not exceed the width between the protrusions of the corrugated ribs.

Butt welding connection. Welded connection is possible due to the large wall thickness of the Korsis pipe and the sufficient width between the stiffeners. The technology of using welding techniques is no different from connecting smooth polyethylene pipes.

When using butt welding machines, pressure, time and temperature parameters are set, which are set based on the pipe wall thickness index.

The welding mode is selected from the wall thickness. There are pipes that are delivered to the installation site with a welded expansion and connection socket. For ease of installation, many manufacturers send a batch of products to the site along with spacer rings, ties and heating elements.

Connection with couplings and sealing rings. If the ring is installed in the grooved groove first in a row, then the diameter of the ring is 120–250 mm, if the connection occurs at the level of the second stiffener, then the size of the circle is 110–1200 mm.

It is recommended to install the coupling with a constant and evenly distributed force in the longitudinal direction. It is impossible to apply shock effects with sledgehammers and jackhammers, which easily damage sealing rings and couplings. To facilitate installation, lever devices are used.

Manhole device

The first type contains a monolithic cast element in the base, which is connected to a vertical section of the pipe. To connect a sewer pipe to it, rubber seals are used in the form of rings, which provide waterproof connection qualities.

The second type differs in that it consists of pipe sections welded together. The connection with the elements of the line occurs with the help of couplings.

If a concrete well is installed, then it must be ensured that the hole in the well corresponds as much as possible to this indicator of the pipe. All joints are coated with cement mortar.

During the work, a support should be installed for the free end of the polyethylene pipe, which is designed to enter the wall of the well. First, work is done on concreting the well, and only after hardening, the pipe is connected.

It is impossible to do two works at the same time, as this can cause deformation of the main line under the influence of heavy concrete masses.

Polypropylene Material Specifications

- Polypropylene melts at a temperature of 168ºС.

- The density is 910 per kg.

- The ultimate tensile strength is 25–28 MPa.

- The limit of relative elongation at break is more than 200%.

- The material becomes brittle at 20ºС frost.

- For the bending modulus, an indicator of 1250–1650 MPa is taken.

- The hardness of the pipe material on the Rockwell scale is assumed to be 55–75 α.

- Thermal conductivity coefficient in the range of 0.17–0.23 W per meter.

- The coefficient of specific heat capacity at a temperature of 20ºС is 1.95 kJ per kg.

The abrasion test is usually carried out in two systems.The first is the amount of material that has been abraded and worn after the advancing abrasive particles. The second indicator indicates the time during which the wear of the particles occurred under the specified conditions.

Abrasion by abrasives occurs due to friction during the rolling of certain abrasive particles, cutting off material components by them, if the flow consists of uneven, sharp and hard elements.

A number of studies conducted by specialists indicate that the mechanism of self-cleaning and deposition of microparticles on the pipe walls are directly related to the process of material abrasion.

Sewer underground and surface piping systems made of polyethylene with a ribbed outer surface are developing and gradually replacing all other materials for the drainage device. Because of their high performance, they are popular with builders.

Design Methods

The customer, designer, contractor and operating service must work in close tandem and optimize all issues when choosing a route scheme, material, using installation methods and technology, and using the finished sewer line.

For work, they use the provisions defined in the SNiP for external networks and structures of water supply and sewerage and the standards for the design and installation of sewer and water supply systems.

For gravity sewers, it is recommended to calculate the speed of movement of effluents in the range from 1 to 4 m per second; for rainwater, a flow of up to 7 m per second is recommended.

Corsis pipe series produced for consumers:

- type PRO is made of multilayer polypropylene, produced with rib stiffness SN 16;

- ECO type is made from polyethylene after reuse and recycling;

- APM type includes products with a reinforced mesh in the pipe walls, has a ring stiffness of SN 16, according to the individual order of the customer, this figure increases to SN 24;

- type PLUS is used in case of requirements for increasing the throughput diameter of pipes, for inner diameter from 1200 to 2400 millimeters, stiffness - SN 2, 4, 6, 8;

- type SVT for external sewerage with spiral fins.

Description of the Korsis pipe

Polyethylene pipes also have some operating features that must be studied before purchasing and installing a Korsis pipe line. To increase the strength characteristics, increase reliability and durability, polyethylene is mixed with active additives.

As a result, products are obtained that have undeniable advantages over reinforced concrete counterparts:

- have significantly less weight while maintaining 75% strength indicators;

- do not belong to materials that absorb moisture, therefore they do not react to freezing and thawing cycles;

- retain their working qualities and characteristics throughout the entire service life, even after 40-50 years, the quality and plastic indicators remain at the same level;

- the properties of polyethylene make it possible to manufacture products with impact and abrasion resistance;

- the material allows the production of products with high ring stiffness;

- due to their low weight, they are easy to transport and quick to install;

- the characteristics of the material make it possible to create and successfully use Korsis pipes of large diameter;

- compared to metal and reinforced concrete products, they have a low cost and constant resistance to corrosion.

For sewer systems that are arranged in the thickness of the earth's surface, the ability to lie for a very long time without destruction and corrosion is the main indicator of reliability.

Professional builders and private developers pay attention to it with confidence

The products are characterized by durability, resistance to chemical destroyers and sufficient strength. The latter indicator gains value when a mass of soil presses on the Korsis pipe, laid at great depths. The ribs of the corrugated surface are located so that they receive and redistribute the load, thereby increasing the compressive and bending strength.

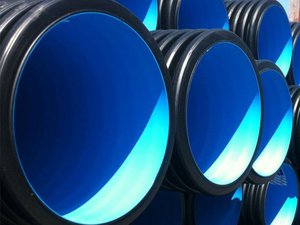

All the little things and details are provided in Korsis pipes, for example, the black wall on the outside resists the effects of ultraviolet rays, and the light inner surface visually facilitates diagnostics during preventive work.

Korsis pipes are produced in two types of geometric ring stiffness (SN 6, SN 6), which makes it possible to use them at different depths. They produce pipes of the PRO series, which have stiffness indicators of SN 16. Standard pieces of products on sale have a length of 12 and 6 meters. At the end of the Korsis pipe, a standard socket is welded, with a length of 300 to 1200 mm.

Pipes of all indicated strength classes differ only in the thickness of the outer wall, and all overall dimensions are the same. This allows, when designing, to make the same calculation for all classes of pipes, to use connecting elements of the same type.

Sewer line requirements

The distribution of two-layer corrugated pipes made of thermoplastics is proceeding at a rapid pace, but it is difficult for non-specialists to find material for laying sewers. To do this, consider the requirements for sewer pipes:

- Long-term ability to ensure hydraulic performance.

- Stability in the perception of external loads.

- The ability to maintain the hermetic performance of seam joints for a long time.

- Resistant to corrosion and damaging chemicals.

- Low ability to accumulate various types of deposits on the inner walls.

- Simplicity and speed of installation and connection.

- Low cost compared to other materials.

The disadvantages of corrugated products include:

- Difficulty in joining pipes with a standard welded method due to an uneven surface.

- It is impossible to repair a destroyed place on a pipe by welding a lining or cutting a hole for a new input.

Corsis sewer pipe laying

They are assembled together using couplings or simple welding. After the final connection and leak test, the trench and pipe are backfilled with fine pebbles or coarse sand. The height of the protective layer should be such that it completely covers the highway.

If the work is carried out correctly, it is planned to lay a warning tape so that during the subsequent excavation, the excavator can stop in time and not damage the Korsis pipe. After that, the trench is covered with soil and rammed.

- Corrugated polyethylene pipe can be laid at various depths underground.

- Regardless of the stiffness index, pipes are produced with the same dimensional parameters, the outer diameter is 110–120 mm.

- A short-term temperature fluctuation in the direction of decrease and increase is permissible up to indicators from -40ºС frost to 65ºС heat.

- With proper use of the line and compliance with all operational standards, the service life is determined at fifty years.